Waste circuit board smelting soot reinforced alkaline leaching debromination recovery method

A technology of waste circuit boards and recycling methods, which is applied in the direction of improving process efficiency, etc., to achieve the effects of shortening reaction time, simple equipment, and green and efficient separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

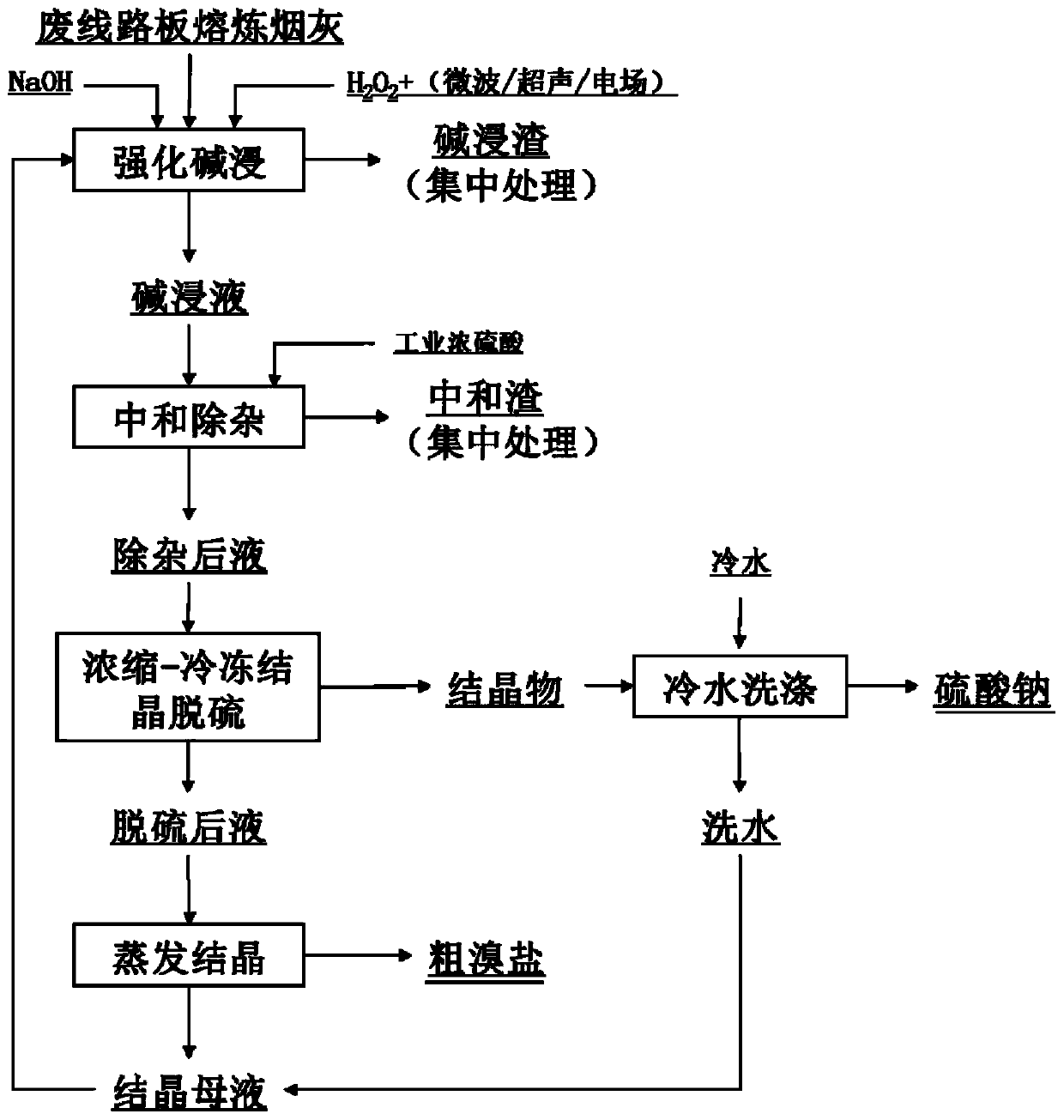

[0019] Follow the steps below to recycle:

[0020] (1) Enhanced alkali leaching: Put the waste circuit board smelting soot into the sodium hydroxide solution to obtain a mixed solution, wherein the concentration of the sodium hydroxide solution is 10%, and the solid-to-liquid ratio of the soot to the sodium hydroxide solution is 1:2g / mL, The obtained mixed solution is placed in a microwave reactor, 5 mL of hydrogen peroxide is added to each liter of the mixed solution, heated by 1000 MHz microwave, the microwave power is 200 W per liter of the mixed solution, and the microwave leaching time is 35 minutes. Alkali leaching residue, centralized treatment of alkali leaching residue;

[0021] (2) Neutralization and removal of impurities: the alkaline leaching solution obtained in step (1) is neutralized and removed to obtain neutralized slag and liquid after removal of impurities, and industrial concentrated sulfuric acid is added to adjust the pH to 7.5, and the reaction temperatu...

Embodiment 2

[0027] Follow the steps below to recycle:

[0028] (1) Enhanced alkali leaching: put the waste circuit board smelting soot into the sodium hydroxide solution to obtain a mixed solution, wherein the concentration of the sodium hydroxide solution is 50%, and the solid-to-liquid ratio of the soot to the sodium hydroxide solution is 1:6g / mL, The obtained mixed solution is placed in an ultrasonic reactor, 10 mL of hydrogen peroxide is added to each liter of the mixed solution, and 20 kHz ultrasonic treatment is adopted, the ultrasonic power is 1250 W per liter of the mixed solution, and the ultrasonic leaching time is 45 minutes. Alkali leaching residue, centralized treatment of alkali leaching residue;

[0029] (2) Neutralize and remove impurities: neutralize and remove impurities from the alkaline immersion solution obtained in step (1), obtain neutralized slag and liquid after removing impurities, add industrial concentrated sulfuric acid to adjust the pH to 8.5, and the reactio...

Embodiment 3

[0035] Follow the steps below to recycle:

[0036] (1) Enhanced alkali leaching: put the waste circuit board smelting soot into the sodium hydroxide solution to obtain a mixed solution, wherein the concentration of the sodium hydroxide solution is 20%, and the solid-to-liquid ratio of the soot to the sodium hydroxide solution is 1:3g / mL, The obtained mixed solution was placed in a constant temperature water bath, and 6 mL of hydrogen peroxide was added to each liter of the mixed solution, and the quaternary alloy electrode (Pb-Ag-Ca-Sr) was inserted into the mixed solution as the cathode and anode plates, and the distance between the cathode and anode plates was 4cm, connected to the power supply and mechanically stirred, the current density is 300A / m 2 Stir, the reaction temperature is 90°C, and the reaction time is 100 minutes. After the reaction is completed, filter to obtain the alkali leaching solution and alkali leaching residue, and concentrate the alkali leaching resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com