Golf club head

a golf club and head technology, applied in golf clubs, golf, sport apparatus, etc., can solve the problems of reducing the restitution performance of the face, the restitution performance other than at the sweet spot is considerably reduced, and the material of the face is difficult to achieve, so as to prevent a large decrease in the restitution performance, suppress the restitution, and maintain the light weight of the face part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Embodiments of a golf club head according to the present invention will now be described with reference to the accompanying drawings.

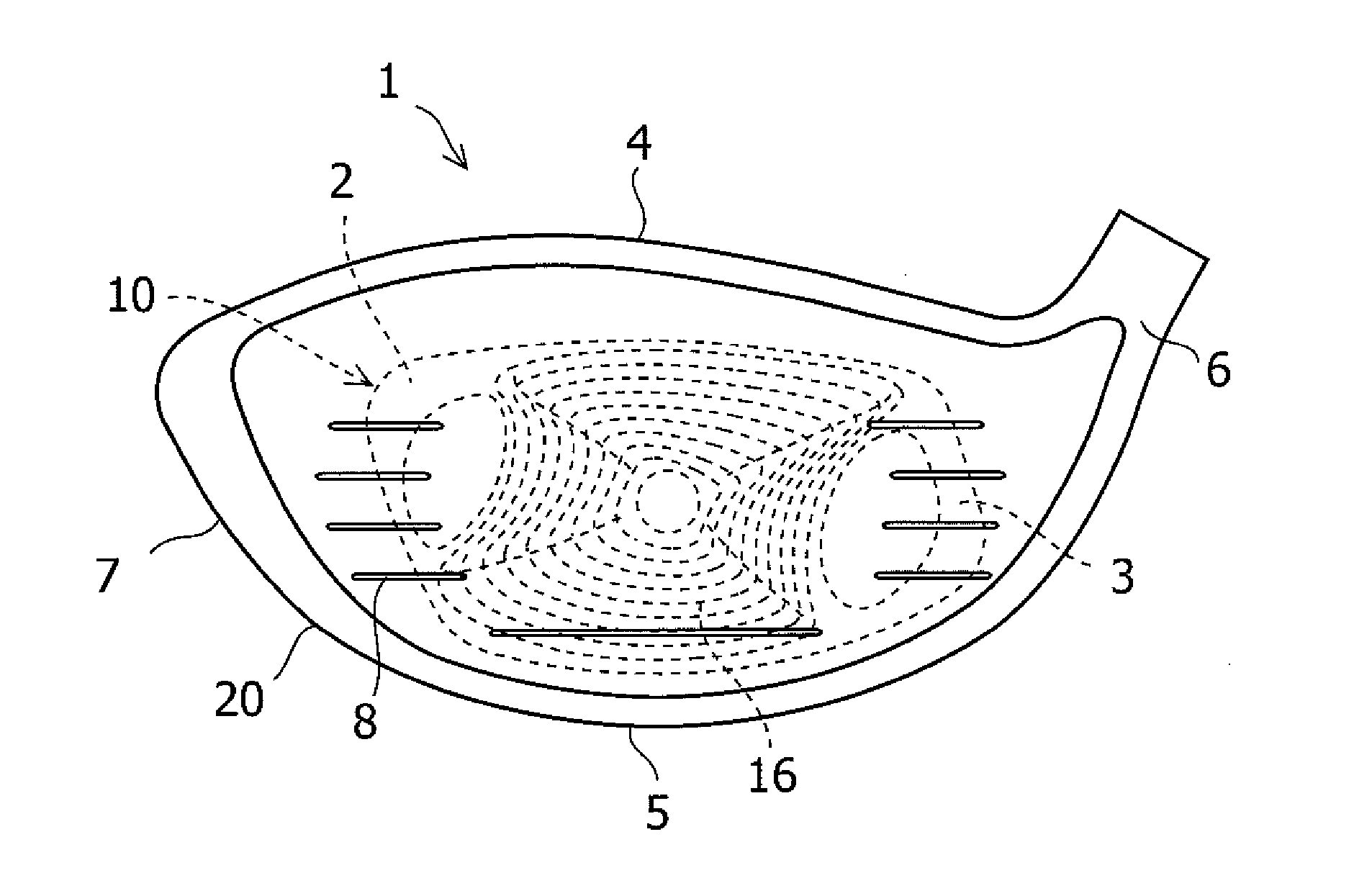

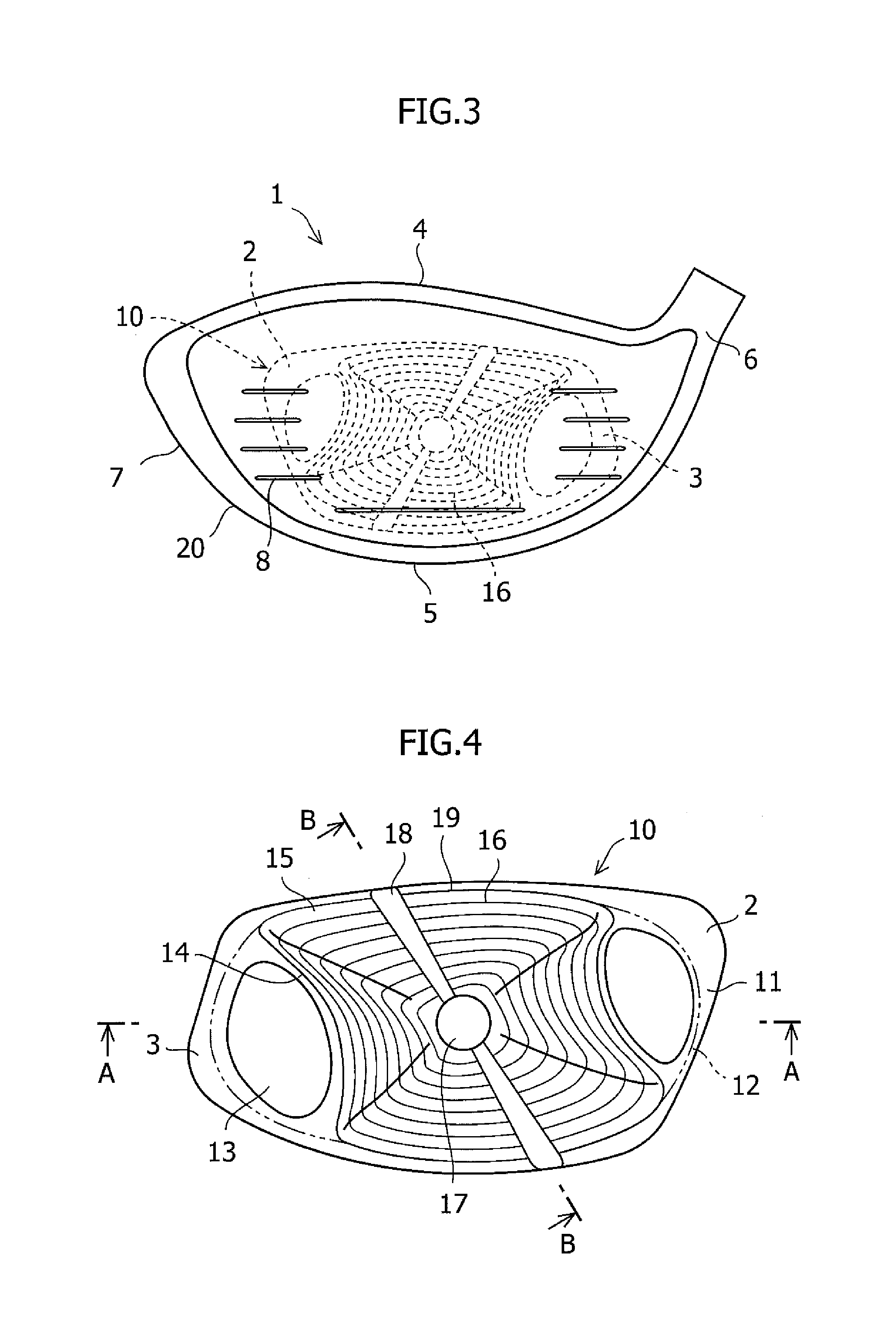

[0027]As shown in FIG. 1, a golf club head 1 is made up of a face member 10 including a part of a face part, and a main body member 20 of the head. The body member 20 includes a crown part 4, a sole part 5, a hosel part 6, and a side part 7, which are integrally formed. The face member 10 and the body member 20 are joined by welding, and thereby the interior of the head is made to be a hollow structure. A construction appearing on the surface on the hollow side of the face member 10, that is, the back surface of the face member 10, is indicated by broken lines. On the back surface of the face member 10, irregularities for altering the thickness of the face member 10 are formed. The back surface of the face member 10 is explained.

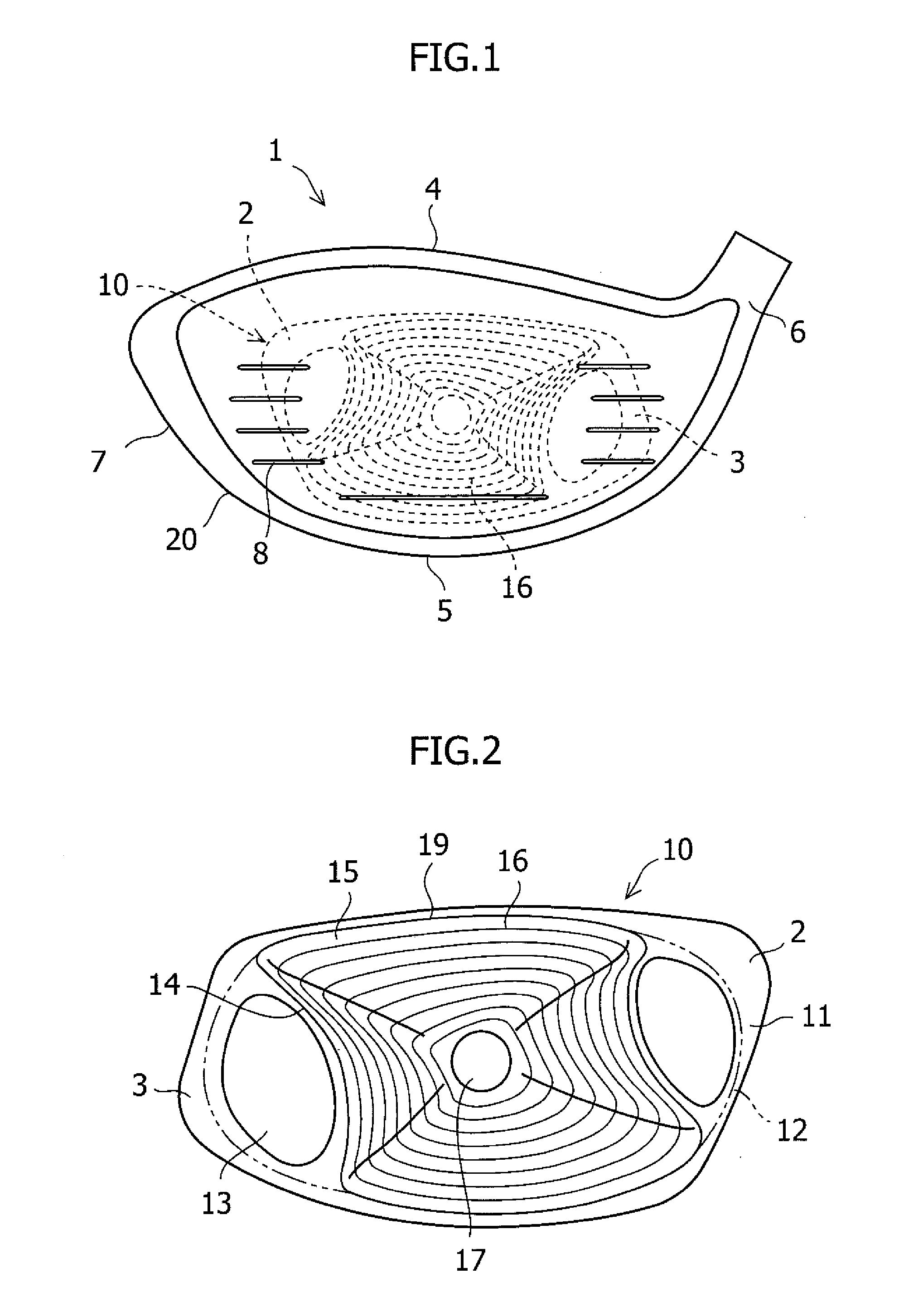

[0028]As shown in FIG. 2, an elliptical line 12 on the back surface of the face member 10 shows an elliptical region in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com