Environment-friendly blackboard writing liquid

A kind of blackboard writing liquid, environmental protection technology, applied in the direction of ink, household utensils, application, etc., can solve the problems of easy drying of the pen tip, poor writing fluency, etc. film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

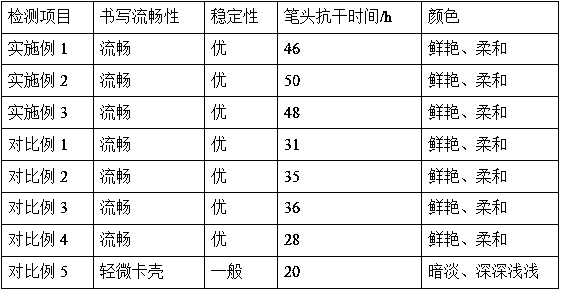

Examples

preparation example Construction

[0023] The preparation method of the lubricating compatibility additive is as follows: take tung oil and mix it with glycerin at a mass ratio of 10-20:3-7, add trimethylolpropane with 30-50% of the mass of tung oil, pass in nitrogen protection, and heat up to 210-220°C Stir and mix for 20-30 minutes to obtain a mixture. Take the mixture and add lithium hydroxide at a mass ratio of 100-150:1-3, keep it at 220-230°C for 1-3 hours, and cool to room temperature to obtain a lubricant-compatible additive.

[0024] The preparation method of cross-linked film-forming active agent is:

[0025] (1) Take methyl methacrylate and add 10% sodium hydroxide solution according to the mass ratio of 10~30:1~3, stir and mix for 20~30min, filter, take the filtrate to adjust the pH to 7~7.2, take the iso To form tridecyl fatty alcohol ether, add sodium lauryl sulfate and deionized water according to the mass ratio of 2~5:1~3:10~15, and stir and mix at 30~40°C for 20~30min to obtain an emulsifier. ...

Embodiment 1

[0034] The preparation method of the lubricating compatibility additive is as follows: take tung oil and add glycerin in a mass ratio of 10:3 to mix, add trimethylolpropane with 30% of the mass of tung oil, pass in nitrogen protection, heat up to 210°C and stir and mix for 20 minutes to obtain a mixture. Lithium hydroxide was added to the mixture at a mass ratio of 100:1, kept at 220°C for 1 hour, and cooled to room temperature to obtain a lubricant-compatible additive.

[0035] The preparation method of cross-linked film-forming active agent is:

[0036] (1) Take methyl methacrylate and add 10% sodium hydroxide solution at a mass ratio of 10:1, stir and mix for 20 minutes, filter, take the filtrate to adjust the pH to 7, take isomerized tridecyl fatty alcohol ether by mass Add sodium lauryl sulfate and deionized water at a ratio of 2:1:10, stir and mix at 30°C for 20 minutes to obtain an emulsifier, and take 5 parts of filtrate and 3 parts of 2-ethylhexyl acrylate , 2 parts ...

Embodiment 2

[0045] The preparation method of the lubricating compatibility additive is as follows: take tung oil and add glycerin in a mass ratio of 20:7 to mix, add trimethylolpropane with 50% of the mass of tung oil, pass in nitrogen protection, heat up to 220°C and stir and mix for 30 minutes to obtain the mixture. Lithium hydroxide was added to the mixture at a mass ratio of 150:3, kept at 230°C for 3 hours, and cooled to room temperature to obtain a lubricant-compatible additive.

[0046] The preparation method of cross-linked film-forming active agent is:

[0047] (1) Take methyl methacrylate and add 10% sodium hydroxide solution at a mass ratio of 30:3, stir and mix for 30 minutes, filter, take the filtrate to adjust the pH to 7.2, take isotridecyl fatty alcohol ether by mass Add sodium lauryl sulfate and deionized water at a ratio of 5:3:15, stir and mix at 40°C for 30 minutes to obtain an emulsifier, and take 10 parts of filtrate and 6 parts of 2-ethylhexyl acrylate , 5 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com