Patents

Literature

41results about How to "Aggregation tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

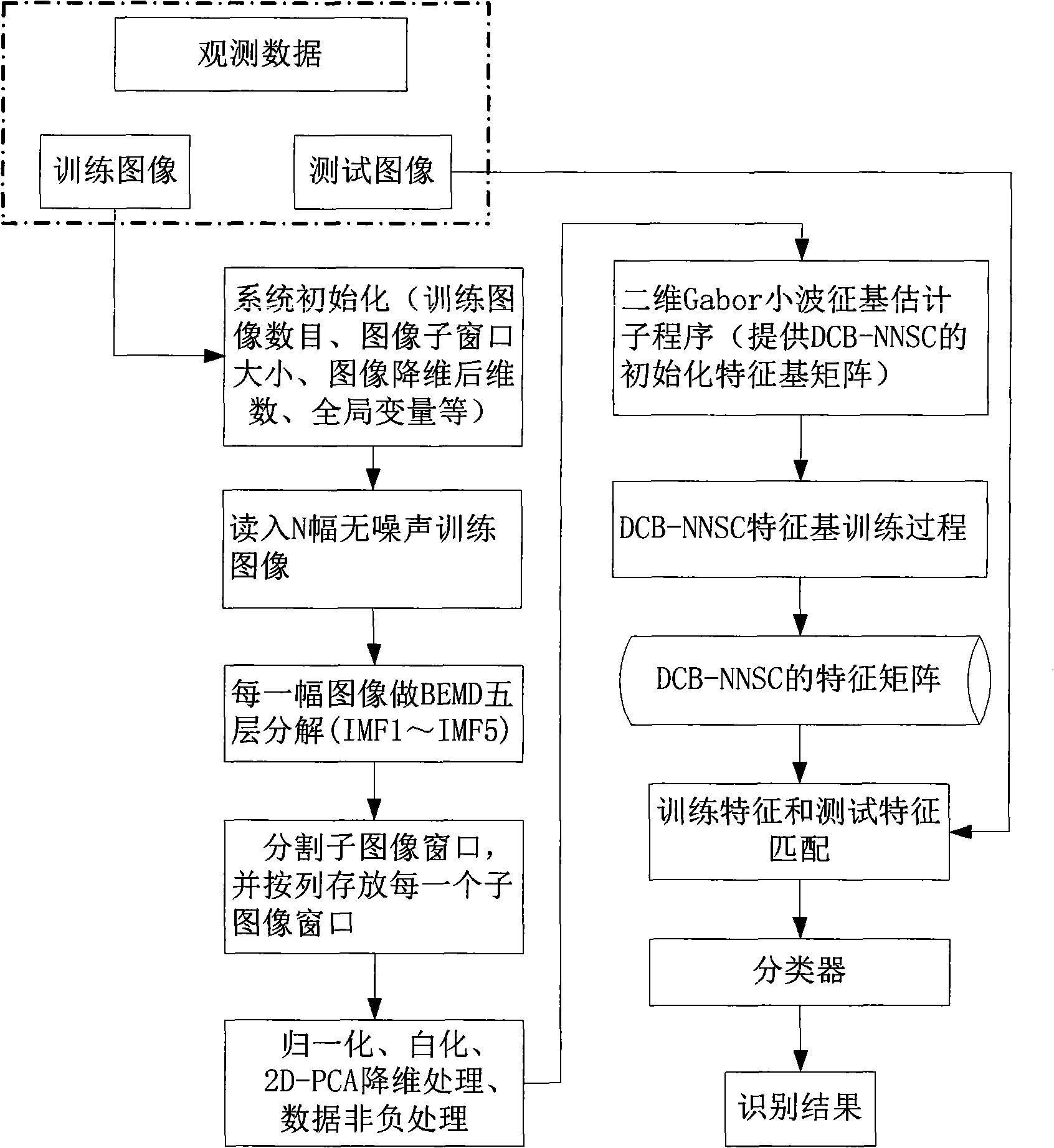

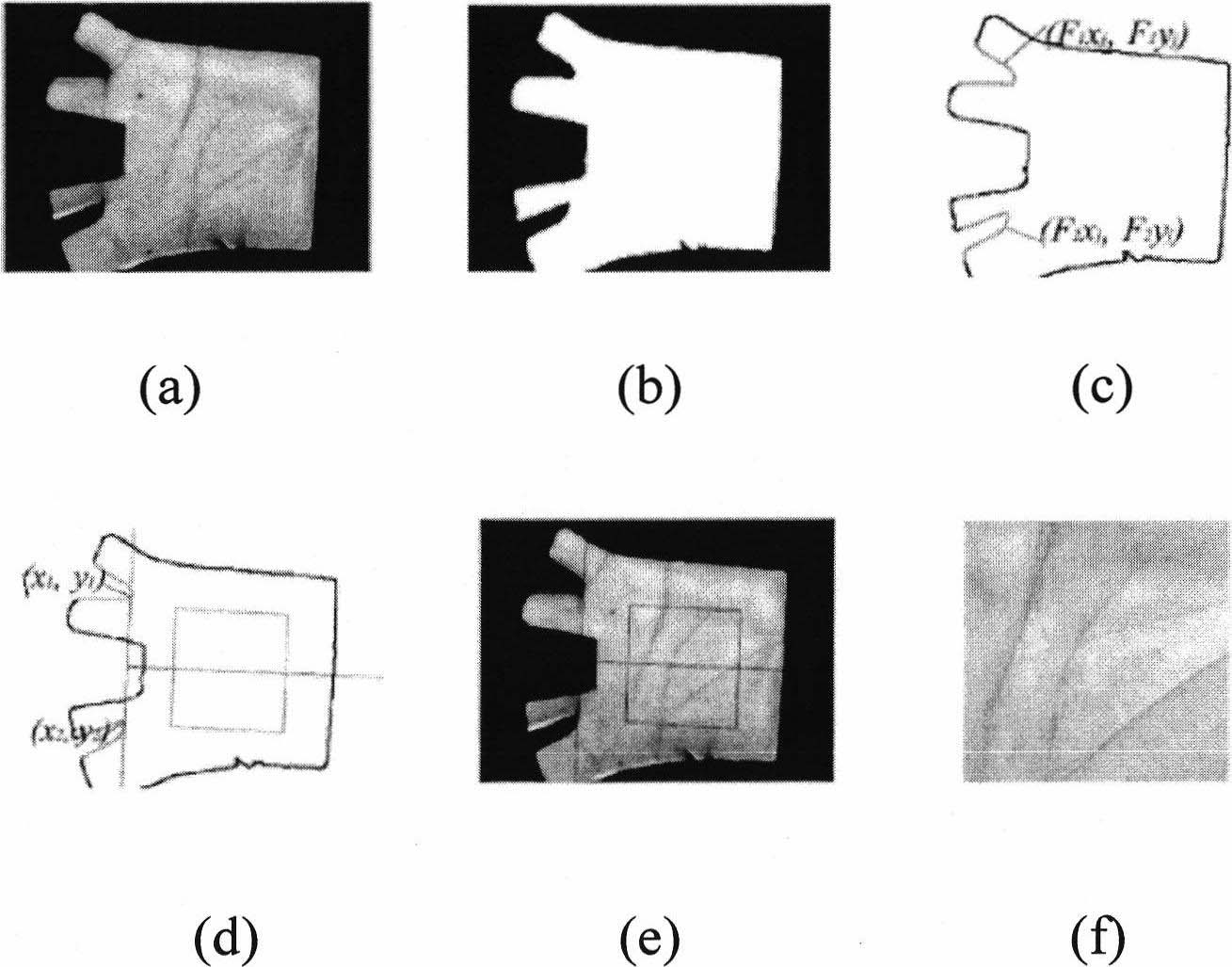

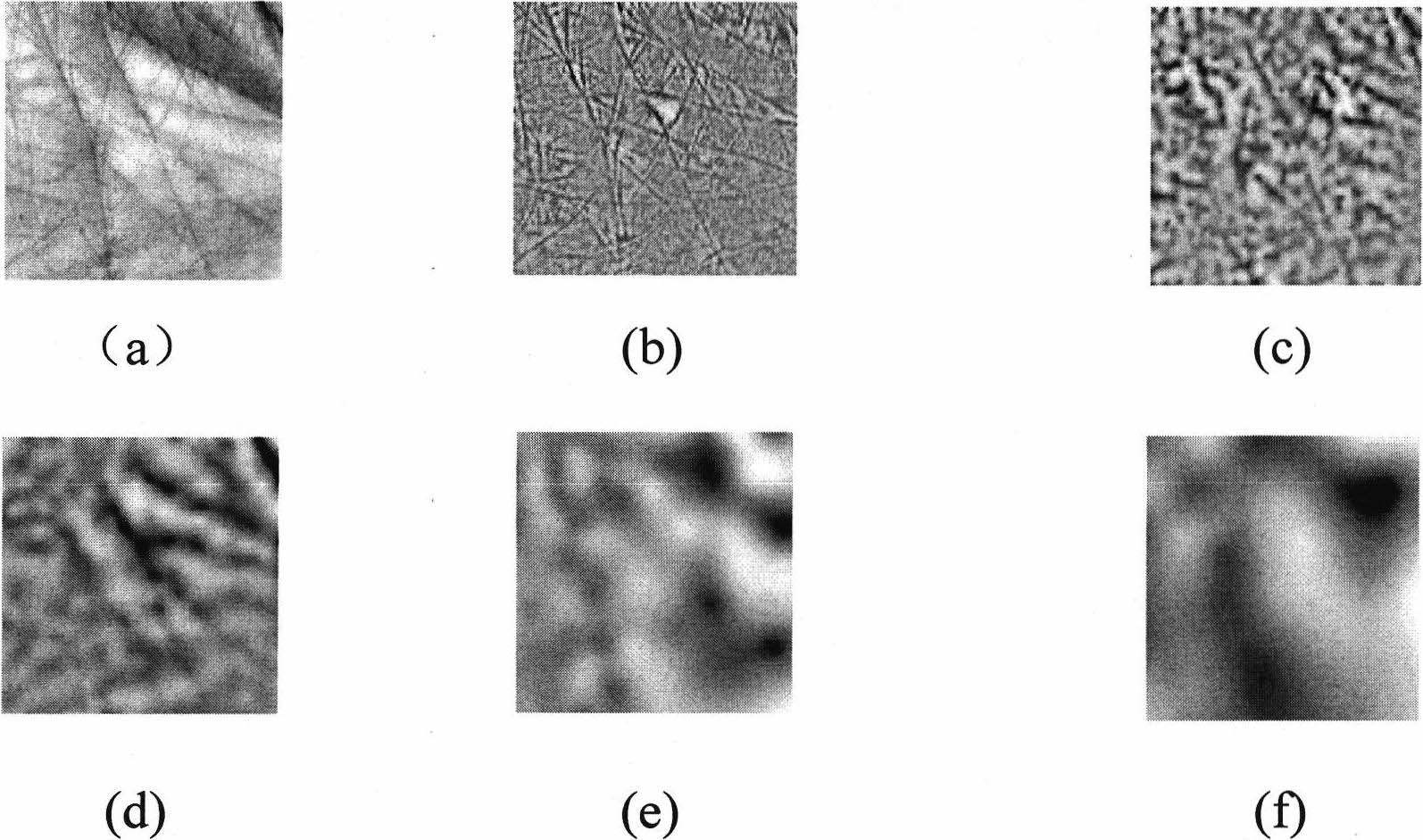

Method for extracting characteristic of natural image based on dispersion-constrained non-negative sparse coding

InactiveCN101866421AAggregation tightEfficient extractionCharacter and pattern recognitionFeature extractionNerve cells

The invention discloses a method for extracting the characteristic of a natural image based on dispersion-constrained non-negative sparse coding, which comprises the following steps of: partitioning an image into blocks, reducing dimensions by means of 2D-PCA, non-negative processing image data, initializing a wavelet characteristic base based on 2D-Gabor, defining the specific value between intra-class dispersion and extra-class dispersion of a sparsity coefficient, training a DCB-NNSC characteristic base, and image identifying based on the DCB-NNSC characteristic base, etc. The method has the advantages of not only being capable of imitating the receptive field characteristic of a V1 region nerve cell of a human eye primary vision system to effectively extract the local characteristic of the image; but also being capable of extracting the characteristic of the image with clearer directionality and edge characteristic compared with a standard non-negative sparse coding arithmetic; leading the intra-class data of the characteristic coefficient to be more closely polymerized together to increase an extra-class distance as much as possible with the least constraint of specific valuebetween the intra-class dispersion and the extra-class dispersion of the sparsity coefficient; and being capable of improving the identification performance in the image identification.

Owner:SUZHOU VOCATIONAL UNIV

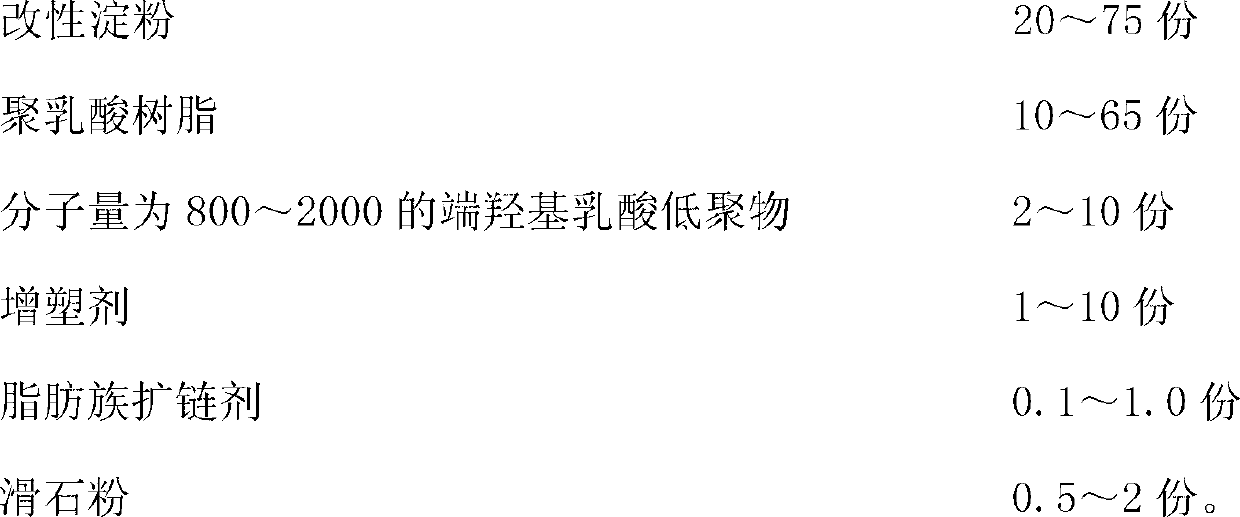

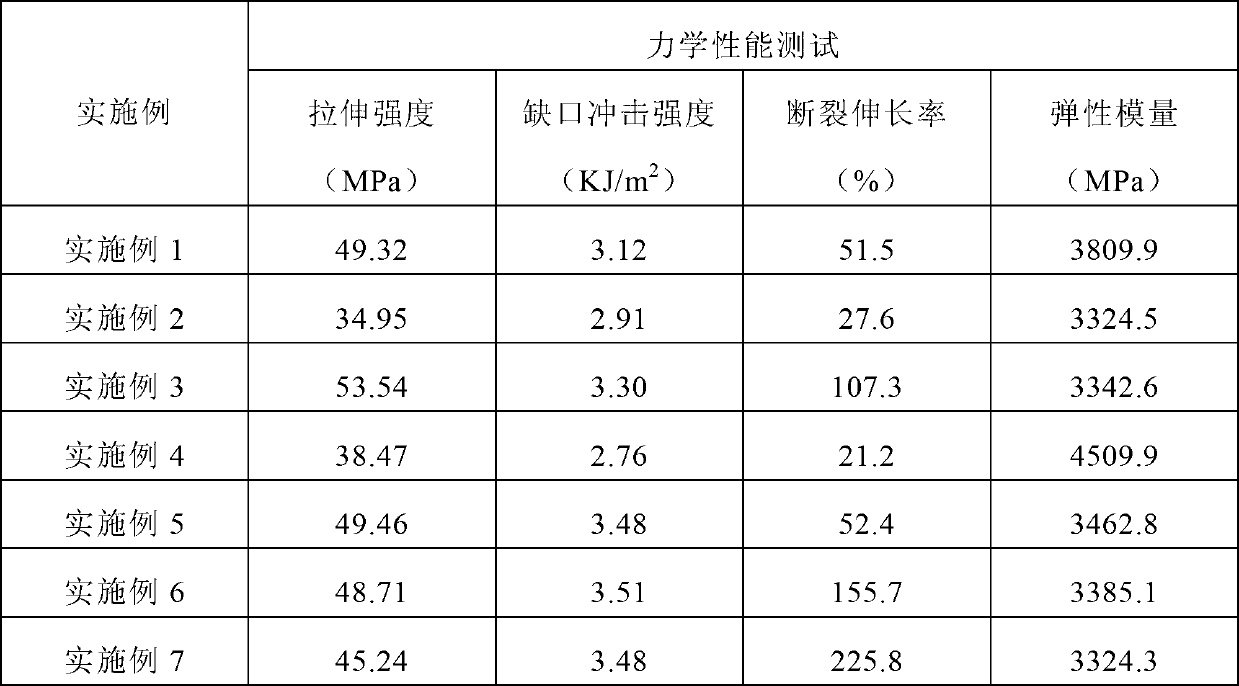

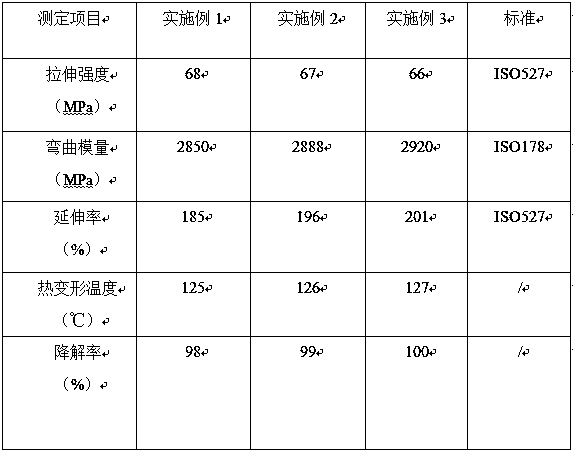

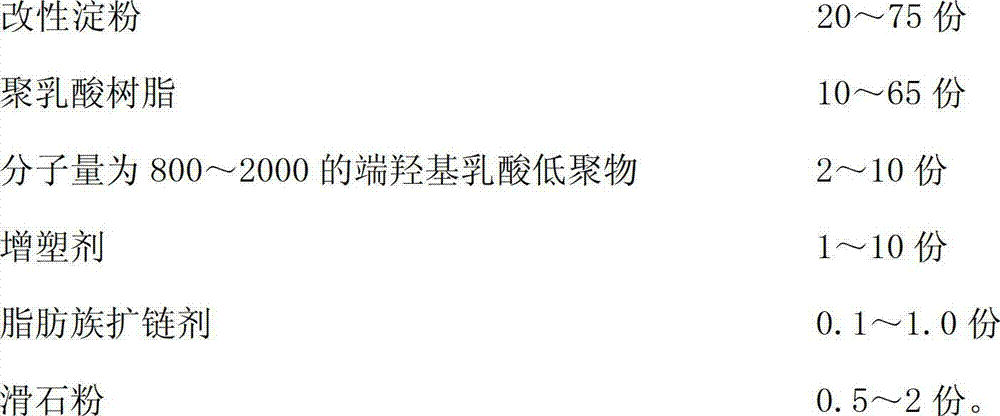

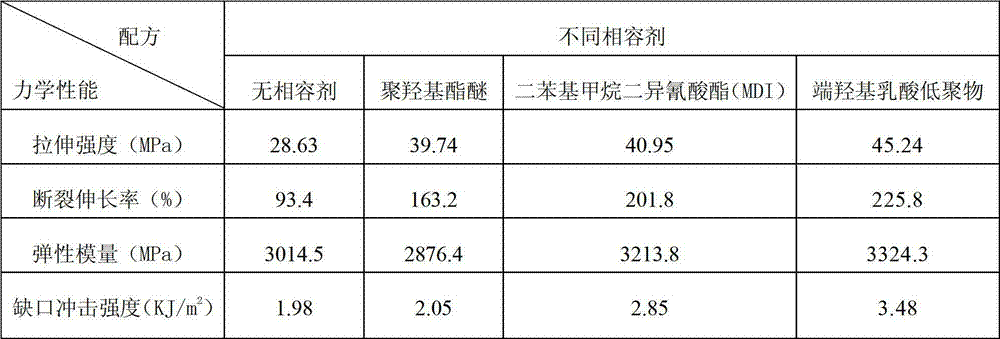

Starch and polylactic acid composite material and preparation method thereof

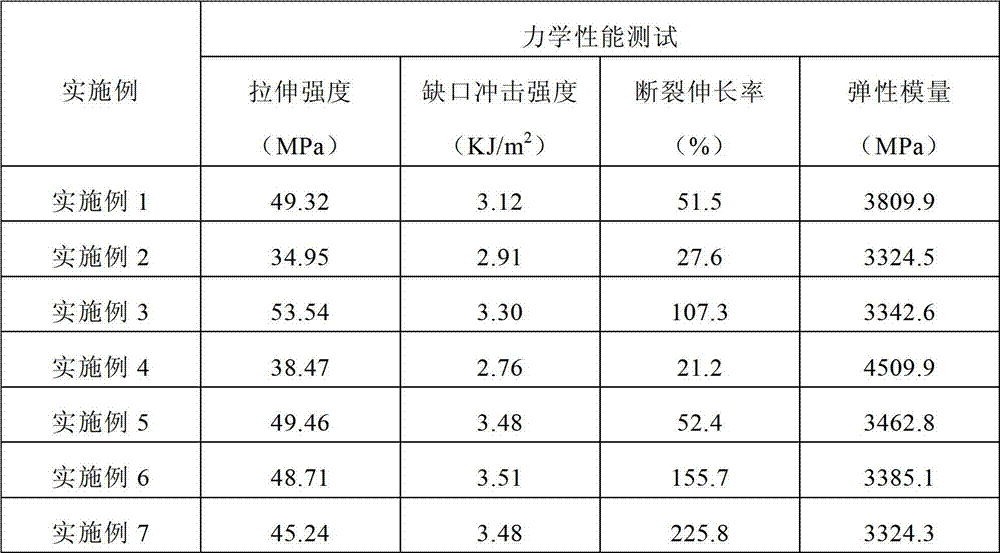

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

Nano composite material of anionic polymerization nylon

A nano-class composite nylon material is prepared through mixing one or more nylon monomers in fused state with one on more nano inorganic material, dewatering, and anionic polymerizing under existance of alkaline catalyst and cocatalyst. Its advantages are high strength, rigidity and size stability, and simple process.

Owner:ANHUI DOUBLE CRANE PHARMA

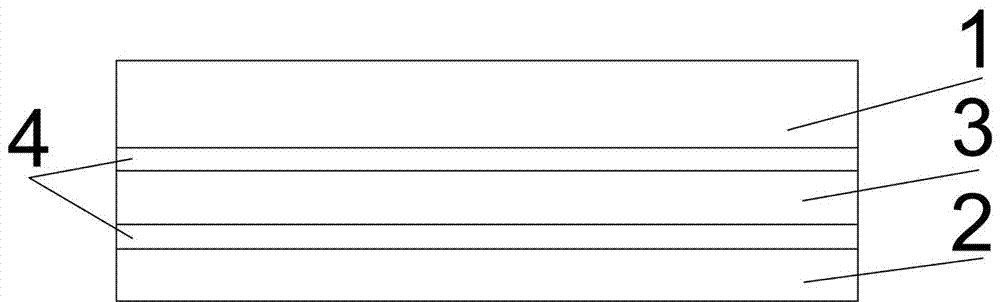

PVC (polyvinyl chloride) foamed artificial leather and preparation method thereof

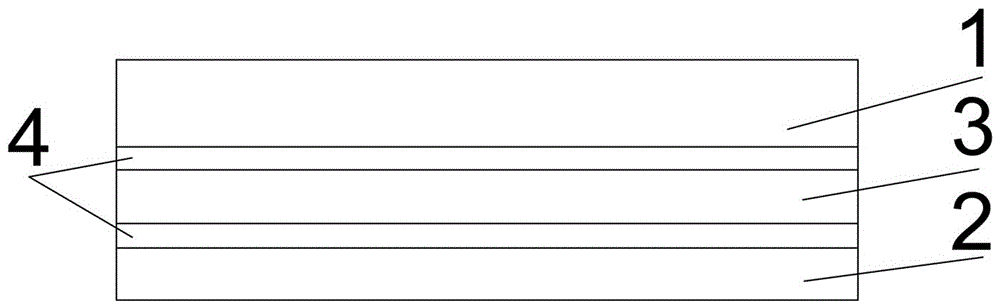

The invention discloses PVC (polyvinyl chloride) foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises a fabric base material, a foaming layer and a surface layer which are attached from inside to outside sequentially, wherein the foaming layer comprises components in parts by weight as follows: 95-105 parts of PVC resin, 75-85 parts of filling powder, 75-85 parts of a plasticizer, 3.5-4.0 parts of a stabilizer, 4.5-5.5 parts of a foaming agent and 9.5-10.5 parts of masterbatch; the surface layer comprises components in parts by weight as follows: 65-75 parts of PVC resin, 6-8 parts of filling powder, 46-52 parts of a plasticizer, 1.5-3 parts of a stabilizer and 4.5-5.5 parts of masterbatch. The preparation method comprises steps as follows: (1), blending; (2), mixing, open milling and filtering; (3), calendering attachment; (4), cooling; (5), foaming; (6), embossing, cooling and rolling-up to obtain a finished PVC foamed artificial leather product. The artificial leather prepared with the method feels good, and is good in texture, high in breathability and good in wear resistance.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

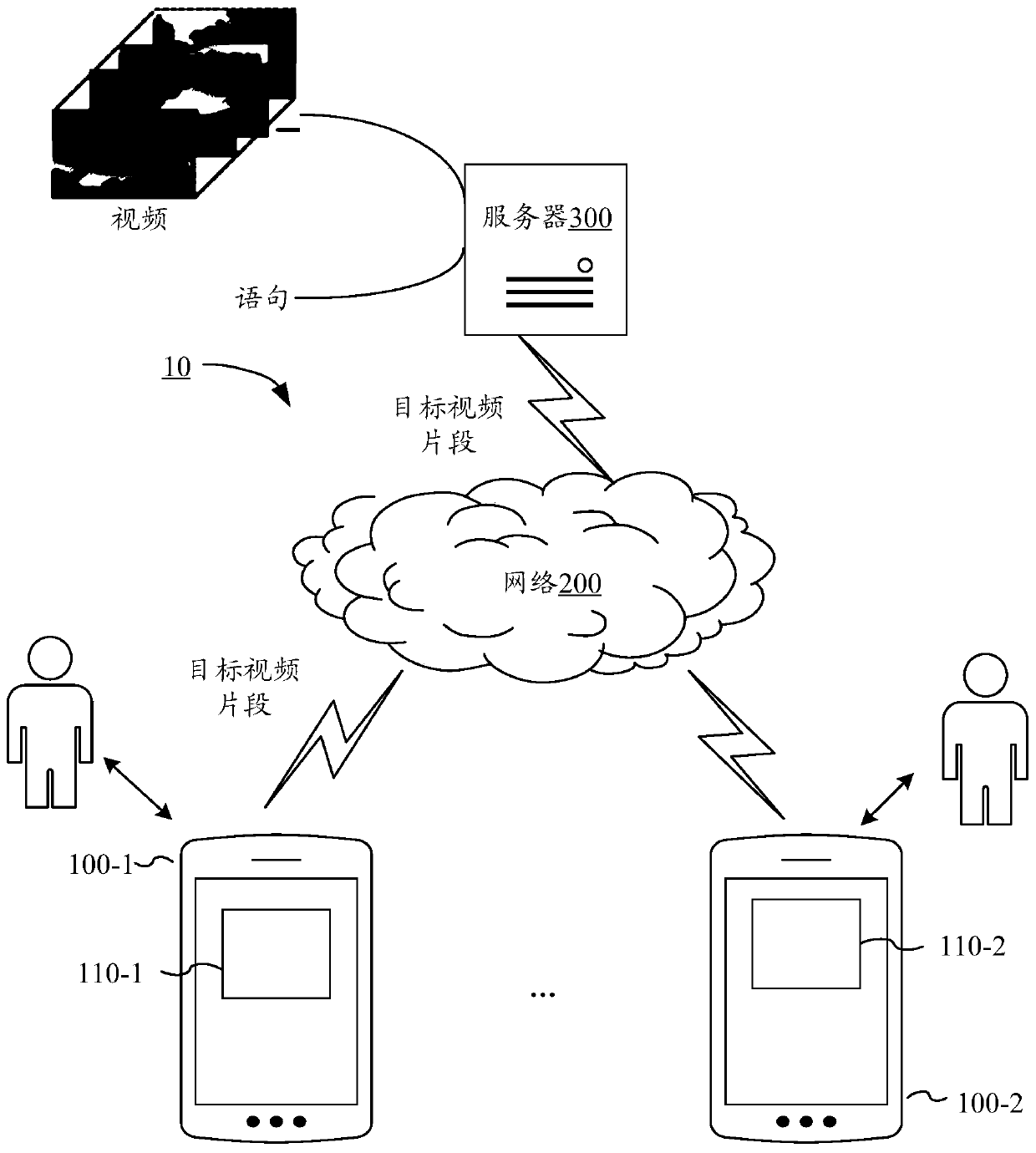

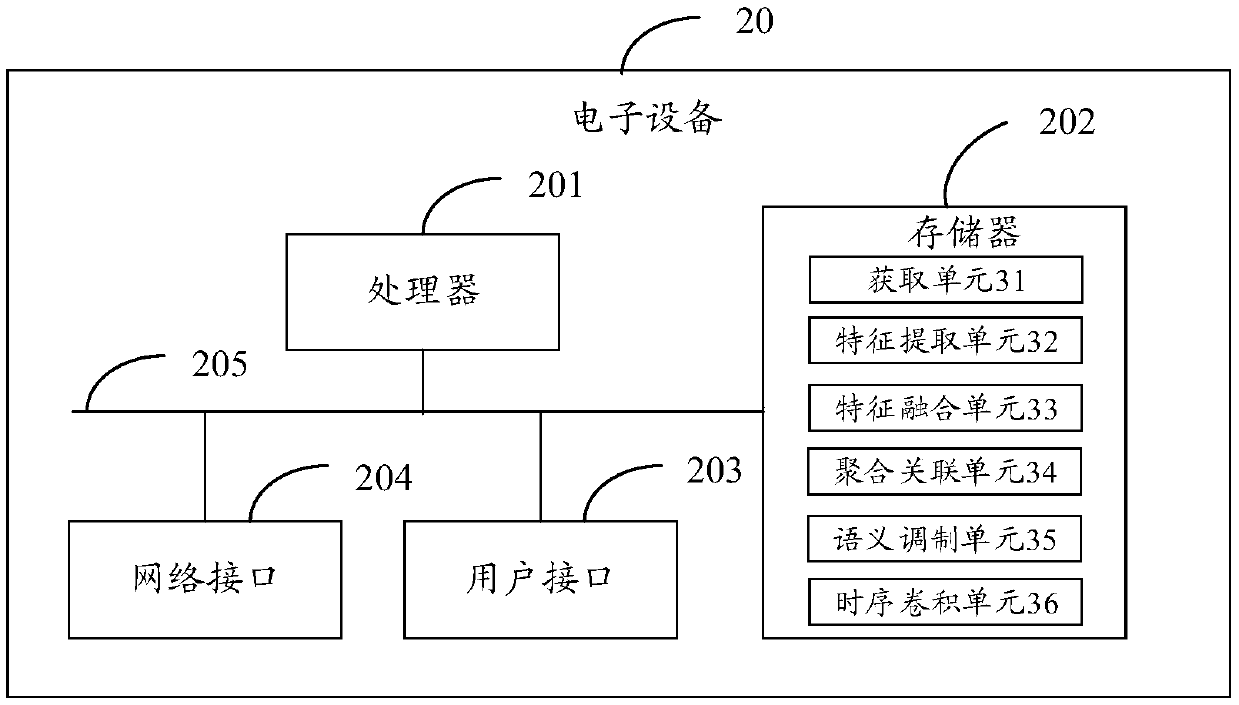

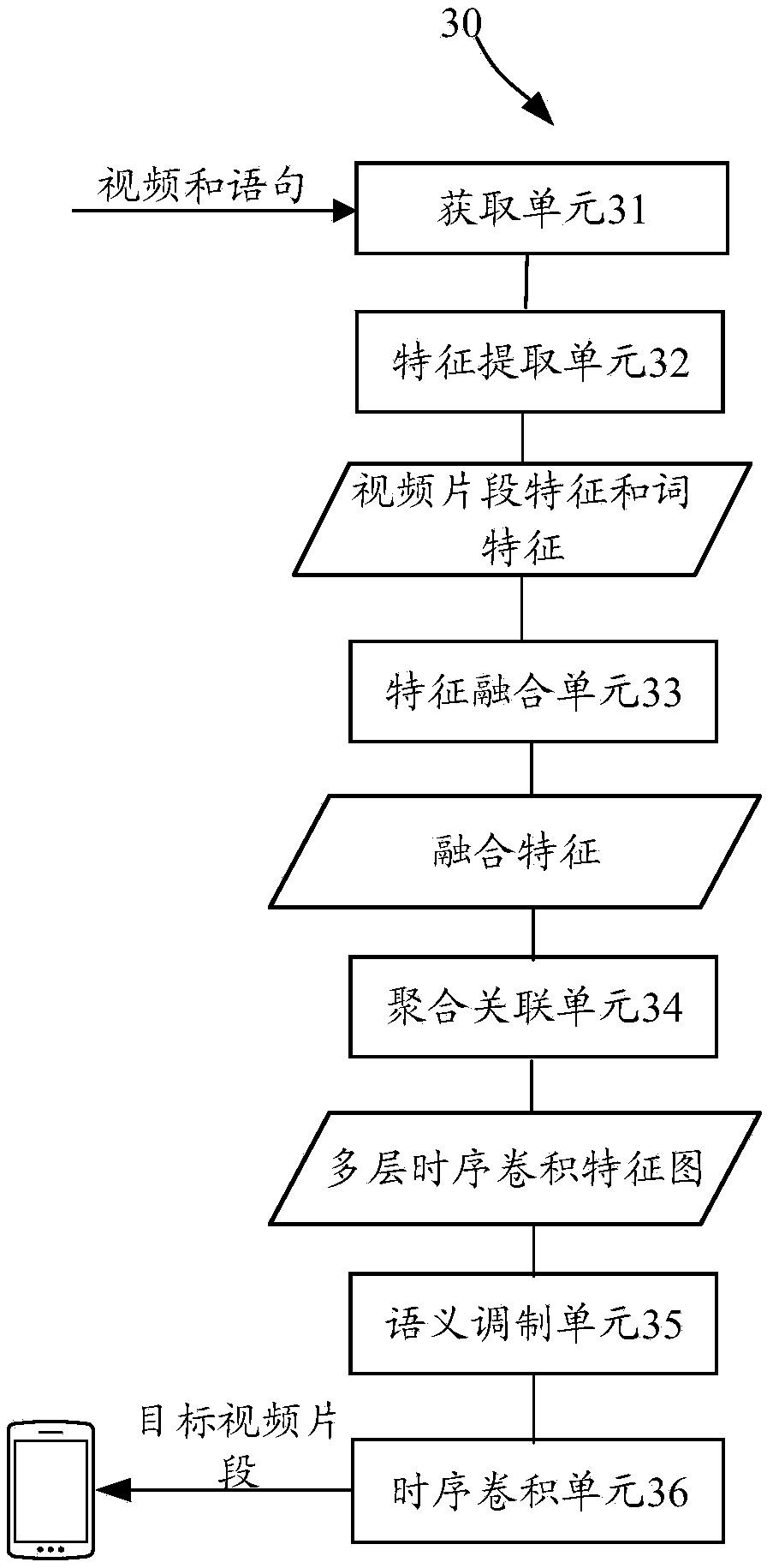

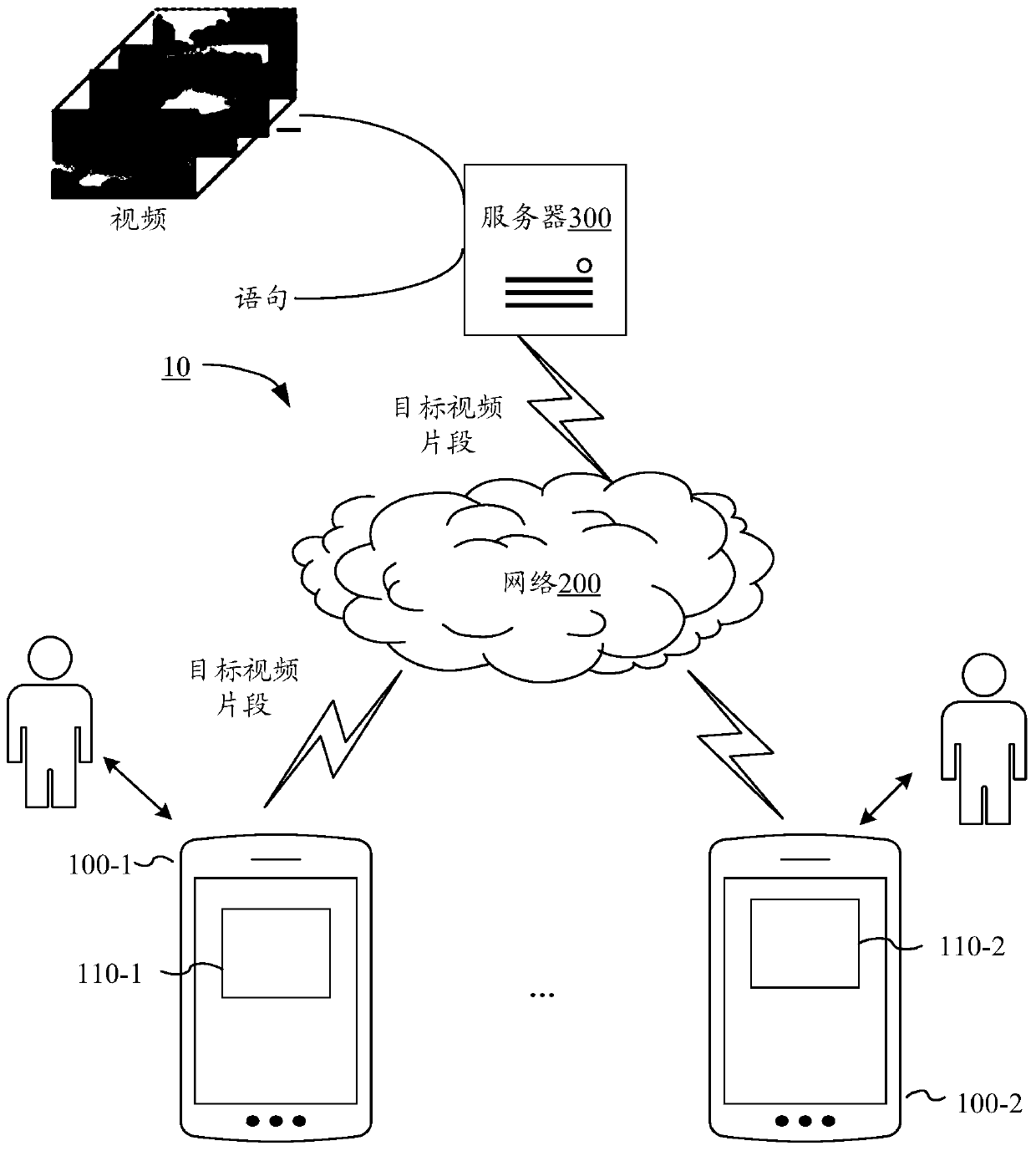

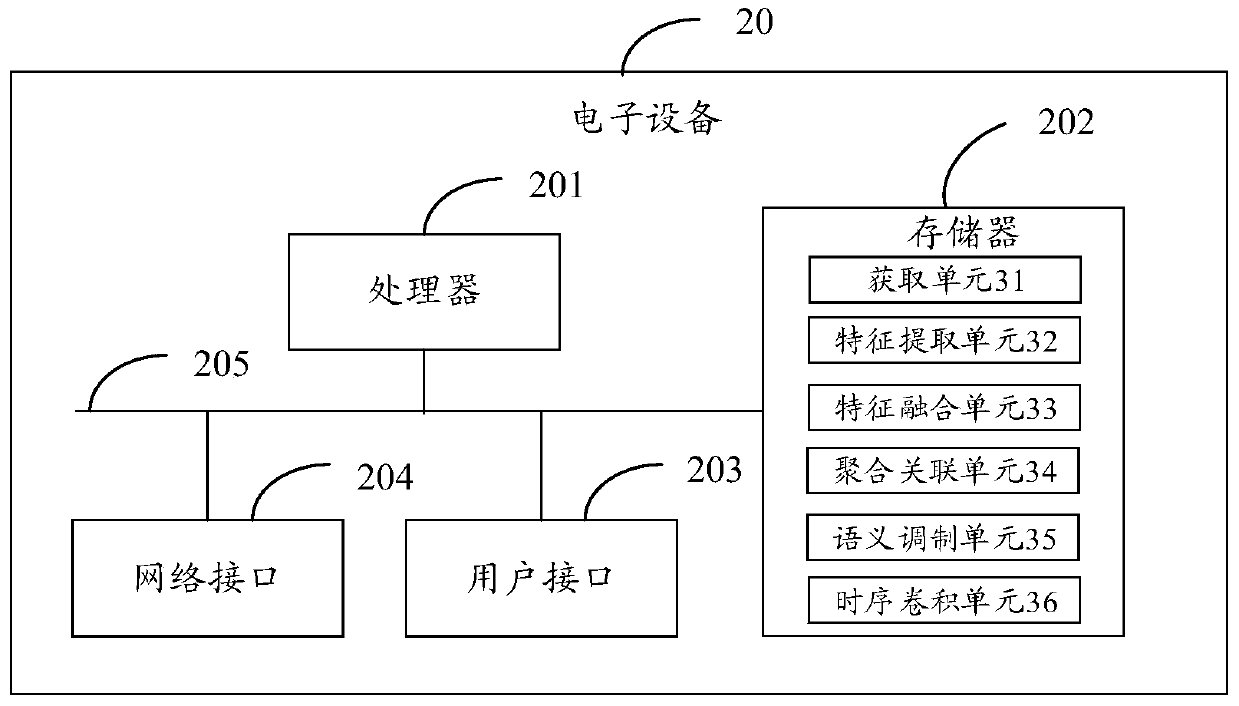

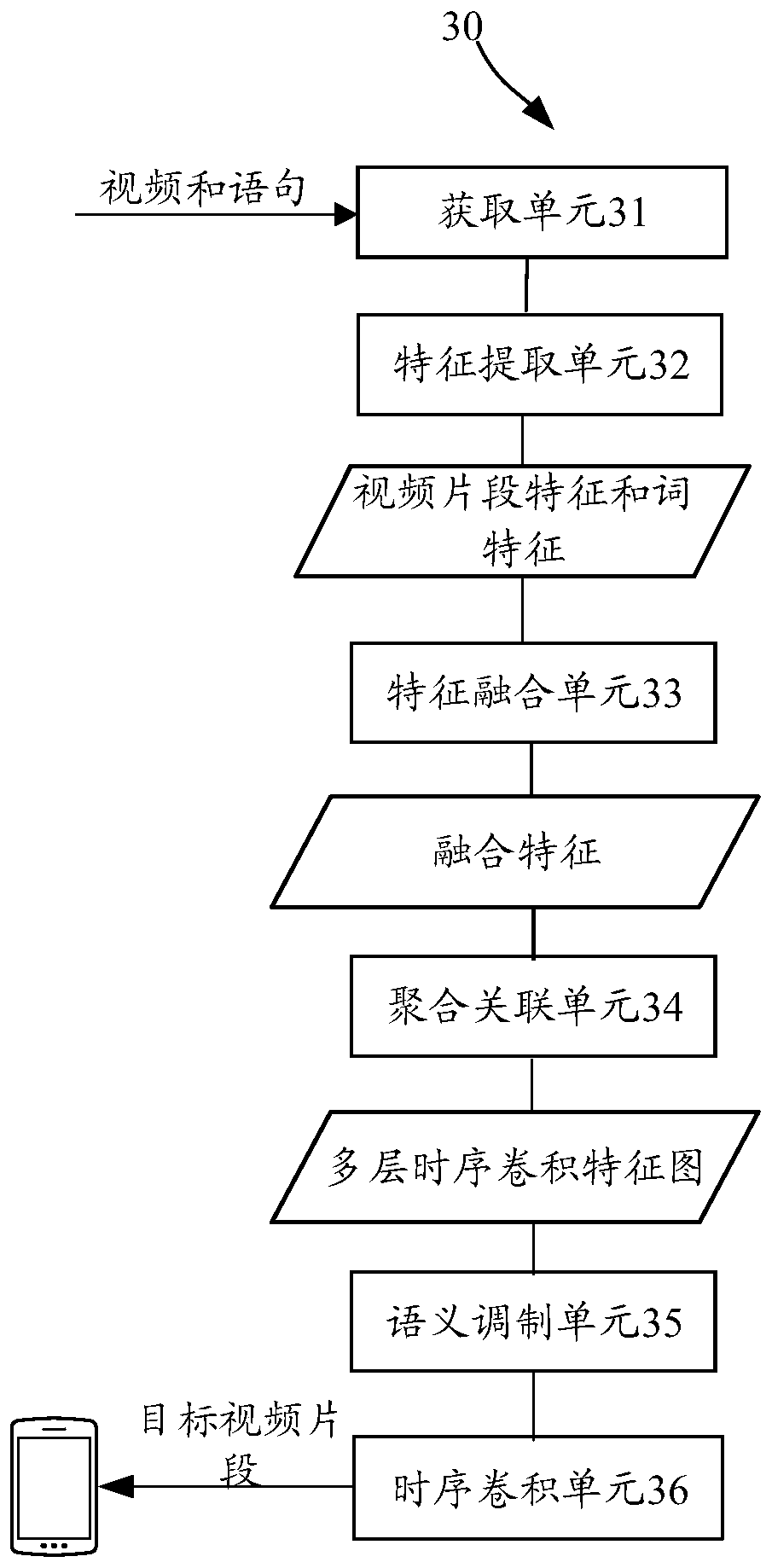

Video positioning method and device and electronic equipment

ActiveCN110225368AFast and high-precision positioningClosely relatedCharacter and pattern recognitionSelective content distributionFeature extractionSemantics

The invention discloses a video positioning method and device and electronic equipment. The method comprises the steps of obtaining a video and a statement; performing feature extraction on the videoand the statement respectively to obtain corresponding video clip features and word features; fusing the video clip features and the word features to obtain fusion features; aggregating and associating the fusion features layer by layer based on a time sequence through a time sequence convolutional neural network to obtain a multi-layer time sequence convolutional feature map; and performing semantic modulation on each layer of feature map in the multi-layer time sequence convolution feature map to obtain a modulated feature map, and performing time sequence convolution operation on the modulated feature map to obtain a target video clip related to semantics of the statement. According to the method and the device, the target video clip related to semanteme of the input statement can be quickly and accurately positioned.

Owner:TENCENT TECH (SHENZHEN) CO LTD

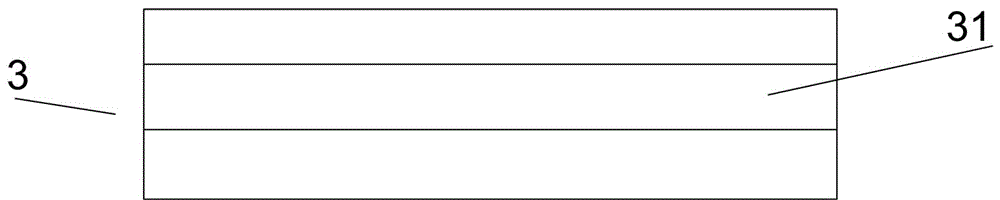

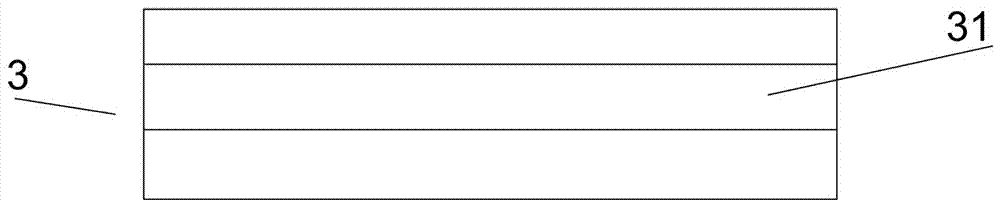

Sound insulating PVB (polyvinyl butyral) laminated glass and preparation method thereof

ActiveCN106003922AStrong sound insulationReduce internal voidsSynthetic resin layered productsLaminationPolyvinyl butyralPolystyrene

The invention relates to sound insulating glass and a preparation method thereof, in particular to sound insulating PVB (polyvinyl butyral) laminated glass and a preparation method thereof. The sound insulating PVB laminated glass comprises a first glass substrate, a second glass substrate, a PVB film between the first glass substrate and the second glass substrate as well as polystyrene films located between the first glass substrate and the PVB film as well as between the second glass substrate and the PVB film, wherein the first glass substrate and the second glass substrate are arranged vertically. The preparation method of the sound insulating PVB laminated glass comprises the following steps: (1) cleaning of the glass substrate; (2) preparation of the polystyrene films; (3) combining operation: the PVB film is arranged in a combining chamber for combination of the glass substrates, the PVB film and the polystyrene films; (4) prepressing for exhausting; (5) high-pressure molding. The prepared PVB laminated glass has good mechanical property, impact resistance and good sound insulating effect, the PVB film cannot fall off the glass when the laminated glass meets external impact or the external environmental temperature changes acutely, and the service life is long.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

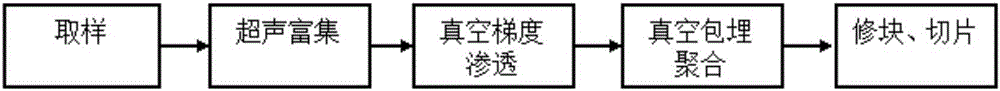

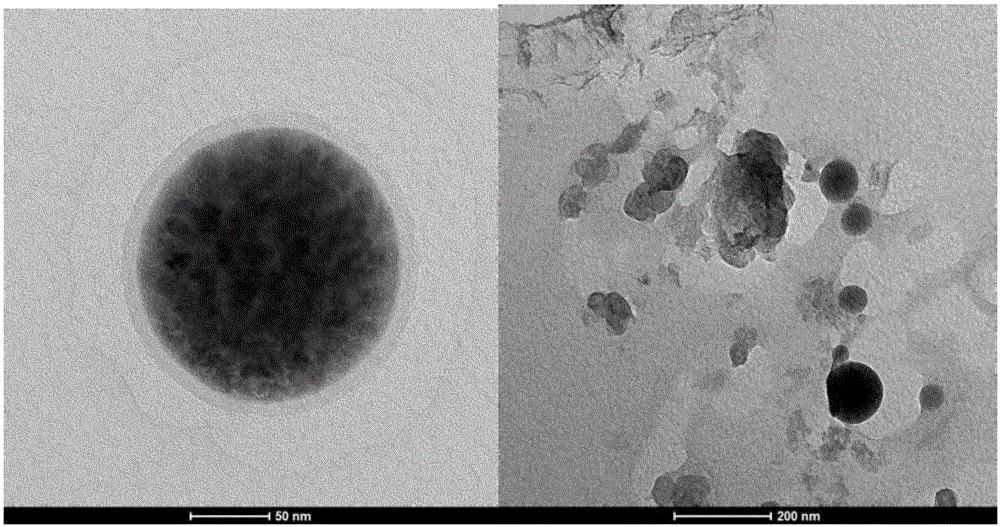

Preparation method of transmission electron microscope samples of atmospheric particulates

InactiveCN105866152ASolve sheddingAggregation tightPreparing sample for investigationMaterial analysis by measuring secondary emissionParticulatesElectron microscope

The invention discloses a preparation method of transmission electron microscope samples of atmospheric particulates, and belongs to the preparation method of atmospheric particulate samples. The atmospheric particulates are collected by a sampler, a collecting membrane with sample particles is immersed in an ethanol solution and enriched sample particles are obtained through ultrasound concussion; enriched sample particles are subjected to gradient penetration of a mixture of ethanol and an embedding medium under a certain vacuum degree, and then polymerized for 48 hours at the temperature of 60 DEG C after stood for 8 hours under vacuum, and embedding blocks of the polymerized particulates are subjected to block repairing and slicing, and finally ultrathin section samples of the atmospheric particulates are obtained. The preparation method of the transmission electron microscope samples of the atmospheric particulates disclosed by the invention effectively eliminates residual gases among the particulates in the embedding process, and better fixes structure states of the particulates. The observation of a transmission electron microscope on the section samples of the atmospheric particulates can provide a technical way for a formation mechanism of the internal structures of the atmospheric particulates, and inference research of a formation reaction mechanism of the atmospheric particulates. The method is applicable to atmospheric particulates, coal particulates and the like.

Owner:CHINA UNIV OF MINING & TECH

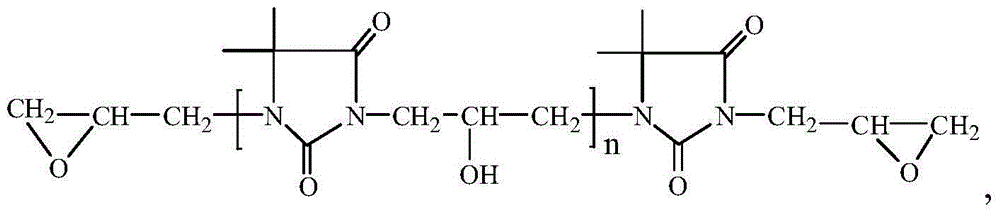

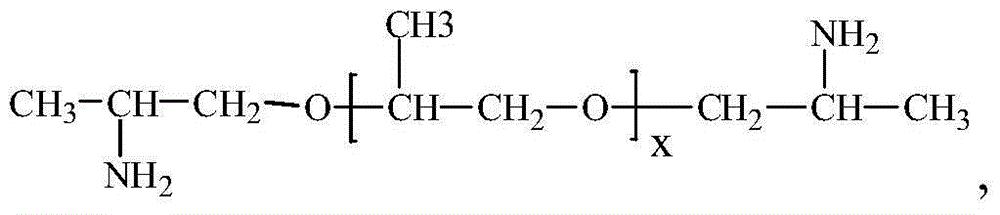

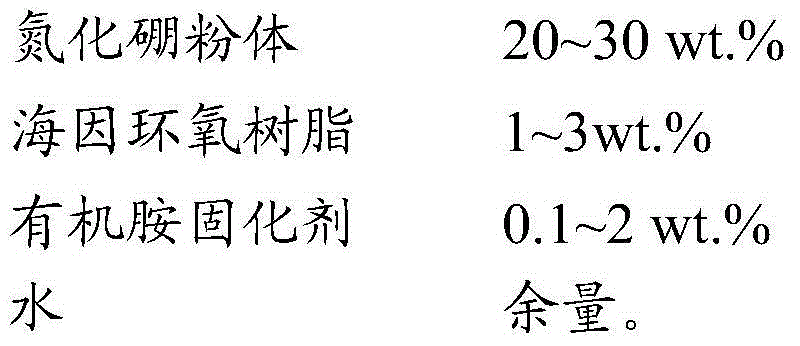

Surface-organically-modified boron nitride powder, preparation method and applications thereof

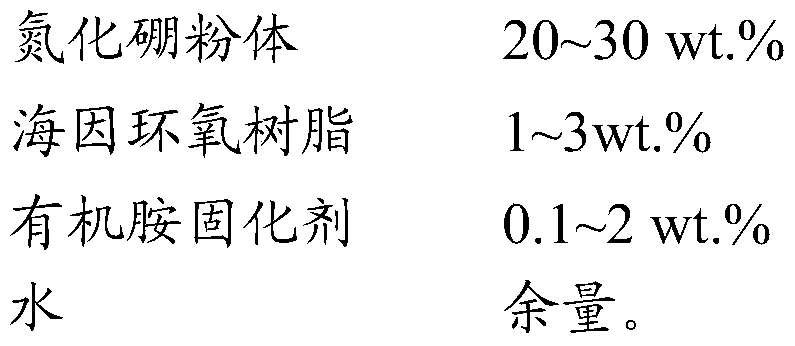

The present invention discloses surface-organically-modified boron nitride powder, wherein a hydantoin epoxy resin cross-linked polymerization product layer is coated on the particle surface, the hydantoin epoxy resin cross-linked polymerization product content in the surface-organically-modified boron nitride powder is 5-10 wt.%, and the raw materials for preparing the surface-organically-modified boron nitride powder comprise 20-30 wt.% of boron nitride, 1-3 wt.% of a hydantoin epoxy resin, 0.1-2 wt.% of an organic amine curing agent, and the balance of water. According to the present invention, the surface-organically-modified boron nitride powder has characteristics of good compatibility with polymer substrates and easy dispersion in the substrate, and can maintain good construction or processing fluidity under the high filling rate of 47.5 wt.%, and the thermal conductivity of the prepared epoxy composite material is up to 2.42 W / m.K.

Owner:FOSHAN SANSHUI JINGE NEW MATERIALS CO LTD

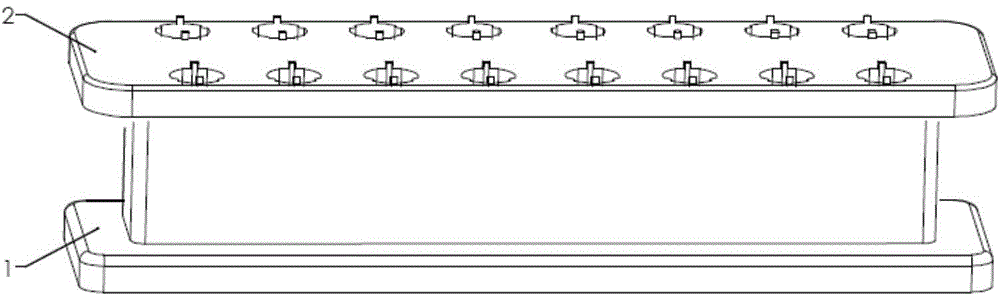

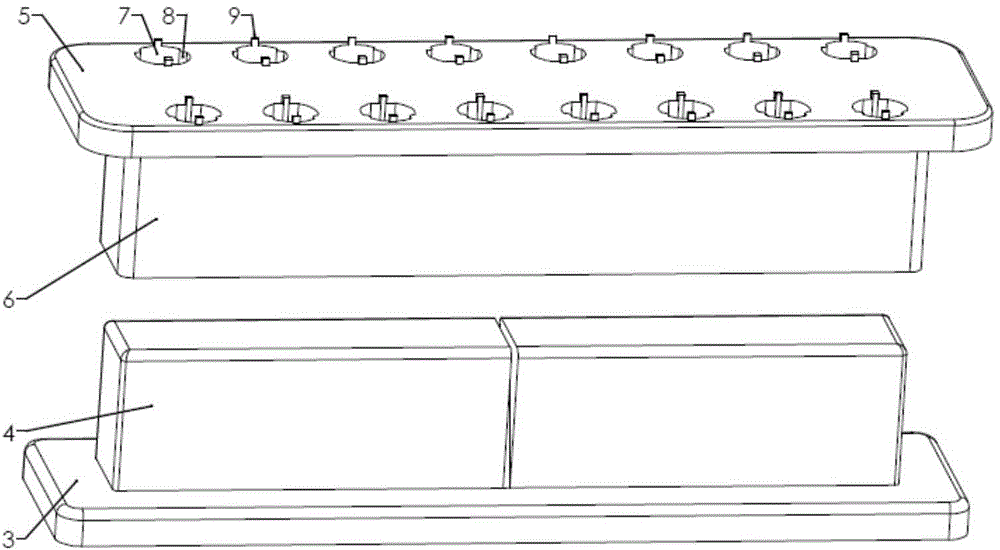

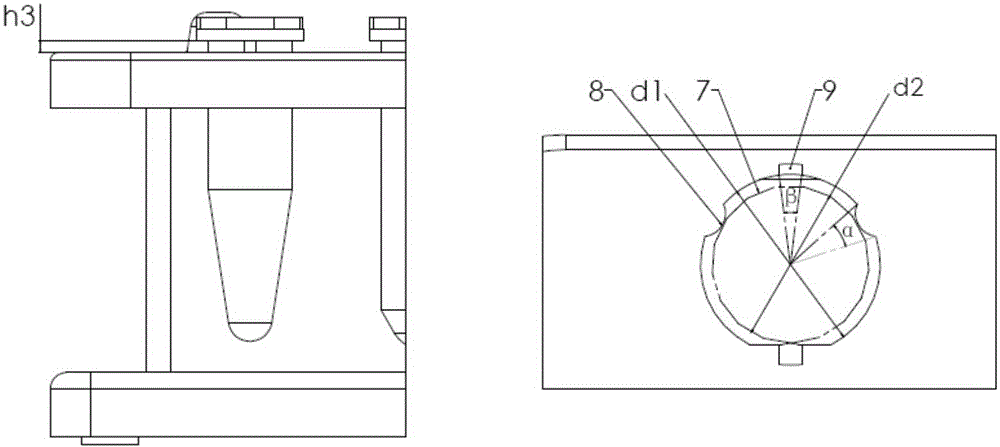

Combined type magnetic frame

The invention discloses a combined type magnetic frame. The combined type magnetic frame provided by the invention comprises a magnet frame and a micro test tube frame. The magnet frame mainly comprises a magnet frame base and a column body part which is perpendicularly fixed to the magnet frame base and internally provided with magnets. The micro test tube frame mainly comprises a micro test tube frame flat plate and a column body part which is perpendicularly fixed to the lower end of the micro test tube frame flat plate and provided with a cavity structure. The column body part which is provided with the cavity structure is matched with the column body part which is perpendicularly fixed to the magnet frame base and internally provided with the magnets, so that separation and combination of the magnet frame and the micro test tube frame are achieved. The micro test tube frame flat plate is provided with micro test tube holes used for holding micro test tubes. The micro test tube holes are internally provided with flanges and boss bodies. Through the combined type magnetic frame provided by the invention, a user can conduct overturning, inclining, rotating, vibrating and other operations with the micro test tubes and the magnetic frame as a whole, and the work efficiency and the operation uniformity of a micro test tube chamber are improved exponentially.

Owner:瀚吉康生物科技(北京)有限公司

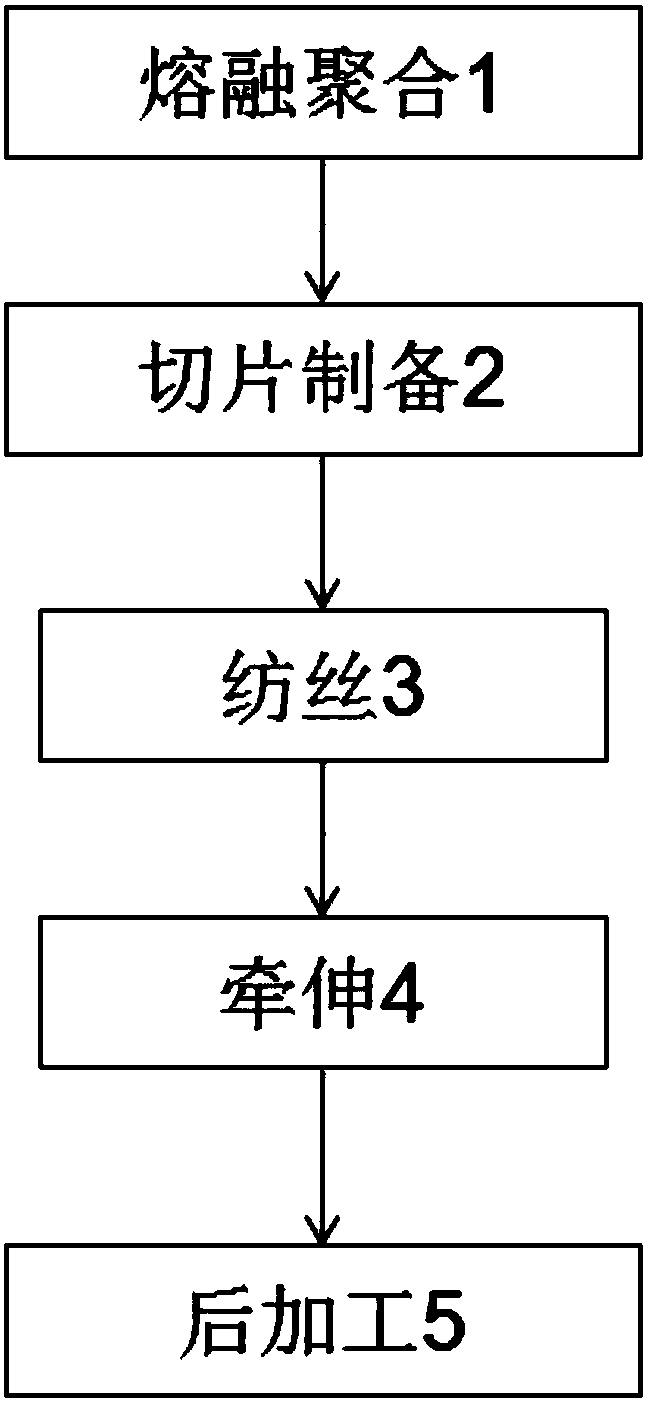

Flame-retardant anti-molten-drop chinlon 6 filament production method

InactiveCN107675284APlay the effect of gradient filteringAggregation tightFlame-proof filament manufactureNon-woven fabricsTemperature controlChemical industry

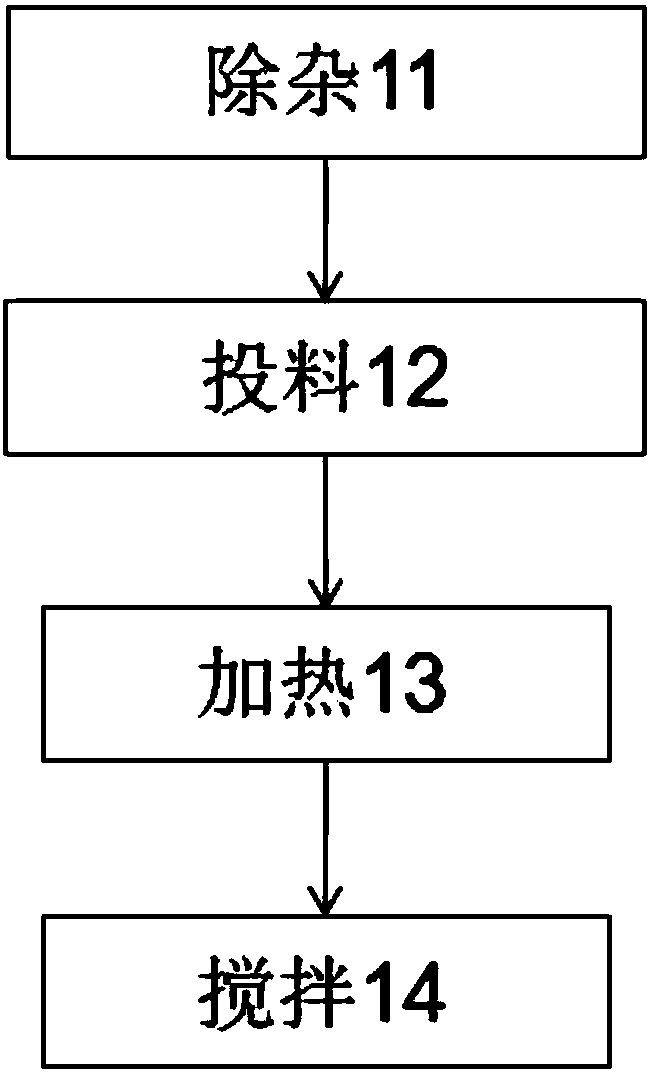

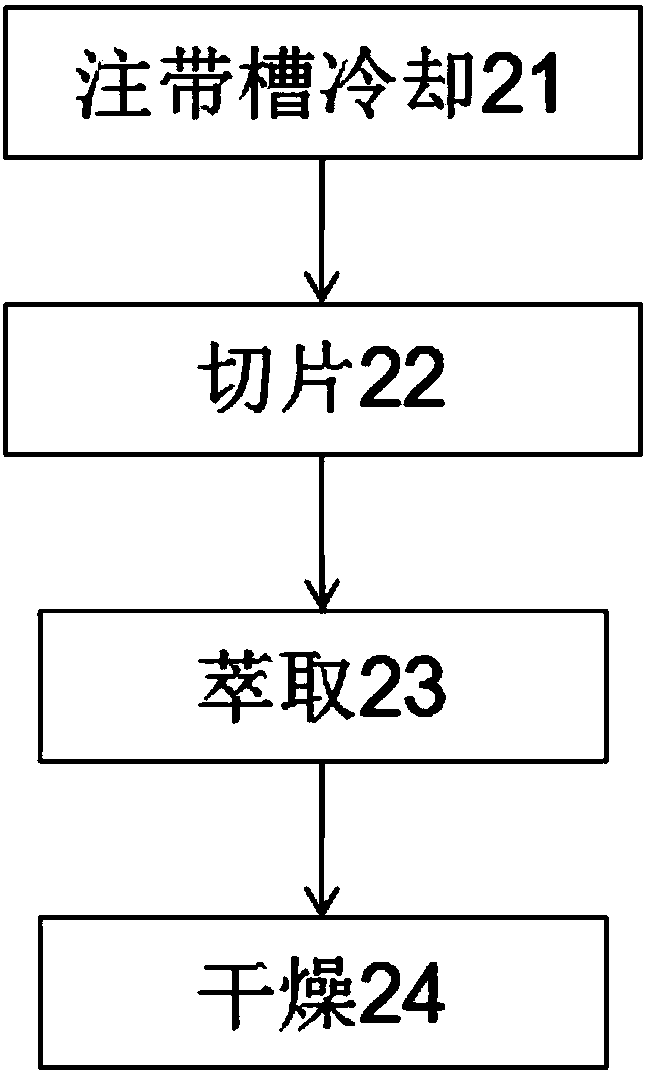

The invention discloses a production method of flame-retardant and droplet-resistant nylon 6 filament, which belongs to the field of chemical industry and includes melt polymerization, slice preparation, spinning, drawing and post-processing in sequence, heating caprolactam into a molten state, and melting the already Add lactam, initiator, stabilizer and graphene evenly into the polymerization tube; heat to control the temperature of the first polymerization zone at 130-150°C, the temperature of the second polymerization zone at 200-220°C, and the temperature of the third polymerization zone The temperature is 250-270°C, the temperature of the polymerization zone in the fourth section is controlled at 230-250°C, and the temperature of the polymerization zone in the fifth section is controlled at 210-230°C; stir evenly, and enter the slice preparation process after the polymerization is completed. The beneficial effects of the present invention are as follows: graphene powder is introduced in the melt polymerization stage, so that graphene and nylon 6 are fully mixed and contacted, and when nylon 6 is burned, the carbon ash produced by graphene combustion will cover nylon 6 melt droplets, preventing nylon 6 The formation of molten droplets, coated on the surface of nylon 6 fiber, also prevents further burning inside the fiber.

Owner:福州市晋安区技智企业管理咨询有限公司

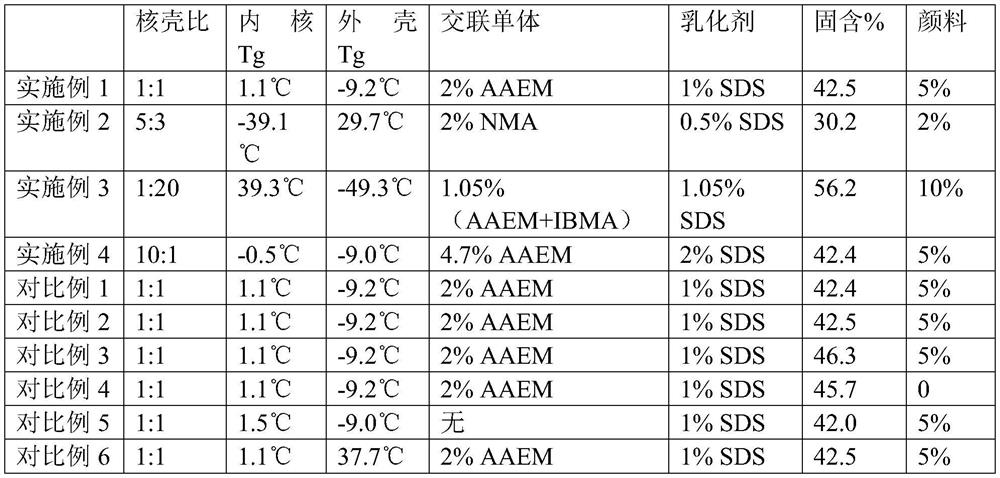

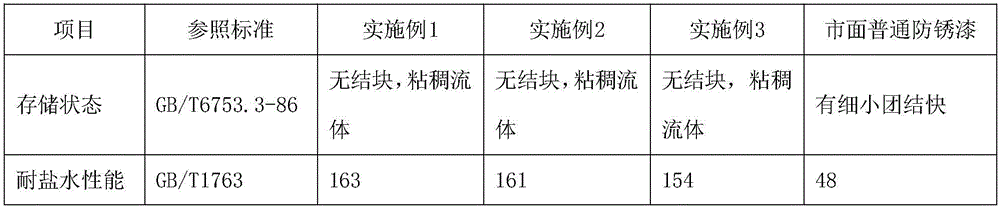

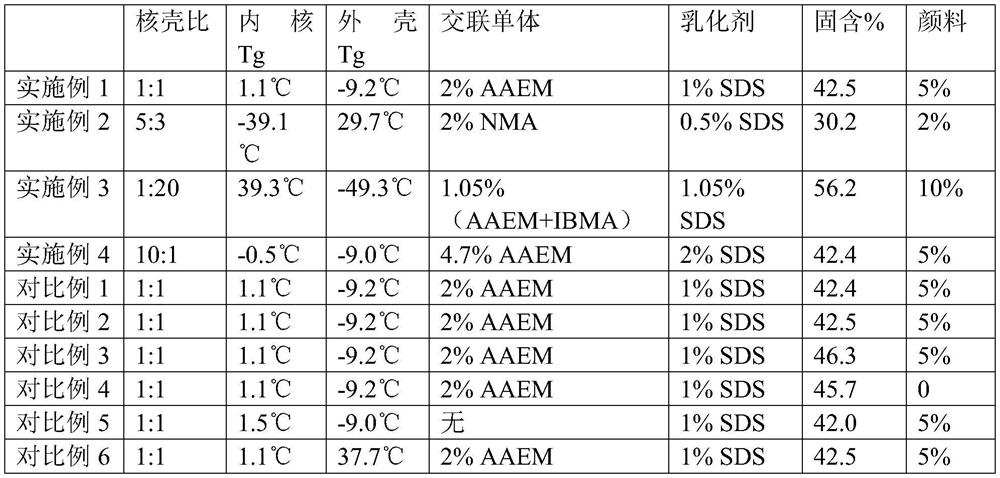

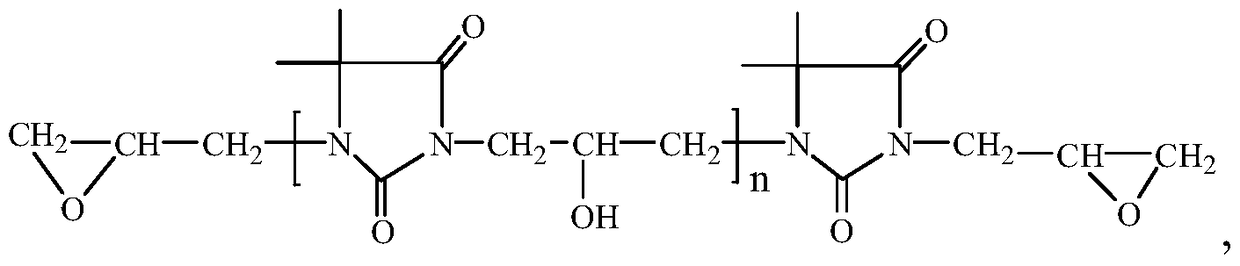

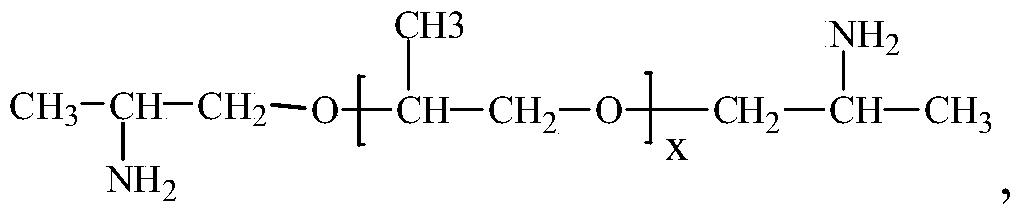

Preparation method of high-color-fastness water-based acrylate resin color paste, resin color paste, and application and use method of resin color paste

ActiveCN112574361AImprove the problem of weak tinting power and uneven coloringImprove color fastness propertiesTextiles and paperPolymer sciencePigment dispersion

The invention relates to a preparation method of high-color-fastness water-based acrylate resin color paste, the resin color paste, and application and the use method of the resin color paste. The water-based acrylate resin color paste is a polymer with a core-shell structure, wherein an inner core polymer is a composition of an acrylate polymer and a pigment, and a shell polymer is a water-basedacrylate polymer synthesized in an emulsion polymerization manner. According to the invention, the pigment is added in a reaction process, a molecular chain in a polymer solution synthesized by solution polymerization and the pigment are dispersed more uniformly and combined more tightly, and after the polymer is self-emulsified to form emulsion particles, the pigment is uniformly dispersed and wrapped in the emulsion particles; and thus, the situation of phase separation caused by nonuniform pigment dispersion and pigment aggregation in the film forming process of the paste is reduced, and the color fastness of the water-based acrylate resin color paste is greatly improved.

Owner:WANHUA CHEM GRP CO LTD

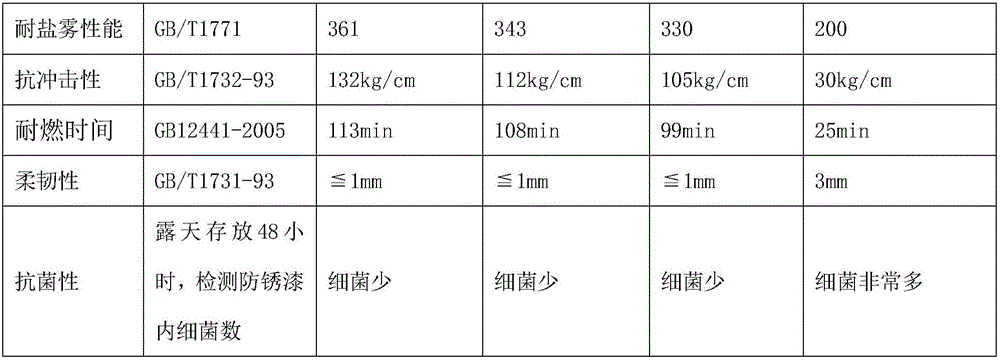

Antirust paint added with magnet powder for food production machine

InactiveCN106118303ALow kinematic viscosityAggregation tightAntifouling/underwater paintsPaints with biocidesWater immersionHigh surface

The invention relates to the field of an antirust paint, in particular to an antirust paint added with magnet powder for food production machine for a food production machine. The antirust paint is prepared from the following raw materials in parts by weight: 30 to 32 parts of acrylic emulsion, 4 to 6 parts of dimethyl silicone oil, 6 to 10 parts of oxaloacetic acid, 4 to 6 parts of isocitric acid, 4 to 6 parts of cyclohexanamine benzoate, 10 to 16 parts of boric acid, 1 to 2 parts of medical chalk ash, 1 to 2 parts of dibenzothiazyl disulfide, 1.5 to 1.5 parts of catechin and 3 to 5 parts of modified magnet powder. The antirust paint provided by the invention has the advantages of non-toxic and antibacterial properties, acid and alkali and salt spray corrosion resistance, low kinematic viscosity, close polymerization between raw materials, very high surface hardness after drying, scratch and impact resistance, oil and water immersion resistance, no peeling and bubbling in long-term oil and water immersion, and service life 3 to 4 years longer than the ordinary antirust paint.

Owner:BENGBU ZHONGZHENG INDAL

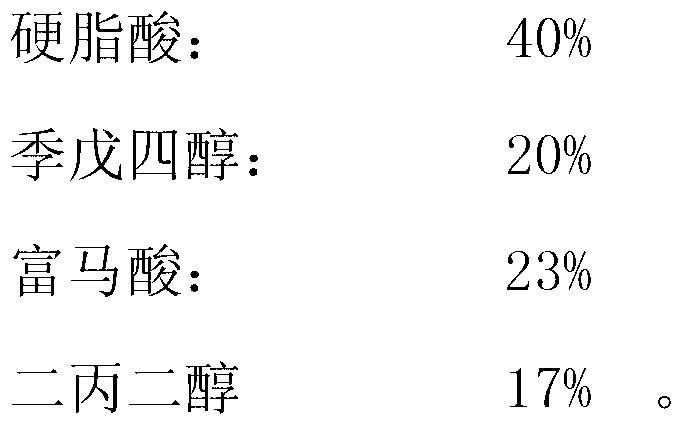

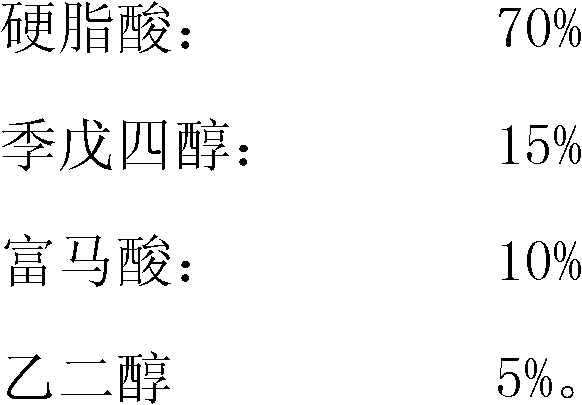

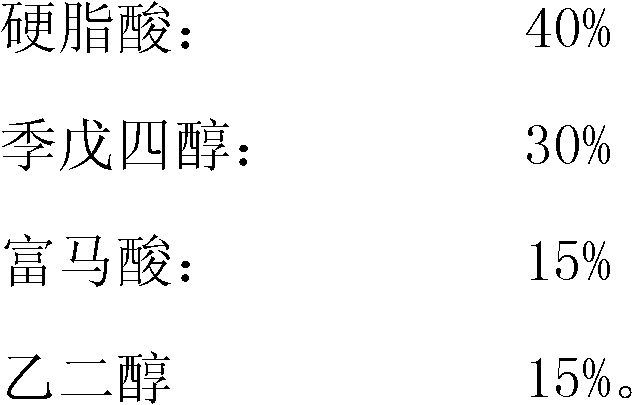

Manufacturing process of PVC (Poly Vinyl Chloride) external lubricant

ActiveCN102604060AImprove polymerization effectImprove conversion rateChemical industryPentaerythritol

The invention aims to solve the problems in the prior art, provide a PVC (Poly Vinyl Chloride) external lubricant and a manufacturing process thereof, reduce the reaction temperature in the machining process and optimize the proportioning of a product. For fulfilling the aims, the manufacturing process comprises the following steps of: firstly, carrying out recovery processing on waste liquor generated in the chemical industry to obtain fumaric acid; in the machining process, firstly, using the fumaric acid as mother liquor according to a certain ratio, then adding polyatomic alcohol according to the ratio, adding pentaerythritol proportioned according to the ratio after sufficiently stirring, and finally, adding stearic acid to carry out esterification; then carrying out polymerization at a high temperature of 150 DEG C to 160 DEG C; after polymerization, carrying out vacuum dealcoholization at a high temperature of 200 DEG C; and slicing after cooling, wherein in the whole machiningprocess, no catalyst is added. The manufacturing process has the beneficial effects of low reaction temperature, good polymerization effect and high finished product conversion rate due to the adoption of the technical scheme.

Owner:夏瑭

Antibacterial wood-like board for indoor decoration and preparation method

The invention provides an antibacterial wood-like board for indoor decoration and a preparation method. The antibacterial wood-like board is prepared from an antibacterial wood-like layer formed on the surface of a polypropylene substrate through surface co-extrusion, the polypropylene substrate is prepared from polypropylene matrix resin, a coupling agent, a bulking agent and an antioxidant through mixing and extrusion, and the antibacterial wood-like layer is prepared as follows: coating natural clinoptilolite with graphene oxide, adding the coated natural clinoptilolite and hydrazine hydrate to a silver salt solution to react to prepare antibacterial filler, then, mixing the antibacterial filler with ASA weather-resistant resin and wood-like pigment and performing extrusion to prepare the antibacterial wood-like layer. In the antibacterial wood-like board, nano-silver and graphene in the antibacterial filler are closely combined and cannot fall off easily, the antibacterial effect is more lasting, the obtained wood-like plate is endowed with good antibacterial and sterilization characteristics, meanwhile, large granules are realized through two times of fixed loading, uniform dispersion is facilitated, and production and processing are easy.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

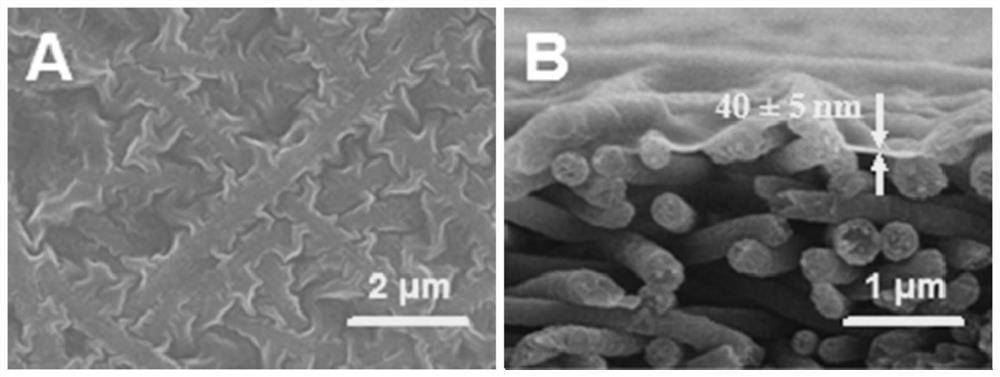

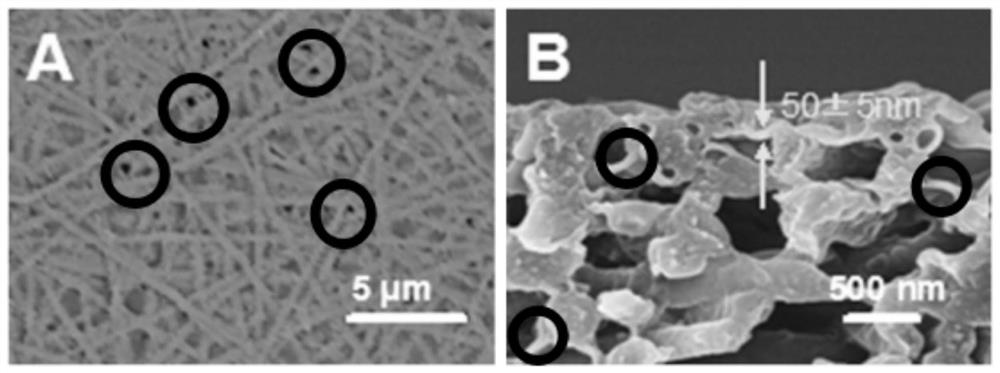

A method for preparing nanofiber-based composite nanofiltration membranes by low-temperature reverse interfacial polymerization

InactiveCN110124517BReduce evaporation rateSolve surface defectsSeawater treatmentWater/sewage treatment bu osmosis/dialysisPolymer scienceElectrospinning

The invention discloses a method for preparing a nanofiber-based composite nanofiltration membrane by low-temperature reverse interface polymerization, which is characterized in that it comprises: electrospinning a polymer solution to obtain a nanofiber non-woven fabric, which is obtained after cold pressing The nanofiber porous base membrane; the surface of the nanofiber porous base membrane is infiltrated with a low-temperature oil phase monomer solution; then the water phase monomer solution is added for reverse interfacial polymerization reaction; the nanofiber base composite nanofiltration membrane is obtained after heat treatment. The invention reduces the volatilization rate of the oil phase under low temperature conditions by controlling the temperature of the oil phase solution, provides a complete and uniform reaction interface for the reverse interface polymerization, and overcomes the skin layer inherent in the reverse interface polymerization caused by the rapid volatilization of the oil phase Defects and infiltration problems, the thickness, uniformity and density of the functional barrier layer are optimized by controlling the temperature of the oil phase solution and the polymerization parameters of the reverse interface, thereby enhancing the nanofiltration performance of the composite membrane.

Owner:DONGHUA UNIV

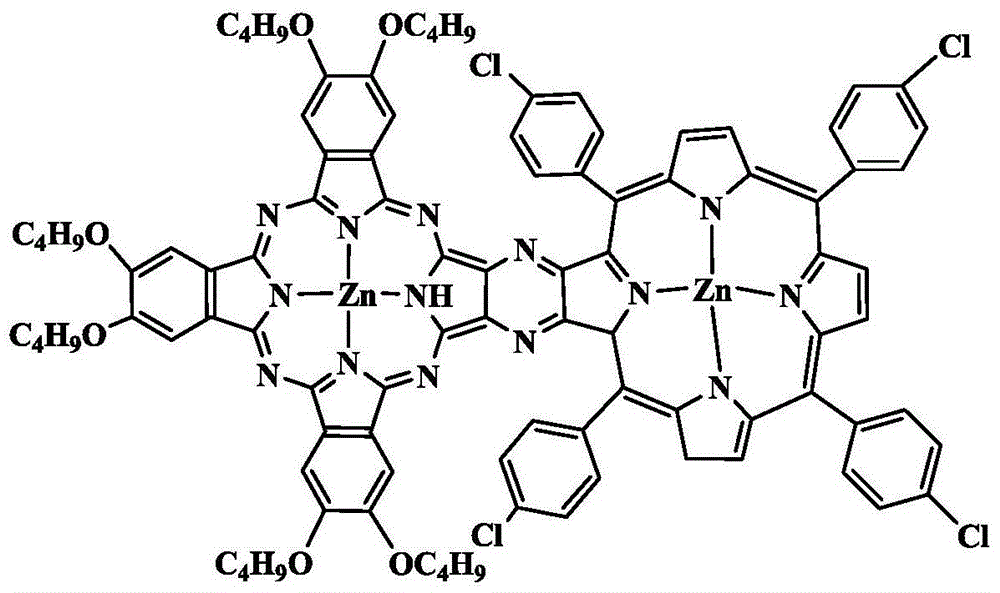

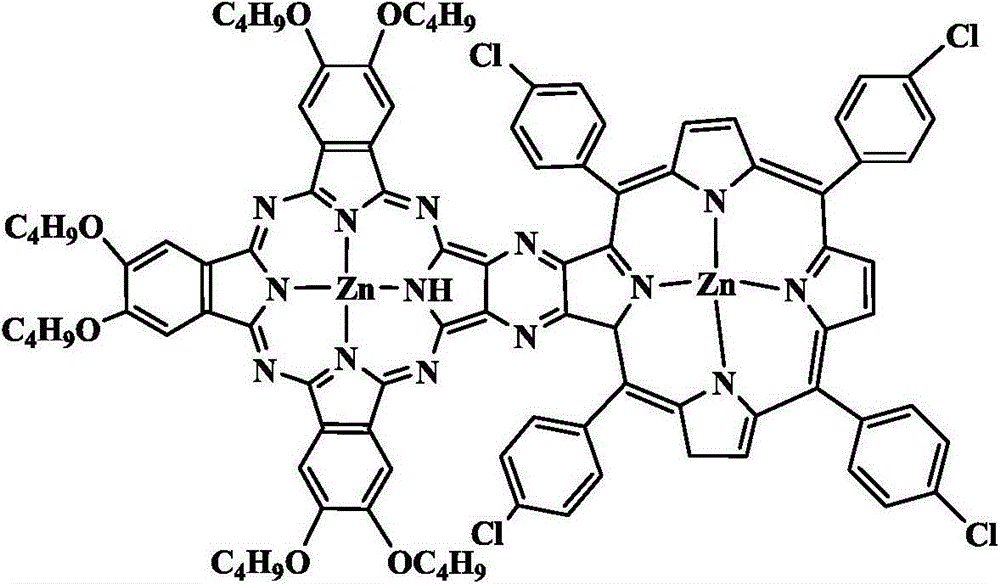

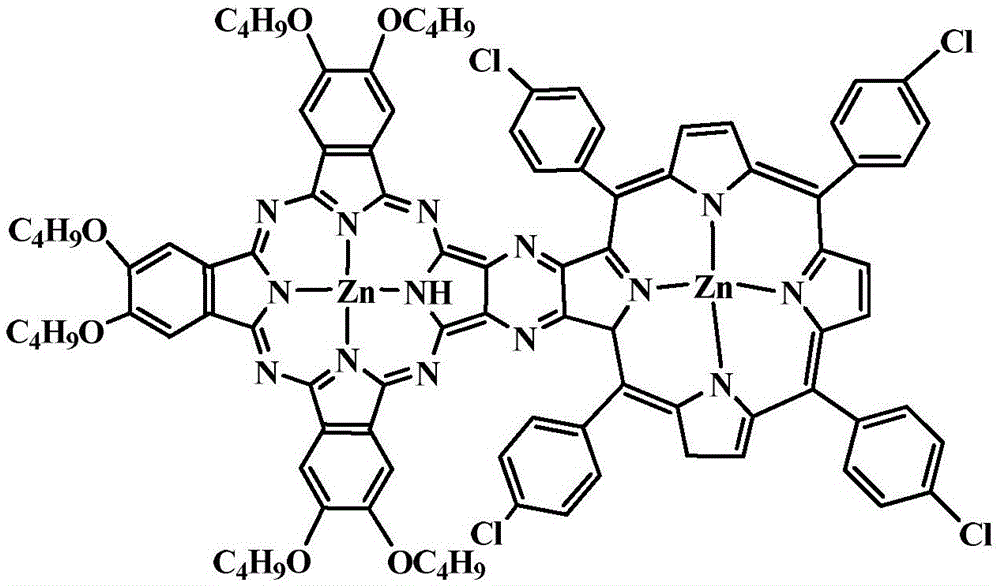

Method for carrying out microcontact printing by employing plane conjugate phthalocyanine-porphyrin coordination compound

The invention discloses a method for carrying out microcontact printing by employing a plane conjugate phthalocyanine-porphyrin coordination compound. The method comprises the following specific steps: with a dichloromethane solution of 5,10,15,20-parachloro-phenyl porphyrin zinc-hexabutoxyphthalocyanine zinc as a printing agent for microcontact printing, transferring a pattern of a PDMS stamp to a polymethyl methacrylate substrate, and adsorbing reduced copper on the substrate to obtain a fine metal pattern. A metal pattern is prepared by taking the dichloromethane solution of 5,10,15,20-parachloro-phenyl porphyrin zinc-hexabutoxyphthalocyanine zinc as microcontact printing ink on the surface of the polymethyl methacrylate substrate which is commonly used in the electron industry, so that the method is available in raw materials, low in cost and stable, and has great potential in industrial application, and a new idea is provided for the microcontact printing industry.

Owner:深圳市润宝印刷科技有限公司

Preparation method of degradable strapping tape material

The invention relates to a preparation method of a degradable strapping tape material and belongs to the technical field of packaging materials. Polylactic acid is treated by argon plasma and graftedwith acrylic acid, and a high polymer material surface is subjected to plasma treatment to be modified; the plasma initiates surface grafting, the surface of polylactic acid can be hydrophilic and keeps hydrophilic for a longer time, thus, biological compatibility of the prepared strapping tape material is improved, and the degradation cycle of the prepared strapping tape material is easy to control; polypropylene is subjected to plasma treatment by plasma polymerization, and a thin film is formed on the surface of a graft copolymer and has good heat stability, good cohesiveness with the material, high strength, uniform and complete film surface and chemical corrosion resistance; polylactic acid is an aliphatic polyester high polymer material which is completely degradable and environmentally friendly, is prepared by polymerization of lactic acid obtained by cereal fermentation and can be completely decomposed under the actions of microorganisms, water, acid, alkali and the like afterbeing discarded.

Owner:NOTTING CHANGZHOU PRECISION MACHINERY

Starch and polylactic acid composite material and preparation method thereof

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

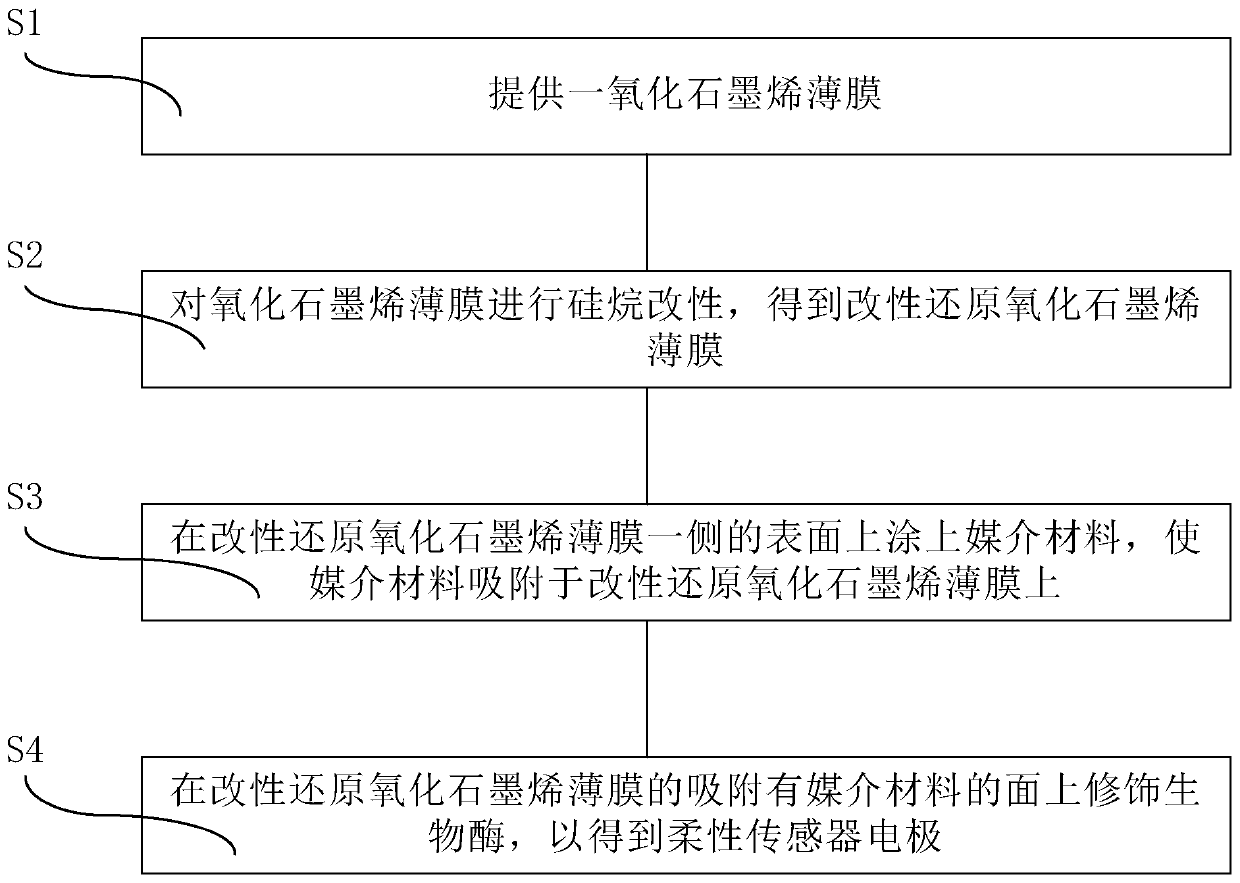

Flexible sensor electrode preparation method, flexible sensor electrode and flexible sensor

PendingCN111007126AAvoid cumbersome electropolymerization processAggregation tightMicrobiological testing/measurementBiological material analysisGraphite oxideElectrode

The invention discloses a flexible sensor electrode preparation method, a flexible sensor electrode and a flexible sensor, and the method comprises the steps: carrying out the silane modification of agraphene oxide film, and obtaining a modified reduced graphene oxide film; and adsorbing a medium material on the modified reduced graphene oxide film, and modifying biological enzyme on the modifiedreduced graphene oxide film adsorbed with the medium material. The preparation method is simple in process, a medium layer and the electrode body can be tightly combined, and the flexibility of the sensor electrode can be realized.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

A kind of PVC foam artificial leather and preparation method thereof

The invention discloses PVC (polyvinyl chloride) foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises a fabric base material, a foaming layer and a surface layer which are attached from inside to outside sequentially, wherein the foaming layer comprises components in parts by weight as follows: 95-105 parts of PVC resin, 75-85 parts of filling powder, 75-85 parts of a plasticizer, 3.5-4.0 parts of a stabilizer, 4.5-5.5 parts of a foaming agent and 9.5-10.5 parts of masterbatch; the surface layer comprises components in parts by weight as follows: 65-75 parts of PVC resin, 6-8 parts of filling powder, 46-52 parts of a plasticizer, 1.5-3 parts of a stabilizer and 4.5-5.5 parts of masterbatch. The preparation method comprises steps as follows: (1), blending; (2), mixing, open milling and filtering; (3), calendering attachment; (4), cooling; (5), foaming; (6), embossing, cooling and rolling-up to obtain a finished PVC foamed artificial leather product. The artificial leather prepared with the method feels good, and is good in texture, high in breathability and good in wear resistance.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

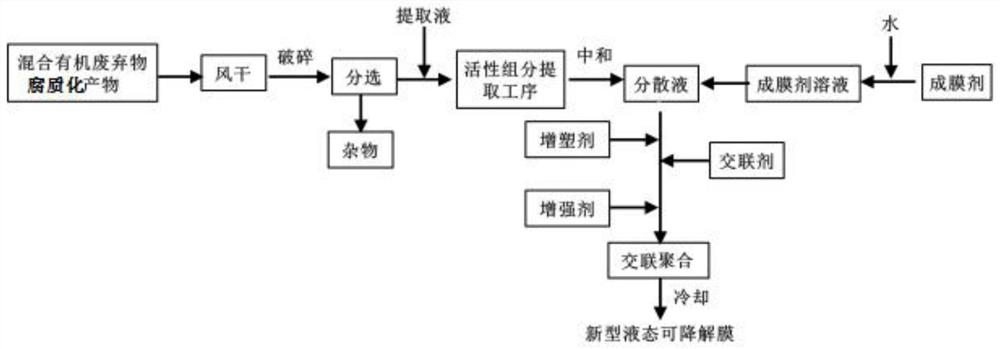

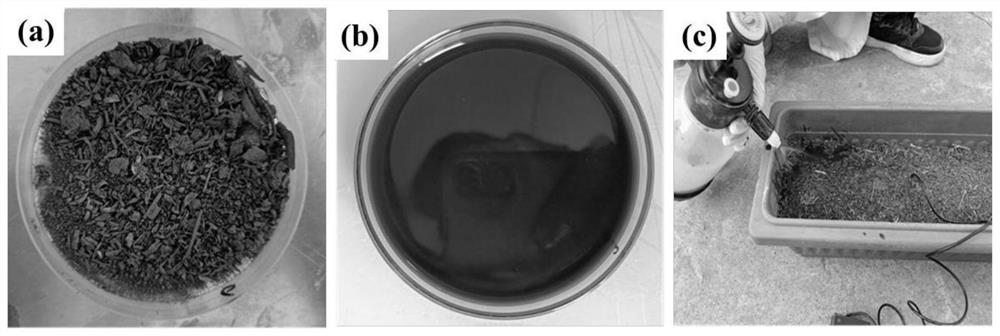

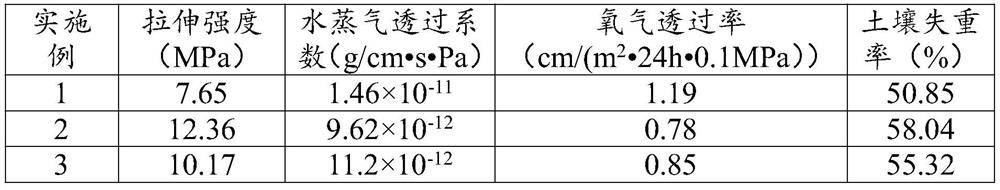

Liquid degradable mulching film produced by utilizing humus product as well as preparation method and application of liquid degradable mulching film

PendingCN114702711AEasy to moveReduce crystallinityBio-organic fraction processingOrganic fertilisersPolymer sciencePlasticizer

The invention belongs to the technical field of solid waste resource utilization, and particularly relates to a liquid degradable mulching film produced by utilizing a humus product as well as a preparation method and application of the liquid degradable mulching film. Rural mixed organic waste humus products are adopted as raw materials, active organic components in the raw materials are extracted through an alkali extracting agent, and then a film-forming agent, a plasticizer, a cross-linking agent and a reinforcing agent are added. The film-forming agent and the active organic component form a stable and dense three-dimensional network macromolecular chain polymer film structure through the cross-linking polymerization effect of the cross-linking agent; plasticizer molecules are inserted among molecular chains of the polymer film structure, so that the acting force among the molecular chains is weakened, the mobility of the molecular chains is increased, and the crystallinity of the molecular chains is reduced, thereby increasing the plasticity of the polymer film structure, adjusting the flexibility of the polymer film structure and improving the mechanical property of the polymer film structure; the reinforcing agent and the polymer form hydrogen bonds and are tightly combined, so that the mechanical property of the polymer membrane structure is improved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A kind of pvb sound insulation laminated glass and preparation method thereof

ActiveCN106003922BStrong sound insulationReduce internal voidsSynthetic resin layered productsLaminationPolystyreneHigh pressure

The invention relates to sound insulating glass and a preparation method thereof, in particular to sound insulating PVB (polyvinyl butyral) laminated glass and a preparation method thereof. The sound insulating PVB laminated glass comprises a first glass substrate, a second glass substrate, a PVB film between the first glass substrate and the second glass substrate as well as polystyrene films located between the first glass substrate and the PVB film as well as between the second glass substrate and the PVB film, wherein the first glass substrate and the second glass substrate are arranged vertically. The preparation method of the sound insulating PVB laminated glass comprises the following steps: (1) cleaning of the glass substrate; (2) preparation of the polystyrene films; (3) combining operation: the PVB film is arranged in a combining chamber for combination of the glass substrates, the PVB film and the polystyrene films; (4) prepressing for exhausting; (5) high-pressure molding. The prepared PVB laminated glass has good mechanical property, impact resistance and good sound insulating effect, the PVB film cannot fall off the glass when the laminated glass meets external impact or the external environmental temperature changes acutely, and the service life is long.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

Microcontact printing method using planar conjugated phthalocyanine porphyrin dyad complex

InactiveCN104387836BAggregation tightEasy to adjustPattern printingInksMicrocontact printingPolymethyl methacrylate

The invention discloses a method for carrying out microcontact printing by employing a plane conjugate phthalocyanine-porphyrin coordination compound. The method comprises the following specific steps: with a dichloromethane solution of 5,10,15,20-parachloro-phenyl porphyrin zinc-hexabutoxyphthalocyanine zinc as a printing agent for microcontact printing, transferring a pattern of a PDMS stamp to a polymethyl methacrylate substrate, and adsorbing reduced copper on the substrate to obtain a fine metal pattern. A metal pattern is prepared by taking the dichloromethane solution of 5,10,15,20-parachloro-phenyl porphyrin zinc-hexabutoxyphthalocyanine zinc as microcontact printing ink on the surface of the polymethyl methacrylate substrate which is commonly used in the electron industry, so that the method is available in raw materials, low in cost and stable, and has great potential in industrial application, and a new idea is provided for the microcontact printing industry.

Owner:深圳市润宝印刷科技有限公司

A video positioning method, device and electronic equipment

ActiveCN110225368BFast and high-precision positioningAggregation tightCharacter and pattern recognitionSelective content distributionFeature extractionComputer graphics (images)

The invention discloses a video positioning method, device and electronic equipment. Wherein, the method includes: acquiring video and sentences; performing feature extraction on the video and the sentence respectively to obtain corresponding video segment features and word features; fusing the video segment features and the word features to obtain fusion features ; Aggregating and associating the fusion feature layer by layer based on time series through a time series convolutional neural network to obtain a multi-layer time series convolution feature map; performing semantic modulation on each layer feature map in the multi-layer time series convolution feature map to obtain modulation After the feature map, and perform temporal convolution operation on the modulated feature map to obtain the target video segment related to the semantics of the sentence. Through the present invention, it is possible to quickly and accurately locate the target video segment related to the semantics of the input sentence.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Manufacturing process of PVC (Poly Vinyl Chloride) external lubricant

ActiveCN102604060BImprove polymerization effectImprove conversion rateChemical industryReaction temperature

The invention aims to solve the problems in the prior art, provide a PVC (Poly Vinyl Chloride) external lubricant and a manufacturing process thereof, reduce the reaction temperature in the machining process and optimize the proportioning of a product. For fulfilling the aims, the manufacturing process comprises the following steps of: firstly, carrying out recovery processing on waste liquor generated in the chemical industry to obtain fumaric acid; in the machining process, firstly, using the fumaric acid as mother liquor according to a certain ratio, then adding polyatomic alcohol according to the ratio, adding pentaerythritol proportioned according to the ratio after sufficiently stirring, and finally, adding stearic acid to carry out esterification; then carrying out polymerization at a high temperature of 150 DEG C to 160 DEG C; after polymerization, carrying out vacuum dealcoholization at a high temperature of 200 DEG C; and slicing after cooling, wherein in the whole machining process, no catalyst is added. The manufacturing process has the beneficial effects of low reaction temperature, good polymerization effect and high finished product conversion rate due to the adoption of the technical scheme.

Owner:夏瑭

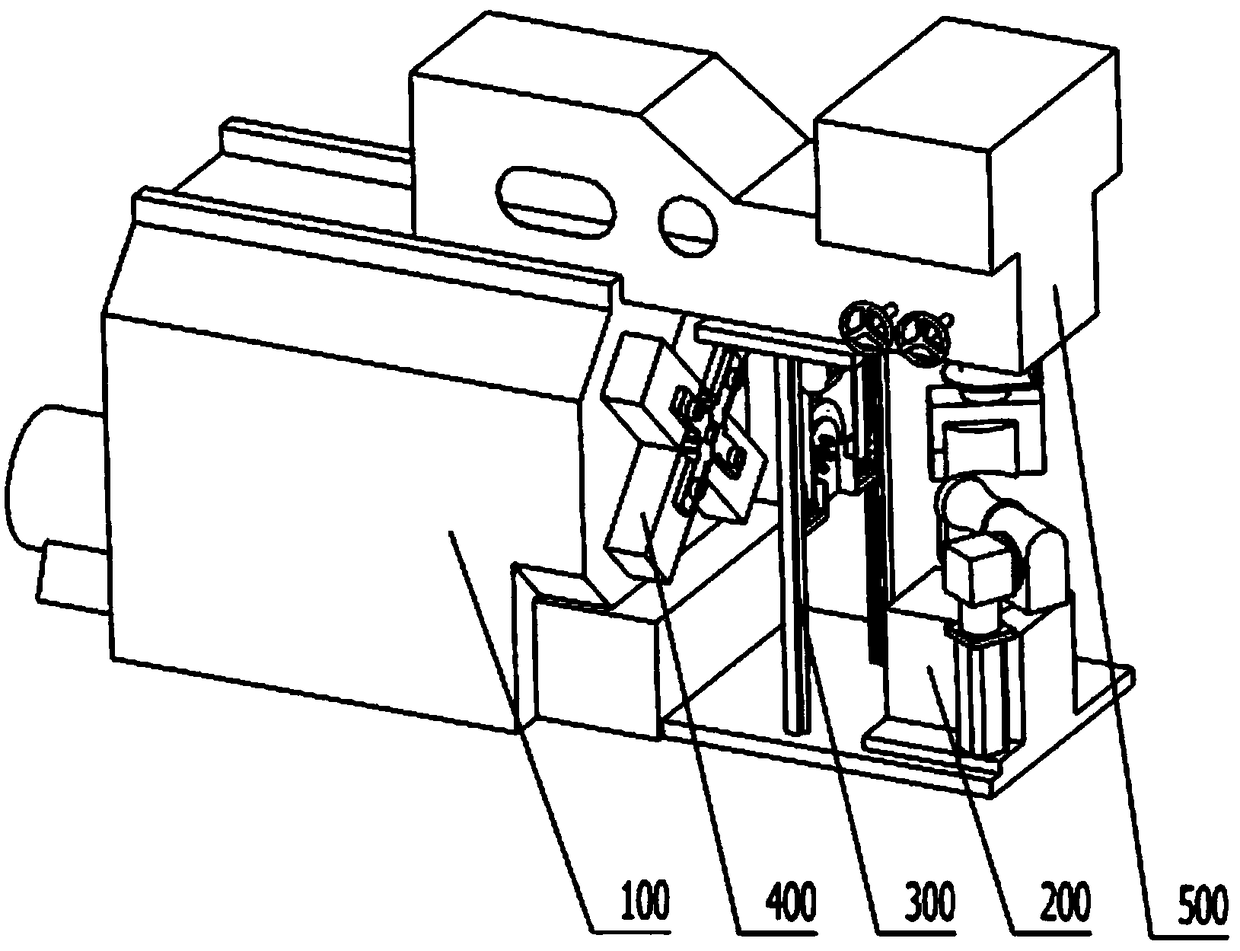

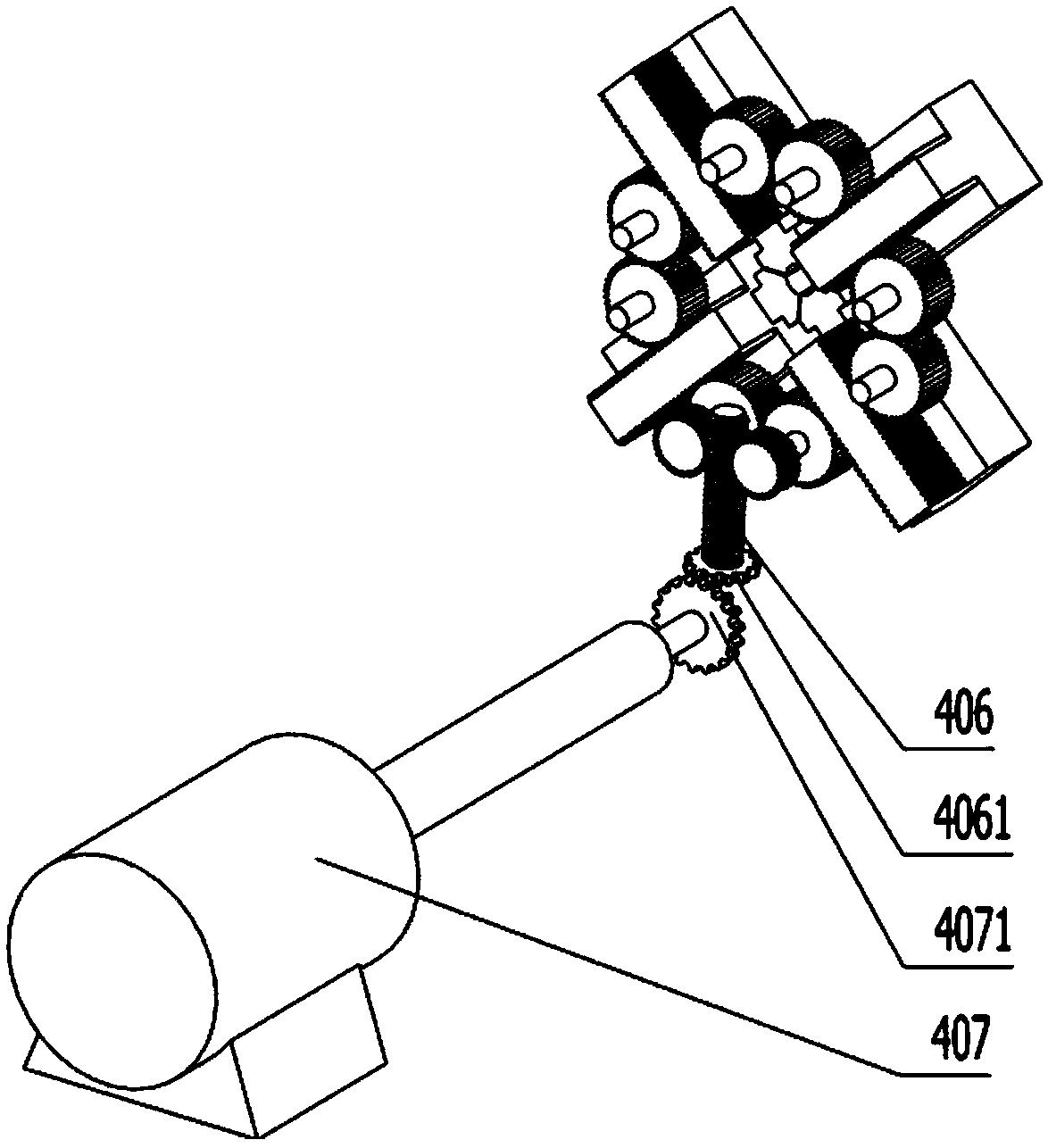

Equipment for stabilizing steel tube punch pin

PendingCN109047529AOffset the impactAvoid damageMetal-working feeding devicesShaping safety devicesEngineeringMechanical engineering

The invention discloses equipment for stabilizing a steel tube punch pin. The equipment for stabilizing the steel tube punch pin comprises a machine body, a punch pin mechanism, a long machine box, asmall machine box and a stabilizing mechanism. The punch pin mechanism is located in the front of the machine body, and a part of the punch pin mechanism is located in the machine body; the long machine box is horizontally arranged in the front of the machine body; the small machine box is located in the front of the long machine box and directly faces the down position, rollers are arranged underthe front ends of the small machine box and the long machine box, and the roller are used for feeding steel tubes into the punch pin mechanism; and the stabilizing mechanism is located between the small machine box and the machine body. The stabilizing mechanism fixes the position of the steel tubes, can counteract the vibration generated in the operation process of the steel tubes, so that the steel tube punch pin is stabilized, and the operation precision of the steel tube punch pin is improved.

Owner:江苏宏宝优特管业制造有限公司

A preparation method of high color fastness water-based acrylate resin color paste, resin color paste and its application and use method

The invention relates to a preparation method of high color fastness water-based acrylate resin color paste, resin color paste and its application and use method. The water-based acrylate resin color paste is a core-shell structure polymer, and the core polymer is acrylate The composition of polymer and pigment, the shell polymer is a water-based acrylate polymer synthesized by emulsion polymerization. In the present invention, by adding pigments during the reaction process, the molecular chains and pigments in the polymer solution synthesized by solution polymerization are more uniformly dispersed and combined more closely, and the pigments are evenly dispersed and wrapped in the latex particles after the polymer self-emulsifies to form latex particles. It reduces the uneven dispersion of pigments and the phase separation caused by aggregation during the film-forming process of the slurry, and greatly improves the color fastness of the water-based acrylic resin colorant.

Owner:WANHUA CHEM GRP CO LTD

A preparation method of special network gel modified talc powder for papermaking

ActiveCN105586803BImprove adsorption capacityGood dispersionInorganic compound additionSilicon compoundsPolymer sciencePlant fibre

The invention belongs to the field of inorganic mineral powder papermaking, and in particular relates to a preparation method of network gel modified talcum powder specially used for papermaking. It is characterized in that the flexible nano talc powder is formed by interspersing talcum powder, surface modifier and three-dimensional polymer network gel according to the weight ratio of 100:1~5:10~20. The modified talc powder uses extrusion technology to make the surface modifier penetrate into the layered structure of the talc powder, improve the hydrophilicity and surface activity of the talc powder, and polymerize with the flexible monomer under the action of the crosslinking agent to form a Three-dimensional network polymer gel, the network gel is interspersed in the layered structure of the modified talc powder, which increases the strength and toughness of the talc powder, and at the same time increases the active groups on the surface of the modified talc powder, improving the performance of the modified talc powder. Excellent softness and dispersibility, increase the bonding force between modified talcum powder and plant fiber. When the modified talcum powder of the present invention is used in papermaking, the softness of paper can be obviously improved, and the paper has good hand feeling, light weight and is easy to print.

Owner:JIANGSU QUNXIN POWDER TECH CO LTD

A kind of surface organically modified boron nitride powder and its preparation method and application

The present invention discloses surface-organically-modified boron nitride powder, wherein a hydantoin epoxy resin cross-linked polymerization product layer is coated on the particle surface, the hydantoin epoxy resin cross-linked polymerization product content in the surface-organically-modified boron nitride powder is 5-10 wt.%, and the raw materials for preparing the surface-organically-modified boron nitride powder comprise 20-30 wt.% of boron nitride, 1-3 wt.% of a hydantoin epoxy resin, 0.1-2 wt.% of an organic amine curing agent, and the balance of water. According to the present invention, the surface-organically-modified boron nitride powder has characteristics of good compatibility with polymer substrates and easy dispersion in the substrate, and can maintain good construction or processing fluidity under the high filling rate of 47.5 wt.%, and the thermal conductivity of the prepared epoxy composite material is up to 2.42 W / m.K.

Owner:FOSHAN SANSHUI JINGE NEW MATERIALS CO LTD

Production technology of PVC external lubricant

The invention aims at solving problems in prior arts, and provides a PVC external lubricant and a production method thereof. According to the invention, a reaction temperature in a processing process is reduced, and a product proportion is optimized. For reaching the purpose, the method comprises steps that: waste liquid produced from chemical industries is recovered and treated, such that fumaric acid is obtained; during processing, fumaric acid is selected as mother liquor according to a certain proportion; polyhydric alcohol is added according to a certain proportion, and the mixture is sufficiently stirred; pentaerythritol with a certain proportion is added; stearic acid is added for esterification; high temperature polymerization is carried out at a temperature of 150 DEG C to 160 DEG C; the polymerized material is delivered through a vacuum dealcoholizing process at a temperature of 200 DEG C; the obtained material is cooled and sliced. No catalyst is added during the whole processing process. The invention is advantaged in that: with the technical scheme, the reaction temperature is low, the polymerization effect is good, and a finished product conversion rate is high.

Owner:夏瑭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com