Automatic transfer device and transfer method

A technology of a transfer device and a trigger device, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of inability to meet the needs of automated production and the low degree of automation of transfer equipment, and achieve the effect of reducing inertia and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

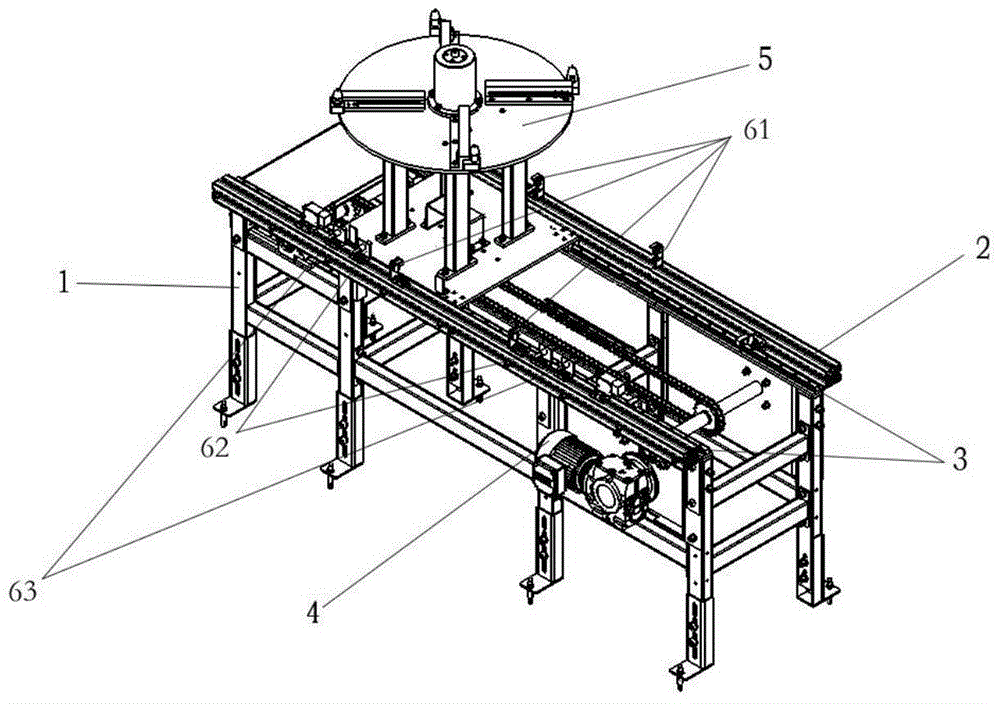

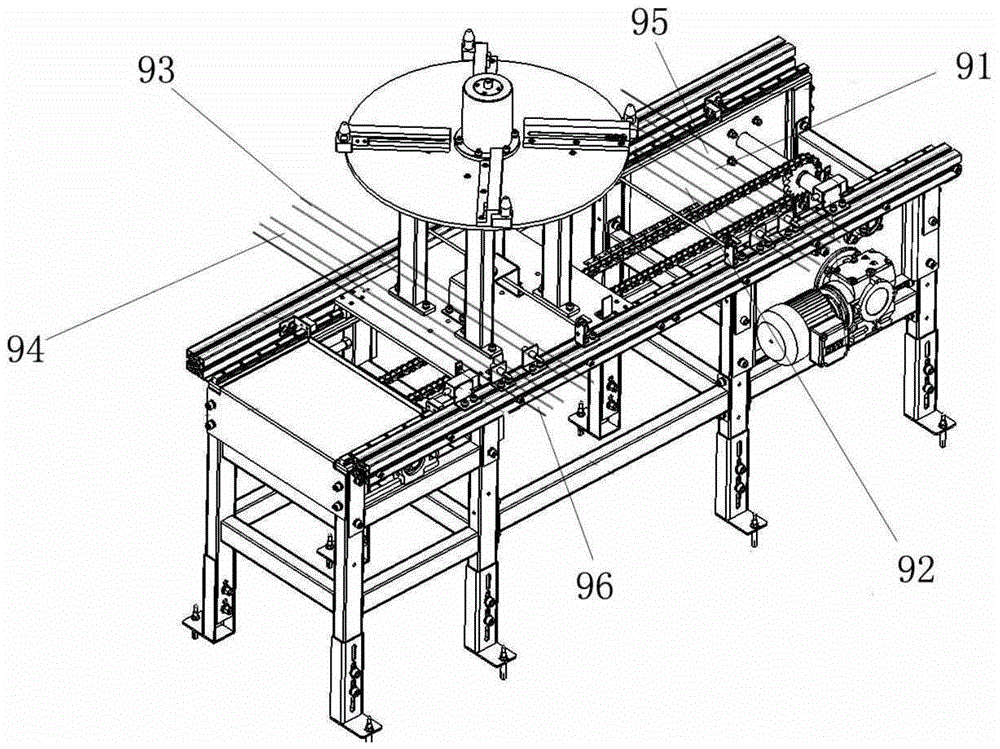

[0038] This embodiment provides an automatic transfer device, such as Figure 1-3 As shown, it includes: a support 1, which forms a transfer zone inside the support 1, a power assembly 4 (usually a motor) arranged on one side of the support 1, a beam 2 arranged at the top of the support 1, and arranged on the top of the support 1. The slide rail 3 on the inner side of the crossbeam 2 is driven by the transmission device of the power assembly 4. Driven by the transmission device, the moving assembly 5 moves back and forth in the transfer space along the slide rail 3. The length direction of the transfer section is The two sides are sequentially provided with a first stop position 95 and a second stop position 96, a first stop position 91 and a second stop position 94, a first deceleration position 92 and a second deceleration position 93 from outside to inside, as image 3 As shown; the transfer device of this embodiment is also provided with an automatic control device, which ...

Embodiment 2

[0053] This embodiment provides a transfer device, which is an improvement made on the basis of Embodiment 1. The difference from Embodiment 1 lies in the addition of safety equipment.

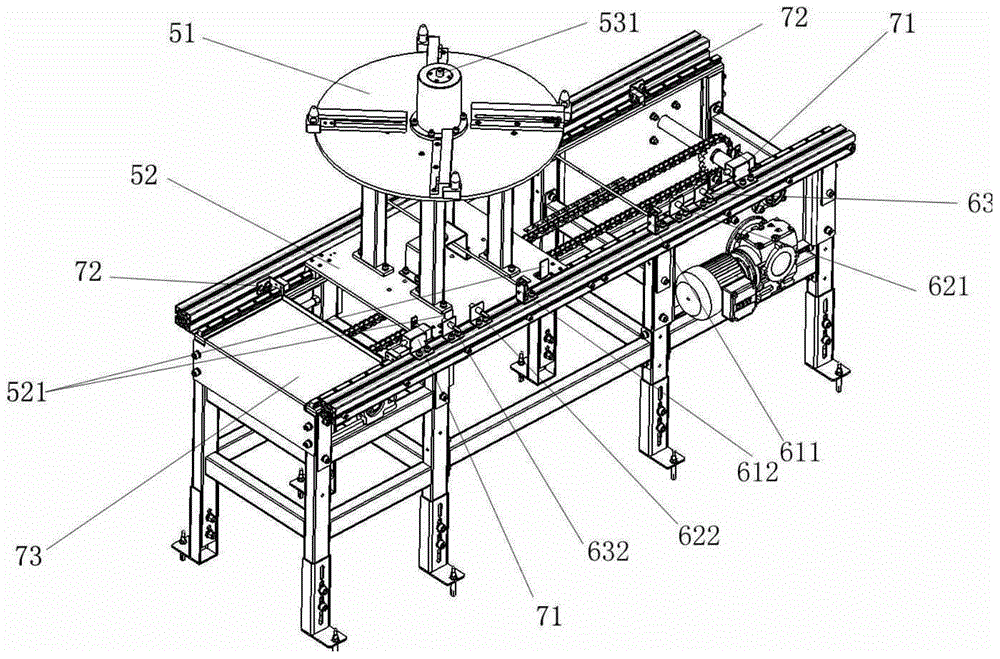

[0054]In the transfer device of this embodiment, the safety equipment includes safety limit switches 71 arranged at both ends of the beam 2 and located outside the transfer section, and a trigger piece 521 arranged on the sliding plate 52, the The trigger piece 521 is in contact with the safety limit switch 71 when the moving component 5 moves beyond the transfer zone, so as to forcibly turn off the power supply of the power component 4 .

[0055] Normally, the moving assembly 5 is controlled by the deceleration sensor 62 and the stop sensor 63 to move back and forth in the transfer zone, so as to realize the transportation of the workpiece. However, in some unexpected cases, the deceleration sensor 62 and the stop sensor 63 may fail, The moving assembly 5 may exceed the transfer interval, and...

Embodiment 3

[0060] This embodiment provides a transfer device, which is an improvement made on the basis of Embodiment 1 or 2. The difference from Embodiment 1 or 2 is that the loading tray 51 is provided with positioning blocks for fixing workpieces 515, such as Figure 5 shown. By arranging the positioning block 515, the workpiece can be fixed on the loading tray 51 to ensure that when the workpiece is running with the moving assembly 5, especially when the moving assembly 5 starts and stops, the workpiece will not be moved from the loading tray 51 by inertia. Falling down further improves the stability and safety of the overall transfer device.

[0061] In the transfer device of this embodiment, the loading tray 51 is provided with an adjustment device for adjusting the position of the positioning block 515, and the adjustment device includes an adjustment slot 513 formed on the side of the loading tray 51 along the radial direction. The rod 511 can move in the adjustment slot 513 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com