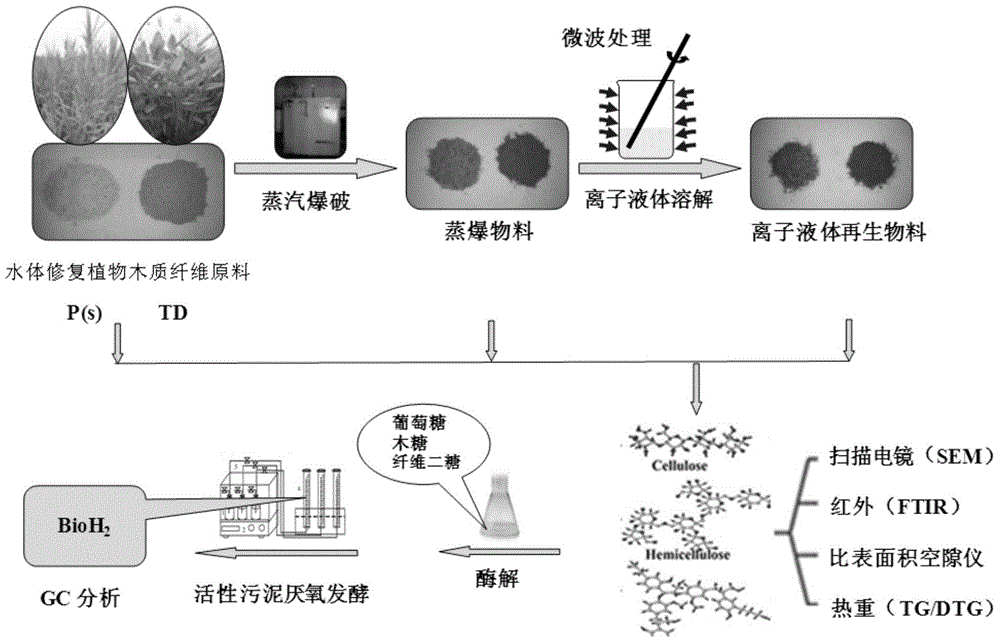

Water body remediation wood fiber raw material pretreatment method and corresponding hydrogen production method

A lignocellulosic raw material and water restoration technology, which can be applied to fermentation and other directions, can solve problems such as different crystalline properties of lignocellulosic cellulose, improve enzymatic hydrolysis and saccharification rate and hydrogen production rate, overcome low hydrogen production rate, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

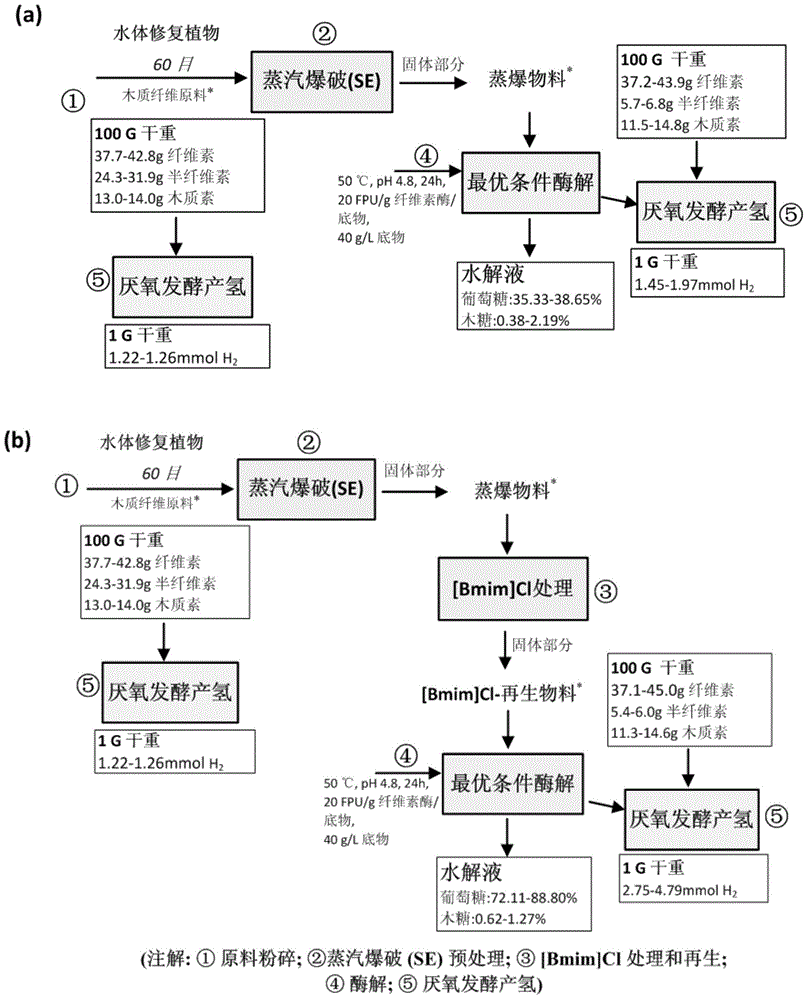

Embodiment 1

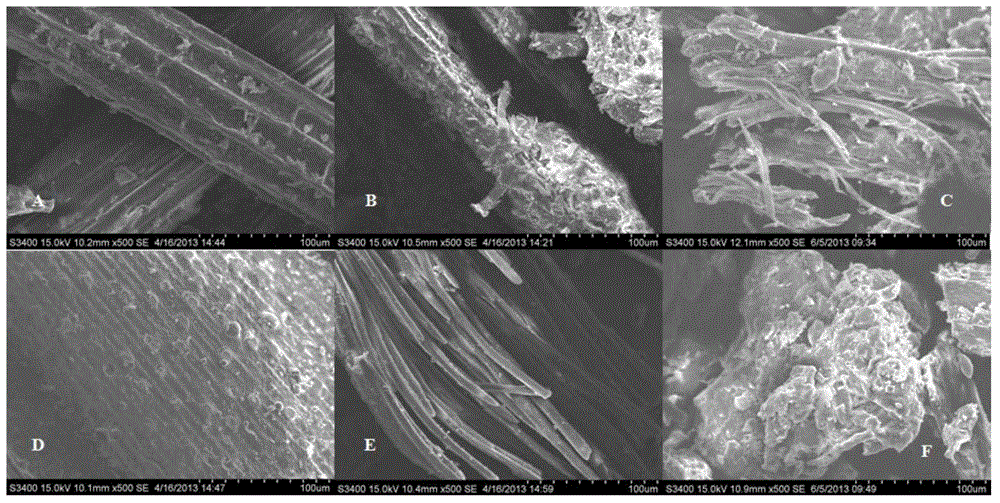

[0063] The green reeds in the ecological wetland purification base are treated with tail water in the mature stage in summer, after being naturally air-dried (moisture content ≤ 0.5% (weight %)), coarsely crushed and passed through a 60-mesh sieve to obtain sifted powder. The cellulose, hemicellulose and lignin in the sieved powder obtained from green reed were 42.8%, 31.9% and 13.0% respectively.

[0064] Take the above-mentioned 750g of sieved powder, place it in a steam explosion reactor (the steam explosion instrument is produced by Zhengdao Heavy Machinery Co., Ltd., Hebi, Henan), and carry out steam explosion under the conditions of steam explosion pressure 3.0MPa and steam explosion maintenance time of 90s. The obtained solid part is collected and dried (air-dried to a moisture content≤0.5% (weight ratio)) to obtain a steam-exploded material.

[0065] Take 20g of the above-mentioned steam-exploded material in a container, add 400g of vacuum-dried ionic liquid [Bmim]Cl (...

Embodiment 2

[0079] Take the Zailihua from the ecological wetland purification base for advanced treatment in the tail water during the ripening period in summer, after natural air-drying (moisture content ≤ 0.5% (weight ratio)), coarsely pulverize and pass through a 60-mesh sieve to obtain sifted powder. The cellulose, hemicellulose and lignin in the above-mentioned sieved powder made of Zailihua raw material are 37.7%, 24.3% and 14.0% respectively.

[0080] Get the above-mentioned 1250g sieved powder, place it in a steam explosion reactor (the steam explosion instrument is produced by Zhengdao Heavy Machinery Co., Ltd., Hebi, Henan), carry out steam explosion under the conditions of steam explosion pressure 2.5MPa, steam explosion pressure maintenance time 90s, steam explosion The obtained solid part is collected and dried (air-dried to a moisture content≤0.5% (weight ratio)) to obtain a steam-exploded material.

[0081] All the other contents are equal to embodiment 1.

[0082] Through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com