Mold press forming die and molded article manufacturing method

A technology of press forming and pressure forming, which is applied in the direction of manufacturing tools, glass forming, glass pressing, etc., and can solve problems such as stamping action obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0159] Next, the present invention will be described in further detail with reference to specific examples.

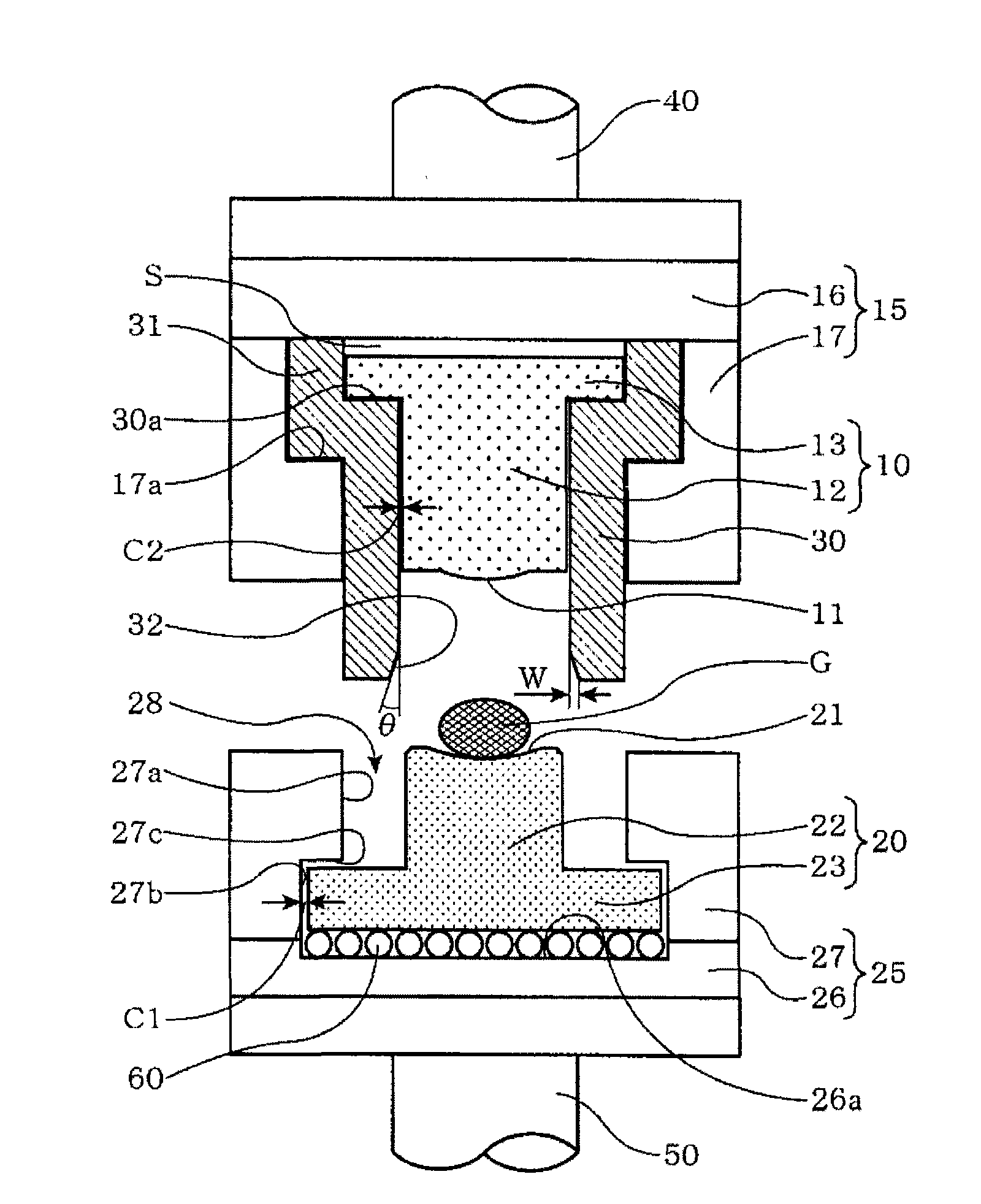

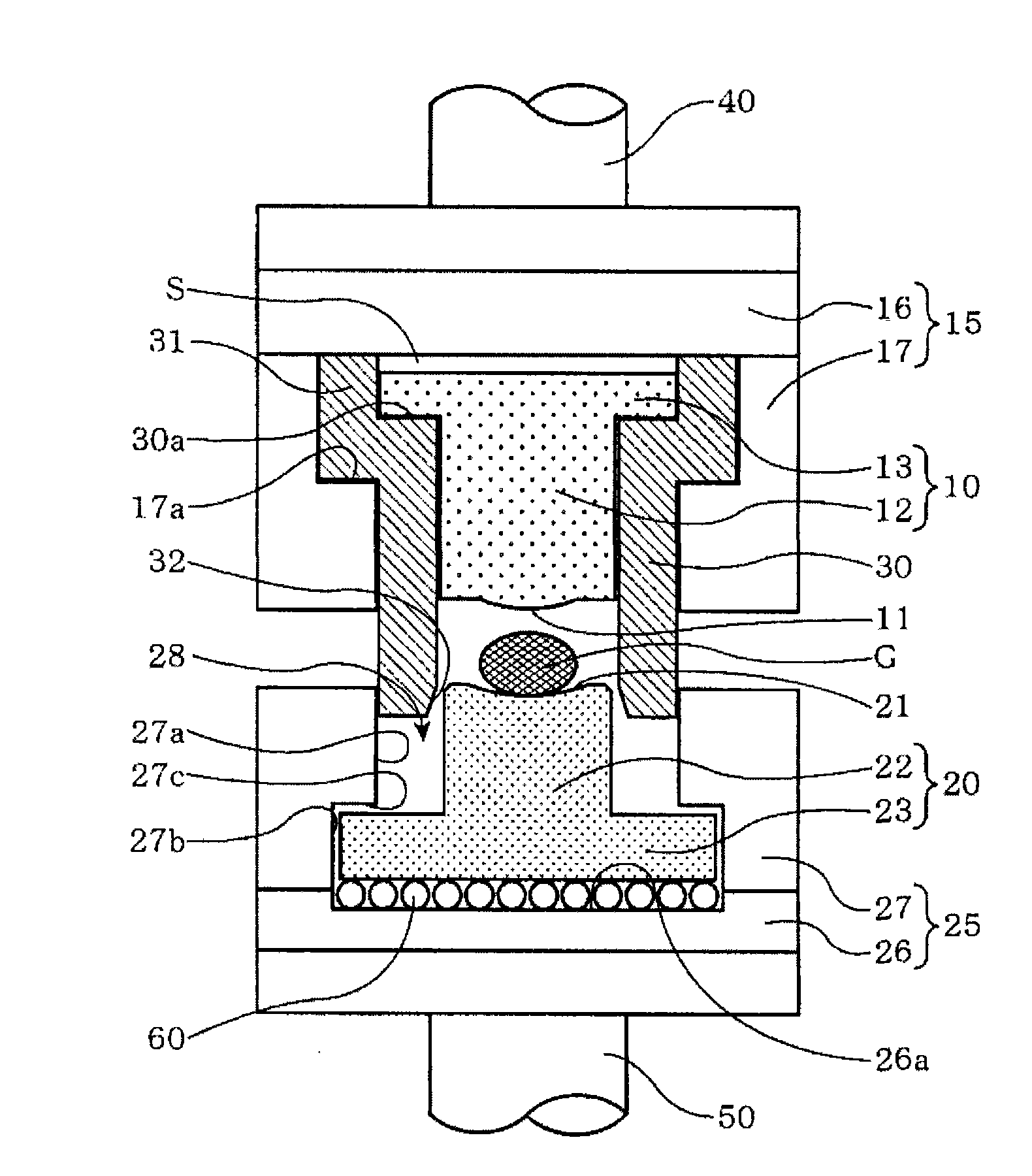

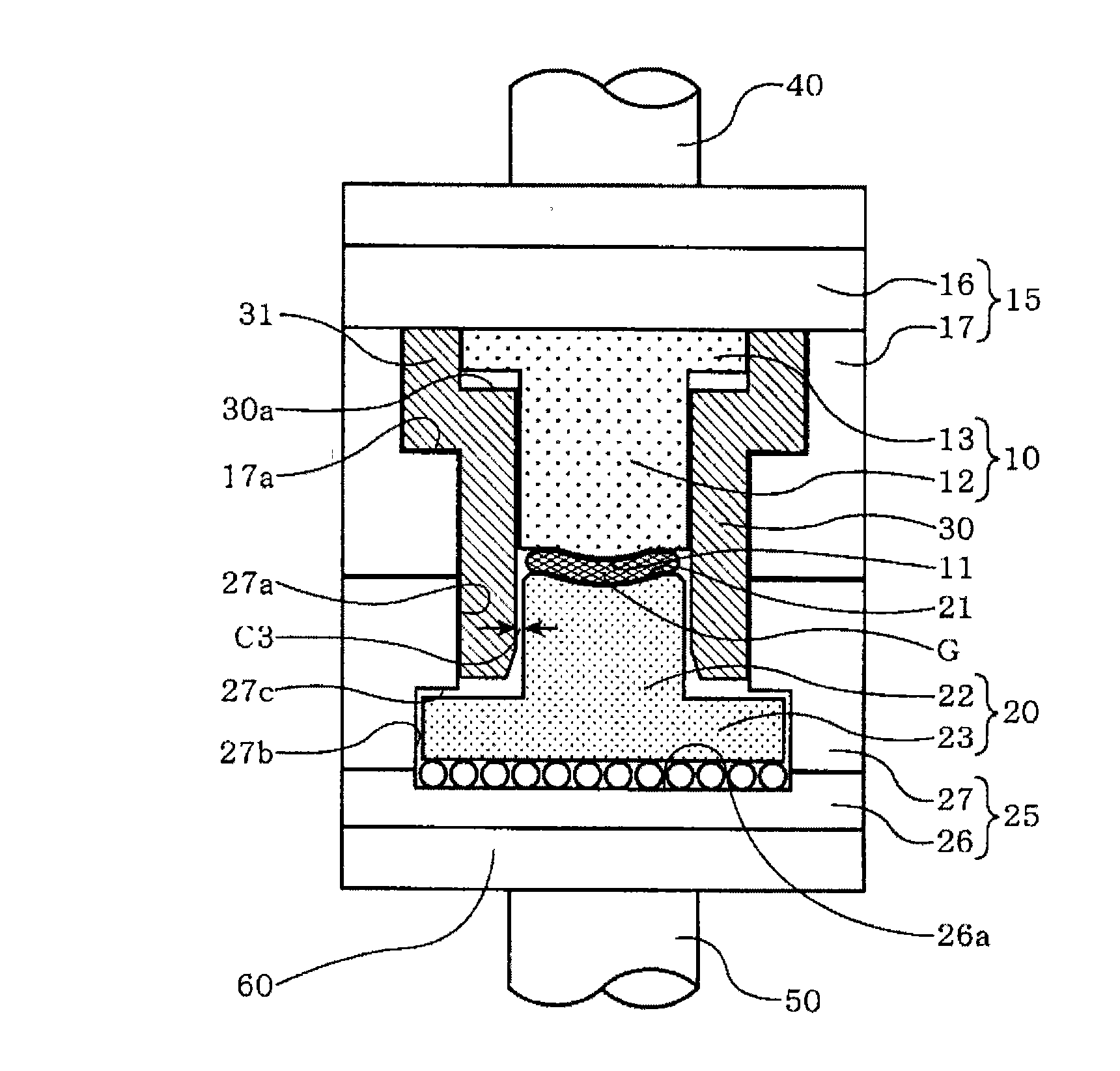

[0160] Will figure 1 The compression molding die shown is mounted on Figure 8 In the press molding apparatus shown, a biconvex lens having an outer diameter of 15 mm was molded using a preform of barium borosilicate glass (transition point 514° C., deformation point 545° C.) as a molding material G.

[0161] First, a glass blank thermoformed into a biconvex shape is preheated to 490° C., and supplied to the forming surface of a lower mold held by a lower master mold preheated to about 470° C. in a forming chamber. The lower die and the lower die were raised by raising the drive shaft immediately, and the lower die was inserted into the cylindrical die held by the upper die that had been preheated to about 470°C.

[0162] At this time, while the lower mold is guided by the guide part of the cylindrical mold, the lower mold is moved in the horizontal direction by a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com