Machining method of three-dimensional pattern-embedded glass cup

A processing method and glass technology, which are applied in the processing field of three-dimensional intarsia glass, can solve the problems of no three-dimensional effect, being ground off or fading, monotonous glass style, etc., and achieving good three-dimensional effect, bright color and rich processing. effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

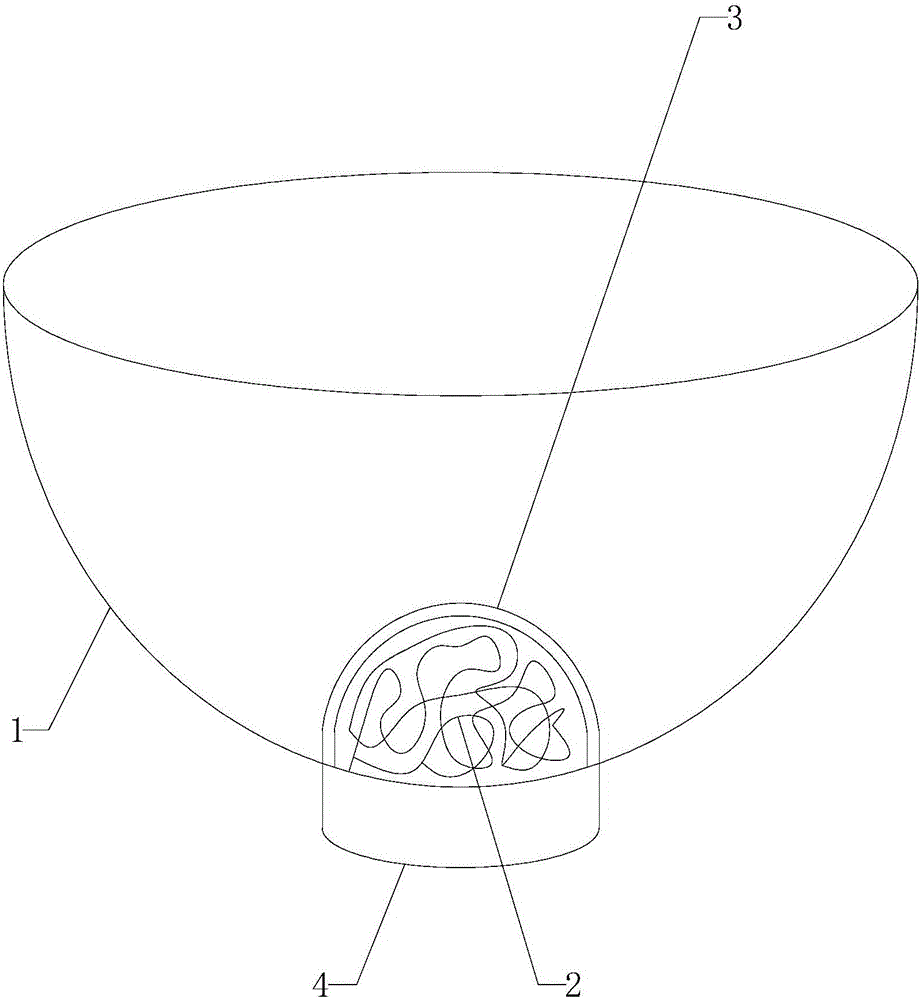

[0012] Such as figure 1 Shown, a kind of processing method of three-dimensional mosaic glass, comprises the following steps:

[0013] 1) Make the cup body: heat the borosilicate glass tube with gas and oxygen flame, the flame temperature is 1200°C, and the heating time is 10-40 seconds. After the middle part of the borosilicate glass tube is red and soft, cut it off slowly , drawn into a cup body 1 with openings at both ends, the shape and size of which meet the requirements;

[0014] 2) Make a flower-shaped spherical crown: heat the color rod with gas and oxygen flame, the flame temperature is 1200°C, and then stretch out the filament; choose another high borosilicate g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com