Preparation method of alginic acid hydrogel matrix for UV 3D printing

A 3D printing and alginic acid technology, applied in medical science, prosthesis, etc., can solve the problems of reduced 3D printing efficiency, difficulty in sol shaping, difficulty in maintaining size, etc., to achieve good adhesion, low cost, and increased grafting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] a. Preparation of gelatinized sodium alginate

[0026] Put sodium alginate and aprotic solvent in deionized water, the mass volume ratio of sodium alginate to deionized water is 1:10-200, the volume ratio of aprotic solvent to deionized water is 1:10-50, stir at room temperature For 1 to 24 hours, dry the mixed solution of sodium alginate, aprotic solvent, and deionized water at a temperature of -10 to -40°C and a pressure of 10 to 100 Pa for 18 to 72 hours to obtain gelatinized alginic acid sodium. The aprotic solvent is one of dimethylformamide, dimethylacetamide or dimethylsulfoxide.

[0027] Sodium alginate is also known as sodium alginate, kelp gum, and alginate. It is a natural polysaccharide isolated from brown seaweed such as kelp and sargassum. It is composed of different proportions of β-L-mannuronic acid (M unit) and α-D-guluronic acid (G unit) connected by 1,4-glycosidic linkages, composed of different GG, MM, GM segments. Due to its superior biocompatibi...

Embodiment 1

[0041] Weigh 5 g of sodium alginate, add it to 50 mL of deionized water, add 50 mL of dimethylformamide, stir at room temperature for 1 hour, place the solution at -10°C and a pressure of 10 Pa, and dry it for 18 hours to obtain a gelatinized sodium alginate.

[0042] Weigh 5g of gelatinized sodium alginate and 0.5g of maleic anhydride, add them to 50mL of dimethylformamide, stir well at room temperature, and react at 25°C for 12 hours. After the reaction, add anhydrous acetone until no precipitation Until the precipitation, the precipitate was collected and dried in vacuum at room temperature for 2 days to obtain maleic anhydride-grafted sodium alginate with a molar substitution of 0.05.

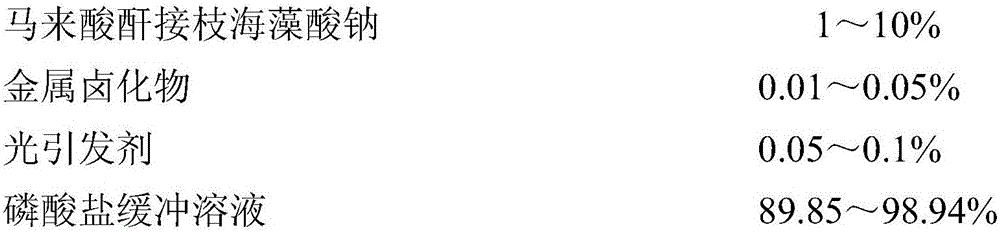

[0043] Weigh 1g of maleic anhydride grafted sodium alginate, 0.01g of calcium chloride, 0.05g of 2-hydroxy-2-methyl-1-p-hydroxyethyl ether phenylacetone, and add to 98.94g of Na with a pH of 7.0 2 HPO 4 -NaH 2 PO 4 In the buffer solution, mix uniformly at room temperature to obtain an a...

Embodiment 2

[0045] Weigh 5 g of sodium alginate, add it to 1000 mL of deionized water, add 250 mL of dimethylacetamide, stir at room temperature for 24 hours, place the solution at -40°C and a pressure of 100 Pa, and dry it for 72 hours to obtain gelatinization sodium alginate.

[0046] Weigh 5g of gelatinized sodium alginate and 50g of maleic anhydride, add them to 1000mL of dimethylacetamide, stir well at room temperature, and react at 90°C for 48 hours. After the reaction, add anhydrous acetone until no precipitation occurs The precipitate was collected and dried in vacuum at room temperature for 2 days to obtain maleic anhydride-grafted sodium alginate with a molar substitution of 0.8.

[0047] Weigh 10 g of maleic anhydride grafted sodium alginate, 0.05 g of zinc chloride, and 0.1 g of 1-hydroxycyclohexyl phenyl ketone, and add it to 89.85 g of K with a pH of 7.4. 2 HPO 4 -KH 2 PO 4 In the buffer solution, mix uniformly at room temperature to obtain an alginic acid hydrogel matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com