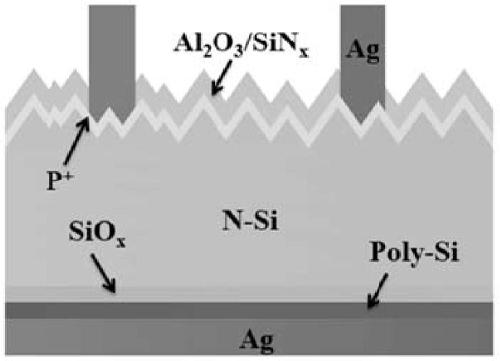

Method for improving passivation performance of tunneling oxygen/polycrystalline silicon passivation contact structure

A technology of contact structure and polysilicon, which is applied in the field of solar cells, can solve problems such as difficulty in mass production of production lines, limited passivation improvement effect, and unstable effect, and achieve obvious passivation effect, good passivation effect, and passivation The effect of the enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

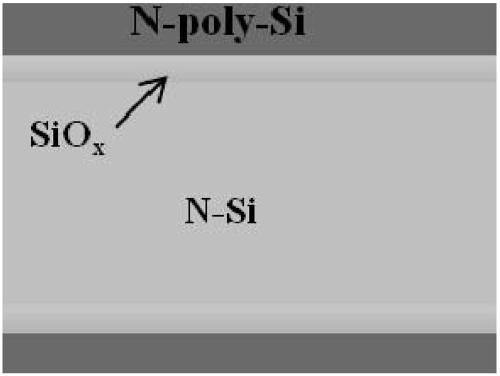

Method used

Image

Examples

Embodiment 1

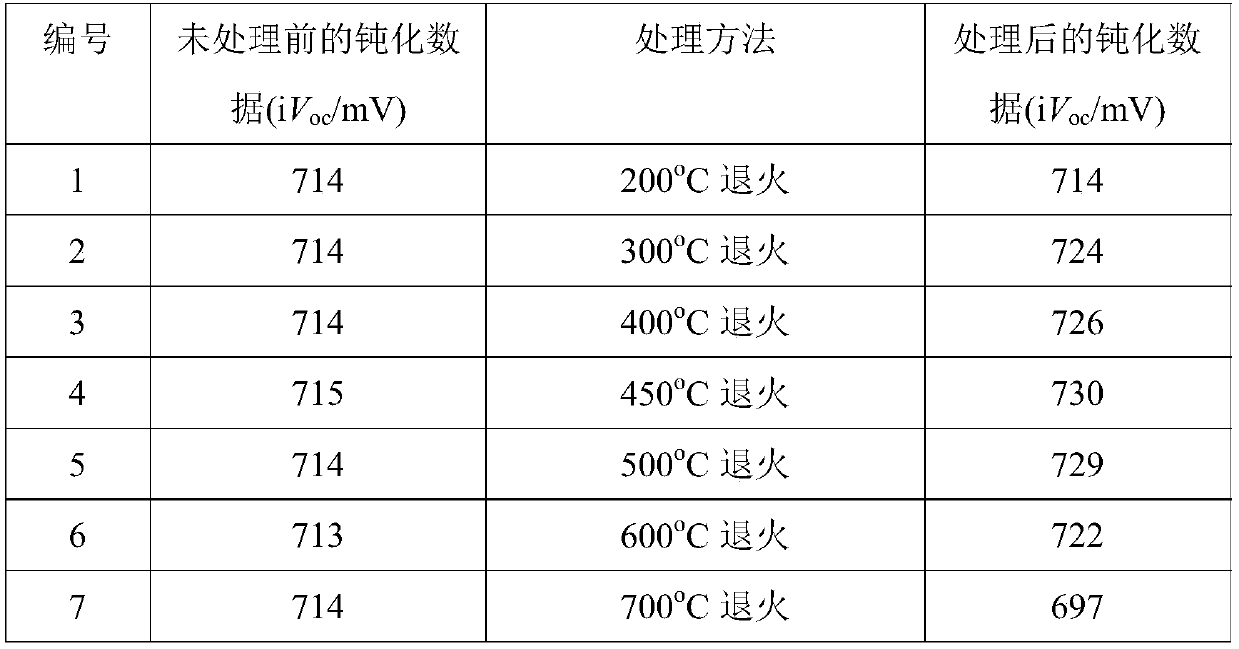

[0022] Post-annealing in atmospheric environment

[0023] In an atmospheric environment, the passivation sheet sample was heated to the following temperature at 20°C per minute, kept at the temperature for 30 minutes, and then cooled.

[0024]

[0025] It can be seen that in an atmospheric environment, the passivation sheet sample is heated at 20°C per minute to 300-600°C, kept at the temperature for 30 minutes and then cooled, the passivation sheet sample iV oc Significantly improved.

Embodiment 2

[0027] Annealing in pure oxygen atmosphere

[0028] Using pure oxygen gas atmosphere, the passivation sheet sample is heated at 5°C per minute to 450°C for 30 minutes, iV oc Significantly improved.

[0029]

Embodiment 3

[0031] Al deposition 2 O 3 And subsequent processing

[0032] Adopt atomic layer deposition method to deposit Al on both sides of the passivation sheet sample 2 O 3 The thickness of the layer is 5nm, 10nm, 15nm, and 20nm, respectively, and then an annealing treatment is carried out in a nitrogen atmosphere at a temperature of 15°C per minute to 450°C for 30 minutes. The passivation effect of the passivation sheet sample is significantly improved. iV oc Significantly improved.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com