Lubricant for automobile chassis stampings and a preparing method thereof

A technology for automobile chassis and stamping parts, applied in the field of lubricating oil, can solve the problems of shortening the life of the mold, reducing the precision, and increasing the temperature, and achieve the effect of improving product performance and superior flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

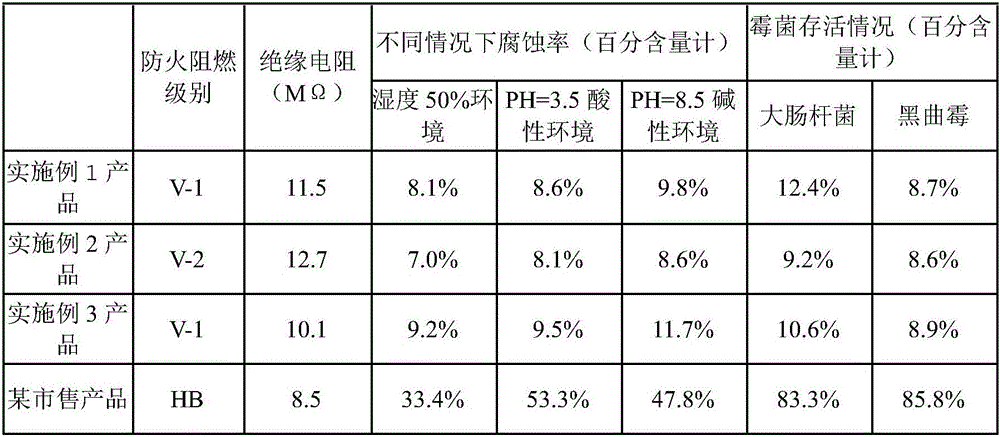

Examples

Embodiment 1

[0016] The lubricating oil for automobile chassis stamping parts in the present embodiment is made up of the component of following mass fraction: 240 parts of light spindle oils, 220 parts of soybean oils, 22 parts of polybutylene terephthalates, molybdenum dioxide 20 parts of powder, 22 parts of polypropylene glycol, 22 parts of soybean oil, 20 parts of sodium fatty acid, 22 parts of polyether silicone oil, 22 parts of dimethylformamide, 20 parts of bromogeramine, 20 parts of garlic oil, 20 parts of chlorhexidine, sorbic acid 22 parts of potassium, 20 parts of chlorothalonil, 18 parts of calcium lignosulfonate, 22 parts of nano-aluminum powder, 20 parts of zinc isooctanoate, 18 parts of nano-active calcium carbonate, 20 parts of polypropylene wax, 18 parts of expanded perlite powder, 18 parts of vanadium pentoxide powder, 18 parts of hexamethylene diisocyanate, 16 parts of polyethylene wax, 12 parts of ethyl orthosilicate, 10 parts of decabromodiphenylethane, 10 parts of hexa...

Embodiment 2

[0022]The lubricating oil for automobile chassis stamping parts in the present embodiment is made up of the component of following mass fraction: 260 parts of light spindle oils, 240 parts of soybean oils, 24 parts of polybutylene terephthalates, molybdenum dioxide 22 parts of powder, 24 parts of polypropylene glycol, 24 parts of soybean oil, 22 parts of sodium fatty acid, 24 parts of polyether silicone oil, 24 parts of dimethylformamide, 22 parts of bromogeramine, 22 parts of garlic oil, 22 parts of chlorhexidine, sorbic acid 24 parts of potassium, 22 parts of chlorothalonil, 20 parts of calcium lignosulfonate, 24 parts of nano-aluminum powder, 22 parts of zinc isooctanoate, 20 parts of nano-active calcium carbonate, 22 parts of polypropylene wax, 20 parts of expanded perlite powder, 20 parts of vanadium pentoxide powder, 20 parts of hexamethylene diisocyanate, 18 parts of polyethylene wax, 14 parts of ethyl orthosilicate, 12 parts of decabromodiphenylethane, 12 parts of hexah...

Embodiment 3

[0028] The lubricating oil for automobile chassis stamping parts in the present embodiment is made up of the component of following mass fraction: 280 parts of light spindle oils, 260 parts of soybean oils, 26 parts of polybutylene terephthalates, molybdenum dioxide 24 parts of powder, 26 parts of polypropylene glycol, 26 parts of soybean oil, 24 parts of sodium fatty acid, 26 parts of polyether silicone oil, 26 parts of dimethylformamide, 24 parts of bromogeramine, 24 parts of garlic oil, 24 parts of chlorhexidine, sorbic acid 26 parts of potassium, 24 parts of chlorothalonil, 22 parts of calcium lignosulfonate, 26 parts of nano-aluminum powder, 24 parts of zinc isooctanoate, 22 parts of nano-active calcium carbonate, 24 parts of polypropylene wax, 22 parts of expanded perlite powder, 22 parts of vanadium pentoxide powder, 22 parts of hexamethylene diisocyanate, 20 parts of polyethylene wax, 16 parts of ethyl orthosilicate, 14 parts of decabromodiphenylethane, 14 parts of hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com