Method for preparing high-strength high-modulus polyvinyl alcohol fibers

A polyvinyl alcohol fiber, high-strength and high-modulus technology, which is applied to the chemical characteristics of fibers, complete sets of equipment for the production of artificial threads, and artificial silk manufacturing. It can solve problems such as high equipment requirements, inability to spin, and complex extraction, and achieve fiber strength. and high modulus, easy industrial production, and the effect of increasing the decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

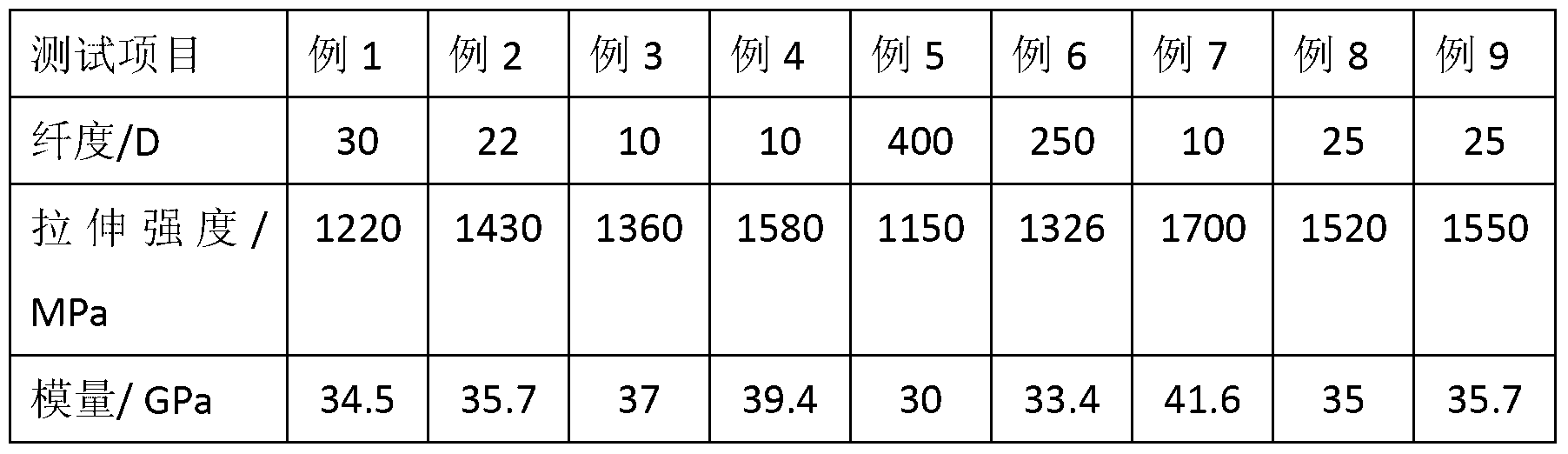

Examples

Embodiment 1

[0030] Mix 100g of tris(hydroxymethyl)aminomethane with 600g of water as a composite modifier, then mix with 30g of magnesium hydroxide and 1000g of polyvinyl alcohol PVA1799 (Note: PVA1799 means that the degree of polymerization of polyvinyl alcohol is 1700, and the degree of alcoholysis is 1700). 99%) in a high-speed mixer to obtain modified polyvinyl alcohol, and the modified polyvinyl alcohol is spun on a melt spinning machine to prepare primary fibers, the spinning temperature is 140 ° C, and the spinneret temperature is 115 ℃, the primary fiber was stretched 3 times at 25 ℃ and then dried in a drying oven at 100 ℃ for 10 minutes, and then subjected to 3-stage heat drawing at 150 ℃, 175 ℃ and 200 ℃ for 3.3 times, and finally heat-set at 210 ℃ for 1.5 times. min, that is, high-strength and high-modulus polyvinyl alcohol fibers are obtained.

Embodiment 2

[0032] Mix 400g of trimethylolpropane with 700g of water as a composite modifier, and then mix with 50g of calcium hydroxide and 1000g of polyvinyl alcohol (PVA2499) in a high-speed mixer to obtain modified polyvinyl alcohol. Polyvinyl alcohol was spun on a melt spinning machine to prepare spun fibers. The spinning temperature was 160°C and the spinneret temperature was 125°C. The spun fibers were stretched twice at 20°C and then dried in a drying oven at 120°C for 8 minutes. , then at 150°C, 180°C, and 220°C for 3-stage thermal stretching for 7 times, and heat-setting at 220°C for 0.5 min to obtain high-strength and high-modulus polyvinyl alcohol fibers.

Embodiment 3

[0034] Mix 300g of 1,3-dihydroxyacetone with 300g of water as a composite modifier, and then mix with 5g of calcium hydroxide and 1000g of polyvinyl alcohol (PVA1788) in a high-speed mixer to obtain modified polyvinyl alcohol. Polyvinyl alcohol was spun on a melt spinning machine to prepare spun fibers. The spinning temperature was 145°C and the spinneret temperature was 105°C. The spun fibers were stretched 2 times at 25°C and then dried in a drying oven at 120°C. 4min, then at 150°C, 175°C, and 195°C for 10 times of 3-stage thermal stretching, and heat-setting at 220°C for 3 minutes, to obtain high-strength and high-modulus polyvinyl alcohol fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com