Carbon-nitrogen-lithium multi-phase doped lithium ion battery negative electrode material, preparation method of material, lithium ion battery negative electrode plate and lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as safety issues and complex preparation methods, achieve low equipment requirements, controllable reaction conditions, and increase the first Coulombic efficiency and cycle life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a carbon-nitrogen lithium heterogeneously doped lithium-ion battery negative electrode material, comprising the following steps:

[0043] 1) Weigh 13.96 g of choline chloride and 21.20 g of lithium chloride at a molar ratio of 1:5, and stir in a constant temperature magnetic stirrer at 70°C for 2 hours to obtain a deep eutectic solvent;

[0044] 2) 17.28 g of lignocellulose and 34.56 g of deep eutectic solvent were weighed according to a mass ratio of 1:2, and stirred at 100° C. for 2 h in a constant temperature magnetic stirrer to obtain a mixture;

[0045] 3) The mixture obtained in 2) was first heated to 300°C at a heating rate of 5°C / min under an air atmosphere, and kept for 2 hours; get carbides.

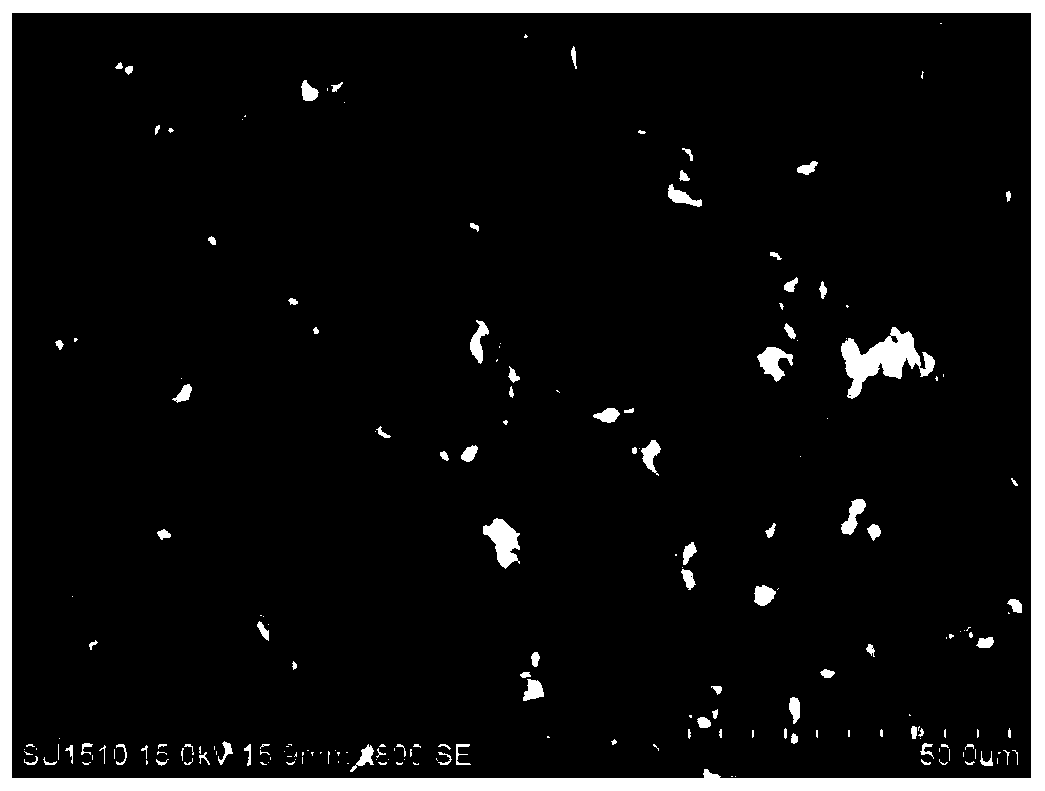

[0046] 4) The obtained carbide was washed with absolute ethanol for 3 times and then filtered; then ball milled in a ball mill at 600r / min for 4h, and screened with a 200-mesh screen to obtain a carbon-nitrogen-lithium heterogeneous doped lithium-...

Embodiment 2

[0048] A method for preparing a carbon-nitrogen lithium heterogeneously doped lithium-ion battery negative electrode material, comprising the following steps:

[0049] 1) Weigh 27.92 g of choline chloride and 21.20 g of lithium chloride in a molar ratio of 2:5, and stir in a constant temperature magnetic stirrer at 70°C for 2 hours to obtain a deep eutectic solvent;

[0050] 2) 17.28 g of lignocellulose and 34.56 g of deep eutectic solvent were weighed according to a mass ratio of 1:2, and stirred at 100° C. for 2 h in a constant temperature magnetic stirrer to obtain a mixture;

[0051] 3) The mixture obtained in 2) was first heated to 300°C at a heating rate of 5°C / min under an air atmosphere, and kept for 2 hours; get carbides.

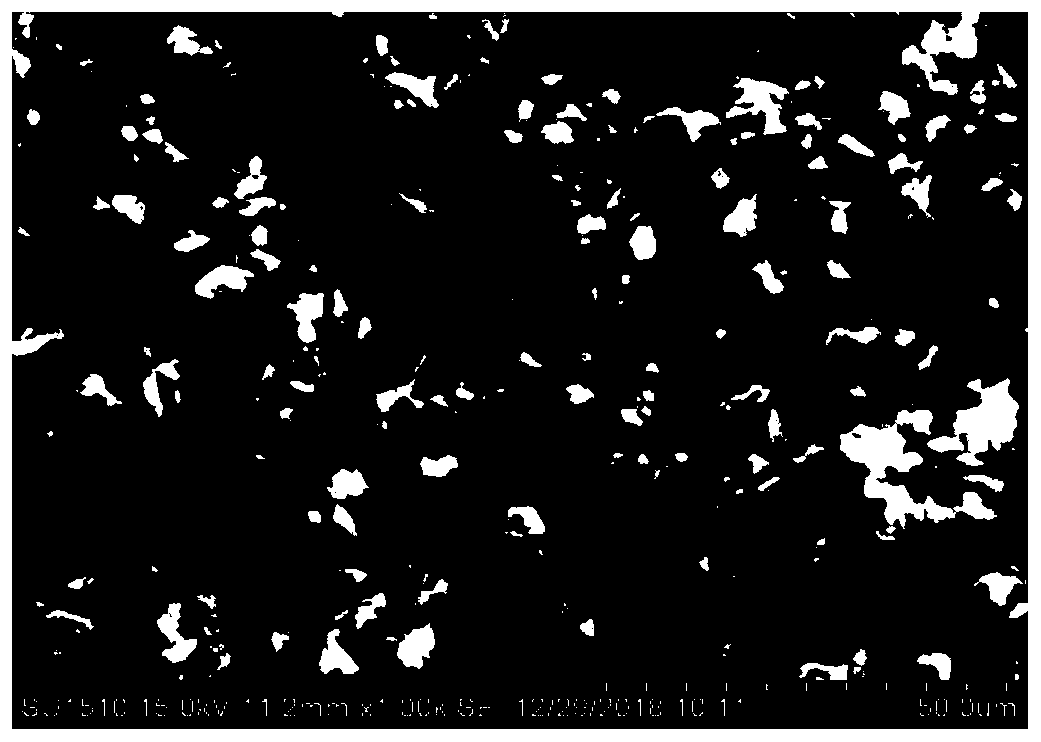

[0052]The obtained carbide was washed with absolute ethanol for 3 times and then filtered; then ball milled in a ball mill at 600r / min for 4h, and screened with a 200-mesh screen to obtain a carbon-nitrogen-lithium heterogeneous doped lithium-ion ...

Embodiment 3

[0054] A method for preparing a carbon-nitrogen lithium heterogeneously doped lithium-ion battery negative electrode material, comprising the following steps:

[0055] 1) Weigh 13.96 g of choline chloride and 21.20 g of lithium chloride at a molar ratio of 1:5, and stir in a constant temperature magnetic stirrer at 90°C for 2 hours to obtain a deep eutectic solvent;

[0056] 2) 11.72 g of lignocellulose and 35.16 g of deep eutectic solvent were weighed according to a mass ratio of 1:3, and stirred in a constant temperature magnetic stirrer at 80°C for 2 hours to obtain a mixture;

[0057] 3) The mixture obtained in 2) was first heated to 300°C at a heating rate of 5°C / min in an air atmosphere, and kept for 2 hours; then under Ar flow, the temperature was raised to 800°C at a heating rate of 5°C / min, and kept for 4 hours. get carbides.

[0058] 4) The obtained carbide was washed with absolute ethanol for 3 times and then filtered; then ball milled at 600r / min for 4h in a ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com