Negative ion solution with ultra-strong antibacterial effect and preparation method thereof

A technology of negative ions and negative ion powder, which is applied in the field of negative ion solution and its preparation, can solve the problems of easy contamination, dissolution, insufficient antibacterial effect, and lack of negative ion release effect, so as to improve the self-electric field strength, increase the production of negative ions, The effect of long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

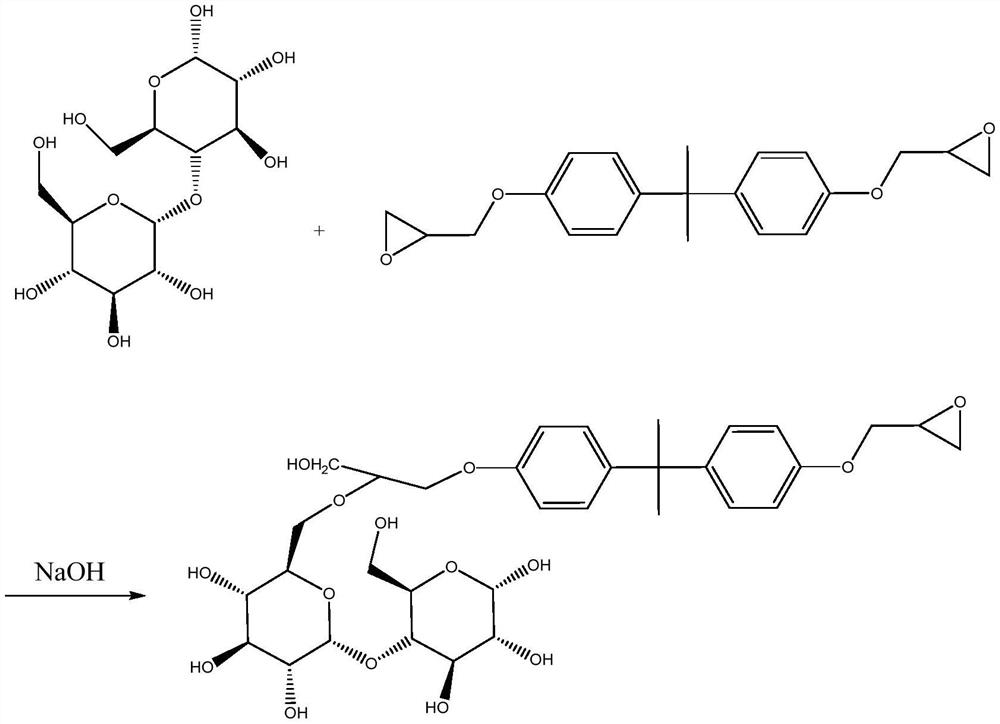

Method used

Image

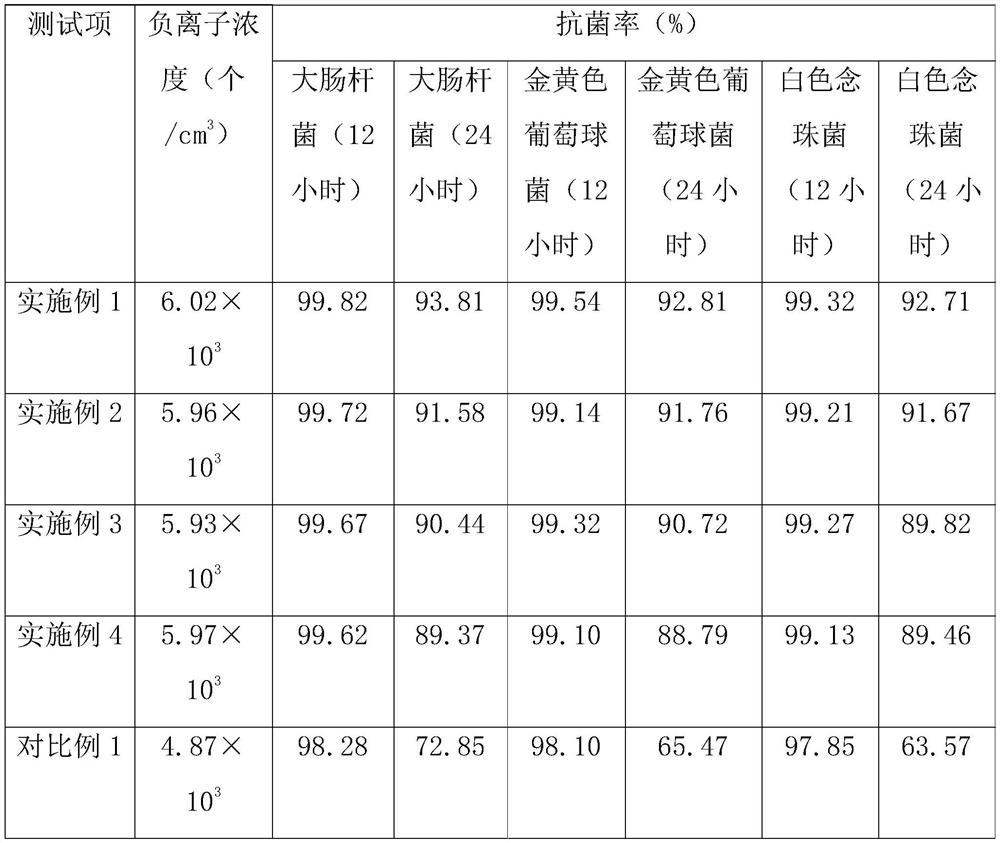

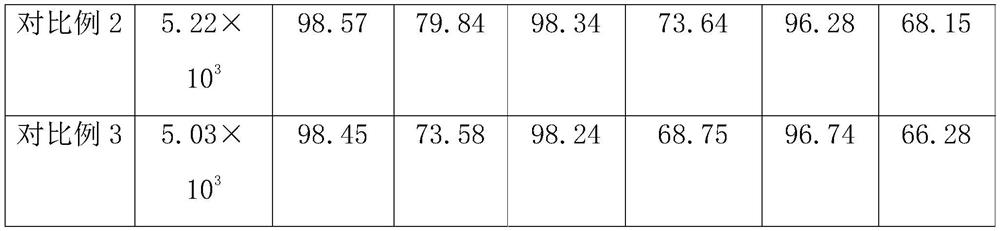

Examples

Embodiment 1

[0028] The present embodiment provides a kind of preparation method of the negative ion solution with super strong antibacterial effect, comprises the following steps:

[0029]Negative ion powder modification: put 100g of tourmaline into a ball mill, grind it for 60 minutes at a speed of 350rpm, pass through a sieve with an aperture of 2.5-3μm, add 0.13g of lanthanum oxide, and mix well to obtain tourmaline powder; After drying at 108°C, add 920g of 75% ethanol solvent, heat up to 72°C, shear and disperse at a speed of 960rpm, add 3.2g of trifluoromethyltrimethylsilane, keep stirring for 1.5 hours, and remove the solvent by suction filtration. Wash with water and ethanol, dry the filter cake at 113°C, and grind to obtain a modified negative ion powder with a particle size of 5-10 μm;

[0030] According to the mass percentage, tourmaline contains 50-53% SiO 2 , 24-27% Al 2 o 3 , 11-13% Fe 2 o 3 , 1.2-1.5% MgO, 0.28-0.31% CaO, 0.91-0.96% Na 2 O, 3.1-3.4% K 2 O, 0.42-0.55%...

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of the negative ion solution with super strong antibacterial effect, comprises the following steps:

[0036] Negative ion powder modification: put 100g tourmaline into a ball mill, grind it for 70 minutes at a speed of 380rpm, pass through a screen with an aperture of 2.5-3μm, add 0.16g of lanthanum oxide, and mix well to obtain tourmaline powder; After drying at 109°C, add 1100g of 75% ethanol solvent, heat up to 76°C, shear and disperse at 1100rpm, add 2.8g of tridecafluorooctyltriethoxysilane, keep stirring for 1.8 hours, and remove the solvent by suction filtration , washed with absolute ethanol, the filter cake was dried and ground at 117°C to obtain a modified negative ion powder with a particle size of 5-10 μm;

[0037] According to the mass percentage, tourmaline contains 50-53% SiO 2 , 24-27% Al 2 o 3 , 11-13% Fe 2 o 3 , 1.2-1.5% MgO, 0.28-0.31% CaO, 0.91-0.96% Na 2 O, 3.1-3.4% K 2 O, 0.42-0.55...

Embodiment 3

[0042] The present embodiment provides a kind of preparation method of the negative ion solution with super strong antibacterial effect, comprises the following steps:

[0043] Negative ion powder modification: put 100g tourmaline into a ball mill, grind it for 65 minutes at a speed of 360rpm, pass through a screen with an aperture of 2.5-3μm, add 0.17g of lanthanum oxide, and mix well to obtain tourmaline powder; After drying at 113°C, add 1080g of 75% ethanol solvent, heat up to 73°C, shear and disperse at 1060rpm, add 3.2g of heptadecafluorodecyltriethoxysilane, keep stirring for 1.6 hours, and remove the solvent by suction filtration , washed with absolute ethanol, the filter cake was dried and ground at 116°C to obtain a modified negative ion powder with a particle size of 5-10 μm;

[0044] According to the mass percentage, tourmaline contains 50-53% SiO 2 , 24-27% Al 2 o 3 , 11-13% Fe 2 o 3 , 1.2-1.5% MgO, 0.28-0.31% CaO, 0.91-0.96% Na 2 O, 3.1-3.4% K 2 O, 0.42-0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com