Texture etching solution of monocrystaline silicon solar cell, preparation method, and application thereof

A technology of solar cells and texturing liquid, applied in chemical instruments and methods, circuits, crystal growth and other directions, can solve the problems of too large pyramid size, too long texturing time, and insufficient uniformity, so as to improve short-circuit current, Good corrosion surface uniformity and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 10g of tetramethylammonium hydroxide (TMAH), 40g of isopropanol (IPA) and 450g of deionized water were added to the texturing tank, and fully stirred to prepare a texturing solution.

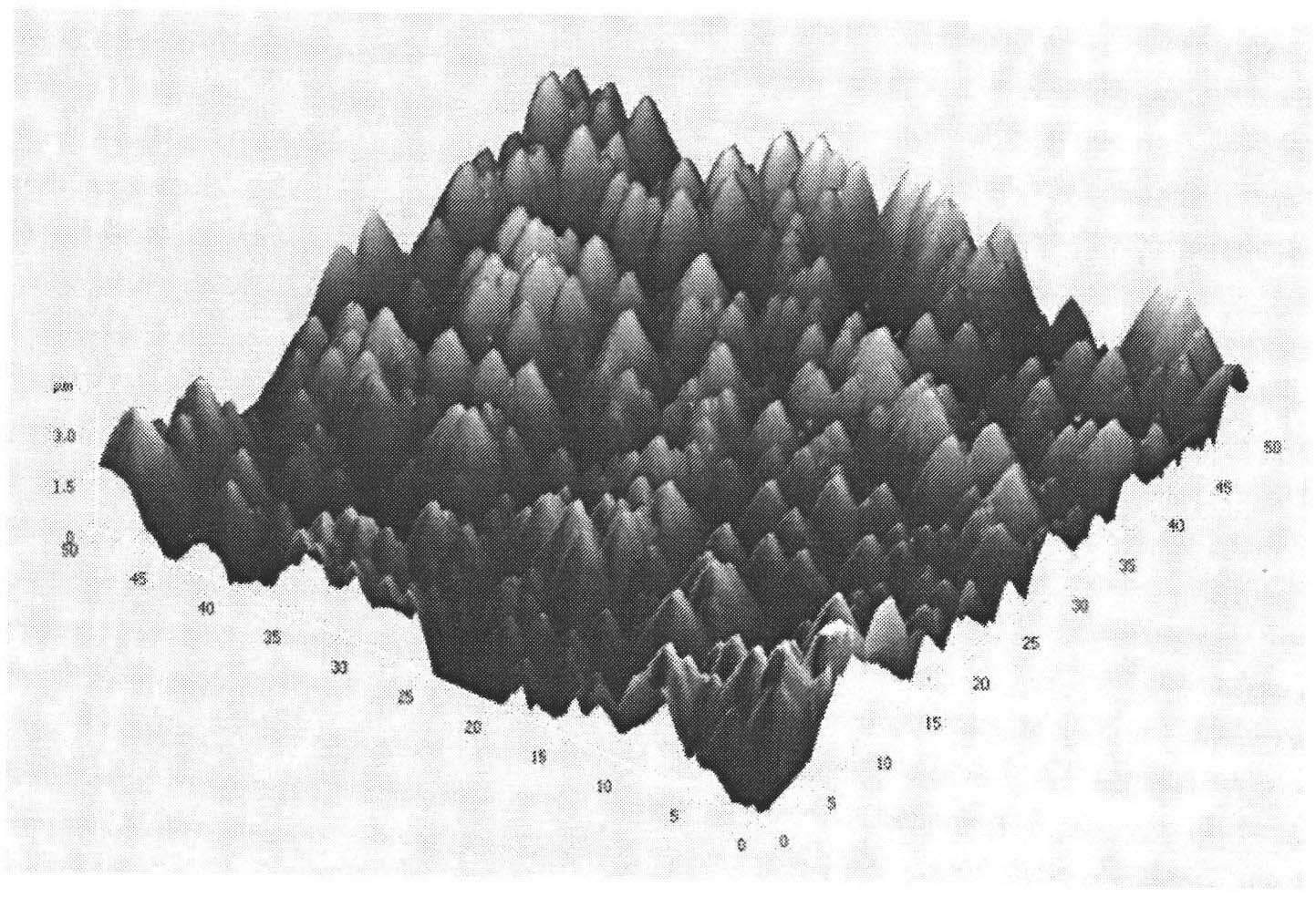

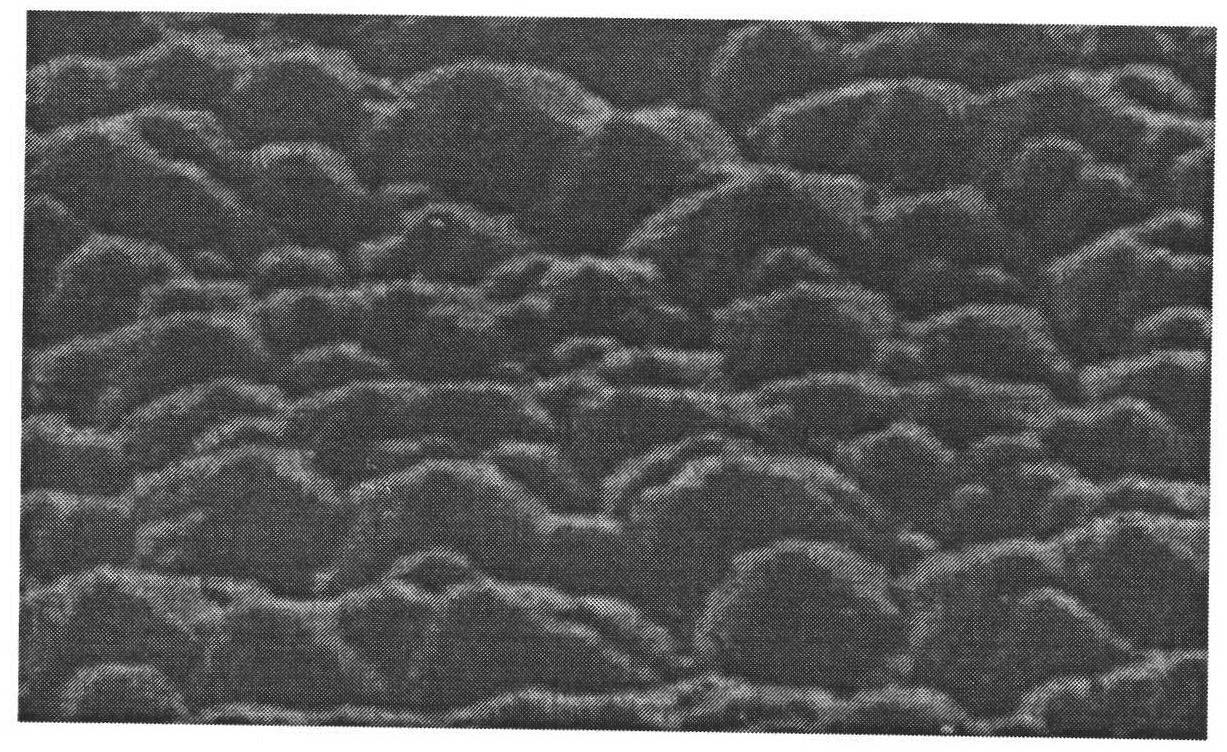

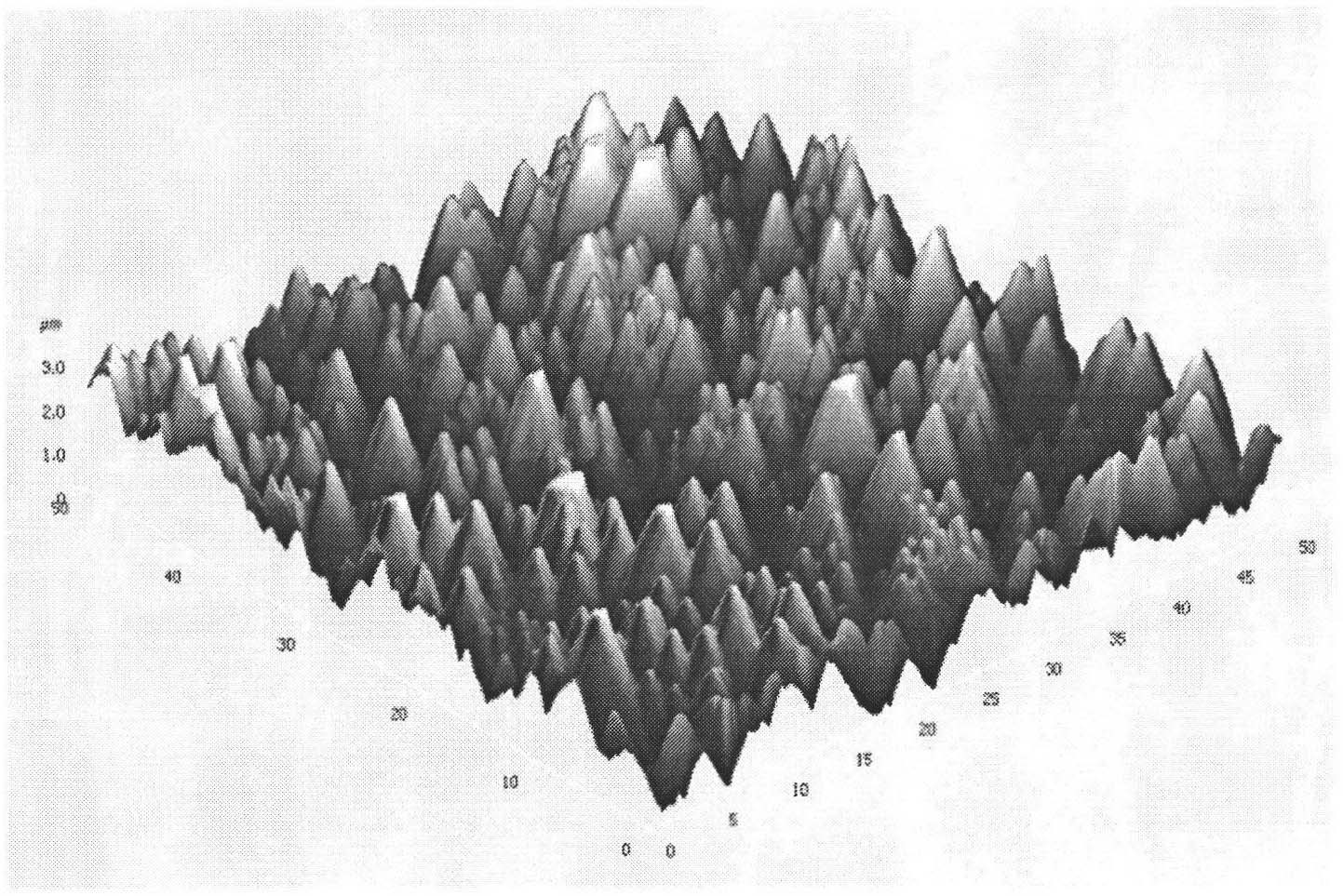

[0030] Choose 50×50mm 2 , oriented p-type CZ monocrystalline silicon wafer, about 200μm thick, resistivity 2-3Ω·cm, minority carrier lifetime 1.65μs. The silicon chip whose surface has been cleaned with deionized water is put into the texturing solution for etching, the etching temperature is 80±2°C, and the etching time is 30 minutes, and finally the etched silicon chip is cleaned with deionized water. The obtained AFM images and SEM images are as follows image 3 and Figure 4 It can be seen that a pyramid structure is formed on the surface of the silicon wafer with uniform size and high coverage.

[0031] Utilize common texturizing corrosion solution (1.3wt% NaOH solution, 10wt% C 2 h 5 OH, 88.7 wt% H 2 O) silicon wafer is processed, the control processing temperature is 83 ± 2 ...

Embodiment 2

[0036] A preparation method of a texturizing solution for monocrystalline silicon solar cells, the method comprising the following steps:

[0037] Prepare materials according to the following components and contents: tetramethylammonium hydroxide 5g, isopropanol 45g, deionized water 450g, first add deionized water to the velvet tank, then add tetramethylammonium hydroxide and isopropanol , control the temperature to 80° C., and then fully stir evenly to obtain the texturing liquid for monocrystalline silicon solar cells.

[0038] Place the silicon wafer whose surface has been cleaned with deionized water in the texturing solution, control the treatment temperature to 80° C., and carry out etching treatment for 30 minutes, and then clean the etched silicon wafer with deionized water.

Embodiment 3

[0040] A preparation method of a texturizing solution for monocrystalline silicon solar cells, the method comprising the following steps:

[0041] Prepare materials according to the following components and contents: Tetramethylammonium hydroxide 10g, isopropanol 45g, deionized water 445g, first add deionized water to the velvet tank, then add tetramethylammonium hydroxide and isopropanol , control the temperature to 80° C., and then fully stir evenly to obtain the texturing liquid for monocrystalline silicon solar cells.

[0042] Place the silicon wafer whose surface has been cleaned with deionized water in the texturing solution, control the treatment temperature to 78° C., conduct corrosion treatment for 35 minutes, and then clean the etched silicon wafer with deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com