Halogen-containing branched polyethylene and preparation method thereof

A branched polyethylene, branched degree technology, applied in coatings, adhesives, etc., can solve the problems of no practical value, low polymerization activity, and high synthesis cost, and achieve the effects of easy industrialization, low halogen content, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

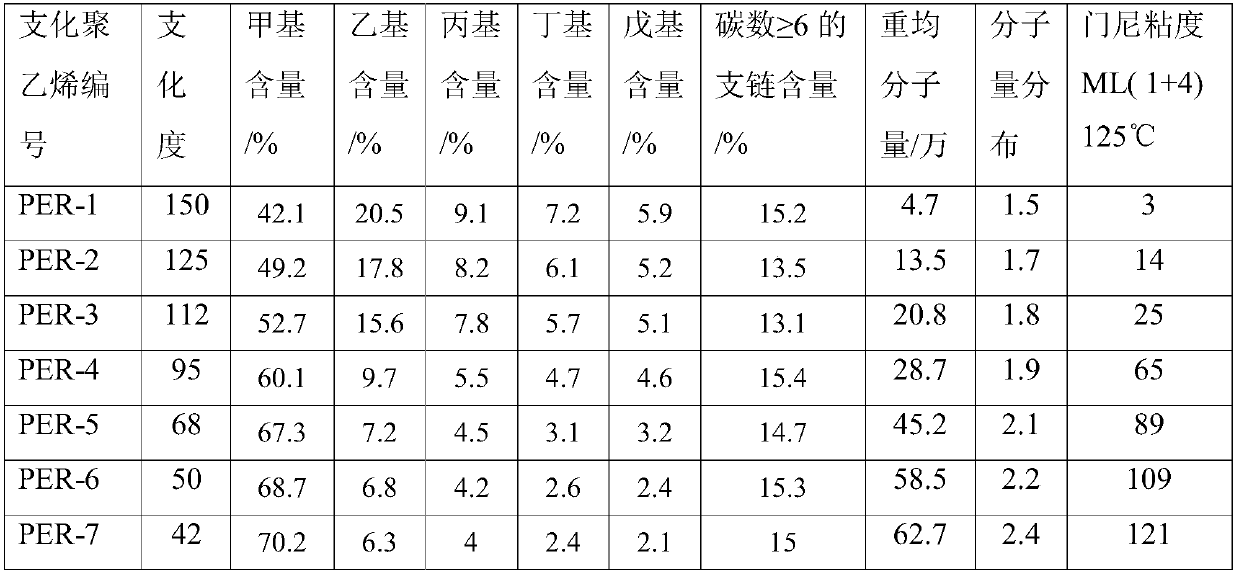

[0048] The number of branched polyethylene used in this example is PER-3.

[0049] The preparation steps are as follows: add 20 milliliters of CCl in a 100 milliliter three-neck flask 4 , 1 g of branched polyethylene cut into small pieces was added with stirring. Nitrogen was passed through the reaction system for 5 minutes, and the air in the system was exhausted, so that it was in a nitrogen atmosphere. Turn off the nitrogen, pass condensed water, and start to heat up to 80°C. Dissolve 0.1 g of initiator azobisisobutyronitrile in 100 ml of CCl 4 , configured as a solution. After the branched polyethylene is completely dissolved, 10 ml of AIBN in CCl 4 The solution was evenly injected into the reaction system with a syringe, and stirred at 300 rpm for about 10 minutes. Open nitrogen, quickly add 0.1 g of N-bromosuccinimide powder into the system, and add 5 ml of CCl 4 Rinse off the NBS powder adhering to the vessel wall, and immediately reseal the system. Timed and rea...

Embodiment 2

[0051] The consumption of NBS is changed into 0.15 gram, other conditions and operation method are with embodiment 1. The obtained brominated branched polyethylene has a bromine content of 2.5 wt%, and a Mooney viscosity ML(1+4) of 26 at 125°C.

Embodiment 3

[0053] Change the consumption of NBS into 0.2 gram, other conditions and operation method are with embodiment 1. The obtained brominated branched polyethylene has a bromine content of 3 wt%, and a Mooney viscosity ML(1+4) of 28 at 125°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com