Method for thermal plasticizing modification of cassava dregs through mechanical activation and enhancement

A technology of mechanical activation and cassava residue, which is applied in the field of modification of biodegradable polymer materials, can solve the problems of complex process, difficult control, long time consumption, and inefficient modification process, and achieve the effect of improving hydrophobicity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

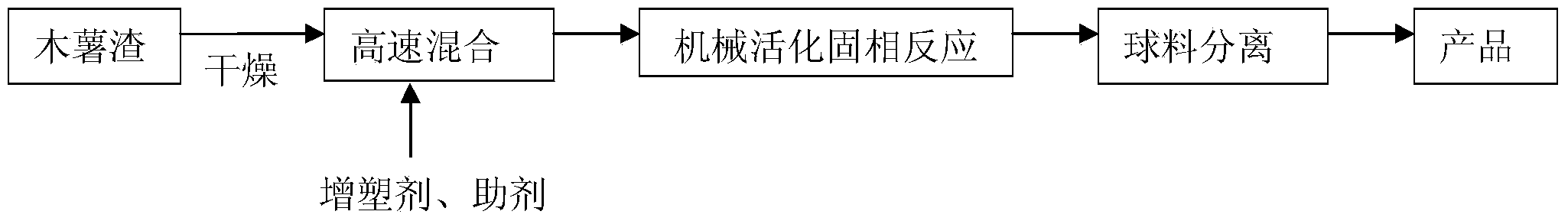

Method used

Image

Examples

Embodiment 1

[0023] In the present embodiment, the water content of the cassava residue is 10-12%, the starch content is 35-40%, the cellulose content is 25-32%, the plasticizer is glycerin, the auxiliary agent is citric acid, and the material ball is a stainless steel ball. The diameter is 6mm.

[0024] Weigh the reaction materials according to the ratio of cassava residue: plasticizer: auxiliary agent = 100g: 10g: 10g, mix the reaction materials at high speed and place them in a ball mill, control the reaction materials and balls (pile volume) = 100g: 300ml, control The temperature of the circulating water bath is 90°C, and the rotation speed is 500r / min. Stirring is carried out for mechanically activating the solid-phase reaction for 80 minutes, and the reaction material is separated from the pellets to obtain a modified cassava residue thermoplastic material.

Embodiment 2

[0026] In the present embodiment, the water content of cassava residue is 10-12%, the starch content is 35-40%, the cellulose content is 25-32%, the plasticizer is glycerin, and the auxiliary agents are citric acid and stearic acid according to the ratio of 13g:2g The composition, the material ball is a zirconia ball, and the diameter of the material ball is 5mm.

[0027] Weigh the reaction materials according to the ratio of cassava residue: plasticizer: auxiliary agent = 100g: 20g: 15g, mix the reaction materials at high speed and place them in a ball mill, control the reaction materials and material balls (pile volume) = 100g: 500ml, control The temperature of the circulating water bath is 70°C, and the rotation speed is 350r / min, and the mechanically activated solid-phase reaction is carried out with stirring for 60 minutes, and the reaction material is separated from the pellets to obtain the modified cassava residue thermoplastic material.

Embodiment 3

[0029] In the present embodiment, the water content of cassava residue is 10-12%, the starch content is 35-40%, the cellulose content is 25-32%, and the plasticizer is glycerin, formamide, urea, ethanolamine according to 10g:5g:5g:5g A composition mixed in proportion, the auxiliary agent is a composition mixed with citric acid and stearic acid in a ratio of 10g:5g, the ball is an alumina ceramic ball, and the diameter of the ball is 15mm.

[0030] Weigh the reaction materials according to the ratio of cassava residue: plasticizer: auxiliary agent = 100g: 25g: 15g, mix the reaction materials at high speed and place them in a ball mill, control the reaction materials and material balls (pile volume) = 100g: 300ml, control Under the condition of circulating water bath temperature of 50°C and rotating speed of 500r / min, mechanically activated solid-phase reaction was carried out with stirring for 60min, and the reaction material was separated from pellets to obtain a modified cassa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com