Patents

Literature

37results about How to "Destroy crystal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

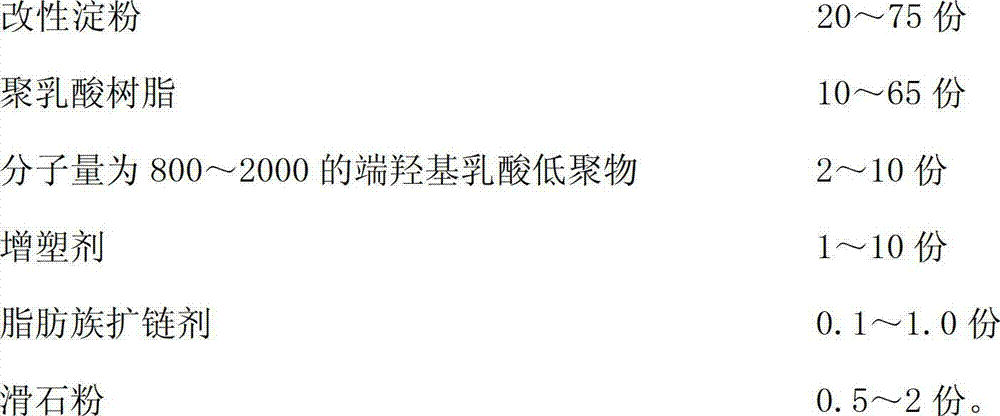

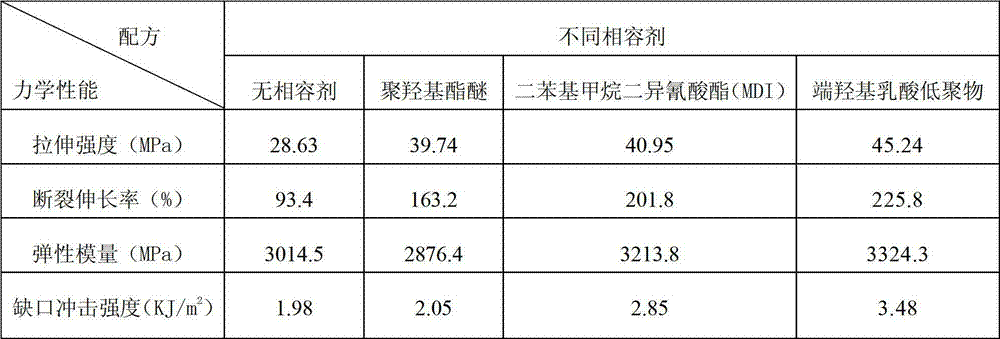

Starch and polylactic acid composite material and preparation method thereof

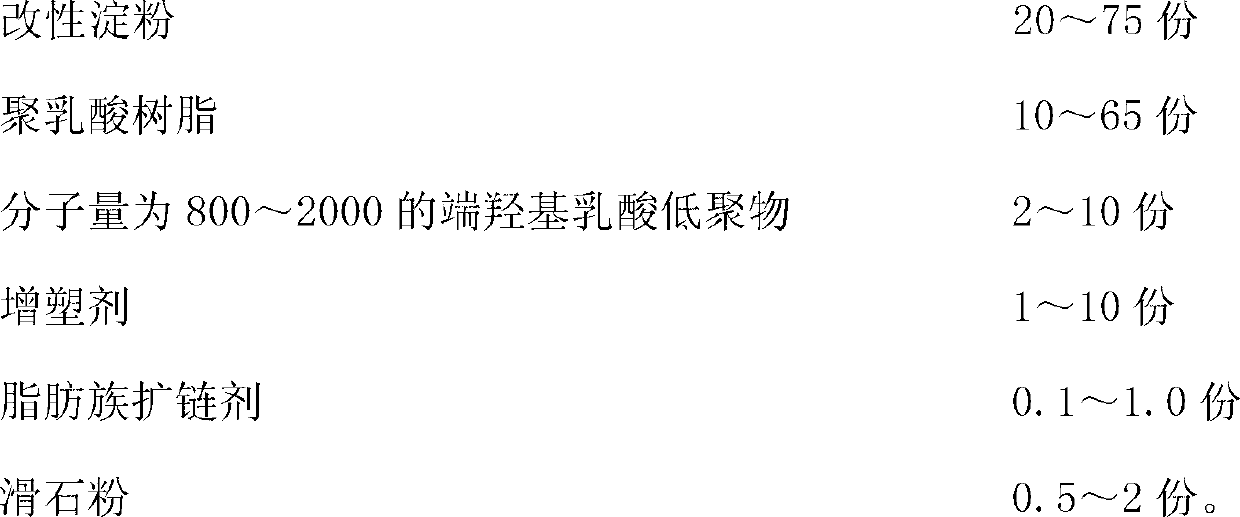

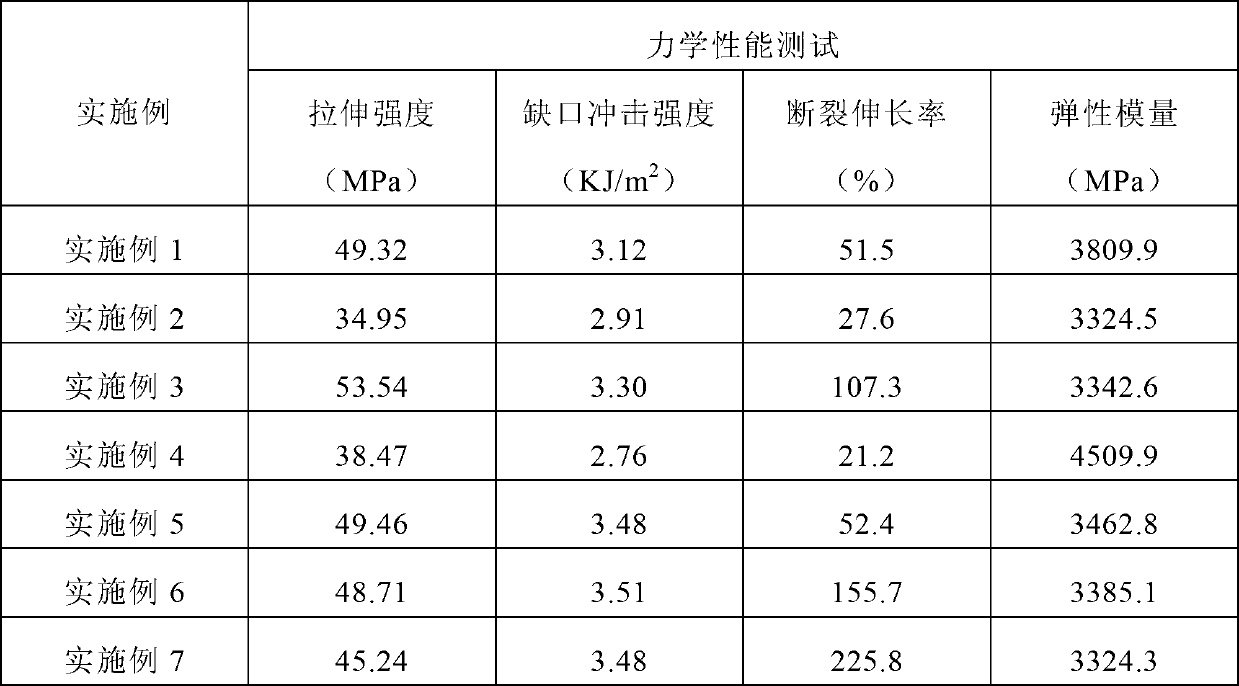

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

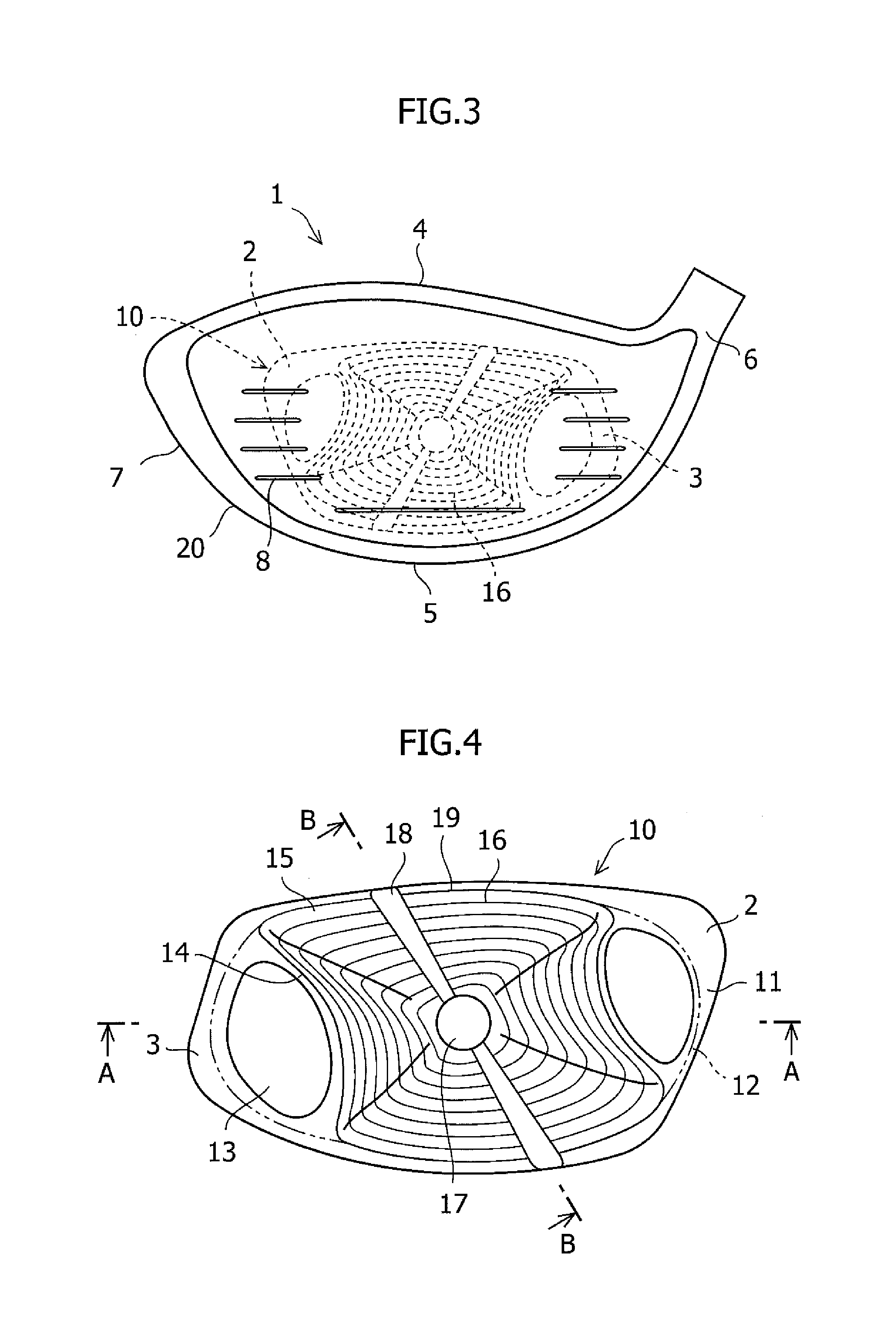

Golf club head

InactiveUS20110159987A1Maintaining light weightAvoid recoveryGolf clubsRacket sportsEllipseArcuate shape

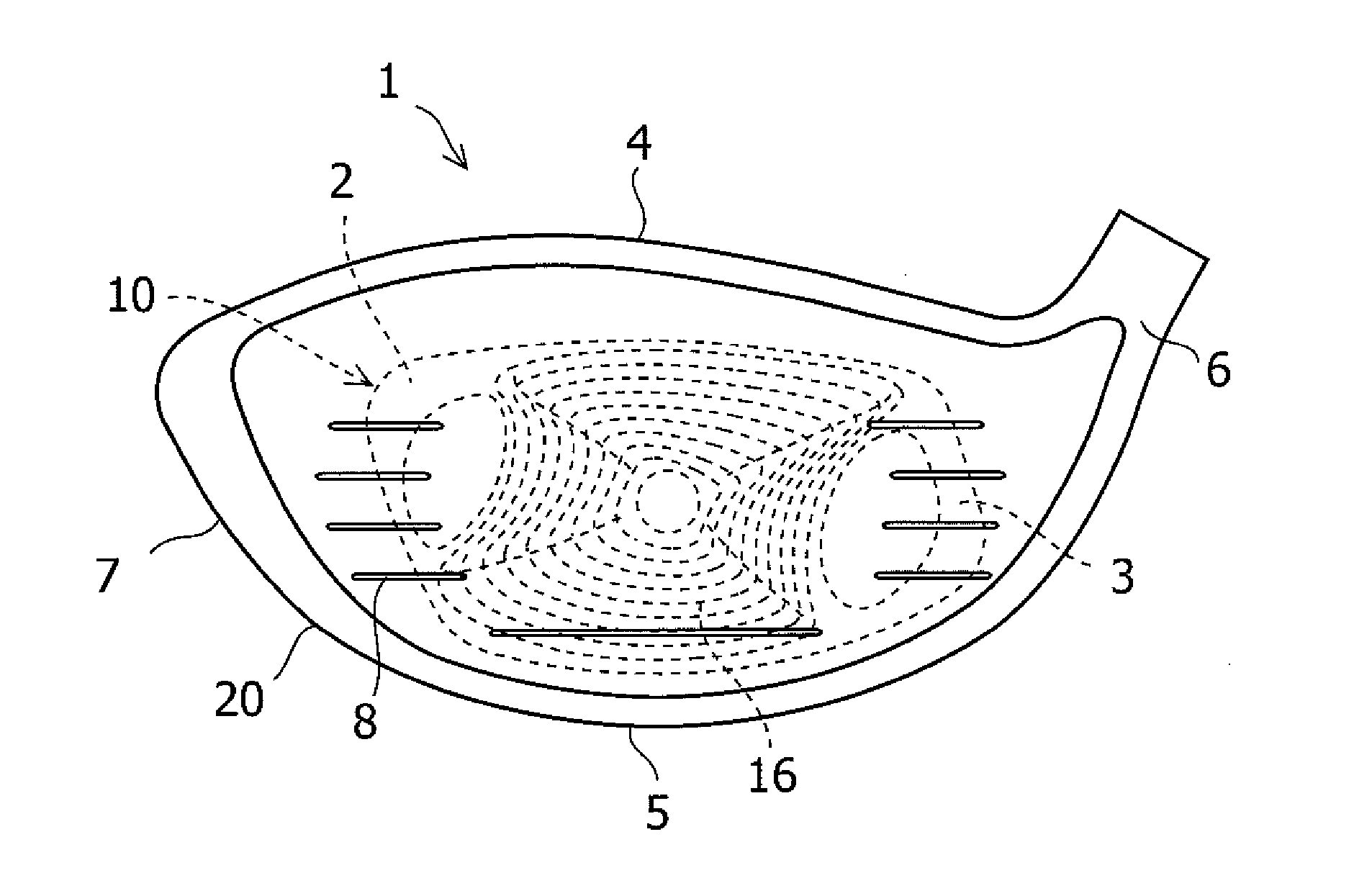

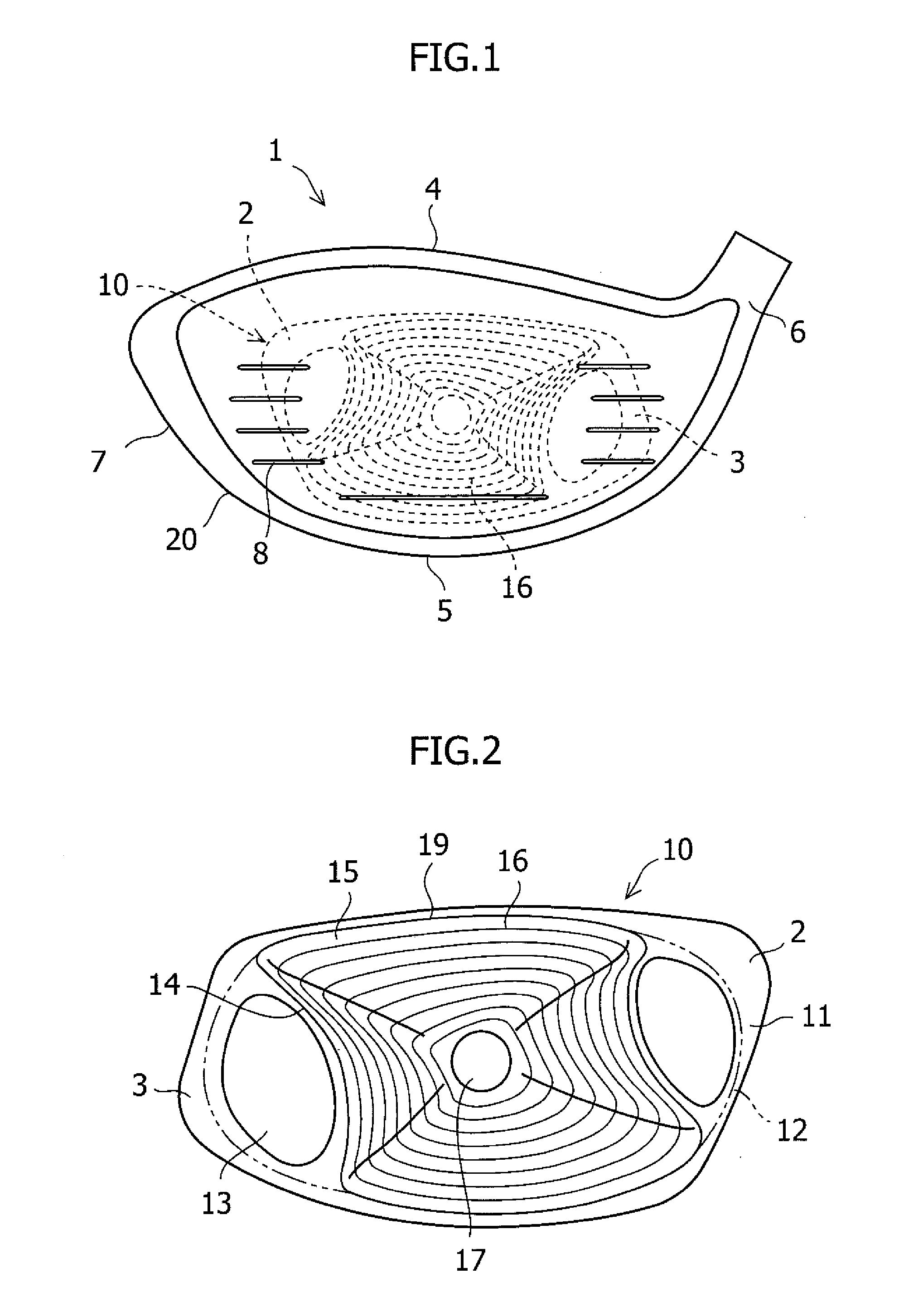

A hollow golf club head has a head body having a face aperture part and a face member held to the face aperture part by welding, the face member formed by forging a rolled material of a titanium alloy having an α phase, and the face member comprising a thick-material part positioned in the center of the face member, an outer peripheral part positioned at the periphery of the thick-material part, and a thin-material part partially positioned between the thick-material part and the outer peripheral part. The thick-material part is formed in an area having a shape obtained by depressing a substantially elliptical or substantially circular shape in a substantially arcuate shape toward the center of the ellipse at two opposite sides thereof. The thick-material part, the thin-material part, and the peripheral part are formed by the forging so as to destroy an orientation of the α-phase.

Owner:BRIDGESTONE SPORTS

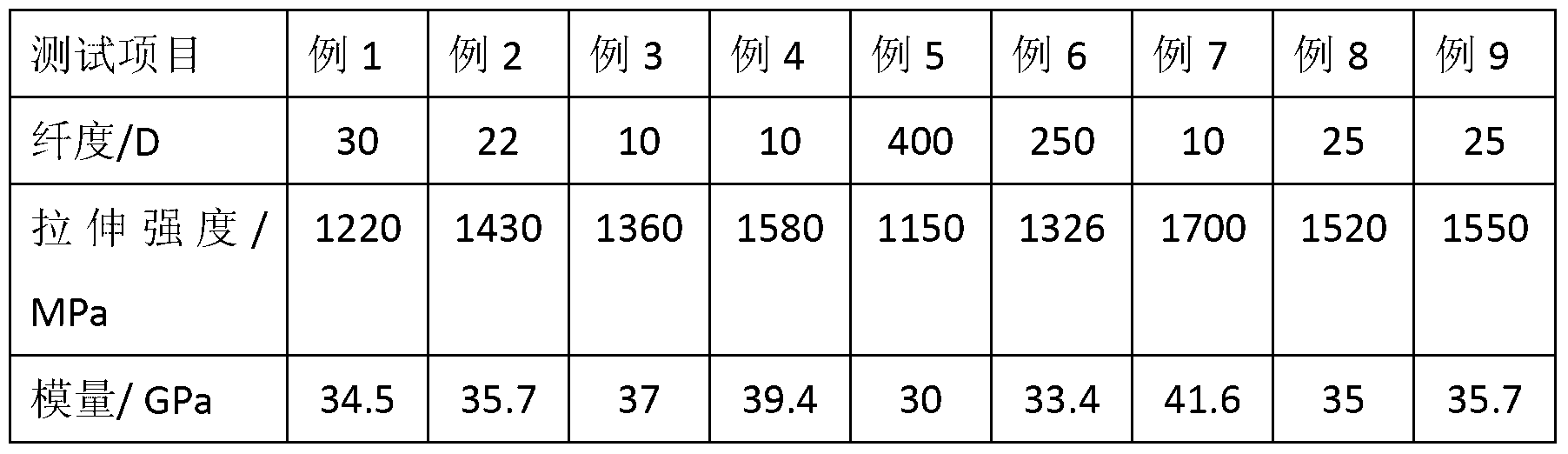

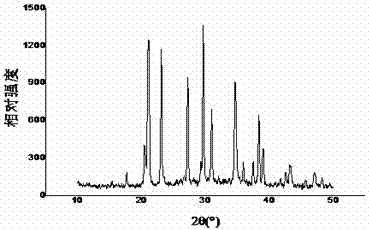

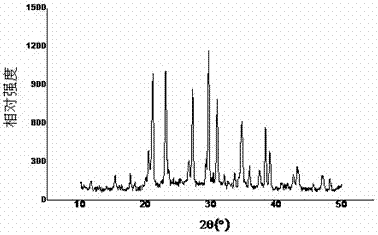

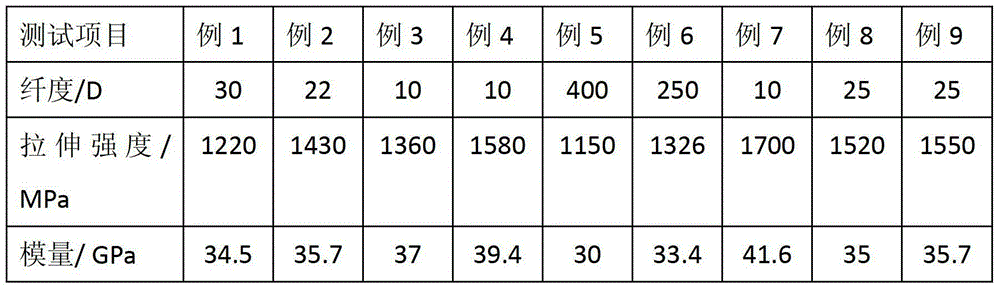

Method for preparing high-strength high-modulus polyvinyl alcohol fibers

ActiveCN103290505ADestroy crystal structureLow melting pointArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentPolymer scienceSolvent

The invention relates to a method for preparing high-strength high-modulus polyvinyl alcohol fibers. The method comprises the following steps of: mixing 10-40 parts by weight of poly-hydroxymethyl compounds with 30-70 parts by weight of water to obtain a mixture serving as a composite modifier; then evenly mixing the composite modifier with 0.01-5 parts by weight of inorganic alkali compounds and 100 parts by weight of polyvinyl alcohol with polymerization degree of 1700-2600 and alcoholysis degree of 88-99% in a high-speed mixer to obtain modified polyvinyl alcohol; then spinning on a melt spinning machine to prepare nascent polyvinyl alcohol fibers; finally implementing cold drawing, drying, multi-stage hot drawing and hot shaping. The method needs neither solvents nor coagulators for wet spinning, thereby being simple in technology and free from pollution; a screw rod with a unique structure is not required; industrial production is easy to realize. The prepared fibers are high in fiber strength and high in modulus and can be used for cement toughening anti-cracking materials, geotextile and tire cords; the prepared fibers also can be used as reinforcing materials for plastics and rubber.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

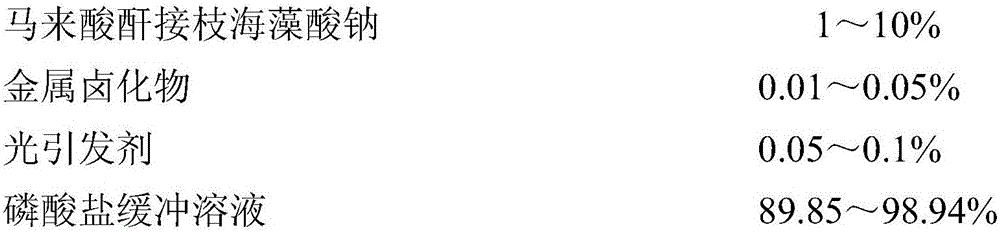

Preparation method of alginic acid hydrogel matrix for UV 3D printing

The invention relates to a preparation method of a hydrogel matrix, especially a preparation method of an alginic acid hydrogel matrix for UV 3D printing, and belongs to the technical field of biological material preparation. According to the preparation method, alkenyl groups are grafted on the molecular chains of sodium alginate prepared by a freeze-dry method, and after dissolving and mixing, the alginic acid hydrogel matrix for UV 3D printing is obtained. The preparation method adopts a freeze-drying technology under mixed solvent environment, the grafting rate of sodium alginate is largely improved, and the problem that the UV curing speed is slow due to low grafting rate is completely solved. The prepared alginic acid hydrogel matrix can rapidly solidify under the irradiation of UV light, the solid state can be maintained, moreover, in the presence of low concentration metal halides, the system can be further solidified, the hydrogel strength is improved, and the problems of conventional 3D printing hydrogel such as difficult moulding, collapse, and the like are overcome. The preparation method is simple, the cost is low, and the preparation method can be applied to industry easily.

Owner:济南科乐医药有限公司

Preparation method of hyaluronic acid biological adhesive

InactiveCN105770983ADestroy crystal structureHigh grafting rateSurgical adhesivesCrystal systemFreeze-drying

The invention relates to a preparation method of a biological adhesive, in particular to a preparation method of a hyaluronic acid biological adhesive, and belongs to the technical field of preparation of a biological material. The preparation method comprises the following steps: grafting an alkenyl group on an amorphous hyaluronic acid molecular chain according to a freeze-drying method, and performing dissolving and mixing so as to obtain the biological adhesive. According to the preparation method disclosed by the invention, a freeze-drying technology is adopted under mixed solvent environment, so that the crystal system structure of hyaluronic acid is greatly destroyed, hyaluronic acid molecules adopting an amorphous structure are formed, the grafting rate of the hyaluronic acid is greatly increased, and the problems that due to a low grafting rate, the ultra-violet curing speed is low and the formed gel is poor in intensity are completely solved. The biological adhesive prepared by the method disclosed by the invention can rapidly form gel under the irradiation of ultraviolet rays, and the gel is safe and good in biocompatibility, and can be completely degraded and absorbed. The preparation method disclosed by the invention is simple, the cost is low, and industrialized production is easy to realize.

Owner:济南科乐医药有限公司

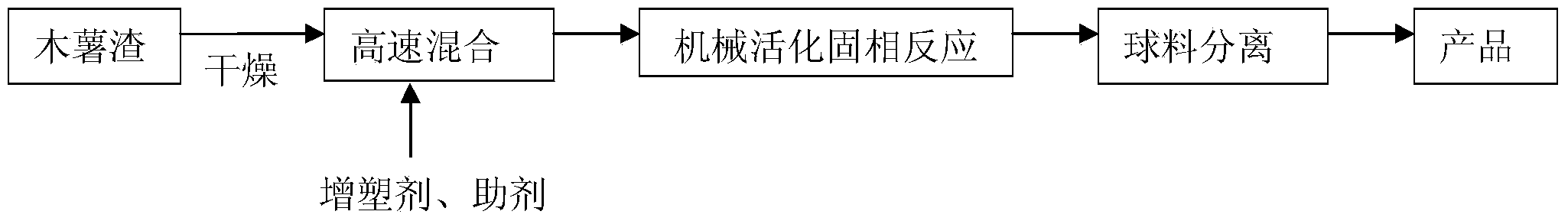

Method for thermal plasticizing modification of cassava dregs through mechanical activation and enhancement

ActiveCN103627035AImprove hydrophobicity and mechanical propertiesDestroy crystal structureSolid phasesChemistry

The invention relates to the field of modification of biodegradable polymer materials, and in particularly relates to a method for thermal plasticizing modification of cassava dregs through mechanical activation and enhancement. The method comprises the following steps: weighing reactants including cassava dregs, a plasticizer and an auxiliary agent in a ratio of 100g:(10-25g):(5-15g), mixing the reactants at a high speed, then putting all the reactants into a ball mill, controlling the ratio of the reactants to pellets (stack volume) at 100g:(300-600ml), controlling the temperature of a circulating water bath at 50-90 DEG C, stirring at a low speed to perform a mechanical activation solid-phase reaction for 40-80 minutes, and separating the reactants and the pellets to obtain a modified cassava dreg thermoplastic material. The modification method disclosed by the invention is easy in operation, high in efficiency and low in cost; for a composite material obtained by performing conventional hot press molding on the modified cassava dreg thermoplastic material, the tensile strength and the bending strength reach 15.33MPa and 28.76MPa respectively, the Young modulus reaches 82.4Mpa, and the extension percentage is 6.6%.

Owner:GUANGXI UNIV

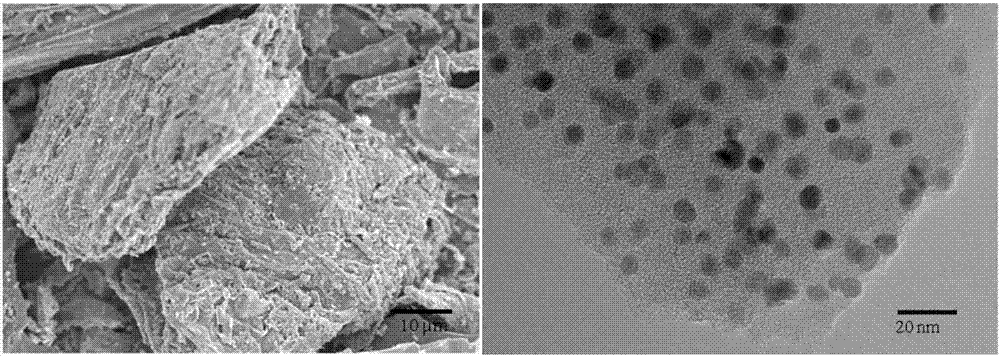

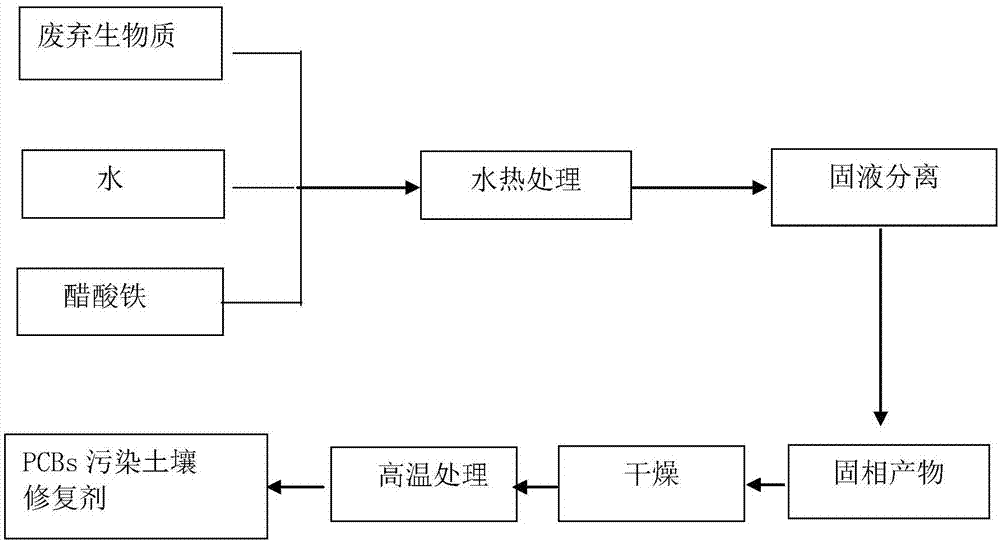

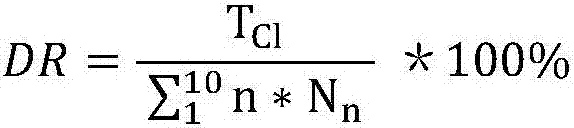

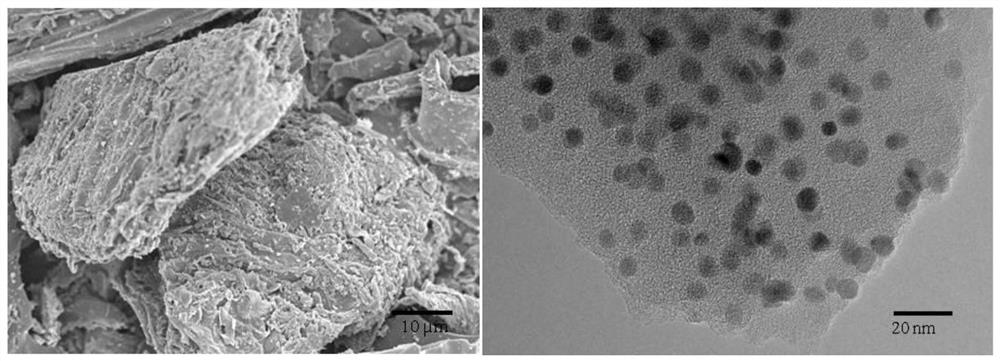

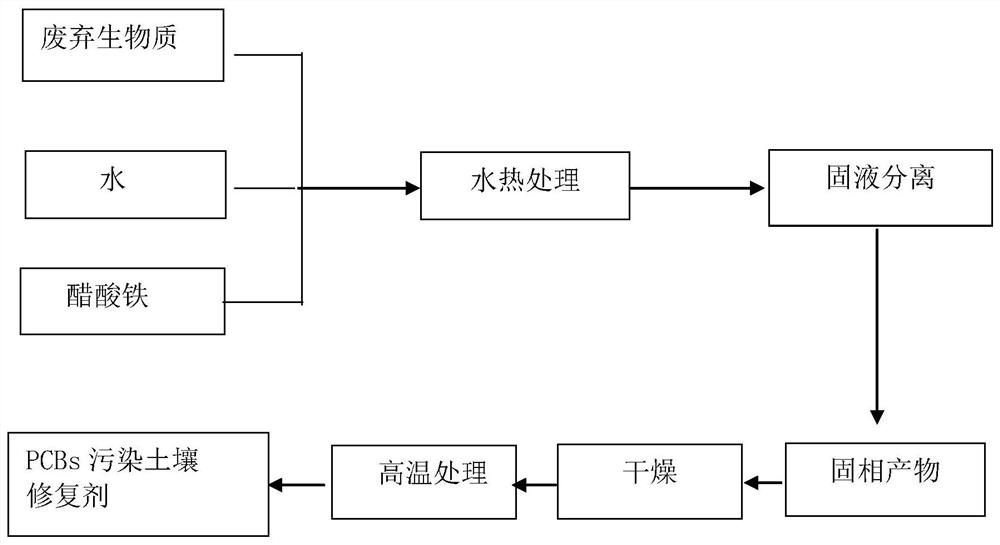

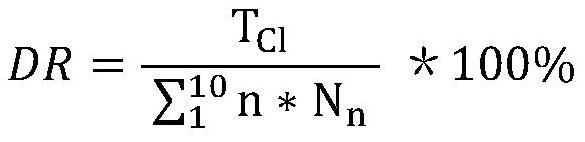

Preparation and using method for in-situ remediation agent for PCBs contaminated soil based on waste biomass

ActiveCN106881349AEasy to useEfficient degradationContaminated soil reclamationIn situ remediationEngineering

Combined with the current situations of serious contamination of soil PCBs and a huge quantity of waste biomass in China, the invention discloses a novel technology suitable for preparing an environmental-friendly in-situ remediation agent for PCBs contaminated soil with the waste biomass serving as raw materials. The novel technology comprises the following steps that (1) the biomass, water and ferric salts are mixed and subjected to hydrothermal coprocessing to prepare iron-loaded hydrothermal carbon; and (2) the iron-loaded hydrothermal carbon is obtained after high temperature heat treatment. The in-situ remediation agent for the PCBs contaminated soil is prepared with the waste biomass serving as a carbon source, the preparation process is simple, rapid and efficient dechlorination degradation of PCBs in the soil can be realized, and the remediation agent has the characteristics of environmental protection, low price and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

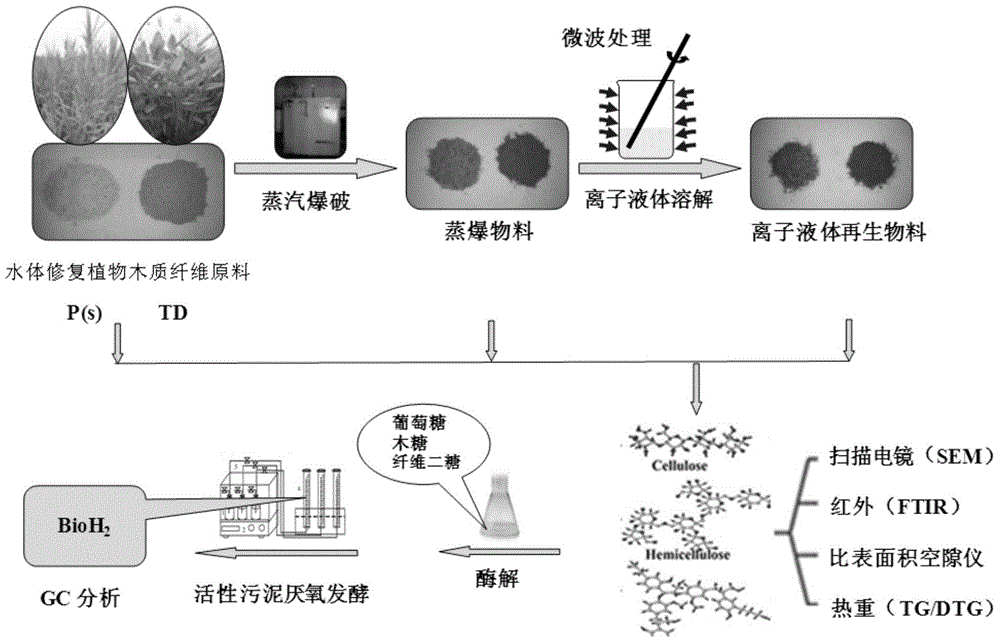

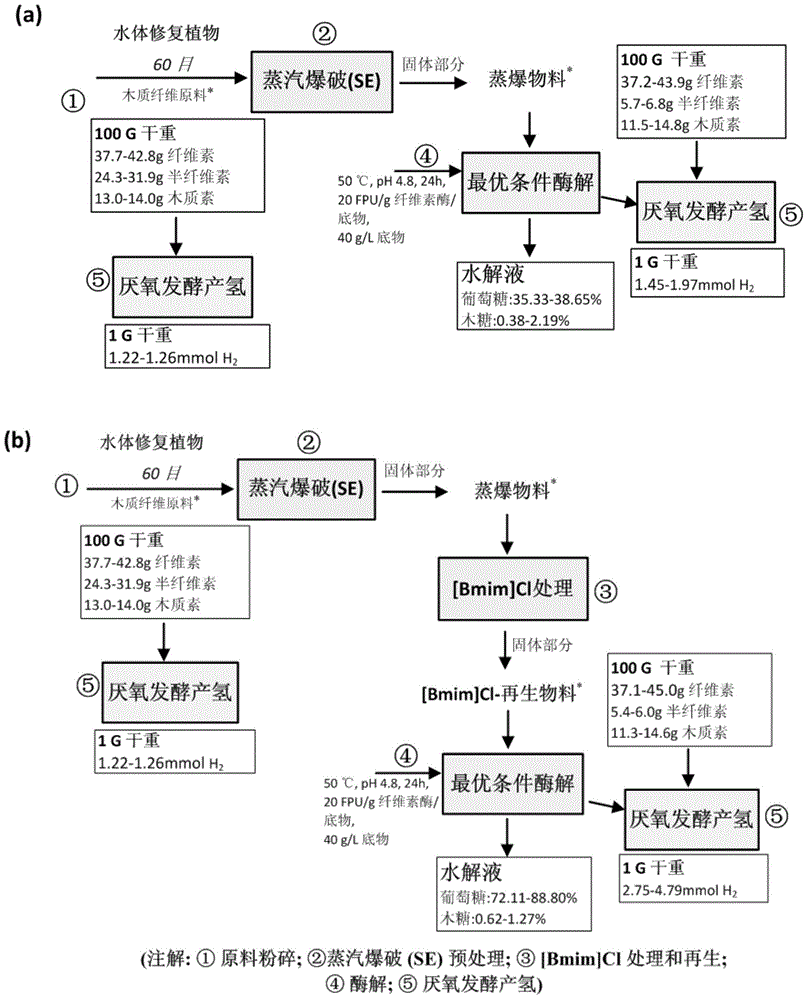

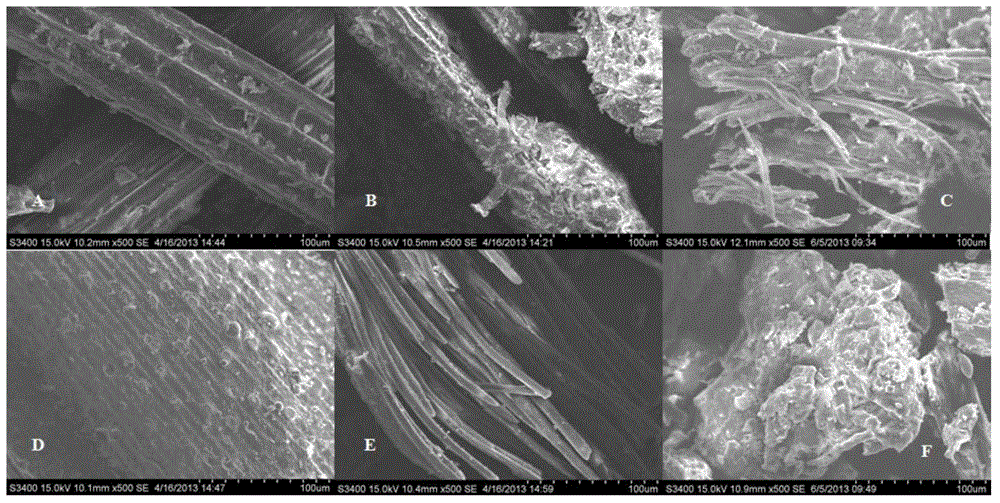

Water body remediation wood fiber raw material pretreatment method and corresponding hydrogen production method

The invention discloses a water body remediation wood fiber raw material pretreatment method sequentially comprising the following steps: (1) coarsely grinding, that is, coarsely grinding a water body remediation wood fiber raw material after air drying; (2) carrying out steam explosion, that is, carrying out steam explosion pretreatment on obtained sieving powder; (3) dissolving with an ionic liquid and regenerating a material, that is, adding the ionic liquid to a steam explosion material for dissolution treatment, and separating out solid from the steam explosion material after dissolution treatment by using water as an antisolvent; and (4) carrying out enzymatic saccharification, that is, carrying out enzymolysis by using the steam explosion material obtained from the step (2) or regeneration material obtained from the step (3) as a substrate to obtain an enzymatic saccharification liquid. The invention also provides a method for carrying out fermentation hydrogen production by utilizing the enzymatic saccharification liquid obtained from the method, that is, applying the enzymatic saccharification liquid to biological hydrogen production.

Owner:ZHEJIANG UNIV

Method for producing high-viscosity and high-degree-of-substitution carboxymethyl cassava starch by utilizing ultrahigh-pressure blasting technique

The invention discloses a method for producing high-viscosity and high-degree-of-substitution carboxymethyl cassava starch by utilizing an ultrahigh-pressure blasting technique. The method comprises the steps such as alkaline treatment, etherification reaction and purification. The method is carried out by primarily achieving the purpose of destroying a crystallization region of cassava starch particles by utilizing sodium hydroxide, sufficiently swelling and alkalifying starch molecules and loosening starch particles under the ultrahigh pressure of a high-pressure homogenizer, so that the hydroxyl of the starch becomes negative oxygen ions and the nucleophilic ability is strengthened, and simultaneously generating an St-O-Na<+> active center, then, preparing the high-viscosity and high-degree-of-substitution carboxymethyl cassava starch through the bimolecular nucleophilic substitution between sodium carboxymethyl starch obtained by alkalifying the starch and chloroacetic acid under the alkaline condition of sodium hydroxide. By utilizing the high-degree destructive effect of the ultrahigh-pressure blasting technique on a crystallization structure of the cassava starch, the technical problems such as degradation of the starch particles in a production process of the high-viscosity and high-degree-of-substitution carboxymethyl cassava starch are solved.

Owner:GUANGXI JINHAN ENVIRONMENTAL PROTECTION CO LTD

Carbon-nitrogen-lithium multi-phase doped lithium ion battery negative electrode material, preparation method of material, lithium ion battery negative electrode plate and lithium ion battery

InactiveCN109888181AIncrease the areaImprove lithium storage performanceCell electrodesSecondary cellsCarbonizationPhysical chemistry

The invention discloses a carbon-nitrogen-lithium multi-phase doped lithium ion battery negative electrode material, a preparation method of the material, a lithium ion battery negative electrode plate and a lithium ion battery. A halogenated choline type low eutectic solvent is uniformly mixed according to a ratio to obtain a low eutectic solvent, and then the low eutectic solvent is mixed with lignocellulose; pretreatment is carried out firstly and then high-temperature carbonization is carried out to obtain a carbon material doped with nitrogen and lithium; and the carbon material can be applied to the lithium ion battery negative electrode material. A precursor adopted in the preparation method is obtained by uniformly mixing halogenated lithium with halogenated choline and derivativesthereof; the precursor is environment-friendly, wide in source and low in cost, and can be obtained on a large scale from the industry; a preparation process adopted by the method is concise, high inyield and high in purity; and a reaction system involved in the method disclosed by the invention is simple in component, convenient to configure, simple to operate, low in equipment requirement andfree of regional limitation, and is suitable for large-scale industrial production.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

High-nickel positive electrode material, nickel-cobalt precursor material, preparation method of high-nickel positive electrode material, preparation method of nickel-cobalt precursor material and lithium ion battery

PendingCN111244459ADestroy crystal structureFree from destructionCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a high-nickel positive electrode material, a nickel-cobalt precursor material, a preparation method of the high-nickel positive electrode material, a preparation method of thenickel-cobalt precursor material and a lithium ion battery. The high-nickel positive electrode material is of a core-shell structure, the core is formed by aggregating primary particles with gradientdoped M element, and M comprises Al and / or Mn. The solid spheres and hollow spheres are contained in the primary particles, the sphere centers of the solid spheres or the hollow spheres are the spherecenters of the primary particles, and the radius of the solid sphere is 0-1 / 5 but not 0 of the radius of the primary particle. The outer spherical surface of the hollow sphere is the spherical surface of the primary particle, and the thickness of the spherical shell of the hollow sphere is 0-1 / 6 but not 0 of the radius of the primary particle. In the primary particles, the content of M is sequentially reduced from outside to inside, the molar ratio of the M element in the solid sphere to all elements in the high-nickel positive electrode material is 0.075%-0.75%, and the molar ratio of the Melement in the solid sphere to the M element in the hollow sphere is 1 / 3-1 / 2. The high-nickel positive electrode material disclosed by the invention is higher in specific capacity, good in cycling stability and better in rate capability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Fully-degradable material for shopping bags, mulching films and greenhouse films and preparation method of fully-degradable material

The invention discloses a fully-degradable material for shopping bags, mulching films and greenhouse films and a preparation method of the fully-degradable material, and relates to the technical fieldof film production. The preparation method comprises the steps: adopting modified polyvinyl alcohol and modified vegetable gelatin or chitosan as main raw materials, adding a cross-linking agent, a waterproofing agent, a stabilizer, an anti-block agent, polyethylene wax, an antioxidant, a coupling agent and other agents, performing high-speed stirring, performing treatment by using a casting method or granulation through a twin-screw machine, and performing treatment by using a film blowing method so as to obtain the shopping bags, mulching films or greenhouse films. The fully-degradable material for the shopping bags, mulching films and greenhouse films and the preparation method of the fully-degradable material have the advantages that the prepared fully-degradable shopping bags, mulching films and greenhouse films have safety, no toxicity, harmlessness, toughness, softness and smoothness, good elasticity, high transparency, high tensile strength and low price, and traditional plastic products can be replaced completely; easy degradation is achieved, the material can be self-denatured through natural factors, and is decomposed and degraded into small molecular compounds, and thedecomposed products have the effect of soil improvement.

Owner:刘杰

Modifying method of nonthermoplastic cellulose derivative material

The invention relates to a method for modifying nonthermoplastic cellulose derivative material, including the main content that 40 wt-80wt percent of matrices of nonthermoplastic cellulose derivative material, 1wt-50wt percent of a reaction monomer and 10 wt-59 wt percent of a plasticizer are evenly mixed and then arranged into a processing and mixing device. The mixing reaction is carried out for 1 minute to 20 minutes at 60 DEG C to 140 DEG C on the condition of the operation of the mixing device. The substance discharged is the nonthermoplastic cellulose derivative material with the modified performance. The method for modifying the nonthermoplastic cellulose derivative material, provided in the invention, does not require completing in a solvent with the addition of an initiating agent, thereby fully avoiding side reactions caused by the initiating agent remaining in the material when the modifying method of the prior art is adopted, such as degradation, oxidation, etc., as well as the environmental pollution caused by the use of the solvent. The method of the invention has simple realization technology and high reaction efficiency, and can obviously improve the heat resistance and processing performance of the nonthermoplastic cellulose derivative material.

Owner:SICHUAN UNIV

A kind of preparation method of hyaluronic acid bioadhesive

InactiveCN105770983BDestroy crystal structureHigh grafting rateSurgical adhesivesCrystal systemAdhesive

The invention relates to a preparation method of a biological adhesive, in particular to a preparation method of a hyaluronic acid biological adhesive, and belongs to the technical field of preparation of a biological material. The preparation method comprises the following steps: grafting an alkenyl group on an amorphous hyaluronic acid molecular chain according to a freeze-drying method, and performing dissolving and mixing so as to obtain the biological adhesive. According to the preparation method disclosed by the invention, a freeze-drying technology is adopted under mixed solvent environment, so that the crystal system structure of hyaluronic acid is greatly destroyed, hyaluronic acid molecules adopting an amorphous structure are formed, the grafting rate of the hyaluronic acid is greatly increased, and the problems that due to a low grafting rate, the ultra-violet curing speed is low and the formed gel is poor in intensity are completely solved. The biological adhesive prepared by the method disclosed by the invention can rapidly form gel under the irradiation of ultraviolet rays, and the gel is safe and good in biocompatibility, and can be completely degraded and absorbed. The preparation method disclosed by the invention is simple, the cost is low, and industrialized production is easy to realize.

Owner:济南科乐医药有限公司

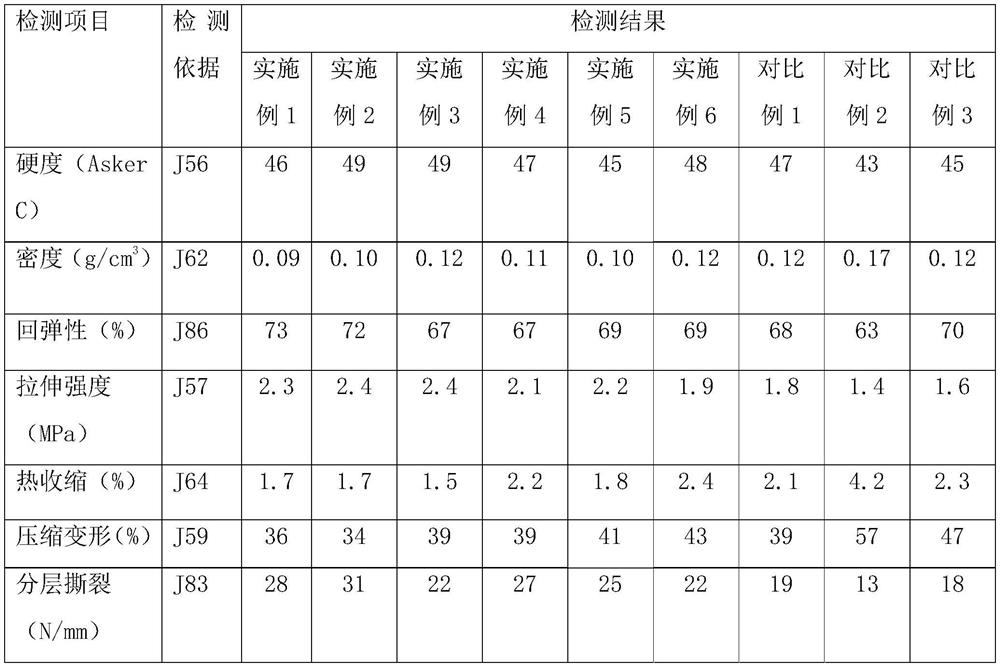

Preparation method of nylon foamed sole

ActiveCN114316343AHigh molecular weightHigh tear strengthSolesBulk chemical productionNylon materialPolymer science

The invention discloses a preparation method of a nylon foamed sole, which comprises the following steps: cross-linking a cross-linking agent and nylon to obtain pre-crosslinked nylon resin with a melt index of 1.5-4g / 10min, the cross-linking agent being an isobutylene maleic anhydride polymer and / or a styrene maleic anhydride polymer, and the number of functional groups of the cross-linking agent being greater than 30; the pre-crosslinked nylon resin and a nucleating agent are mixed to obtain a modified nylon material, the weight percentage of the pre-crosslinked nylon resin is 96-99%, and the weight percentage of the nucleating agent is 1-4%; performing injection molding on the modified nylon material to obtain a plate; the board is placed in a nitrogen supercritical fluid to be subjected to pressure maintaining for 3-8 h, pressure relief is conducted at the speed of 10-15 MPa / min, and a foamed board is obtained; and carrying out mold hot pressing on the foamed sheet to obtain the nylon foamed sole. The preparation method disclosed by the invention is simple in production process and high in foaming efficiency, and the prepared nylon foamed sole is low in density, good in rebound resilience and high in tearing strength.

Owner:ANTA CHINA

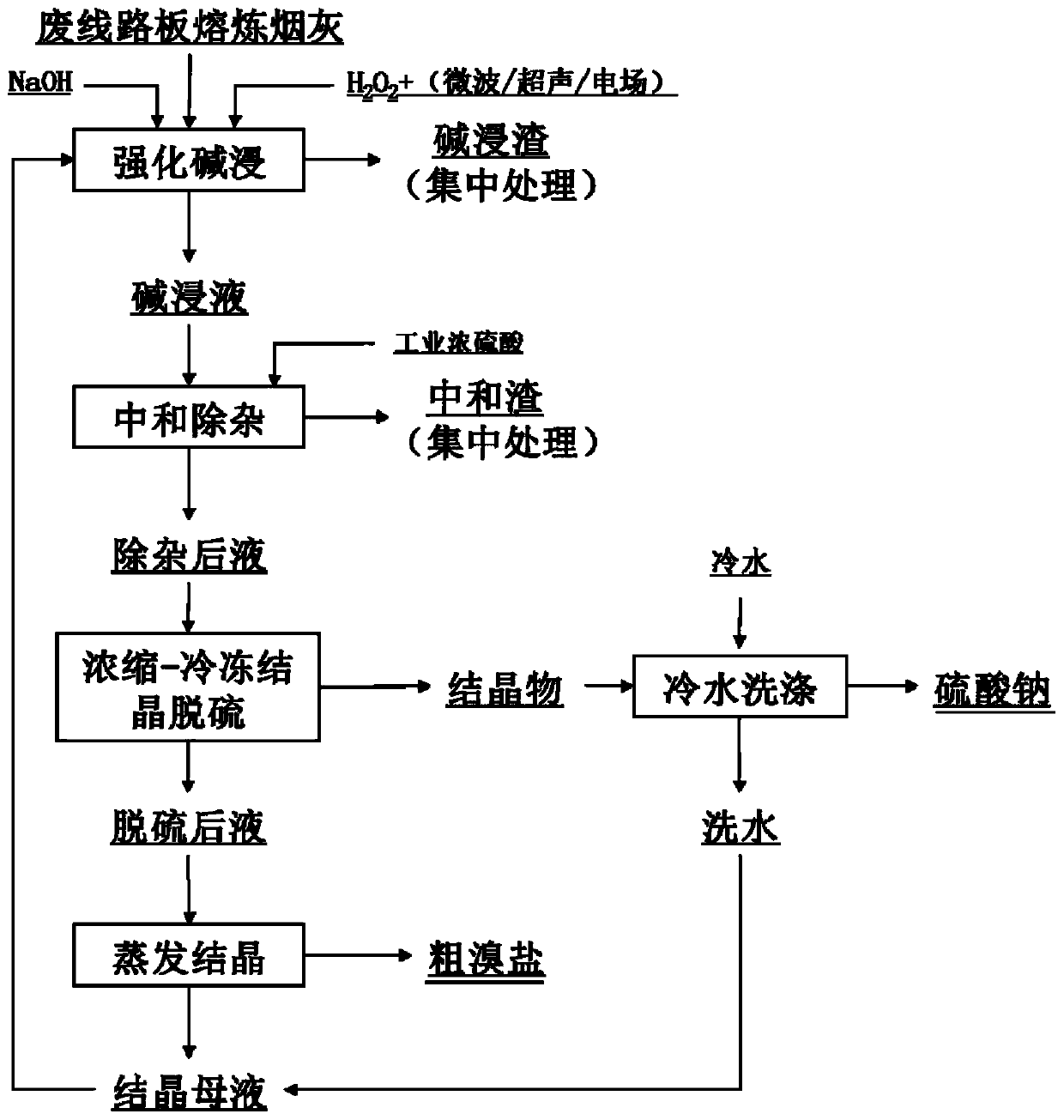

Waste circuit board smelting soot reinforced alkaline leaching debromination recovery method

ActiveCN110724823AEnhanced mass transferFacilitates chemical bond breakingProcess efficiency improvementBromineExhaust gas

The invention provides a waste circuit board smelting soot reinforced alkaline leaching debromination recovery method, belongs to the field of bromine-containing smelting sootwhole-wet efficient and green bromide removal and particularly relates to a method for converting, debrominating and separating cuprous bromide in smelting soot in a waste circuit board melting tank through reinforced alkaline leaching. The method comprises the main following steps of reinforced alkaline leaching, neutralization and impurity removal, concentration-freezing crystallization and desulfuration, cold water washing and evaporative crystallization. Compared with the traditional alkaline leaching technology, the recovery method has the advantages that through the electric field / ultrasonic / microwave and otherreinforcement means, the crystalline structure of CuBr is further destroyed, fracture of a chemical bond is accelerated, the mass transfer effect is improved, the reaction activation energy is reduced, the reaction time is shortened, energy consumption is reduced, and the debromination rate is increased. The recovery method has the characteristics of being simple in process, easy to implement, green and free of pollution in the recovery process, efficient, energy-saving, free of tail gas and tail liquid emissions and the like.

Owner:BEIJING UNIV OF TECH

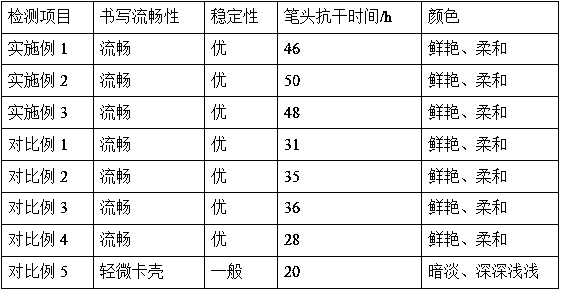

Environment-friendly blackboard writing liquid

The invention discloses an environment-friendly blackboard writing liquid, and belongs to the field of environment-friendly teaching. The lubricating compatible additive increases adhesive film performance of the blackboard writing liquid formed film, the blackboard writing liquid is not prone to pasting and can better perform drying film forming, and compatibility and flow performance of the components are increased by lubricating performance of grease molecules; by means of a prepared cross-linked film-forming active agent, latex particles are not prone to interaction, stability of the blackboard writing liquid is increased, adhesion fastness is increased, and water resistance, acid resistance and alkali resistance are enhanced. A prepared moisture retention additive increases water holding capacity, has higher moisture absorption and moisture retention properties, not only can adjust moisture, but also has emulsifying property, and can be well mixed with ink to form a moisture retention film on the surface of the blackboard writing liquid, and a dispersion system is formed; a prepared active pigment has good dispersion stability and low viscosity, and dispersion performance of the blackboard writing liquid is improved by modified pigment dispersion color paste. The problems that writing fluency of a current blackboard writing liquid is poor and a nib dries easily are solved.

Owner:高俊

Starch and polylactic acid composite material and preparation method thereof

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

Method for pretreating wood fiber raw material by adopting molten salt hydrate system

The invention provides a method for pretreating a wood fiber raw material by adopting a molten salt hydrate system. The method comprises the following steps of crushing the wood fiber raw material toa proper particle size, and adding the crushed wood fiber raw material into the molten salt hydrate system; stirring and reacting at the temperature of 20-100 DEG C for 0.1-72 hours, and then adding aproper amount of water to terminate the reaction; and after the reaction is finished, performing solid-liquid separation, and cleaning and desalting the separated wood fiber solid with water to obtain the wood fiber solid capable of being used for enzyme hydrolysis saccharification treatment. The method disclosed by the invention is low in cost, simple to operate and high in matching property with a saccharification stage, the molten salt can be recycled, and the whole process is green and sustainable, so that the method has important significance for application of the wood fiber raw materials. Besides, efficient pretreatment of the wood fiber raw material is achieved under the condition that cellulose does not dissolve, operation convenience is provided for subsequent solid-liquid separation, the method has very important significance in practical application, and the complexity and the operation cost of separation operation are greatly reduced.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

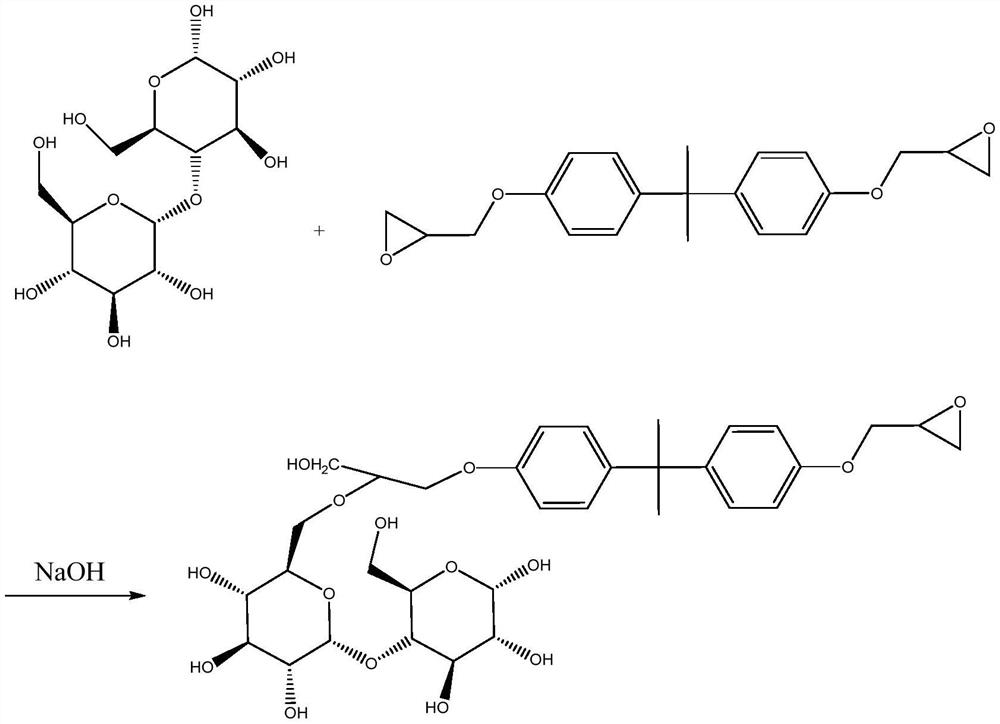

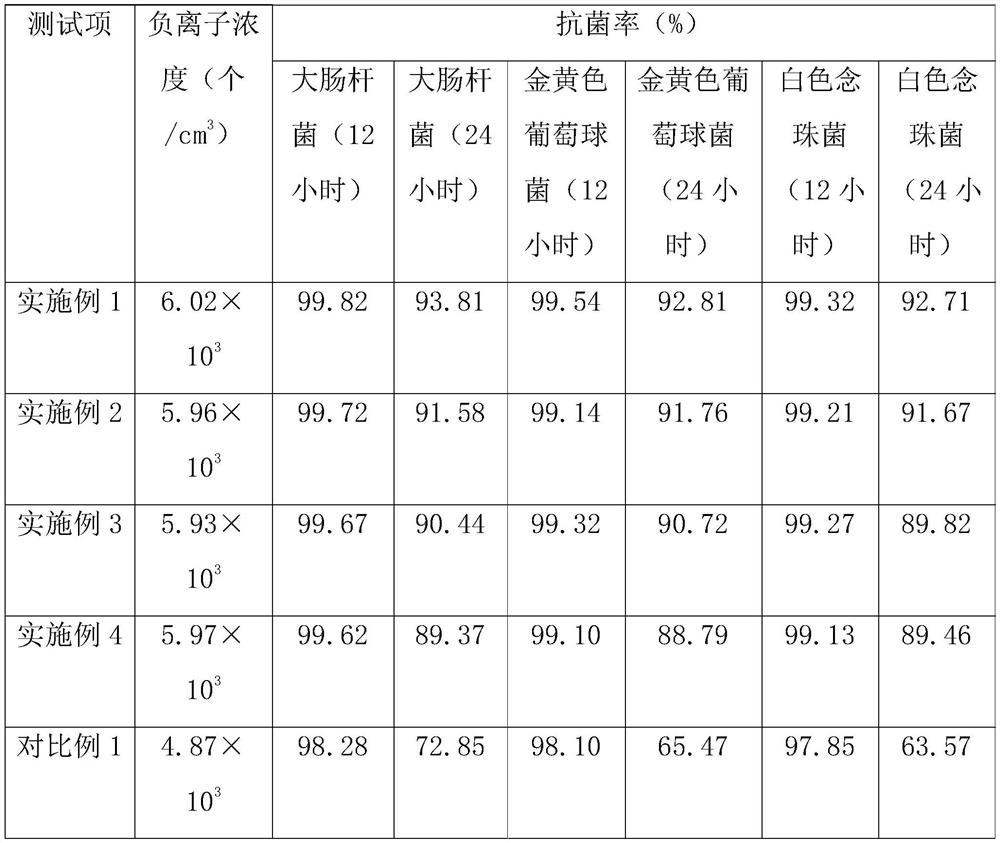

Negative ion solution with ultra-strong antibacterial effect and preparation method thereof

InactiveCN114410205AIncrease the strength of the self-electric fieldImprove the ionization effectAntifouling/underwater paintsPaints with biocidesPhysical chemistryFilm-forming agent

The invention discloses a negative ion solution with an ultra-strong antibacterial effect and a preparation method thereof, and relates to the technical field of negative ion antibacterial solutions, and the preparation method of the negative ion solution comprises the following steps: carrying out ball milling on tourmaline, sieving, adding lanthanum oxide, and uniformly mixing to obtain tourmaline powder; the tourmaline powder is modified through fluorosilane to obtain modified negative ion powder; mixing the modified negative ion powder with a dispersing agent and waterborne polyurethane, and performing wet ultrafine grinding to obtain a nano negative ion mother solution; the nano anion mother liquor is mixed with a film-forming agent, triethanolamine and water. After lanthanum oxide is added into tourmaline powder, the self-generating field intensity of the tourmaline powder can be improved, the ionization capacity is improved, and the negative ion yield is increased; the hydrophobic and oleophobic properties of the modified negative ion powder are improved through fluorosilane; due to the hydrophobic and oleophobic properties and good film-forming property, a film layer formed by the negative ion solution is not easy to stain and dissolve, a long-acting negative ion release effect is achieved, and an excellent and lasting antibacterial effect is achieved.

Owner:广州天科科技发展有限公司 +1

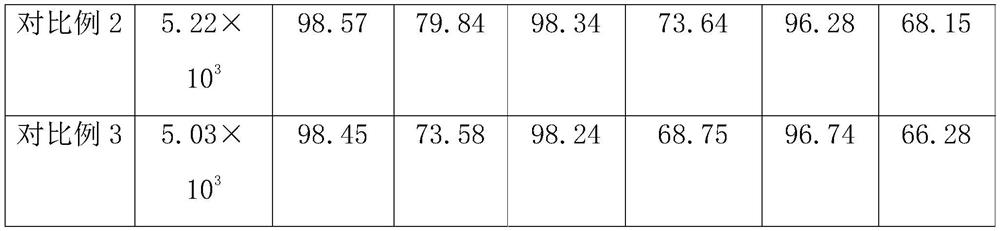

Halogen-containing branched polyethylene and preparation method thereof

The invention relates to the technical field of polyolefin functionalization, and aims to provide halogen-containing branched polyethylene and a preparation method thereof. The halogen-containing branched polyethylene contains a halogen group and is obtained by modifying an ethylene homopolymer with the branching degree not lower than 42 branched chains / 1000 carbon atoms by using a halogen-containing modifier. The halogen in the halogen group is one or more of fluorine, chlorine and bromine. Compared with the prior art, the halogen-free flame-retardant polyolefin material is a novel polyolefinmaterial and has elasticity in a wider halogen content range; due to the lower halogenation degree, the crystal structure of the branched polyethylene with lower branching degree is effectively broken, so that the branched polyethylene has elasticity; the processing and application methods of the branched polyethylene can be enriched, and the branched polyethylene can be used as an elastomer material, a sealing material, a binder, a coating and the like; particularly, when the method is applied to branched polyethylene with low branching degree and high molecular weight, the branched polyethylene with low halogen content and high physical and mechanical properties can be obtained. And the adopted halogenation method is easy to operate and low in cost, and industrialization is easy to achieve.

Owner:ZHEJIANG UNIV

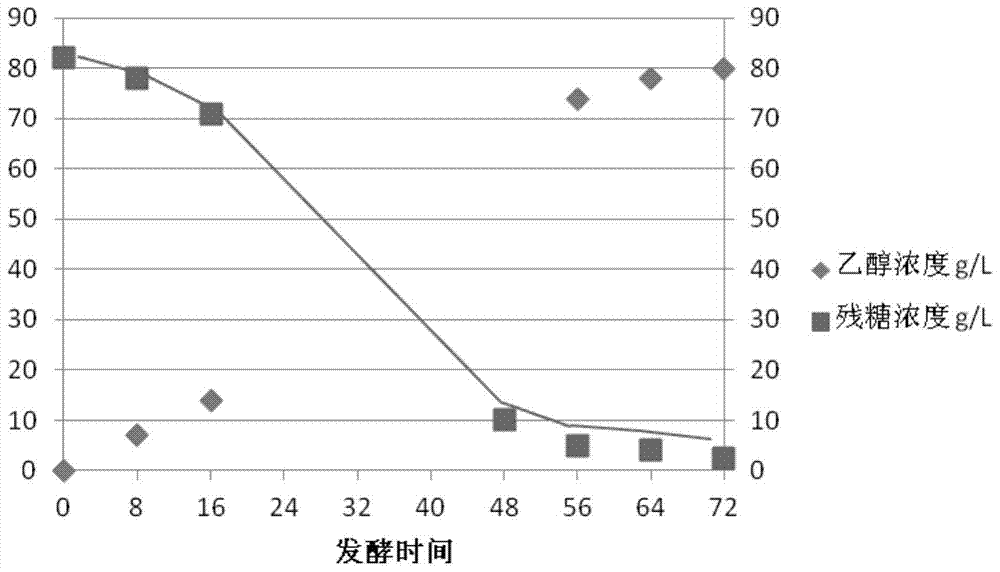

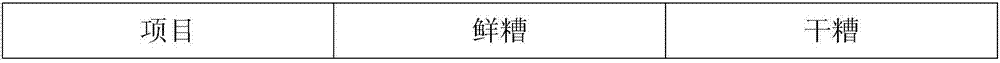

A kind of method for producing fuel ethanol by fermentation of koji distiller's grains

ActiveCN104372032BImproved disassembly and cutting abilityEfficient decompositionBiofuelsMicroorganism based processesEnzyme systemAlpha-amylase

The invention discloses a method for producing fuel ethanol by fermenting wine lees. The method disclosed by the invention can be used for voluntarily preparing a complex enzyme system, namely high temperature-resistant alpha-amylase, saccharifying enzyme, cellulase and acid protease, can be used for greatly enhancing the effect of decomposing and cutting capacity and effectively decomposing cellulose, xylogen, crude starch, crude protein and pectin in the wine lees, and can be used for solving the problem of pollution of solid wastes on the environment and increasing the demand of energy fuel of a company by producing fuel ethanol by using the wine lees and well solving the problem of organic combination of the cellulose, acid hydrolysis and enzyme hydrolysis and transforming the biological substances into ethanol again by continuously carrying out non-isothermal simultaneous liquefaction, saccharification and fermentation in a same container. According to the method, residues generated in a production process can be taken as feeds for developing the animal husbandry, and microbes are fermented to produce biogas, organic fertilizers and planting edible fungi for developing the planting industry.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

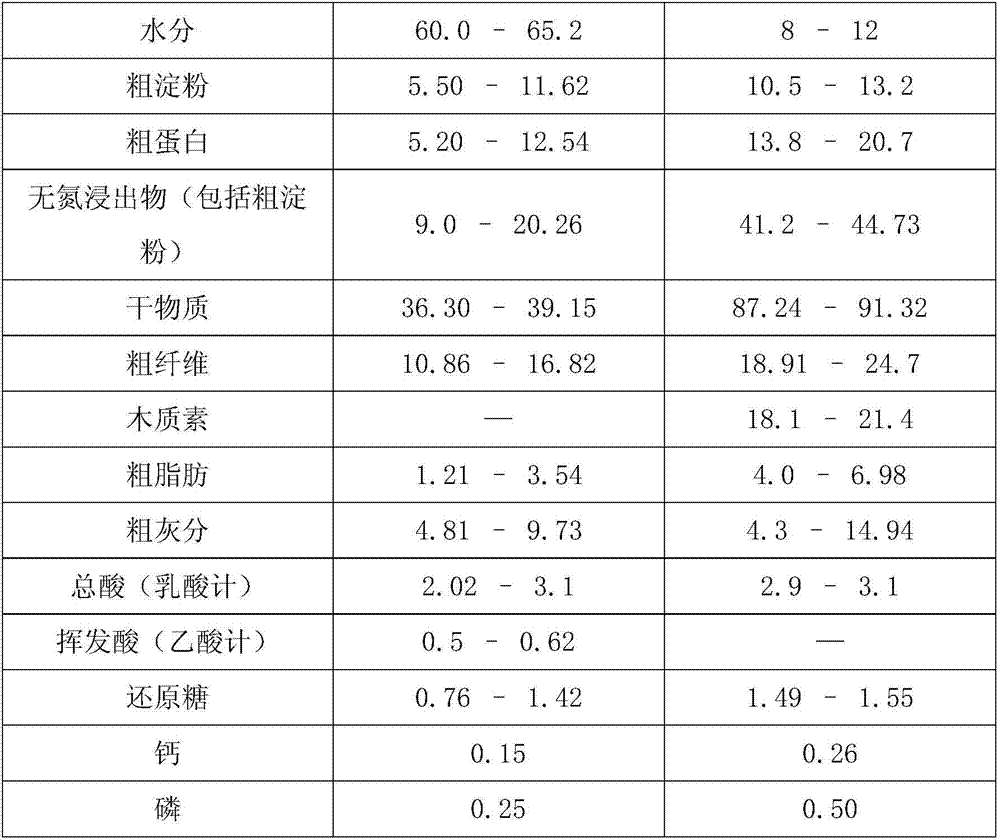

A kind of method utilizing fly ash and active carbon to synthesize sodium type zeolite

The invention discloses a method for synthesizing sodium type zeolite from fly ash and active carbon. The method comprises the following steps: 1, crushing: carrying out ball milling on the fly ash, and sieving the ball-milled fly ash for later use; 2, calcining: calcining the fly ash in a muffle furnace, taking out the calcined fly ash, and cooling the fly ash; 3, removing iron: mixing the fly ash with a hydrochloric acid solution, heating and stirring the obtained mixture, filtering the heated and stirred mixture, washing the filtered mixture with water until neutrality, and drying the washed mixture for later use; 4, ageing: uniformly mixing the fly ash with sodium carbonate, calcining the obtained mixture in the muffle furnace, taking out the calcined mixture, cooling the mixture, and carrying out fine grinding on the cooled mixture; 5, adding active carbon: adding the active carbon to the fly ash, and mixing to obtain a mixture for later use; 6, crystallizing: mixing the mixture obtained in step 5 with a sodium hydroxide solution, and stirring and ageing the obtained mixture at room temperature; and 7, washing and drying: placing the mixture obtained in step 6 in a reaction kettle, heating and crystallizing the mixture, washing the crystallized mixture with water, and drying the washed mixture to prepare the sodium type zeolite. The sodium type zeolite synthesized in the invention has the advantages of large surface area, strong adsorption ability, increased pore volume and large cation exchange amount.

Owner:ANHUI UNIV OF SCI & TECH

A kind of preparation method of alginic acid hydrogel matrix for ultraviolet 3D printing

InactiveCN105936674BDestroy crystal structureHigh grafting rateProsthesisFreeze-dryingUltraviolet lights

The invention relates to a preparation method of a hydrogel matrix, especially a preparation method of an alginic acid hydrogel matrix for UV 3D printing, and belongs to the technical field of biological material preparation. According to the preparation method, alkenyl groups are grafted on the molecular chains of sodium alginate prepared by a freeze-dry method, and after dissolving and mixing, the alginic acid hydrogel matrix for UV 3D printing is obtained. The preparation method adopts a freeze-drying technology under mixed solvent environment, the grafting rate of sodium alginate is largely improved, and the problem that the UV curing speed is slow due to low grafting rate is completely solved. The prepared alginic acid hydrogel matrix can rapidly solidify under the irradiation of UV light, the solid state can be maintained, moreover, in the presence of low concentration metal halides, the system can be further solidified, the hydrogel strength is improved, and the problems of conventional 3D printing hydrogel such as difficult moulding, collapse, and the like are overcome. The preparation method is simple, the cost is low, and the preparation method can be applied to industry easily.

Owner:济南科乐医药有限公司

Method for preparing high-strength high-modulus polyvinyl alcohol fibers

ActiveCN103290505BDestroy crystal structureLow melting pointArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentPolymer scienceSolvent

The invention relates to a method for preparing high-strength high-modulus polyvinyl alcohol fibers. The method comprises the following steps of: mixing 10-40 parts by weight of poly-hydroxymethyl compounds with 30-70 parts by weight of water to obtain a mixture serving as a composite modifier; then evenly mixing the composite modifier with 0.01-5 parts by weight of inorganic alkali compounds and 100 parts by weight of polyvinyl alcohol with polymerization degree of 1700-2600 and alcoholysis degree of 88-99% in a high-speed mixer to obtain modified polyvinyl alcohol; then spinning on a melt spinning machine to prepare nascent polyvinyl alcohol fibers; finally implementing cold drawing, drying, multi-stage hot drawing and hot shaping. The method needs neither solvents nor coagulators for wet spinning, thereby being simple in technology and free from pollution; a screw rod with a unique structure is not required; industrial production is easy to realize. The prepared fibers are high in fiber strength and high in modulus and can be used for cement toughening anti-cracking materials, geotextile and tire cords; the prepared fibers also can be used as reinforcing materials for plastics and rubber.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

A kind of production method of modified cassava starch

Owner:GUANGXI JINHAN ENVIRONMENTAL PROTECTION CO LTD

Modifying method of nonthermoplastic cellulose derivative material

The invention relates to a method for modifying nonthermoplastic cellulose derivative material, including the main content that 40wt to 80wt percent of matrices of nonthermoplastic cellulose derivative material, 1wt to 50wt percent of a reaction monomer and 10wt to 59wt percent of a plasticizer are evenly mixed and then placed into a processing and mixing device. The mixing reaction is carried out for 1 minute to 20 minutes at 60 DEG C to 140 DEG C on the condition of the operation of the mixing device. The substance discharged is the nonthermoplastic cellulose derivative material with the modified performance. The method for modifying the nonthermoplastic cellulose derivative material provided by the invention does not require completing in a solvent with the addition of an initiating agent, thereby fully avoiding side reactions caused by the initiating agent remaining in the material when the modifying method of the prior art is adopted, such as degradation and oxidation, etc., as well as the environmental pollution caused by the use of the solvent. The method of the invention has simple realization technology and high reaction efficiency, and can obviously improve the heat resistance and processing performance of the nonthermoplastic cellulose derivative material.

Owner:SICHUAN UNIV

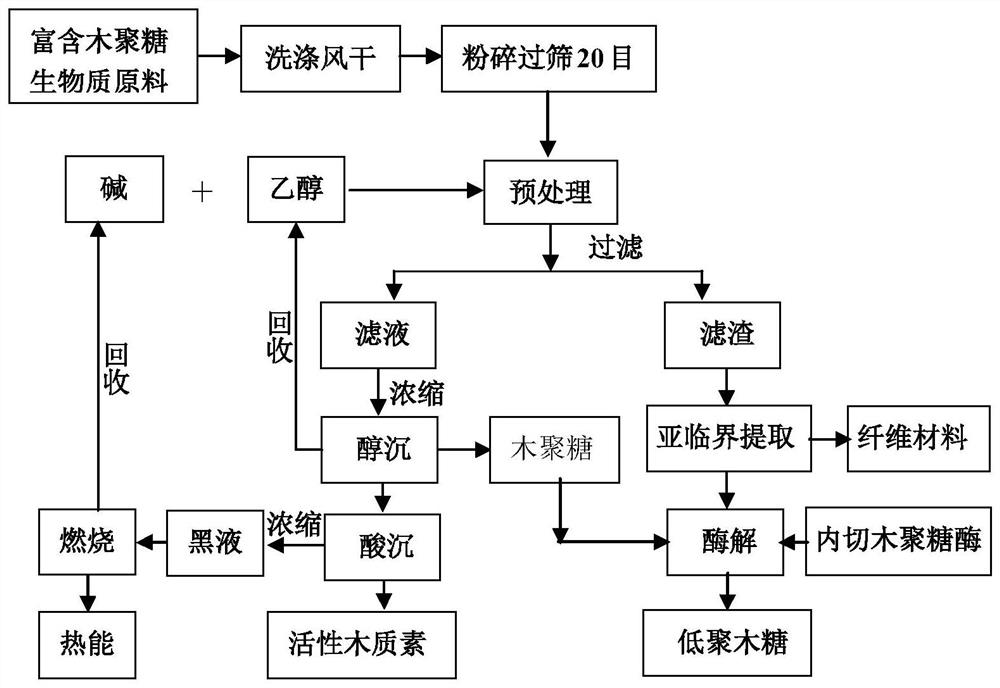

A kind of preparation method of xylo-oligosaccharide

The invention relates to a preparation method of xylo-oligosaccharides, the main innovations of which are the pretreatment of lignin fiber materials with an alkali-ethanol solution, and the extraction of xylans with a subcritical water extraction method. The pretreatment method of the present invention can remove a large amount of lignin, reduce the bondage of lignin to carbohydrates, destroy the internal compact structure that hinders the enzymatic hydrolysis and saccharification of endoxylanase; it can also destroy the crystal structure of carbohydrates, and make biomass The contact between the raw material and the biocatalyst is more sufficient, and the enzymatic hydrolysis efficiency of the endoxylanase is improved. The xylan prepared by the method of the present invention has high purity and high yield, and the amount of endoxylanase used in the preparation of xylo-oligosaccharides in the subsequent process is small; and the cellulose content of the residue after subcritical water extraction of xylan is high , is a high-quality raw material for the preparation of fiber materials.

Owner:BEIJING FORESTRY UNIVERSITY

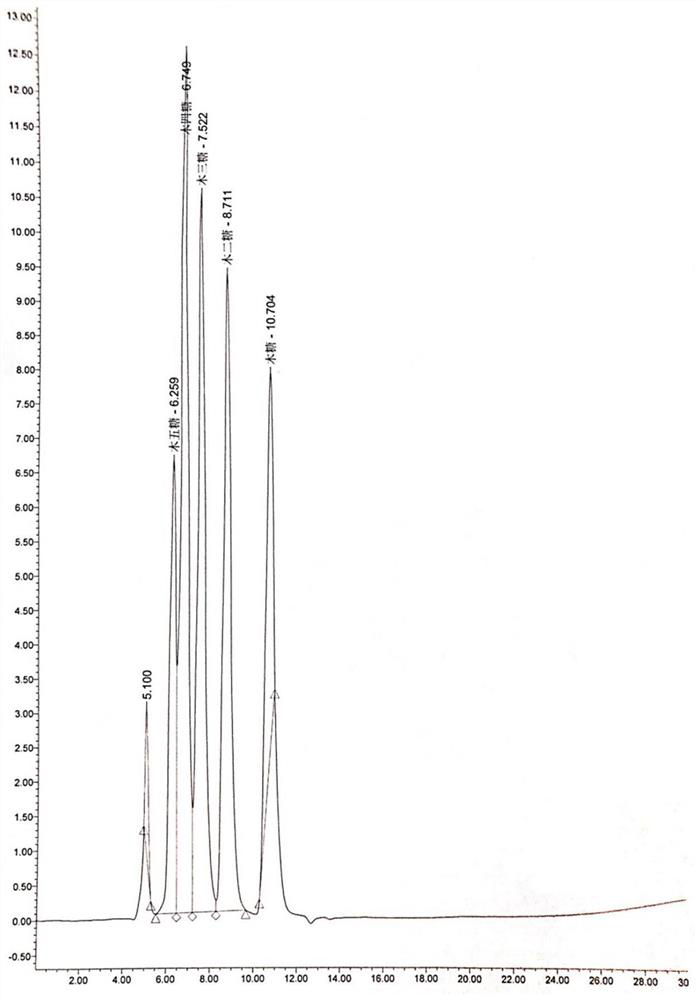

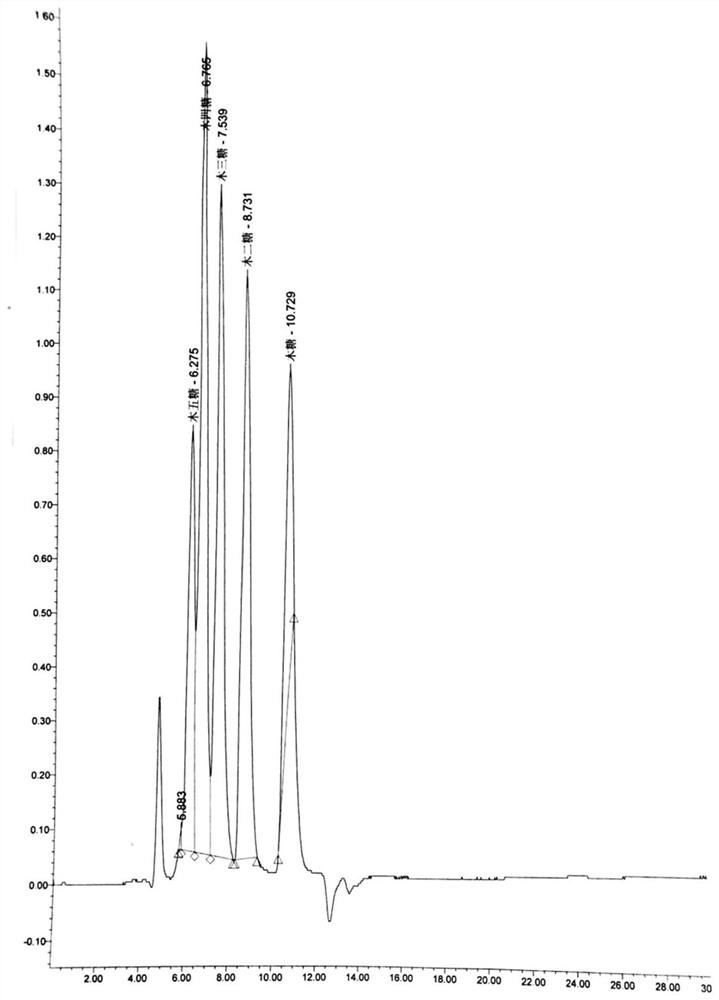

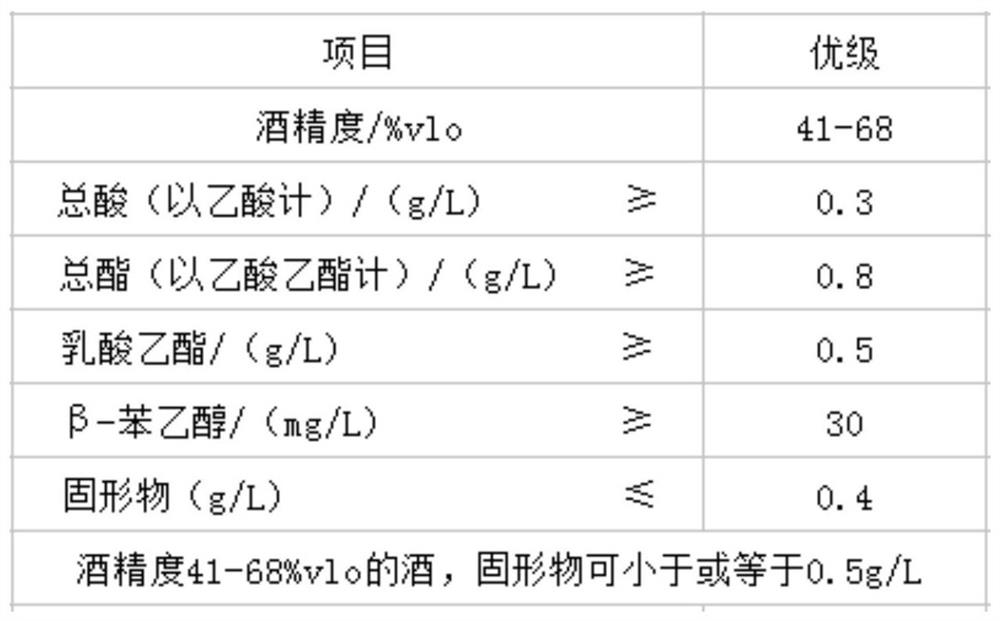

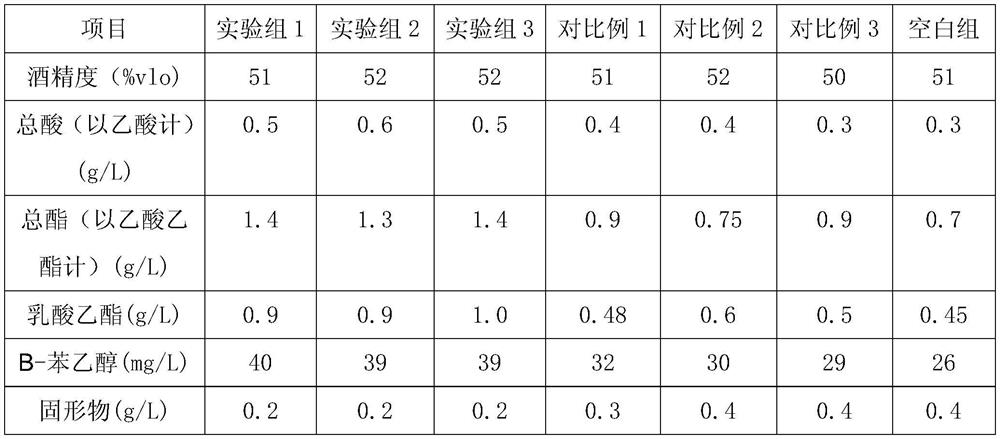

A kind of brewing method of Sanhua wine

ActiveCN107699432BDestroy crystal structureCrystalline structure releasedDigestive systemAlcoholic beverage preparationUltrasonic assistedChaptalization

The invention belongs to the technical field of food processing, and specifically discloses a brewing method of Sanhua wine. The brewing method of Sanhua wine of the present invention comprises the following steps: (1) selecting rice; (2) washing rice; (3) pretreatment: adopting ultrasonic auxiliary treatment; (4) soaking rice; (6) Spreading to dry; (7) Mixing koji: evenly mixing in medicinal koji powder; (8) Saccharification in the lower vat; (9) Fermentation; (10) Distilling; (11) Aging blending. The Sanhua liquor brewed by the brewing method of the present invention has a high rate of superior grade and high quality of the Sanhua liquor, can effectively meet people's requirements for liquor quality, and has high production efficiency.

Owner:桂林国农生态农业科技有限公司

A preparation and application method of PCBS-contaminated soil in-situ remediation agent based on waste biomass

ActiveCN106881349BHigh yieldDestroy crystal structureContaminated soil reclamationIron saltsIn situ remediation

Combining the serious soil PCBs pollution and the huge amount of waste biomass in my country, the present invention establishes a new process suitable for preparing an environmentally friendly PCBs-contaminated soil in-situ remediation agent using waste biomass as a raw material, including the following steps: 1) The hydrothermal co-processing of biomass, water and iron salt is carried out to prepare iron-loaded hydrothermal charcoal; 2) the iron-loaded hydrothermal charcoal is obtained after high-temperature heat treatment. The invention uses waste biomass as a carbon source to prepare a PCBs-contaminated soil in-situ remediation agent. The preparation process is simple, and not only can realize the rapid and efficient dechlorination and degradation of PCBs in soil, but also the remediation agent has the characteristics of greenness, environmental protection, and low price.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com