A kind of method utilizing fly ash and active carbon to synthesize sodium type zeolite

A technology for sodium-type zeolite and fly ash, which is applied in the synthesis field of sodium-type zeolite, can solve the problems of low zeolite purity and poor ion exchange performance, and achieve the effects of increasing pore volume, increasing reaction activity, and refining particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

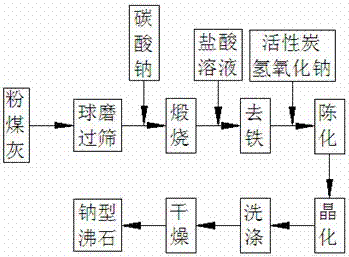

[0034] A kind of method that utilizes fly ash and activated carbon to synthesize sodium-type zeolite that the present embodiment provides, comprises the following steps:

[0035] Step 1, crushing: Carry out ball milling to fly ash, sieve standby; The mass percentage content of silicon dioxide and aluminum oxide in the fly ash raw material ≥ 80%, silicon dioxide and aluminum oxide in the fly ash raw material The ratio of the amount of aluminum is 3:1; and the particle size of the fly ash obtained in step 1 is ≤200 mesh.

[0036] Step 2. Calcination: put the fly ash obtained in step 1 into a muffle furnace for calcination, take it out and cool it for later use; for 2 hours.

[0037] Step 3, iron removal: mix the fly ash obtained in step 2 with hydrochloric acid solution, filter after heating and stirring, wash with water until neutral, and dry for later use; the concentration of hydrochloric acid solution is 10%, and the pulverized coal obtained in step 2 The mixing ratio of a...

specific Embodiment 2

[0043] A kind of method that utilizes fly ash and activated carbon to synthesize sodium-type zeolite that the present embodiment provides, comprises the following steps:

[0044] Steps 1 to 4 are the same as Steps 1 to 4 in Example 1.

[0045] Step 5, adding activated carbon: add activated carbon to the fly ash obtained in step 4, and mix it for later use; the mixing mass ratio of the fly ash and activated carbon obtained in step 4 is 2:1, and the particle size of the activated carbon is ≤ 200 mesh .

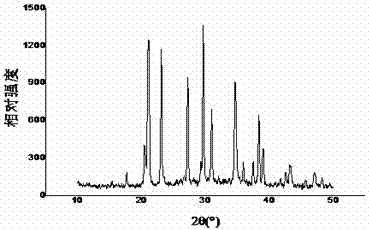

[0046] Step 6, crystallization: mix the mixture prepared in step 5 with sodium hydroxide solution, stir and age at room temperature for later use; the concentration of sodium hydroxide solution is 4 mol / L; the mixture prepared in step 5 is mixed with hydroxide The mixing ratio of the sodium solution is that every gram of the mixture prepared in Step 5 corresponds to 5 milliliters of sodium hydroxide solution; the aging time with stirring at room temperature is 6 hours.

[0047...

specific Embodiment 3

[0049] A kind of method that utilizes fly ash and activated carbon to synthesize sodium-type zeolite that the present embodiment provides, comprises the following steps:

[0050] Steps 1 to 4 are the same as Steps 1 to 4 in Example 1.

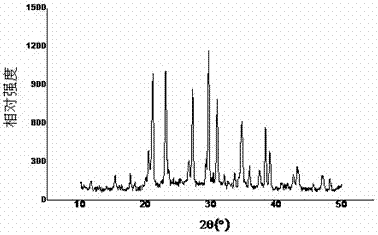

[0051] Step 5, adding activated carbon: add activated carbon to the fly ash obtained in step 4, and mix it for later use; the mixing mass ratio of the fly ash and activated carbon obtained in step 4 is 4: 1, and the particle size of the activated carbon is ≤ 200 mesh .

[0052] Step 6, crystallization: mix the mixture prepared in step 5 with sodium hydroxide solution, stir and age at room temperature for later use; the concentration of sodium hydroxide solution is 2 mol / L; the mixture prepared in step 5 is mixed with hydroxide The mixing ratio of the sodium solution is that every gram of the mixture prepared in Step 5 corresponds to 15 milliliters of sodium hydroxide solution; the aging time with stirring at room temperature is 24 hours.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com