Starch and polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of biodegradable polymer materials, can solve the problems of less starch addition, easy diffusion, and limited performance improvement, so as to improve elongation at break, impact strength, and good thermoplasticity Processability and effect of heat deflection temperature improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

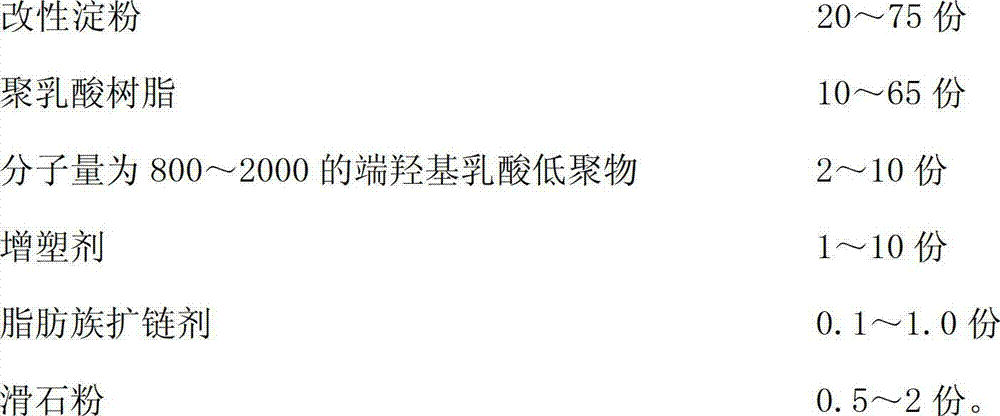

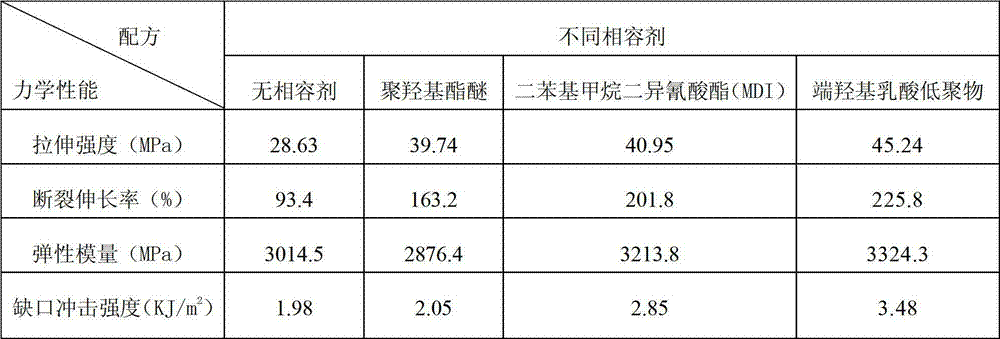

Method used

Image

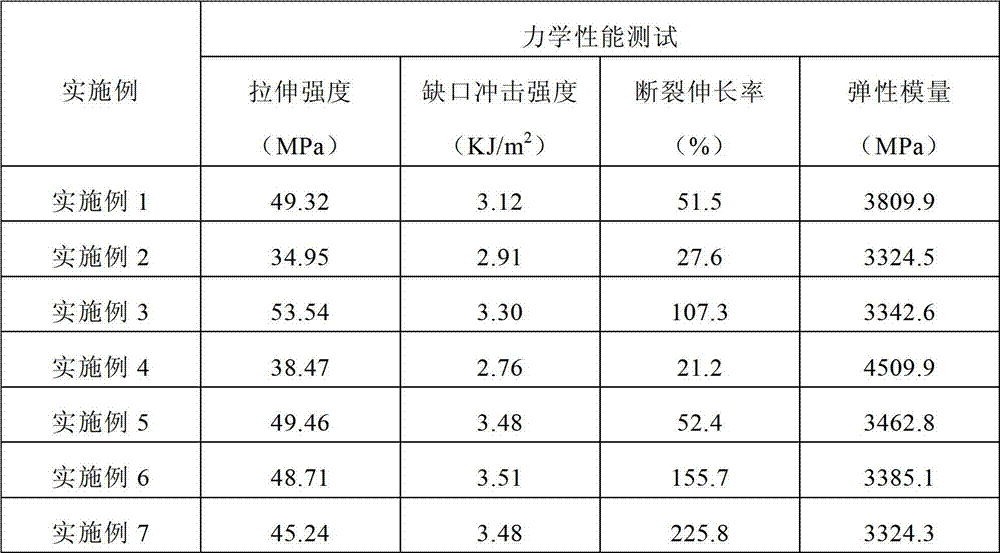

Examples

Embodiment 1

[0040] In this embodiment, the preparation method of the composite material of starch and polylactic acid is as follows:

[0041] Step 1) Mix 100 parts of vegetable starch with 1 part of polyethylene glycol with a molecular weight of 600, 1 part of polyethylene glycol with a molecular weight of 800, 1 part of polyethylene glycol with a molecular weight of 1000 and 0.5 parts of an aluminate coupling agent at 70 Blending was carried out in a high-speed mixer at ℃, and the stirring time was 20 minutes to obtain modified starch.

[0042] Step 2) In parts by weight, weigh 20 parts of the modified starch obtained in step 1), 65 parts of polylactic acid resin with a brand name of 4032D, 7 parts of hydroxyl-terminated lactic acid oligomers with a molecular weight of 1900, and polyethylene glycol with a molecular weight of 6000. 5 parts of diol, 0.5 part of ADR-4370S chain extender, 2 parts of talcum powder, 0.5 part of aluminate coupling agent, 1 part of white oil, set aside;

[0043...

Embodiment 2

[0048] In this embodiment, the preparation method of the composite material of starch and polylactic acid is as follows:

[0049] Step 1) Blend 100 parts of vegetable starch with 5 parts of polyethylene glycol with a molecular weight of 600, 3 parts of polyethylene glycol with a molecular weight of 1000, and 0.1 part of an aluminate coupling agent in a high-speed mixer at 80 ° C, The stirring time is 30min, and the modified starch is obtained.

[0050] Step 2) In parts by weight, weigh 75 parts of the modified starch obtained in step 1), 10 parts of polylactic acid resin with a brand name of 4032D, 2 parts of hydroxyl-terminated lactic acid oligomers with a molecular weight of 1700, and polyethylene glycol with a molecular weight of 6000. 2 parts of diol, 3 parts of polyethylene glycol with molecular weight of 20000, 5 parts of PBAT of BASF, 1 part of ADR-4370S chain extender, 0.5 part of talc powder, 0.5 part of aluminate coupling agent, 1 part of white oil, stand-by;

[00...

Embodiment 3

[0056] In this embodiment, the preparation method of the composite material of starch and polylactic acid is as follows:

[0057] Step 1) Blend 100 parts of vegetable starch with 2 parts of polyethylene glycol with a molecular weight of 600, 3 parts of polyethylene glycol with a molecular weight of 1000, and 0.5 parts of an aluminate coupling agent in a high-speed mixer at 90 ° C, The stirring time is 18 minutes, and the modified starch is obtained.

[0058] Step 2) In parts by weight, weigh 30 parts of the modified starch obtained in step 1), 60 parts of polylactic acid resin with a brand name of 4032D, 2 parts of hydroxyl-terminated lactic acid oligomers with a molecular weight of 1300, and polyethylene glycol with a molecular weight of 8000. 5 parts of diol, 0.5 part of ADR-4370S chain extender, 1 part of talc powder, 0.5 part of titanate coupling agent, 1 part of white oil, set aside;

[0059] Step 3) Add the weighed polylactic acid, modified starch obtained in step 1, hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com