Patents

Literature

96results about How to "No exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly motor-driven coach car for driving schools

InactiveCN102054379ASave energyReduce use costSpeed controllerCosmonautic condition simulationsMotor speedMotor drive

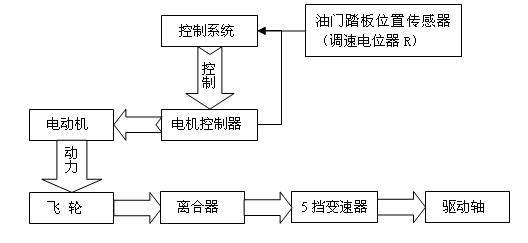

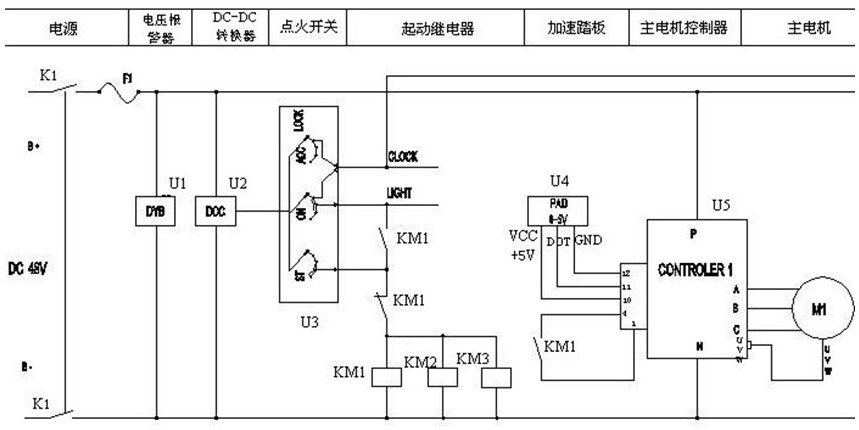

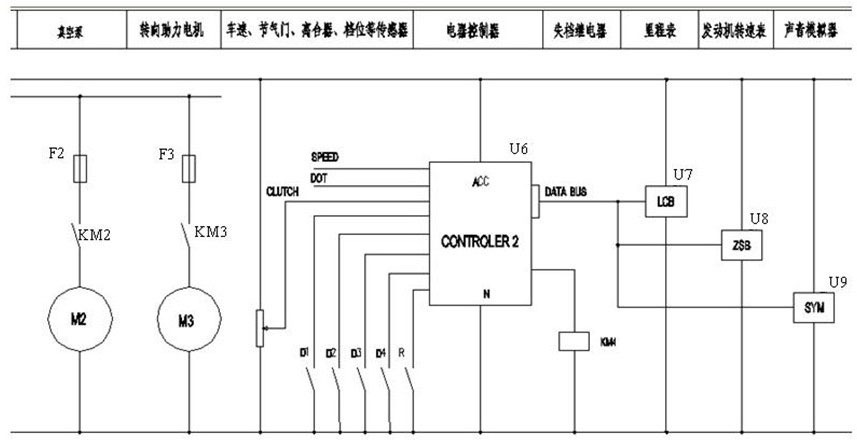

The invention relates to an environment-friendly motor-driven coach car for driving schools. The dynamic system assembly of the coach car comprises a motor, a motor control circuit, a transmission connection mechanism, a fixed support, an enclosure, a transmission shaft and the like. An engine is removed, and a flywheel, a clutch, a transmission gear and the like are kept; after configuration, power is supplied for an electrocar by a storage cell, and the electrocar is driven by the motor to drive; in the driving process, a driver steps on the clutch to shift gears; the motor and a motor speed regulation control circuit are connected with the enclosure in an insulated mode; the output shaft of the motor is connected with the flywheel and the clutch by a transmission mechanism; an originalvacuum servobrake pump is changed into a customized direct-current vacuum servobrake pump; and the original hydraulic assistance steering pump is changed into a customized direct-current hydraulic assistance steering pump. The coach car satisfies the training requirements of drivers, is simple and effective to control driving operation, is reliable in working and safe in travelling, and has durable mechanical devices and electric devices and small possibility of maintaining, and the product can be subjected to on-batch trail production and demonstration run.

Owner:福建交通职业技术学院 +1

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

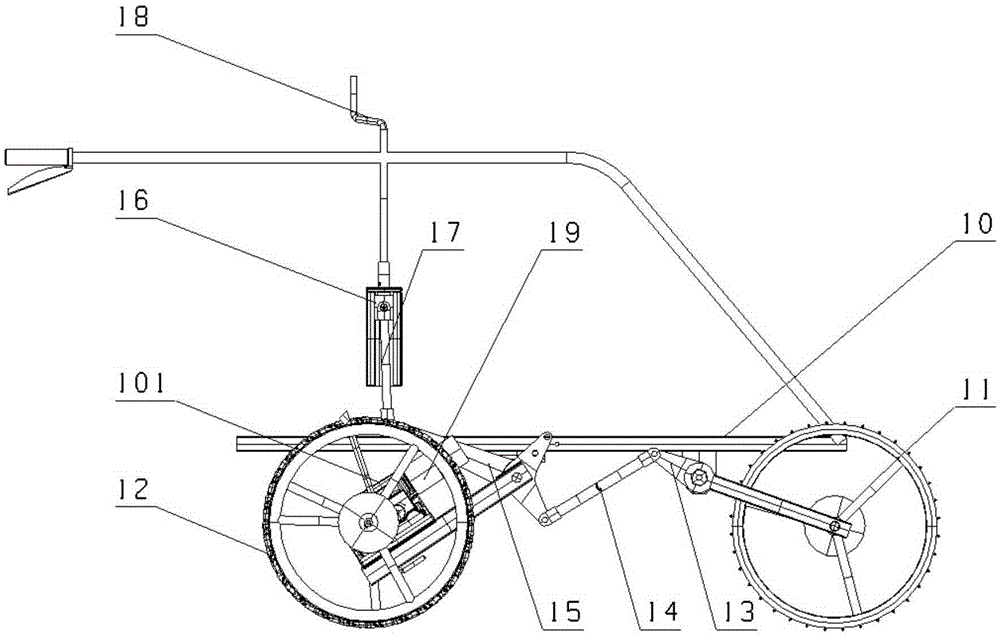

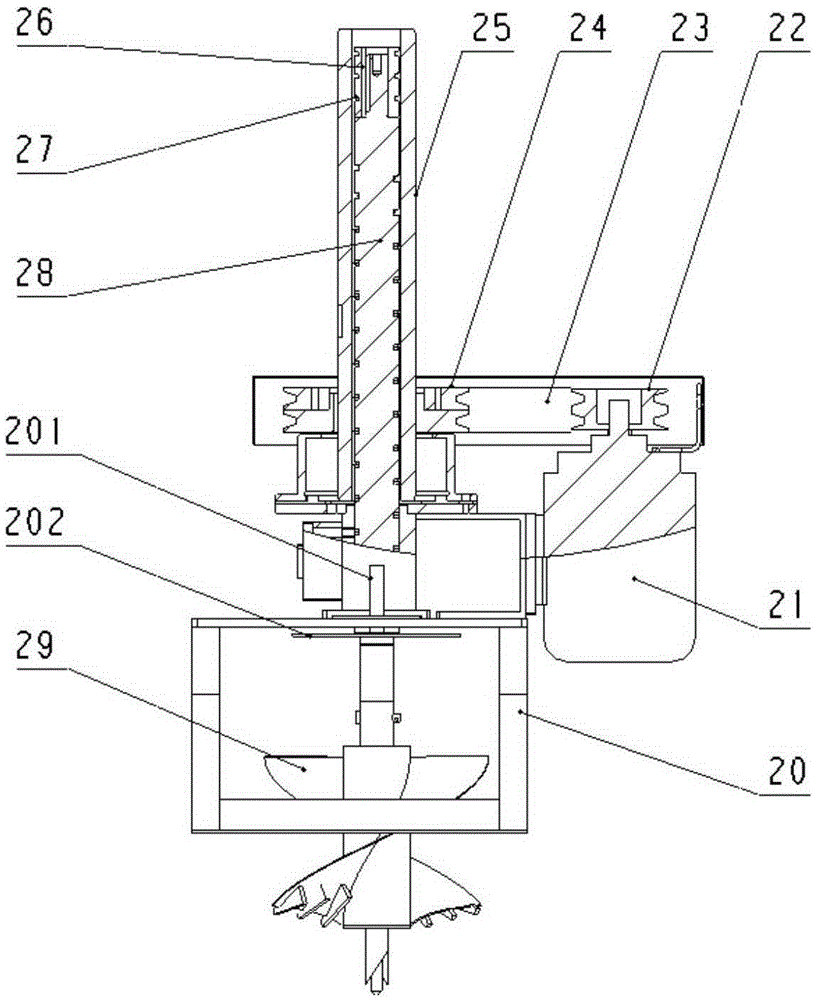

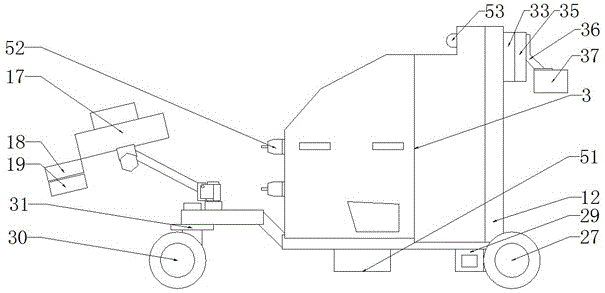

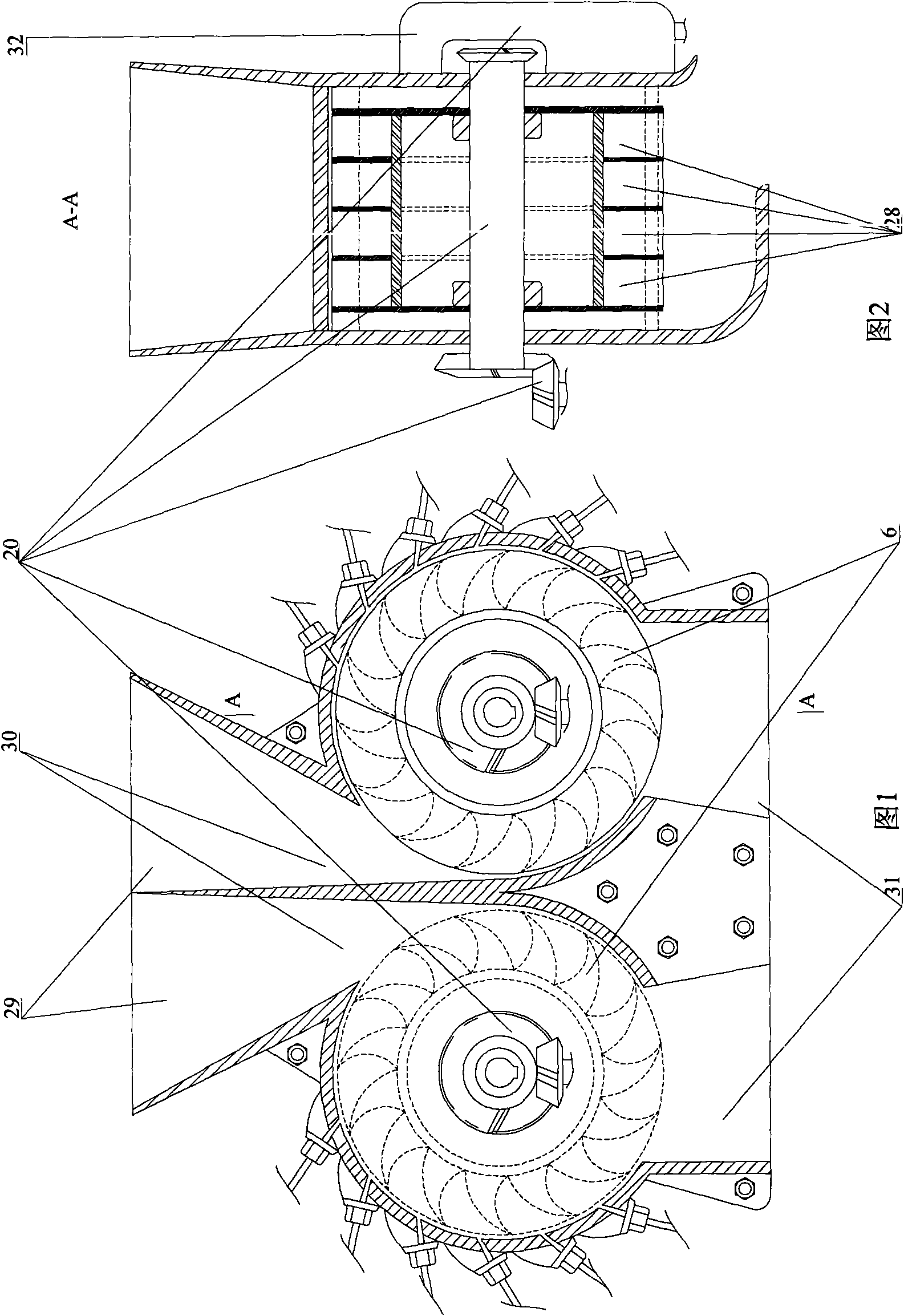

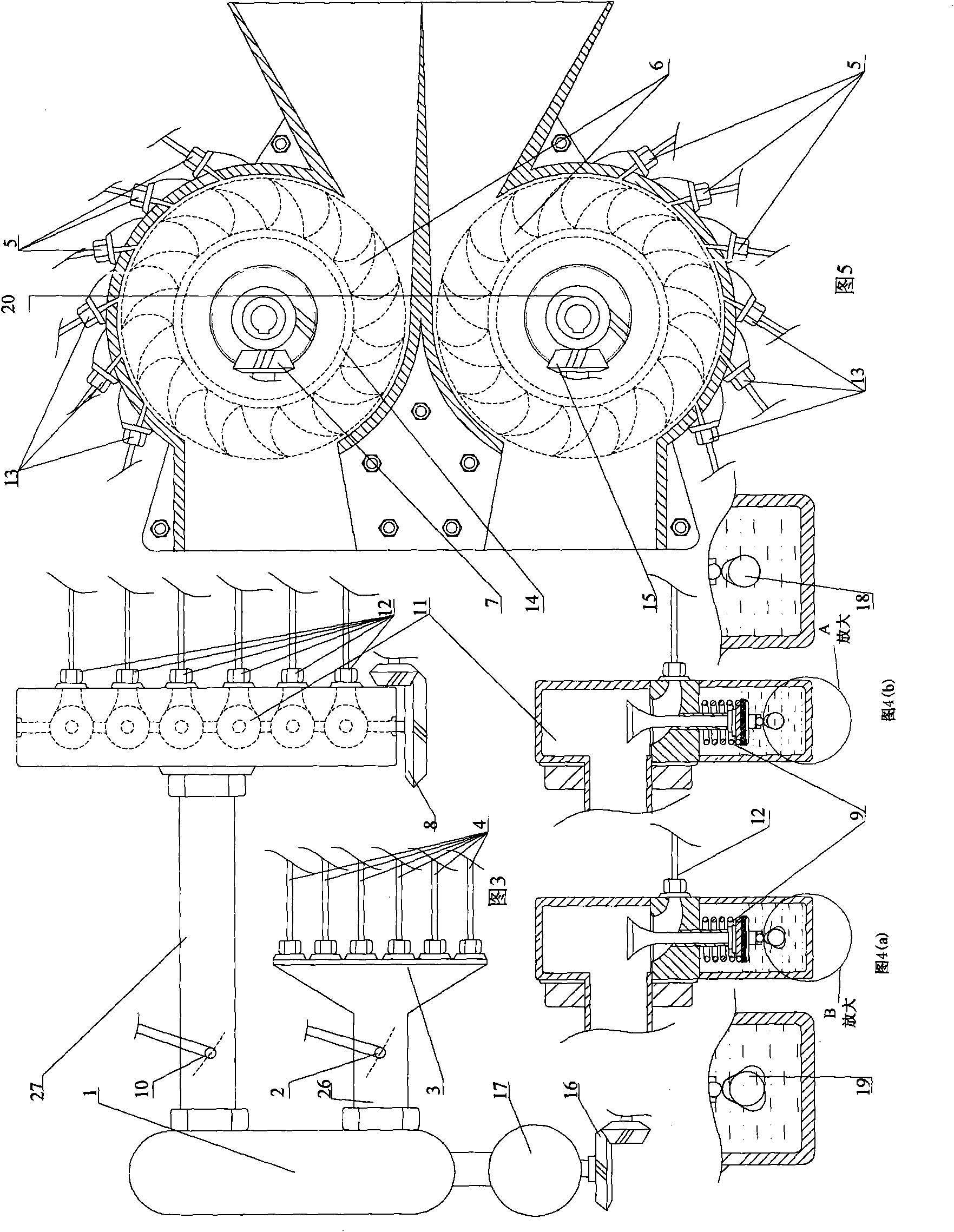

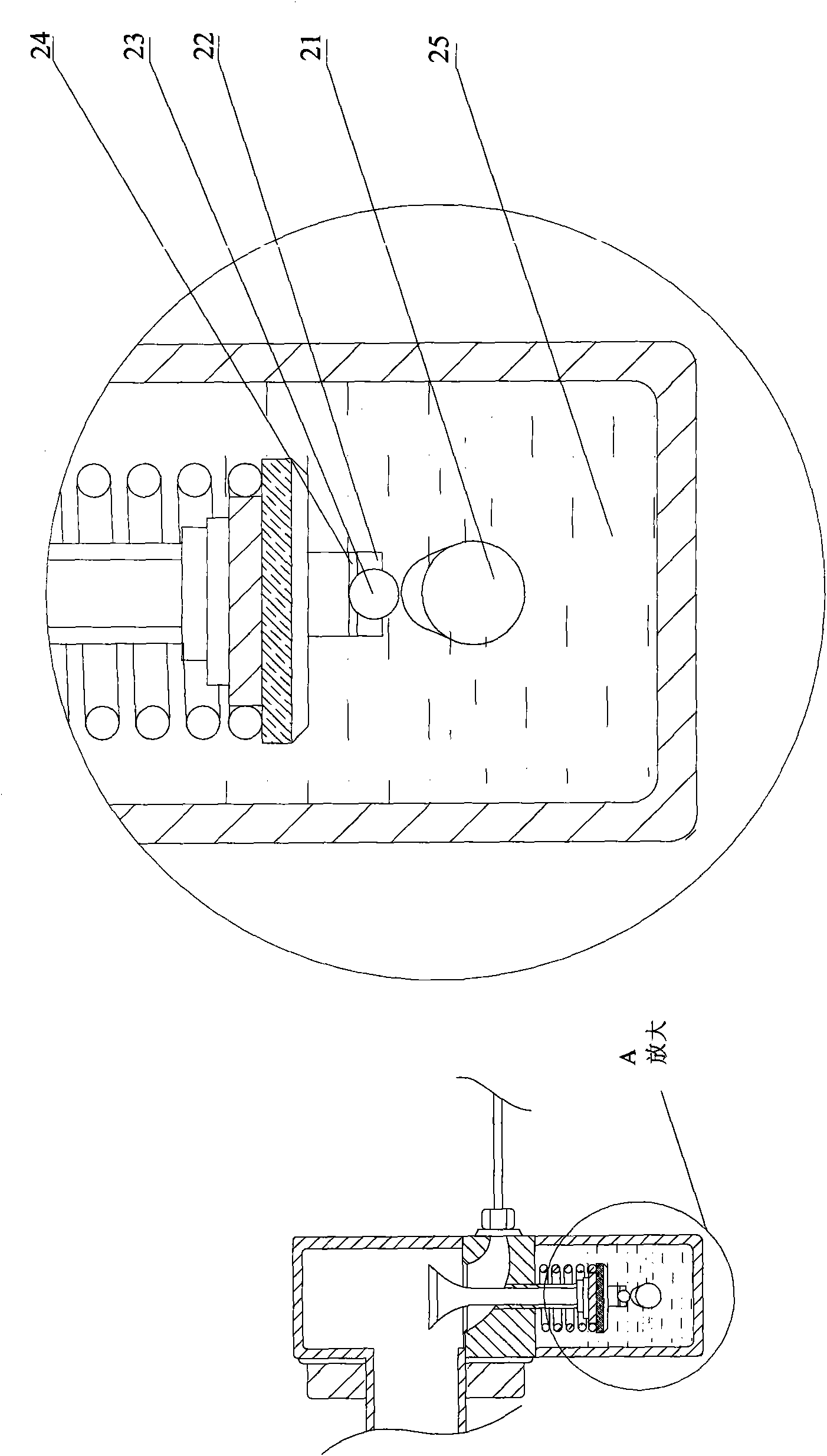

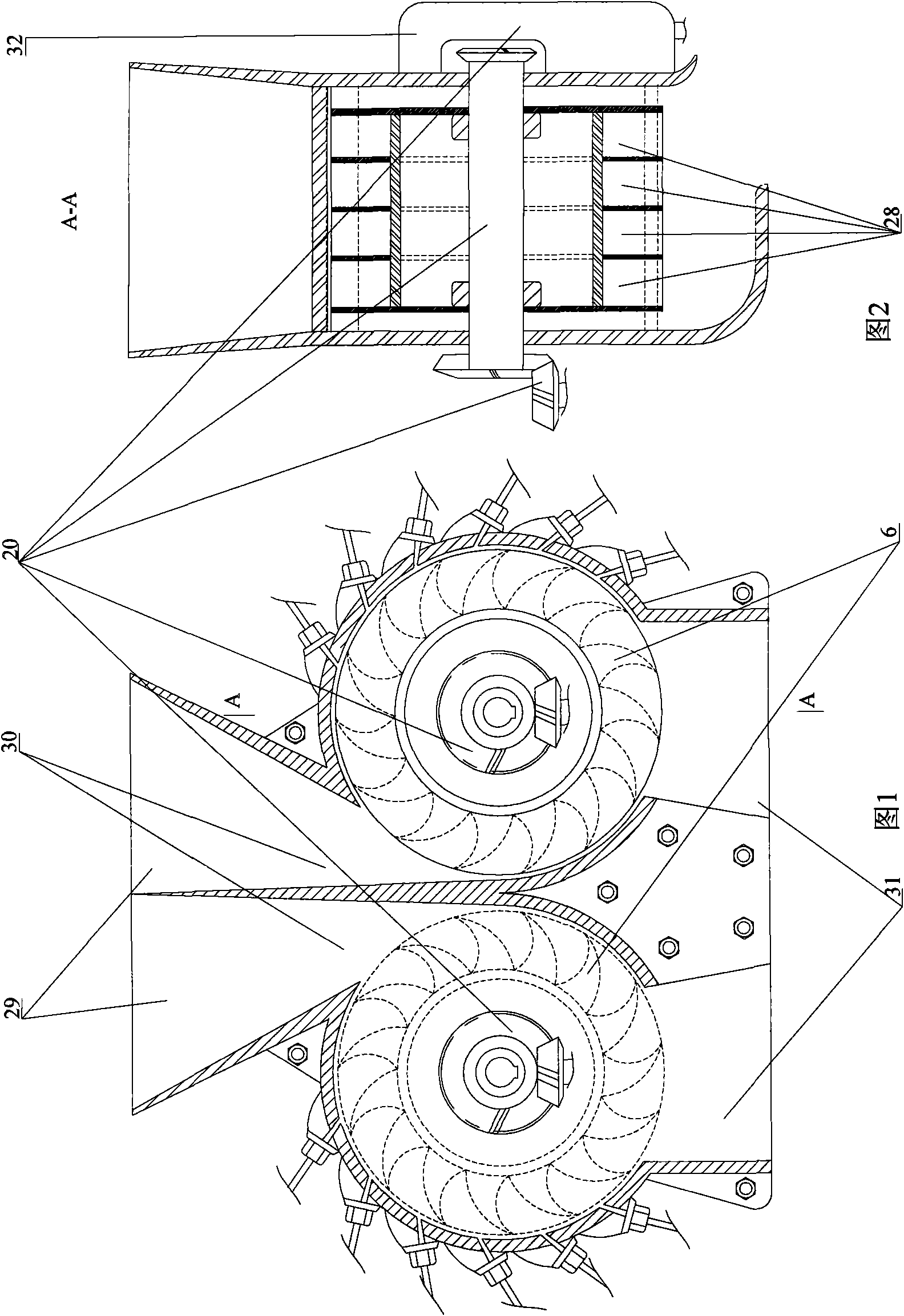

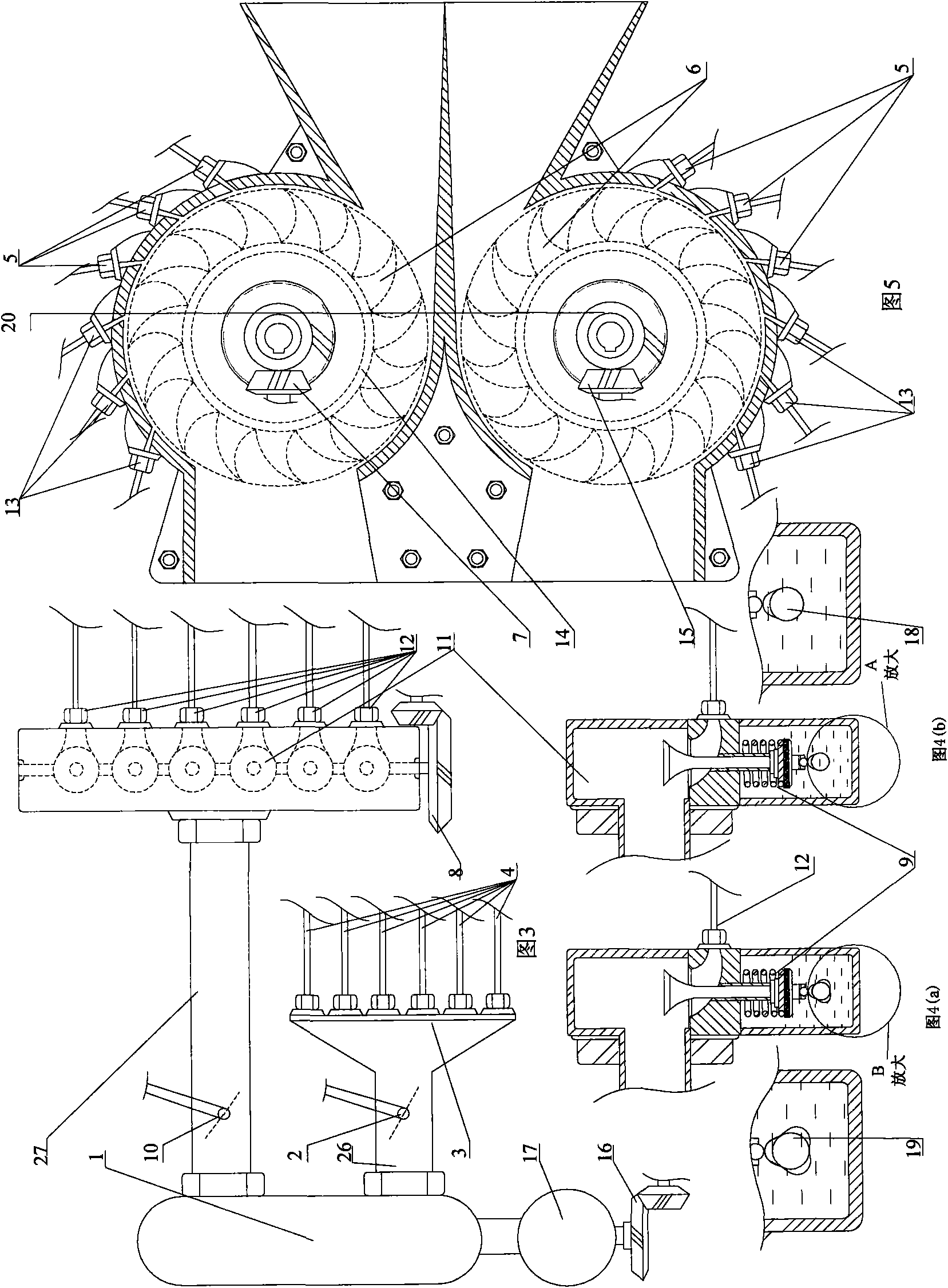

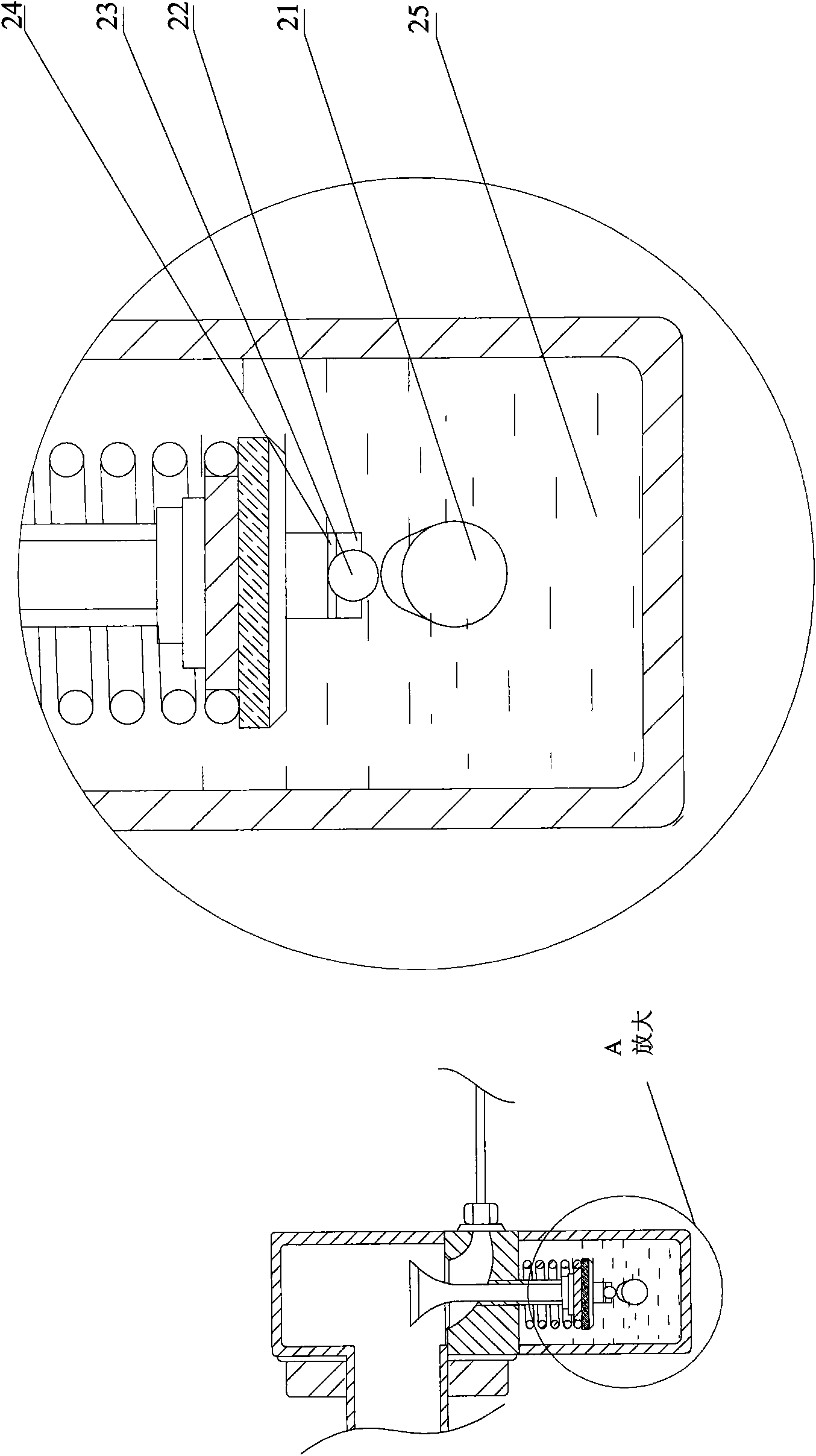

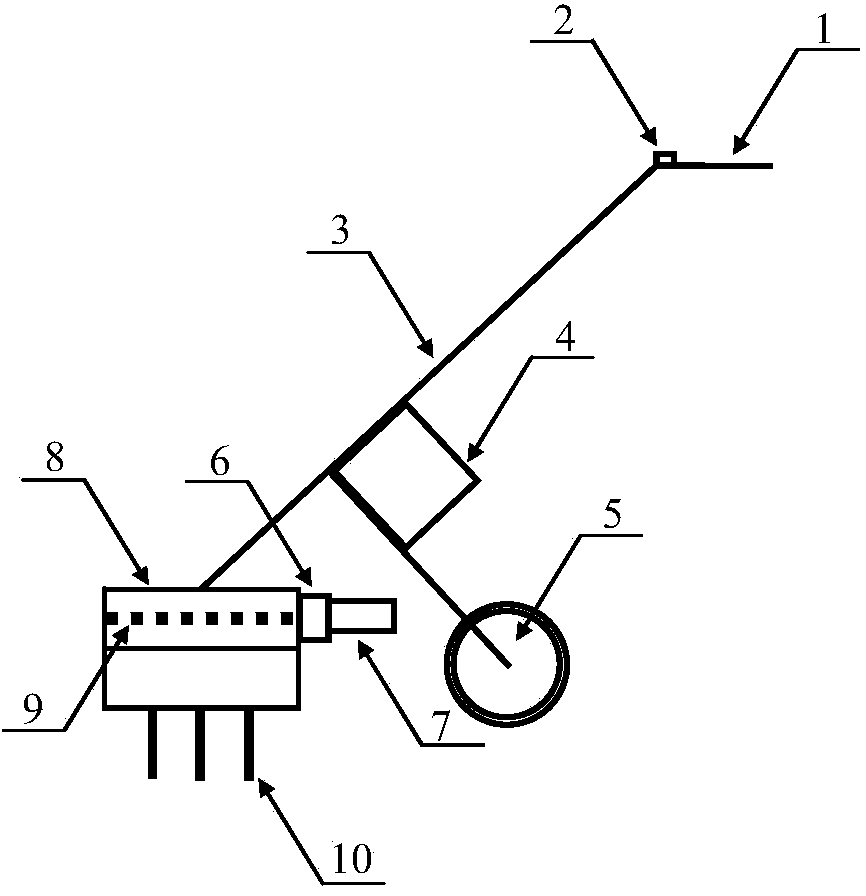

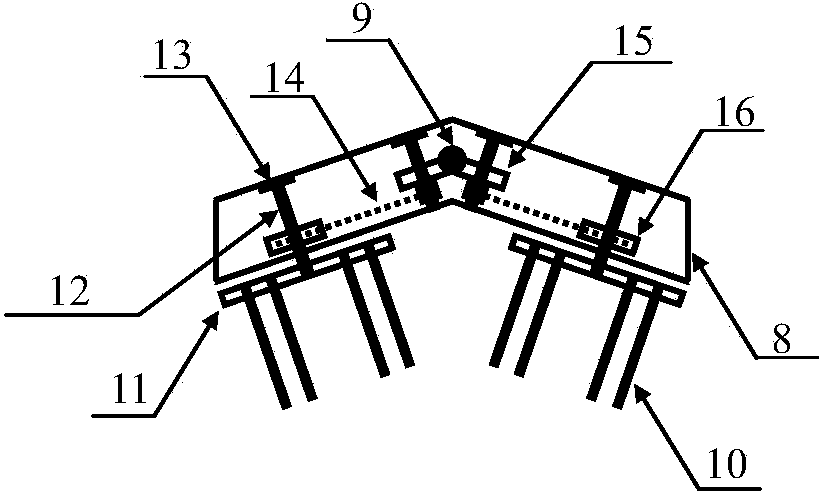

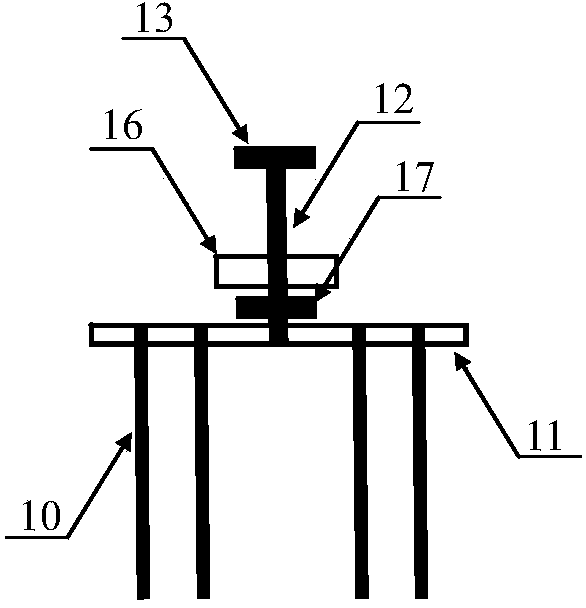

Electric rotating digging self-propelled tobacco seedling transplanter

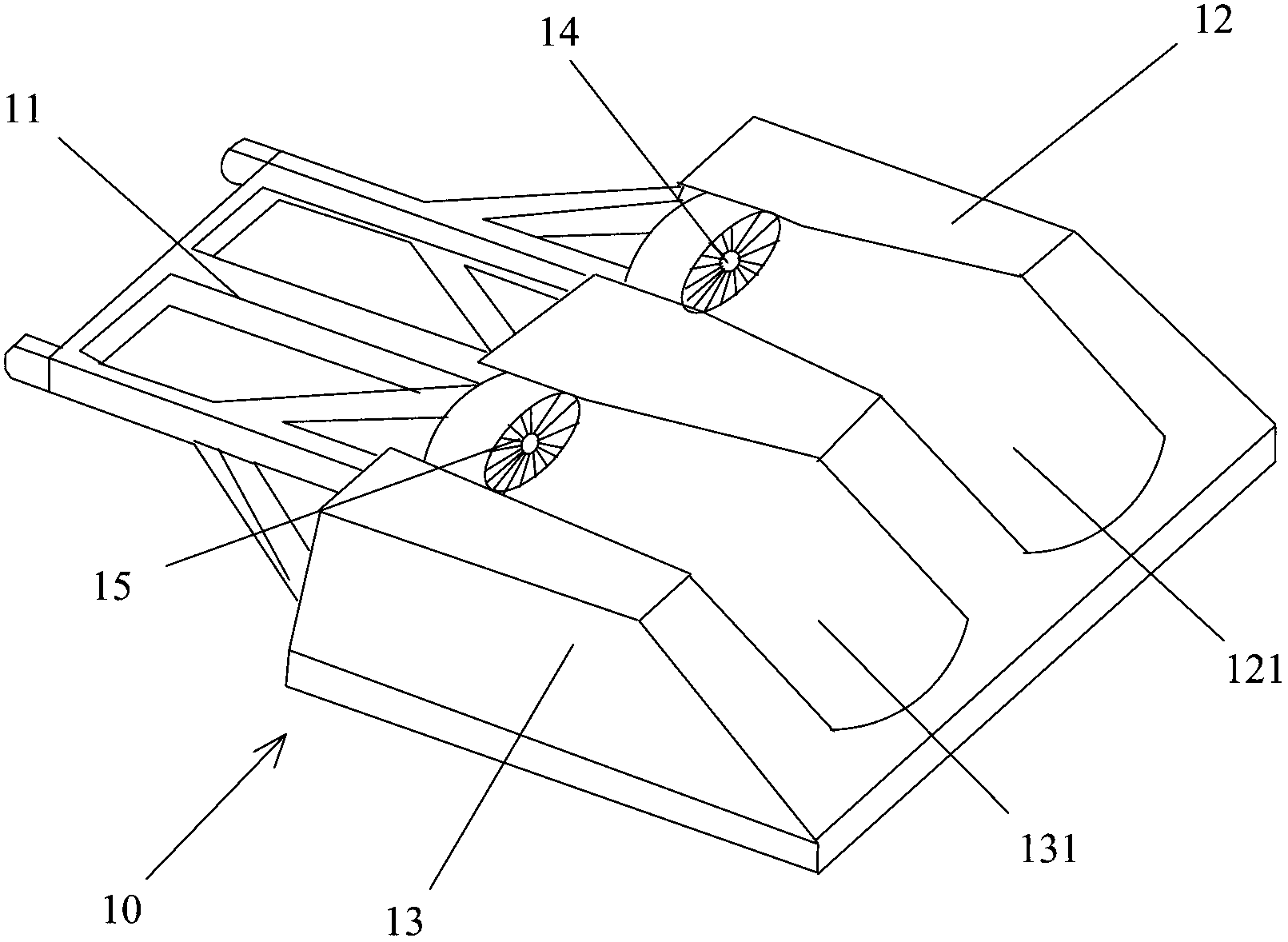

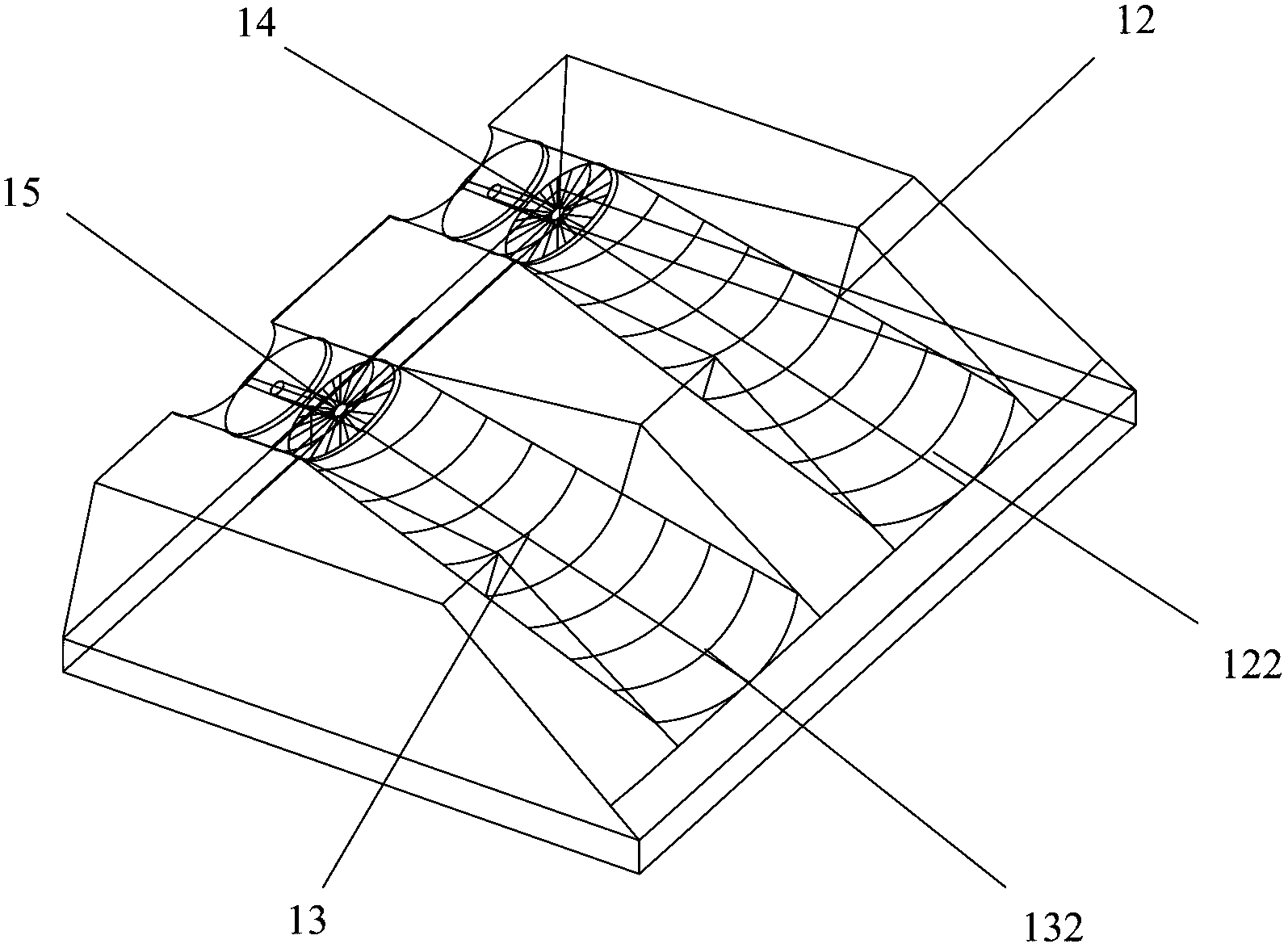

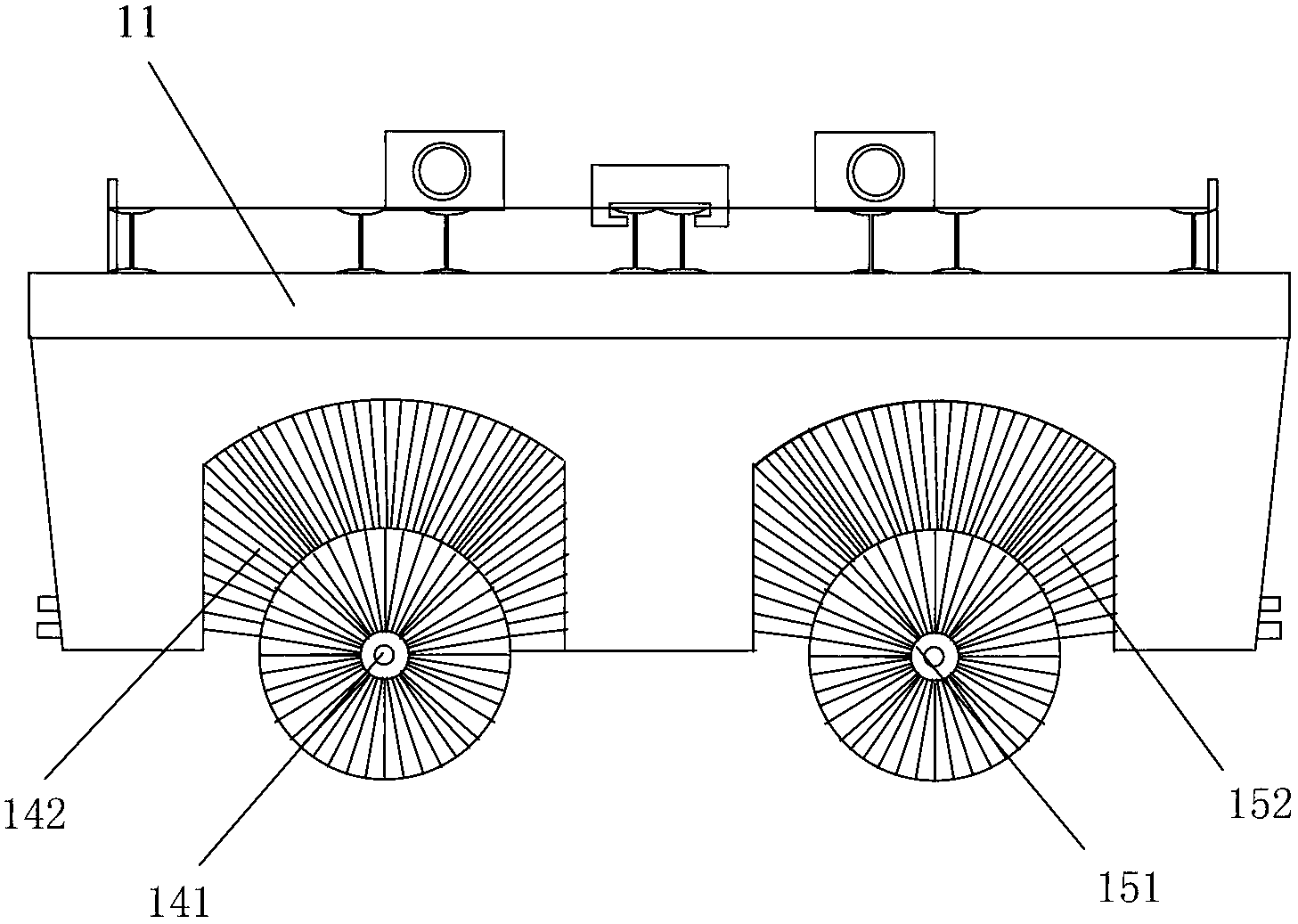

ActiveCN105340437AEasy to moveEasy to transportTransplantingFurrow making/coveringControl systemEngineering

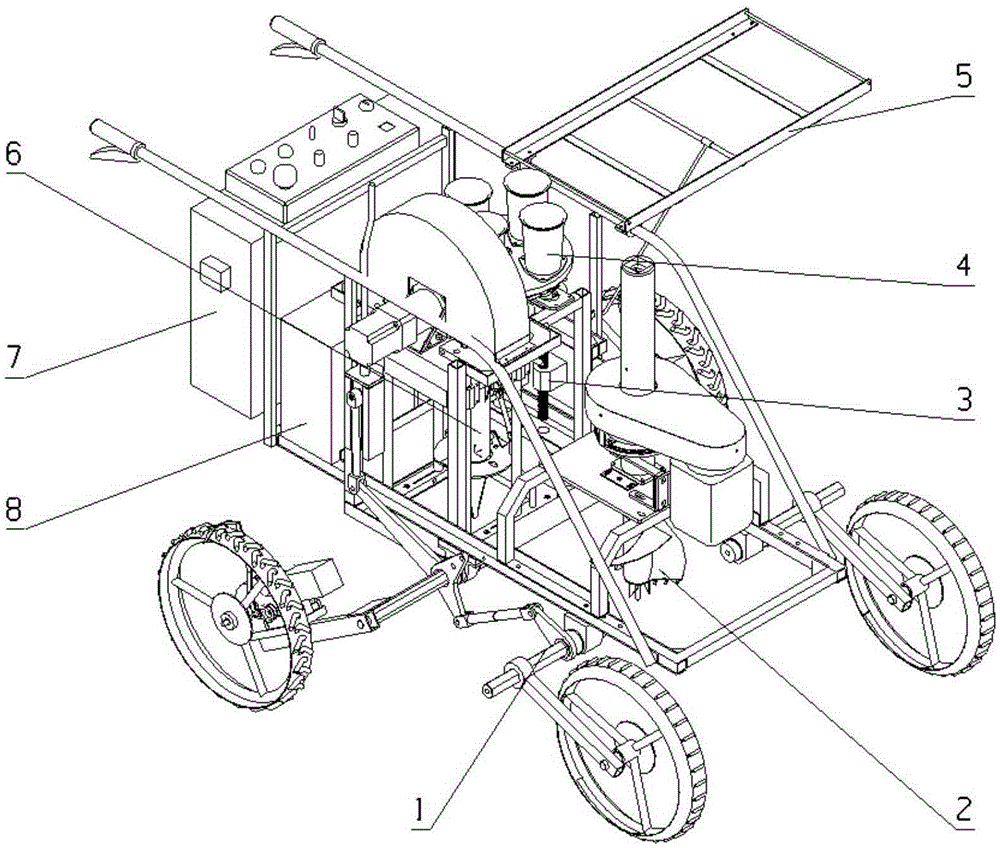

The invention relates to an electric rotating digging self-propelled tobacco seedling transplanter. The electric rotating digging self-propelled tobacco seedling transplanter is composed of an adjustable machine frame which can be adjusted along with ridges, a rotating digging mechanism, a transplanting depth adjusting machine frame, a seedling disk mechanism, a nursery seedling plate support, a crank connecting rod transplanting mechanism, a control system, a lithium battery pack, and an operation system; the lithium battery pack, the control system, and the operation system are arranged on the back part of the adjustable machine frame; the seedling disk mechanism and the crank connecting rod transplanting mechanism are immobilized on the transplanting depth adjusting machine frame, and the transplanting depth adjusting machine frame and the nursery seedling plate support are arranged on a machine body of the adjustable machine frame; the rotating digging mechanism is arranged on the front part of the machine body of the adjustable machine frame; and the adjustable machine frame is capable of realizing increasing or decreasing of the height of the electric rotating digging self-propelled tobacco seedling transplanter based on ridge height via manual operation. According to the rotating digging mechanism, a continuous rotating digging manner is adopted; the transplanting depth adjusting machine frame is capable of adjusting tobacco seedling root planting depth independently based on requirements; the control system is used for controlling start and stop, moving, and transplanting of the electric rotating digging self-propelled tobacco seedling transplanter; the electric rotating digging self-propelled tobacco seedling transplanter can be used for replacing artificial planting in tobacco fields processed via ridging.

Owner:云南烟草机械有限责任公司 +1

Molding sand adhesive for casting

InactiveCN1721103AReduce residual gas concentrationReduce dosageFoundry mouldsFoundry coresSoluble glassMetallurgy

Sand sticking collapse agent for casting comprises raw material of weight per cent: soluble glass 94.5-98úÑ, dextrose powder 1.5-2.5úÑ, light calcium carbonate powder 0.2-2úÑ, suspending agent 0.2-0.5úÑ and antiseptic 0.1-0.5úÑ. It succeeds to integrate aforementioned raw material, has good high temperature collapsibility and anti-sticking ability, can fit to multiple hardening ways, cut baking time for CO2 and can increase recovery rate for used sand.

Owner:王继启

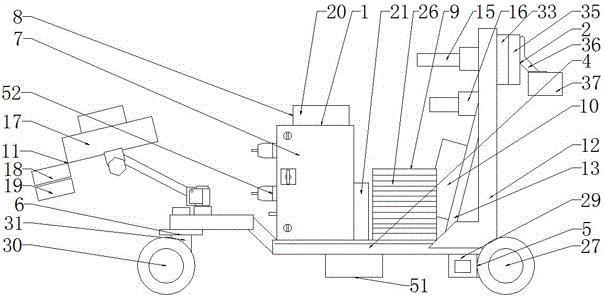

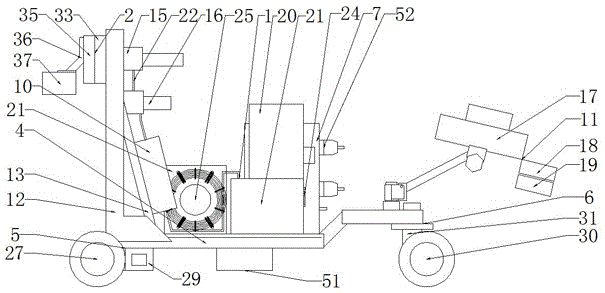

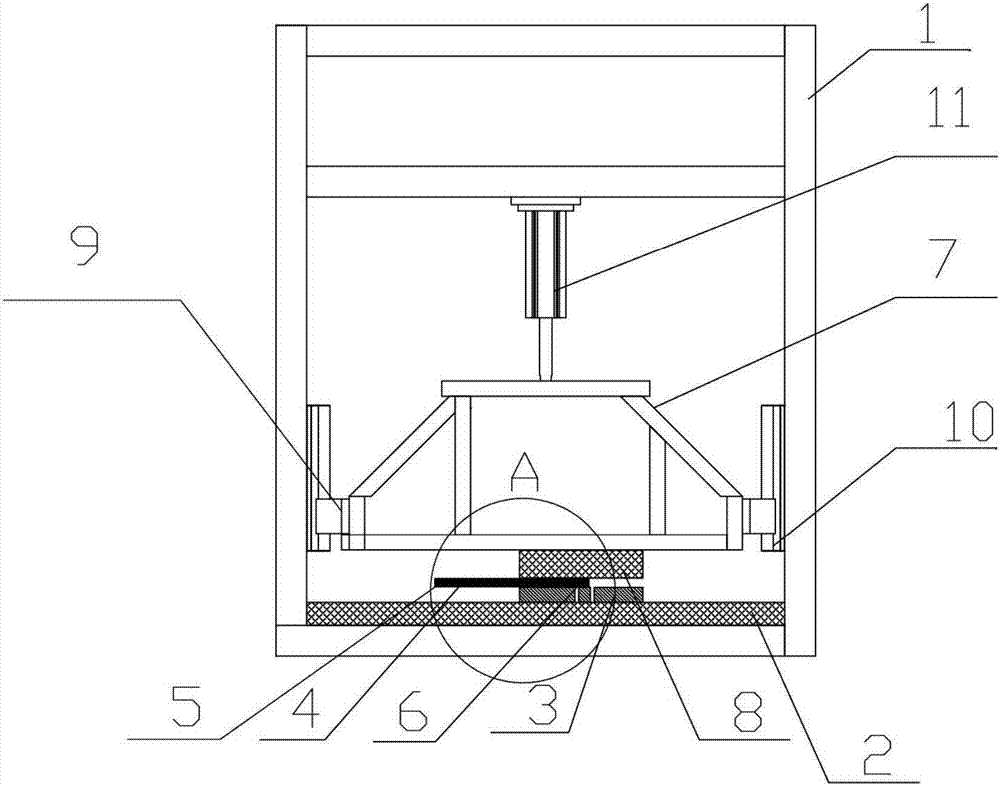

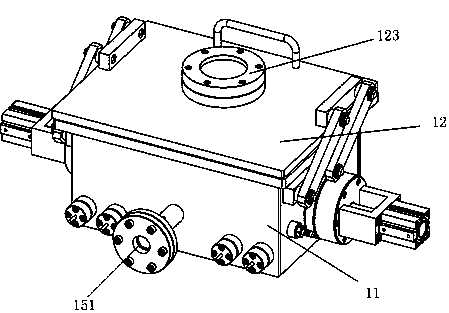

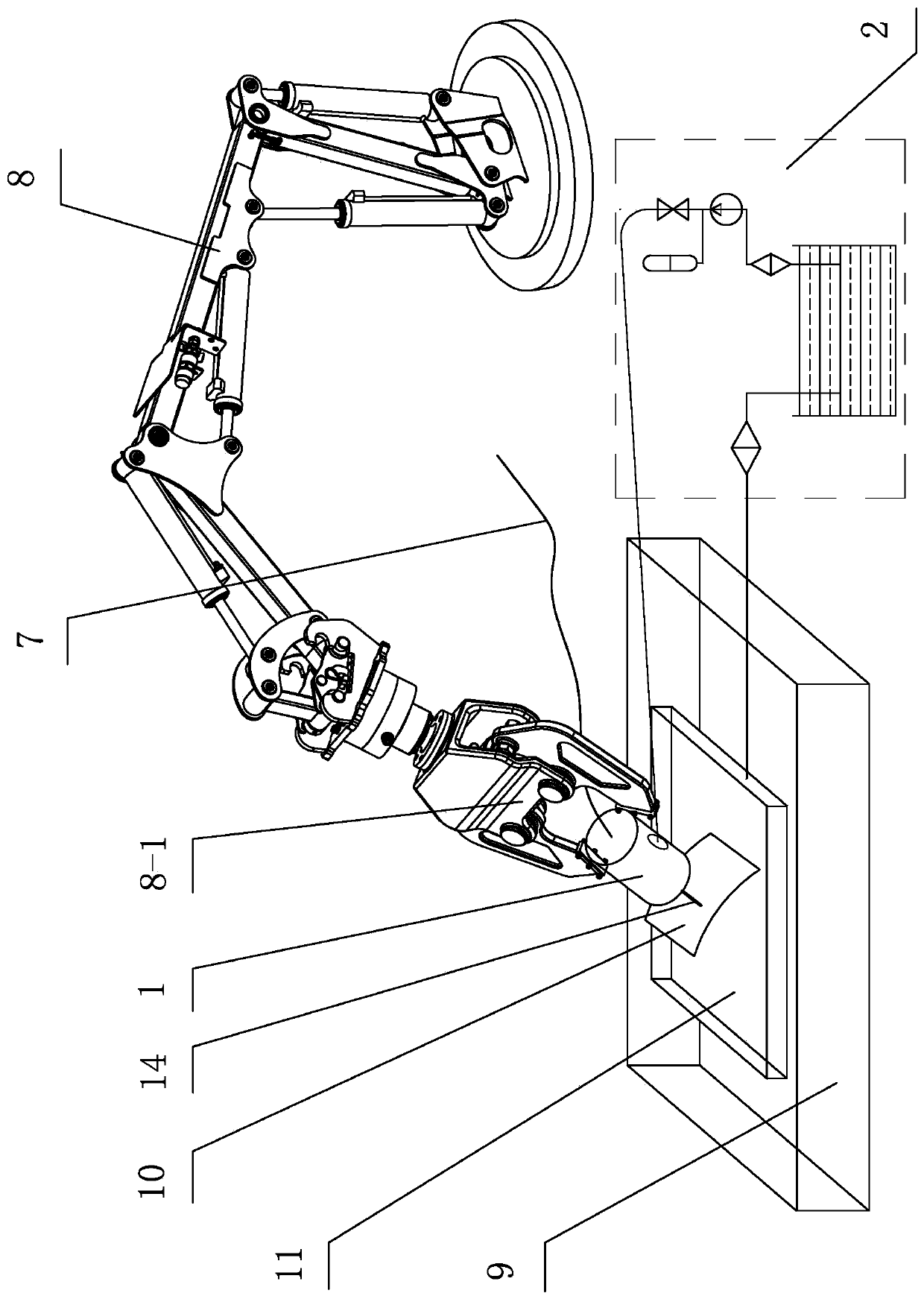

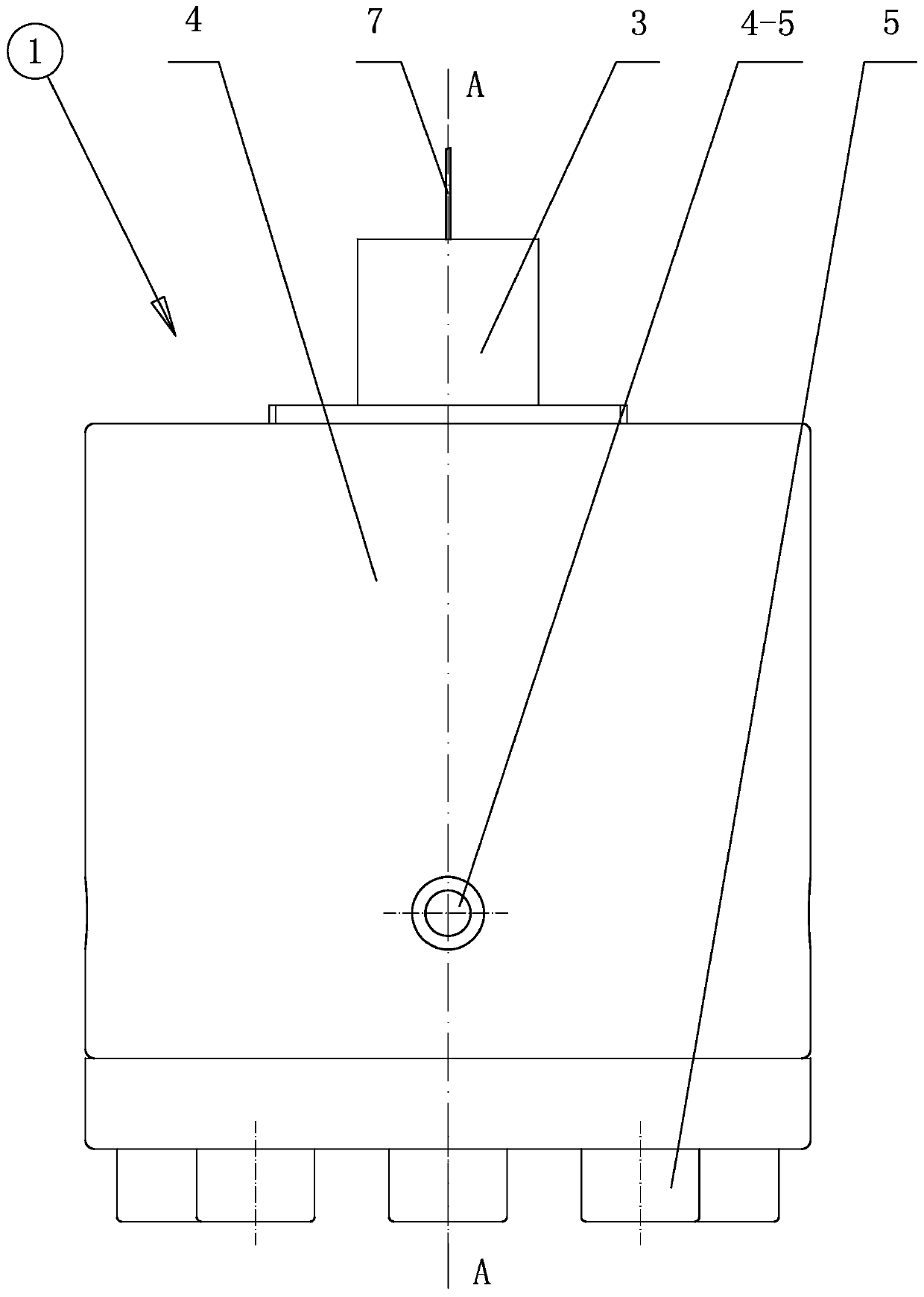

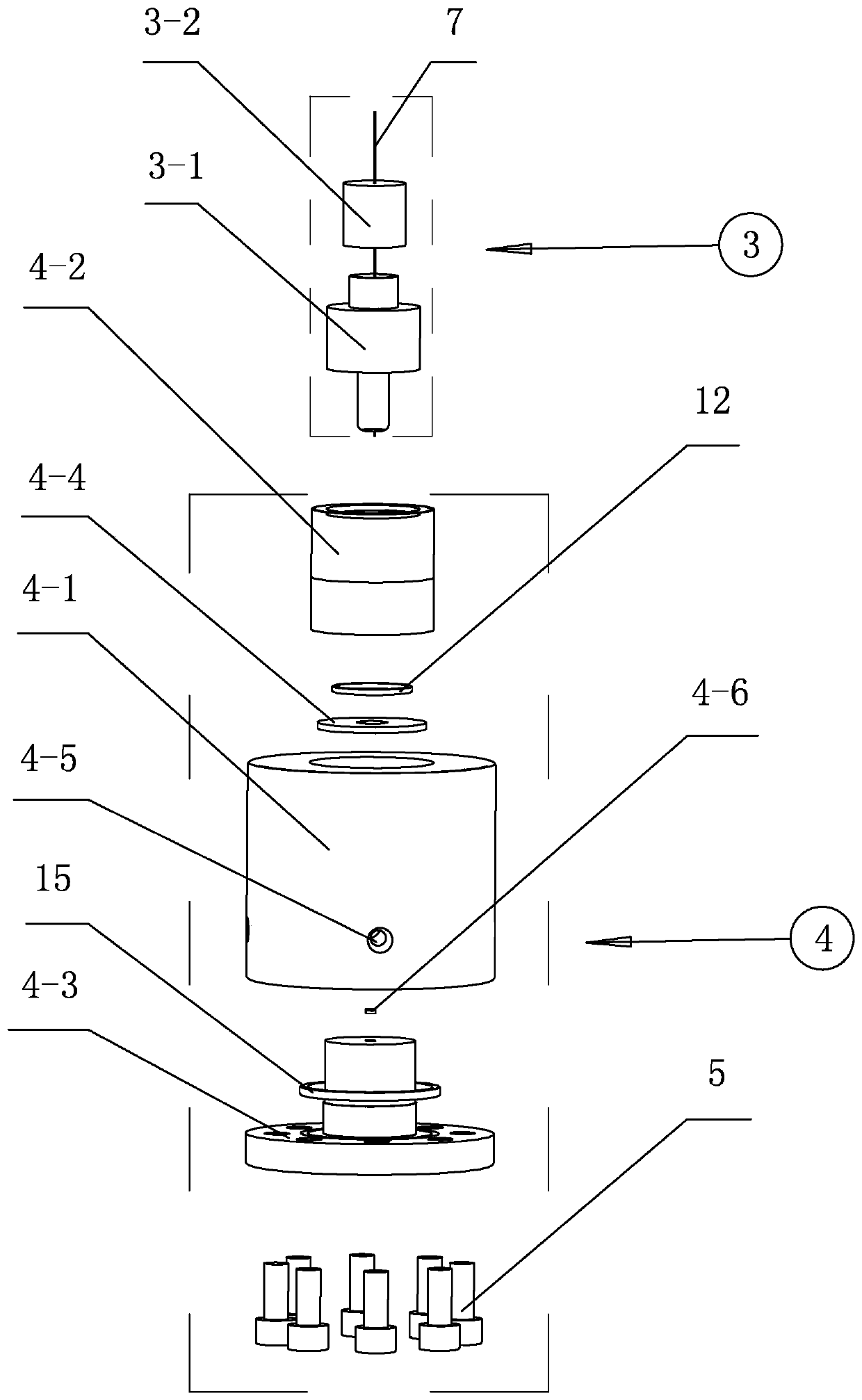

Water jet milling concrete-removing robot

ActiveCN105603887AQuick connectionFirmly connectedBuilding repairsBridge erection/assemblyRemote controlControl system

The invention discloses a water jet milling concrete-removing robot which comprises a robot body and a telescopic arm. The robot body consists of a protective cover, a chassis, a front drive system, a rear steering system, a distribution box, a power system, a cooling system, a magnetic valve group, a control system and a supporting frame, wherein the supporting frame is arranged at the right end of the chassis, a tilted support is arranged between the chassis and the supporting frame, the front drive system is arranged under the right end of the chassis, the power system is arranged on one side of the left end of the upper side face of the chassis, the distribution box is arranged on the other side of the left end of the upper side face of the chassis, the magnetic valve group is arranged on one side above the middle of the chassis, and the cooling system is arranged on the other side above the middle of the chassis. As a whole, the water jet milling concrete-removing robot can perform wired and wireless remote control, can execute concrete removal work of facades, tunnels, abrupt slopes, columns and planes lower than wheels and has the advantages of having multiple functions and being large in working range, high in efficiency, good in stability, wide in application range, high in automation degree, simple in operation, safe and reliable.

Owner:河南伯淼水处理有限公司

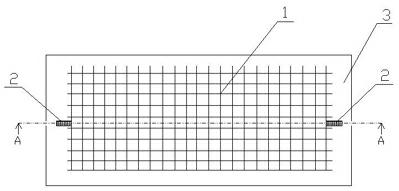

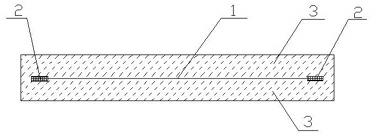

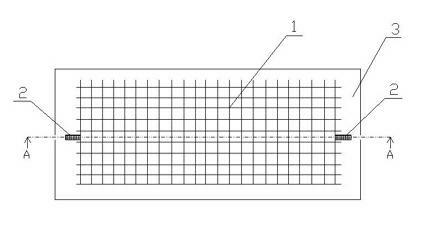

Novel carbon fiber composite electric heating film and preparation method thereof

InactiveCN102123529AReduce energy lossImprove efficiencyHeating element materialsPlastic filmMetal electrodes

The invention discloses a novel carbon fiber composite electric heating film which comprises a conductive carbon fiber layer, wherein the conductive carbon fiber layer is of a meshy structure weaved by carbon fibers, two ends of the conductive carbon fiber layer are connected with metal electrodes, and the conductive carbon fiber layer is entirely cladded by an insulated heat conduction plastic film to form a laminated structure. The carbon fiber electric heating film provided by the invention is resistant of high temperature and not easy to oxidize; and the outer-layer heat conduction plastic of the carbon fiber electric heating film is an insulated material and can resist high temperature of 300 DEG C and high voltage; and therefore, the carbon fiber electric heating film provided by the invention has extremely high safety and can be guaranteed to be used for over 50 years. The carbon fibers supply heat to the external environment in an infrared irradiation mode, is free of dust, noise, wastes and waste gases and is basically free of electromagnetic irradiation. The invention has the advantages of concise preparation process, low cost, energy source saving and eco-environmental protection and accords with the environment protection and energy source development directions.

Owner:ANHUI UNIVERSITY +1

Cement-free calcination-free shale pressing bearing brick and preparation thereof

InactiveCN101209909AImprove performance indicatorsLow costSolid waste managementEngineeringCalcination

The invention relates to a cement-free and baking-free shale suppression bearing brick and a manufacturing method thereof, which relates to a construction-used bearing brick and a manufacturing method thereof. Ordinary shale is used as main raw material and various 'wastes' are used as ingredients in the method; no open fire, waste gas, ash or waste water is produced in the manufacturing process which ensures low water and electricity consumption; various primary technical performances of a product are excellent. The method comprises steps that: (1) the materials are prepared according to following weight ratio: 40 to 50 percent of shale rock, 20 to 21 percent of auxiliary material, 4 to 6 percent of taillings powder, 7 to 9 percent of heavy calcium carbonate, 4 to 6 percent of gravel soil, 3 to 4 percent of alkali residue, 4 to 7 percent of construction waste, 5 to 6 percent of MSH polymerization condensate material especially used for shale and proper amount of water; (2) raw material treatment; the primary material and the auxiliary material are grinded; (3) ingredient stirring; (4) well-proportioned mixing and ageing; (5) mulling and plasticizing; (6) suppressing and forming; (7) steaming, pressing and solidification into finished product. The practice of the invention is environment friendly, and the quality of manufactured products is excellent, which reaches the standard of the bearing brick but has low cost and can be taken as the bearing brick for replacing a clay brick.

Owner:天津国威科技有限公司

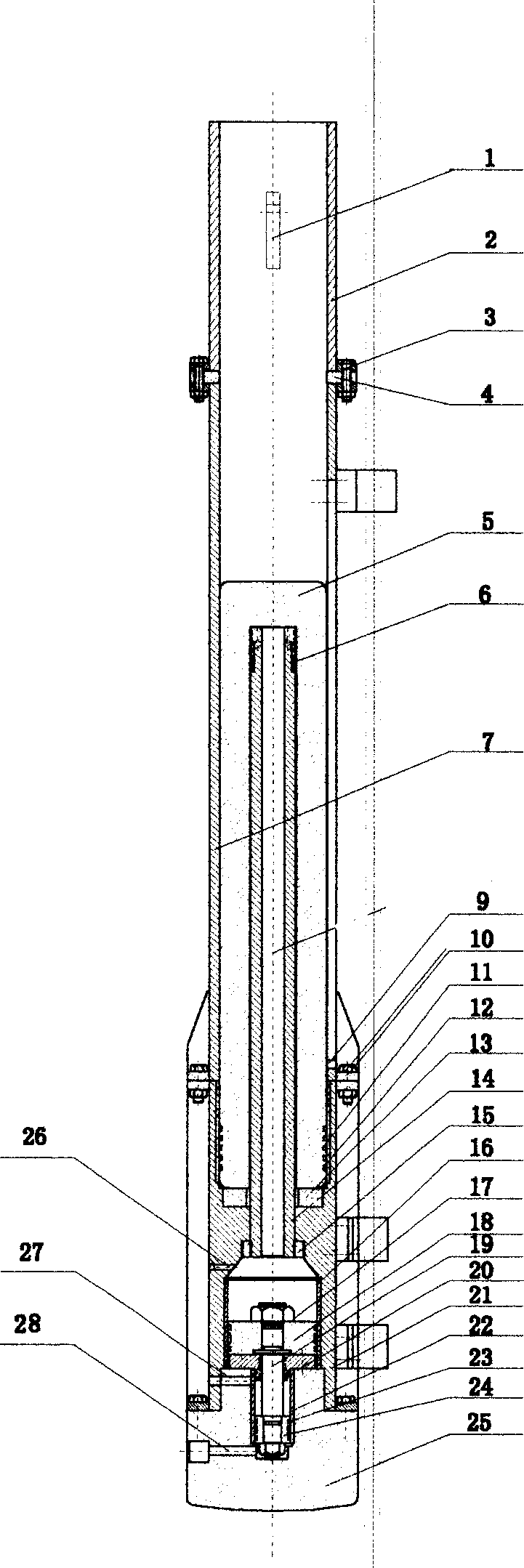

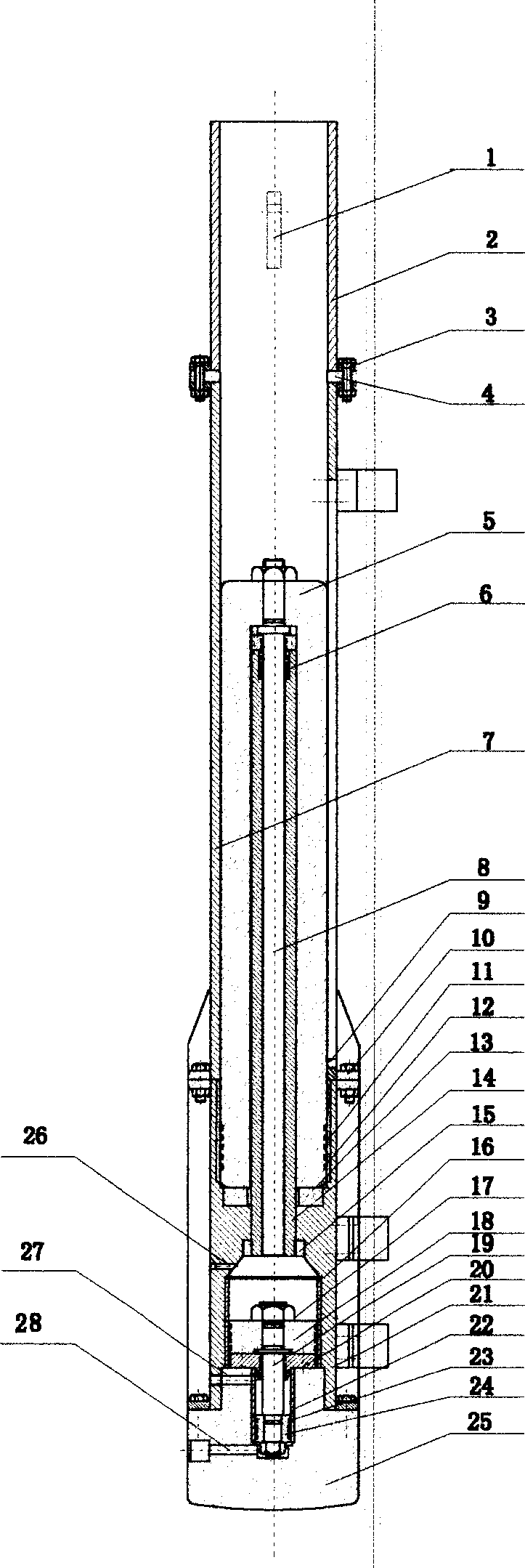

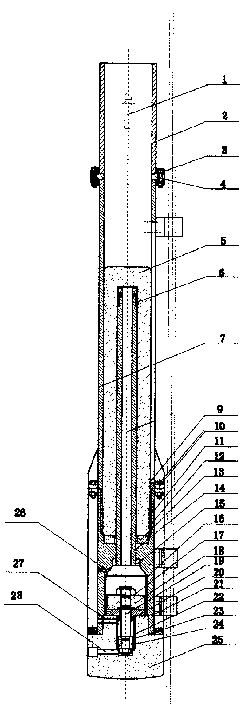

Pile-driving hydraulic hammer

InactiveCN1389630AStructural scienceSimple and fast operationBulkheads/pilesEngineeringAtmospheric pressure

It is a kind of piling work hydraulic pressure hammer. The main character lays on that, the hammer comprises oil chamber, air chamber and piston chamber hammer. The said air chamber is set on the oil chamber seat. The said piston chamber hammer is set in the outer long chamber. The said hydraulic pressure hammer, out-set liquid pressure source or air pressure source and electrical source get combined to use. When it works, because of the corporation of liquid or air pressure and electric system, the liquid spray through the oil chamber mouth from oil chamber, that propel the pistol chamber to go up, according to the freedom dropping theory, the air is pressed in the air chamber that make the pistol chamber hammer to press the pile-head to produce piling.

Owner:周荣珍

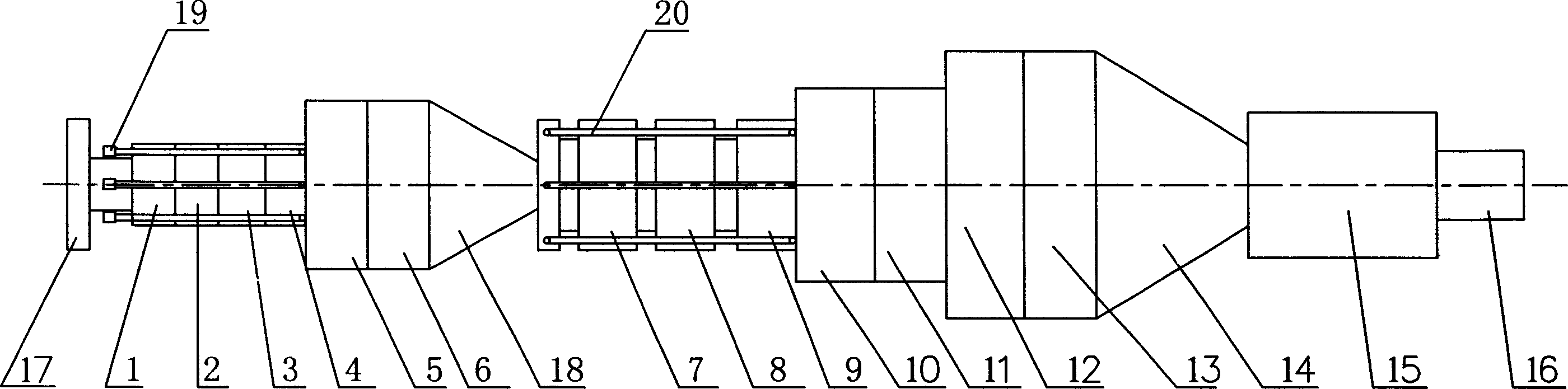

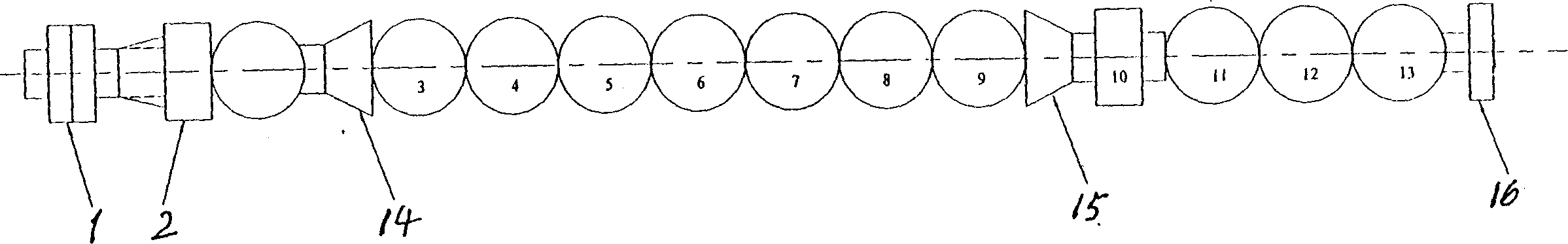

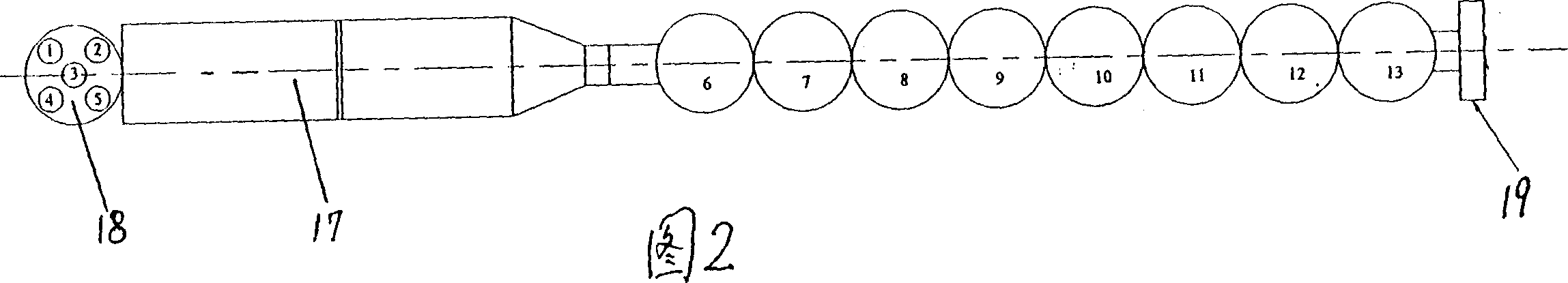

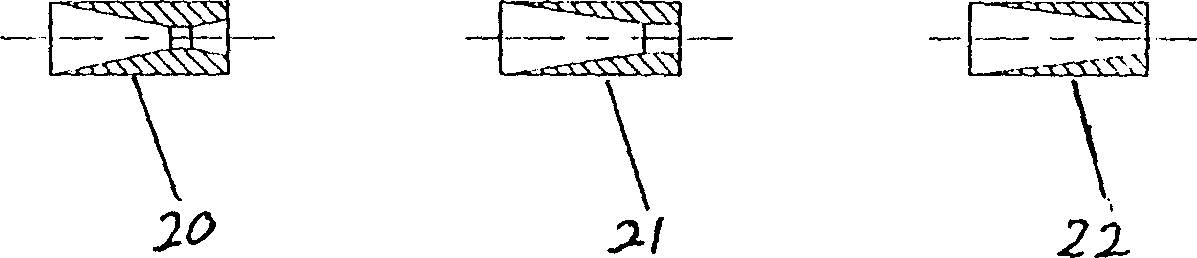

Intergrated monentum exchager for preventing and treating motor vehicle emission pollution

InactiveCN1529042AImprove thermal combustion efficiencyEliminate pollutionExhaust apparatusSilencing apparatusMomentumEngineering

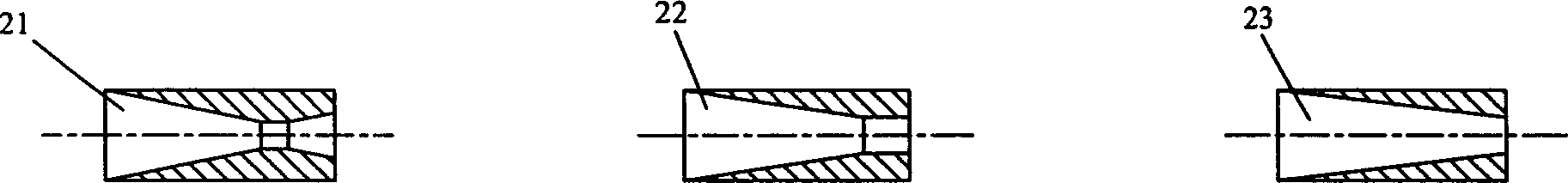

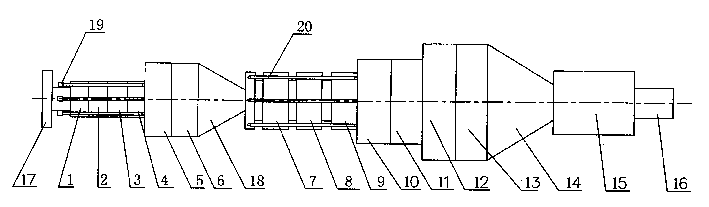

The invention provides a kind of integrate momentum exchanger for preventing the contamination of car tail gas. The character lies in: it is formed by connecting several grades of integral exchangers, each grade of exchanger is made up of receiving pipe, dispersing pipe and negative hole integrated on a mechanism processing flat with the same quantity, and there sets parallel fixed three pressure enhancing pipe of ejection receiving pipe between the first grade and the fourth grade, there sets three parallel pressure adjusting pipe of dispersant pipe between the seventh grade and the ninth grade, one end of the first grade exchanger connects with the air discharging outlet of the car engine, the other end is connected with the current adjusting device and the end tail gas discharging outlet; the invention can eliminate contamination entirely, it also can replace the current discharging and voice resisting system in car.

Owner:SHENZHEN XUANJU TECH CO LTD

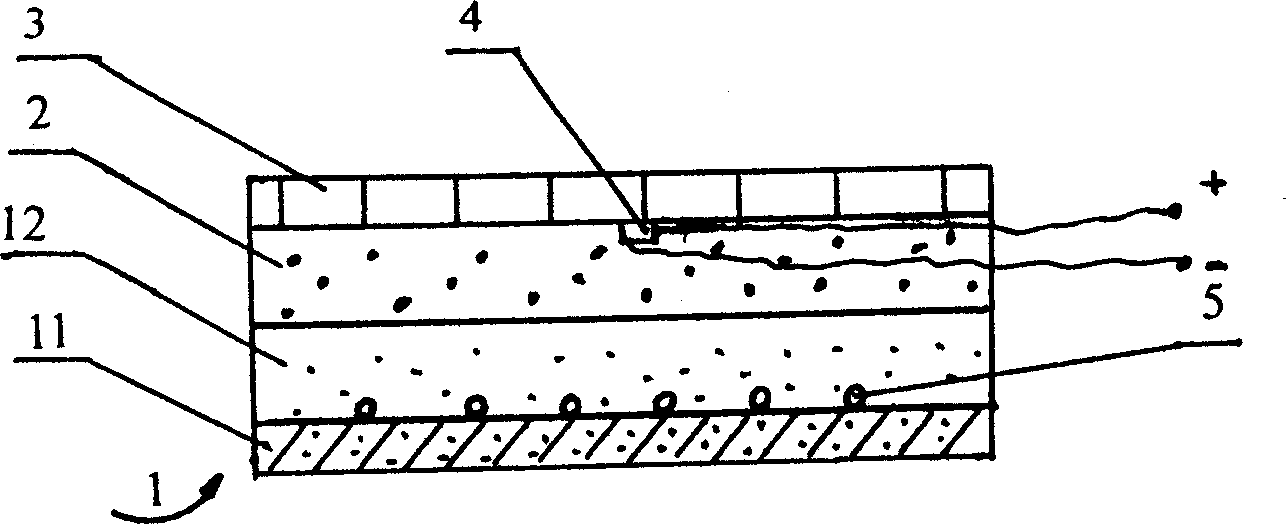

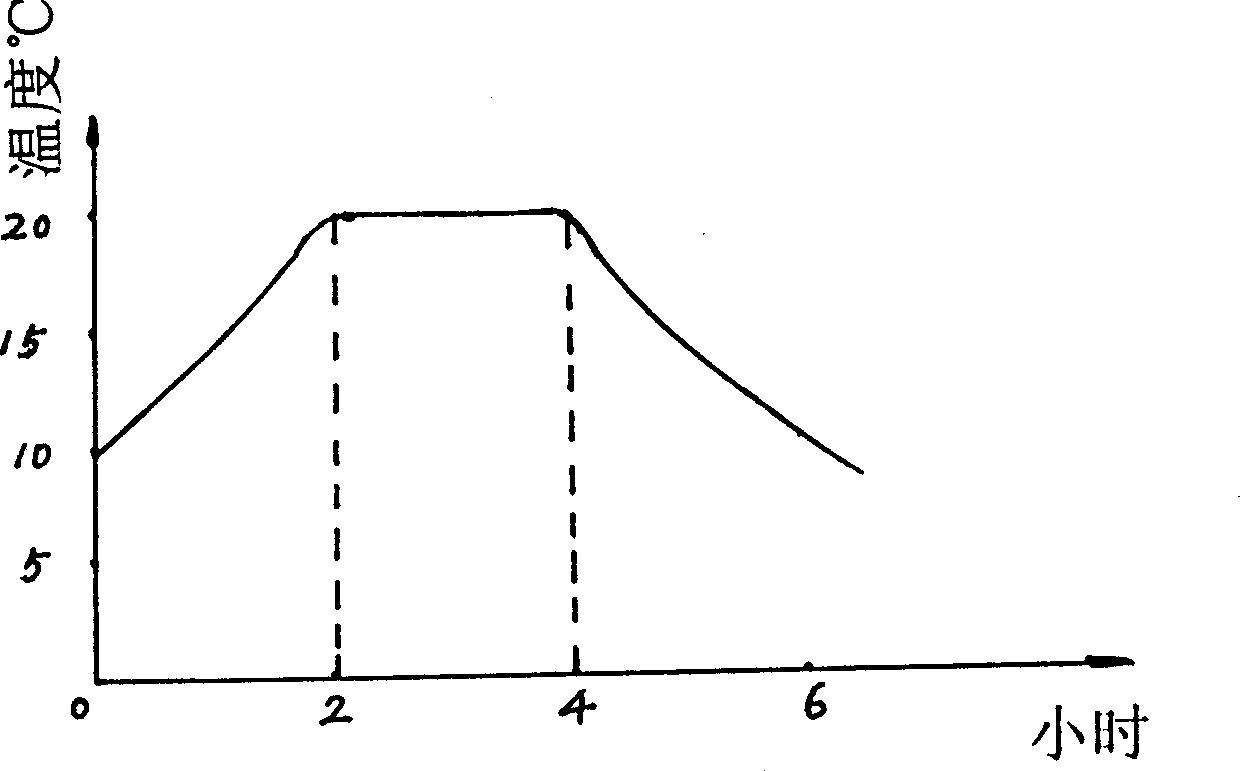

Static thermal-storage heating-amount slow-release structure and construction process and use thereof

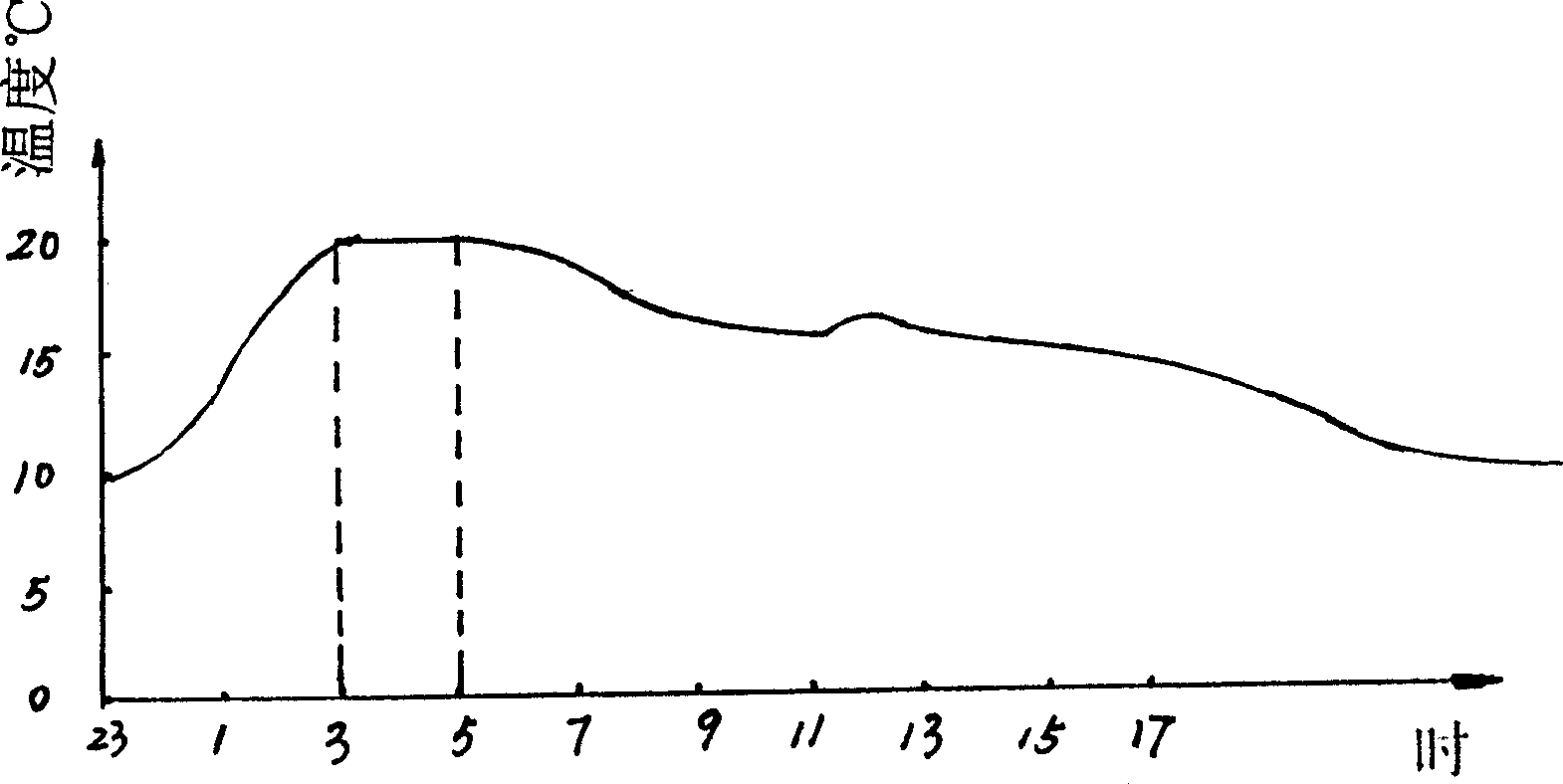

InactiveCN1488895APreferential electricity priceLower heating costsLighting and heating apparatusElectric heating systemControl modeElectric energy

The present invention relates to a geothermic electric heating static heat-stored heating heat quantity slowly-releasing structure, its construction process and application. Its structure comprises up-down laminated heat-storing layer and heat quantity slowly-releasing layer, the geothermic cable is embedded in the heat-storing layer formed from heat-storing material whose heat-conducting coefficient is 0.3-0.79w.m(-1).k(-1), said heat-storing layer is covered with the slowly-releasing layer formed from slowly-releasing material whose heat-conducting coefficient is 0.04-0.07 w.m(-1).k(-1), and the temp. sensor is embedded in the slowly-releasing layer, and is series-connected with geothermal cable loop. Its application includes the following steps: starting power supply to supply power to geothermic cable, and storing heat energy in heat-storing layer, then slowly-releasing the heat energy to heating space by means of slowly-releasing layer.

Owner:孙侠

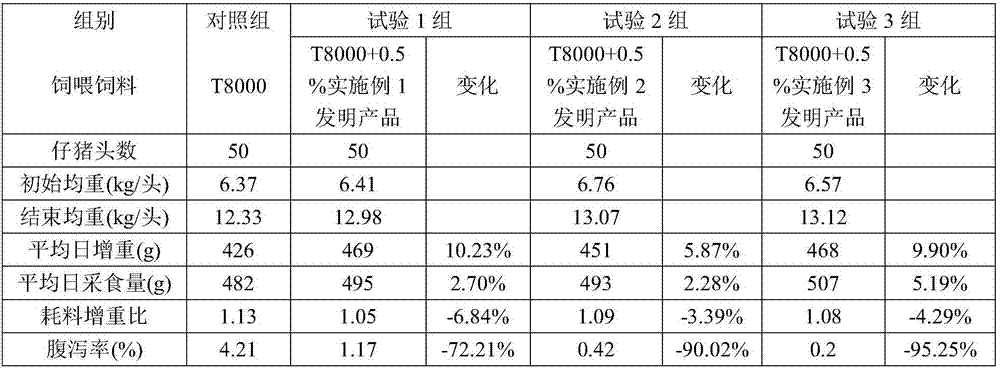

Method for preparing functional feed additive through bagasse and prepared functional feed additive

PendingCN107410704ATake advantage ofRealize secondary useFood processingAnimal feeding stuffFeed additiveFodder

The invention relates to a method for preparing a functional feed additive through fermentation and enzymolysis of bagasse. The method comprises the following steps of: (1), activating No.1 bacterial liquid and No.2 bacterial liquid; (2), stirring and uniformly mixing the activated No.1 bacterial liquid with the activated No.2 bacterial liquid, the bagasse, a starch source and No.1 compound enzymes, and then performing a first enzymolysis and fermentation reaction to obtain a first enzymolysis and fermentation product; (3), adding the first enzymolysis and fermentation product obtained in step (2) into a reaction kettle, and performing steam explosion treatment to obtain a steam explosion product; (4), stirring and uniformly mixing the steam explosion product obtained in step (3), with a starch source, No.1 bacterial liquid, No.2 bacterial liquid and No.2 compound enzymes, and then performing a second enzymolysis and fermentation reaction to obtain a second enzymolysis and fermentation product; and (5), baking the second enzymolysis and fermentation product obtained in step (4), and crushing the baked second enzymolysis and fermentation product to obtain the functional feed additive. In the whole technological process of the method disclosed by the invention, mutual cooperation is realized, and the technology is simple; and after the functional feed additive is added into a feed, the palatability is good, and the feed intake of animals is high.

Owner:湖南百宜科技集团有限公司

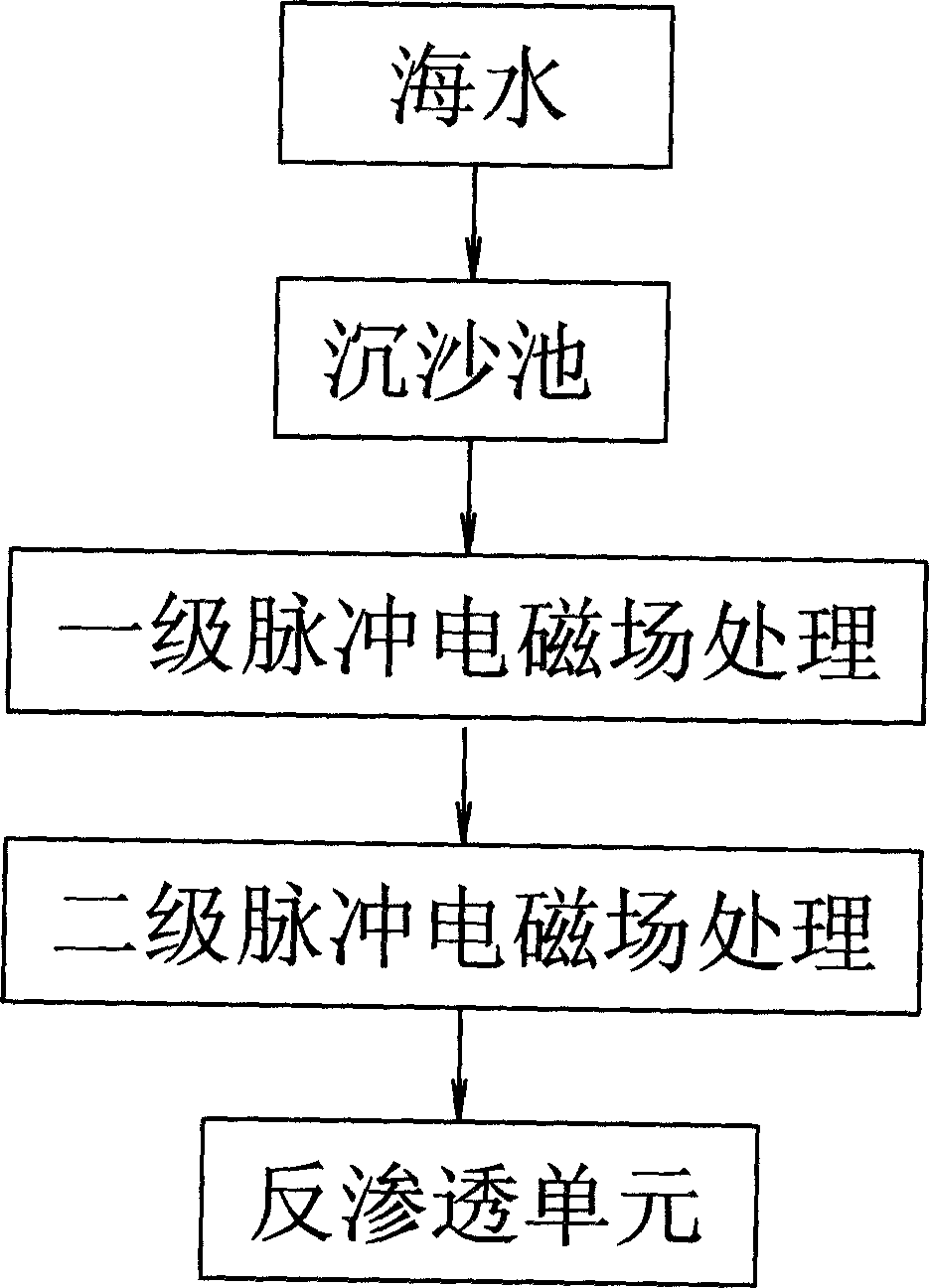

Pretreating method for reversing asmose seawater desalinating pulsing electromagnetic field

InactiveCN1613786AExtended service lifeShorten the preprocessing processGeneral water supply conservationWater/sewage treatment by magnetic/electric fieldsPretreatment methodReverse osmosis

A reverse osmosis seawater desalting pulsing electromagnetic field pretreatment is carried out by: passing seawater into the first and the second stage pulsing electromagnetic field treating apparatus by grit chamber, treating it there, and entering reverse osmosis unit at pulsing voltage 1-1000V and pulsing frequency 0.1-500Hz. Its advantages include low cost, no pollution, to improve water quality and decrease pretreatment process.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

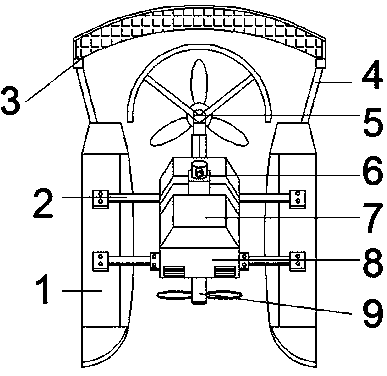

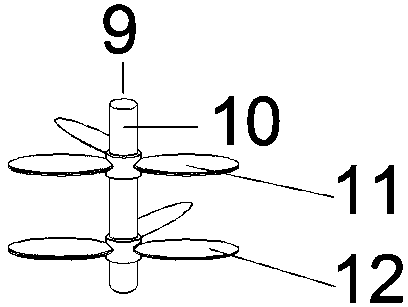

Wind air engine and automobile

InactiveCN101550915AIncrease motivationSave high pressure gas volumeBraking element arrangementsWind motor controlInner loopAir compressor

The present invention discloses a checking braking pressurization system, including a checking braking supercharger brake disk inner loop intermeshing actuator for transferring a deceleration brake force, a checking braking supercharger and an air compressor with a large load. The output of the checking braking supercharger brake disk inner loop intermeshing actuator drives the checking braking supercharger, the output of the checking braking supercharger drives the air compressor, and the air compressor regenerates and translates the brake force into a high pressure gas to output. The invention also discloses a wind air engine including the checking braking pressurization system capable of regenerating the brake force to use. By means of the invention, it is capable of recovering and regenerating and using the brake force when an automobile being checking braking in time, and the energy resource consumption will be saved greatly.

Owner:丛洋

Small multifunctional unmanned cleaning ship for river channel

InactiveCN107757835AImprove attendanceEasy to operateWater cleaningMeasurement devicesFiberElectricity

The invention discloses a small multifunctional unmanned cleaning ship for a river channel. The small multifunctional unmanned cleaning ship for the river channel comprises glass hulls, carbon fiber frameworks, a garbage interception net, frame rods, a moving motor, a monitor, a storage battery, a data acquisition detection box and a weed cutting machine. The double glass hulls are fixedly installed through the two carbon fiber frameworks. The garbage interception net is fixedly installed on sterns of the glass hulls through the frame rods and bolts. The data acquisition detection box is installed at the upper ends of the carbon fiber frameworks. The monitor electrically connected with the storage battery is installed on the data acquisition detection box. The moving motor is installed atthe rear end of the data acquisition detection box. The weed cutting machine is fixedly installed at the bottom ends of the carbon fiber frameworks through bolts. By the adoption of the small multifunctional unmanned cleaning ship for the river channel, the device design is suitable for river bottom sonic detection. The cleaning ship has the beneficial effects of being capable of sweeping floatinggarbage, cutting and collecting weed, obtaining water quality samples, acquiring water surface information, detecting the water level and conducting water flow detection, economical, applicable, convenient and quick to use, high in attendance rate, easy to operate, quiet, environment-friendly, and free of tail gas emission.

Owner:唐贵亮

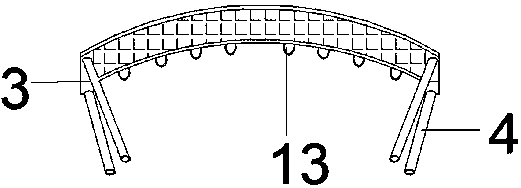

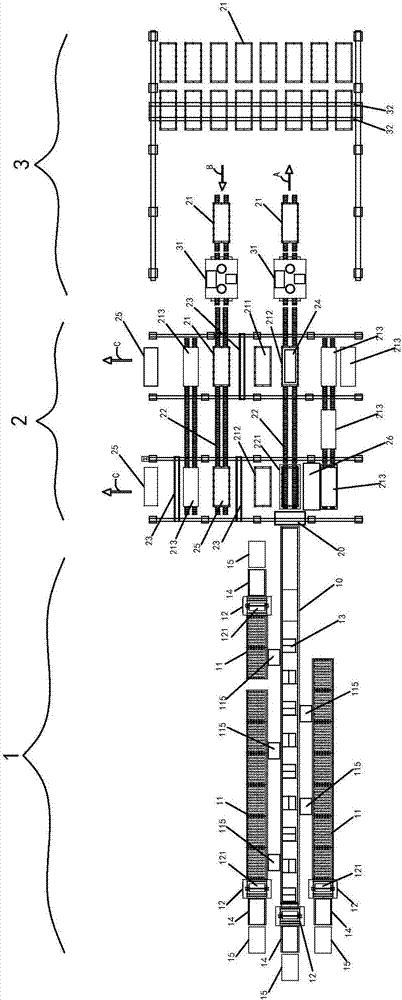

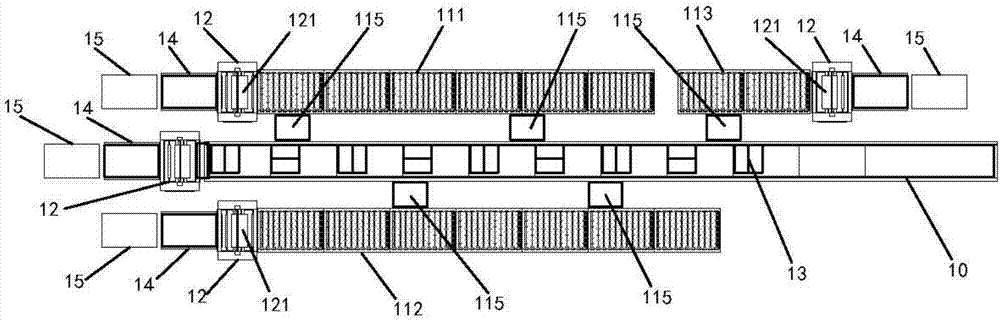

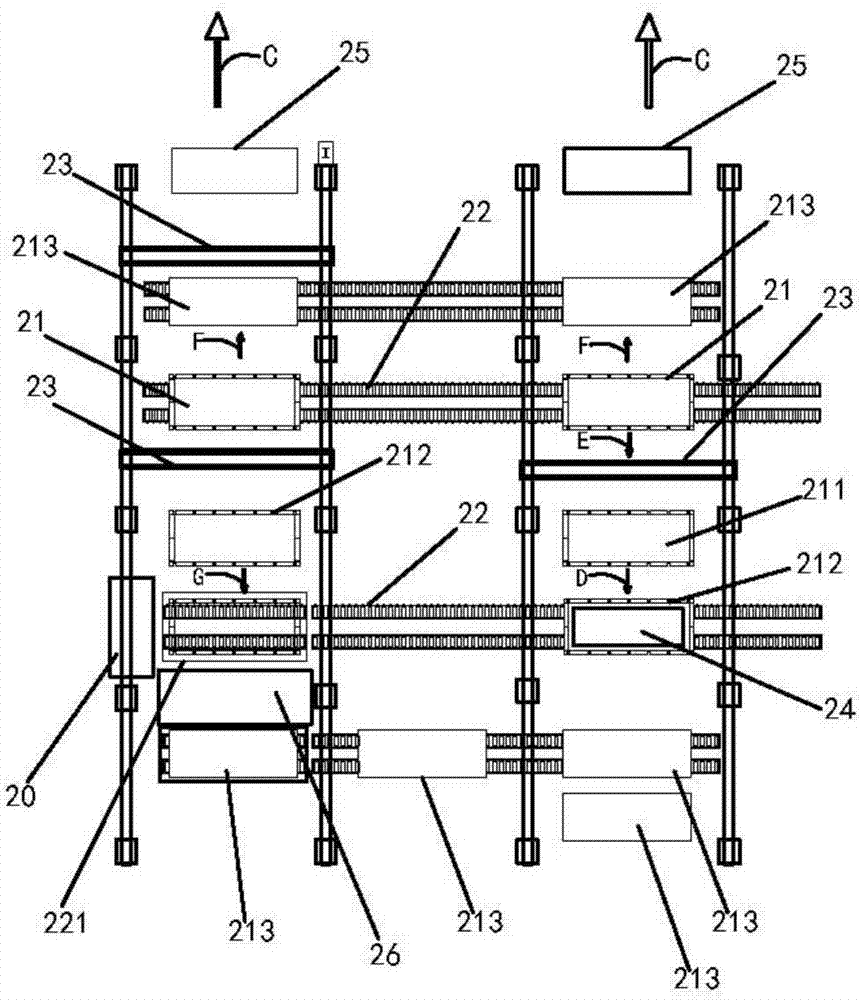

Plywood molding system

PendingCN107379142ANo need to occupyCompression conditions are easy to achieveOther plywood/veneer working apparatusWood veneer joiningSingle plateMechanical engineering

The invention provides a plywood molding system. The system comprises a conveying and stacking area, a slab molding area and a mold locking and pressure maintaining area in sequential connection; the conveying and stacking area comprises single board conveying lines, a planking line and laminators arranged on the single board conveying lines and the planking line, single boards are gelatinized through the laminators, and the gelatinized single boards are conveyed to the planking line for stacking and conveying through the single board conveying lines; the slab molding area comprises a fixed-size cutting machine and molds, the slab molding area is connected with the conveying and stacking area through the fixed-size cutting machine, the stacked single boards on the planking line are cut into slabs in fixed size, and the molds are used for containing and compacting single slabs or multiple slabs; the mold locking and pressure maintaining area comprises presses, and pressurized mold locking and depressurized mold disassembly are conducted on the molds through the presses. According to the system, molding can be conducted only through cold pressing and pressure maintaining, compacting conditions are easily achieved, energy consumption is low, and it is not necessary to occupy a large amount of large press equipment, so that the production efficiency is improved.

Owner:中山市富木木制品有限公司

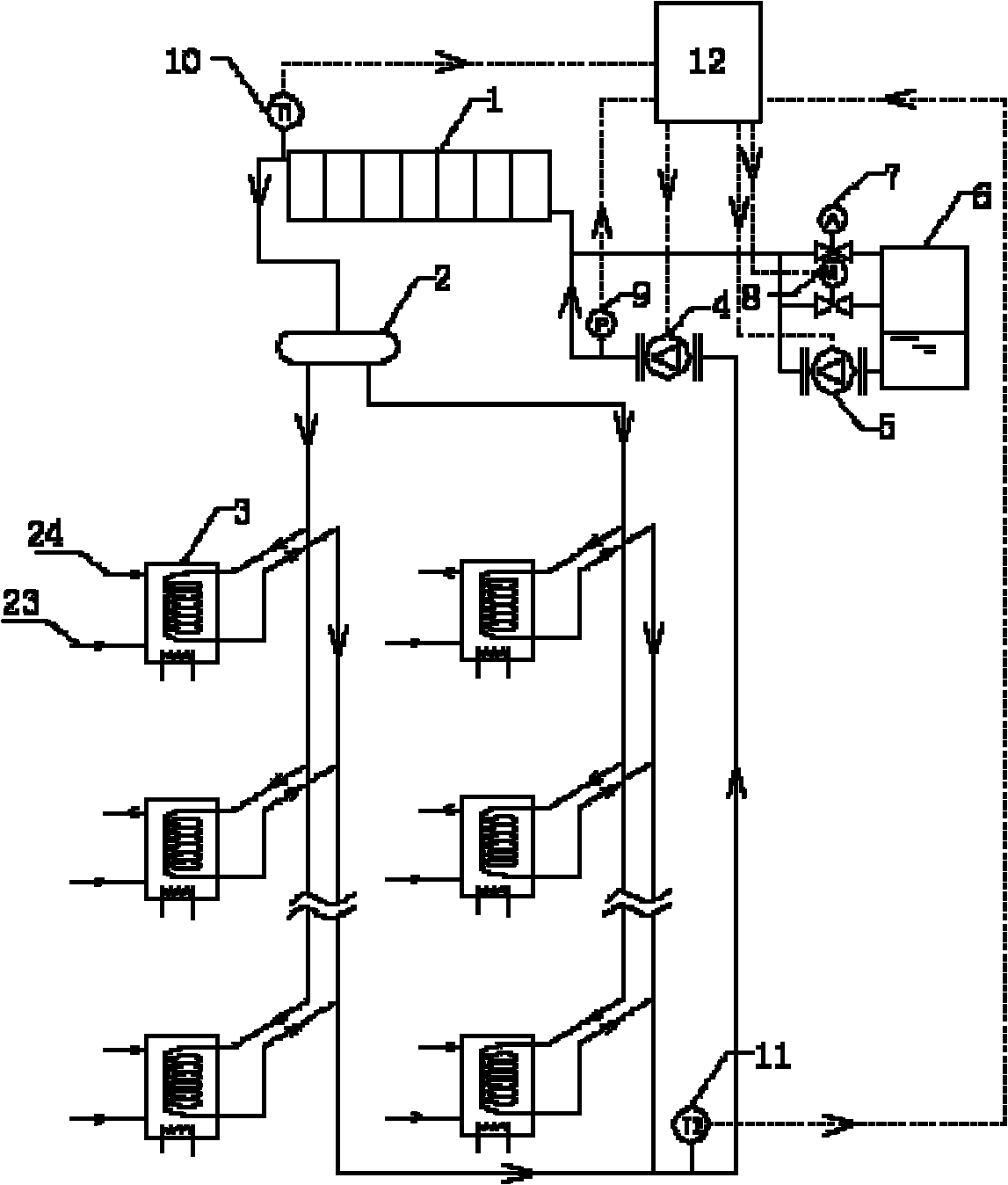

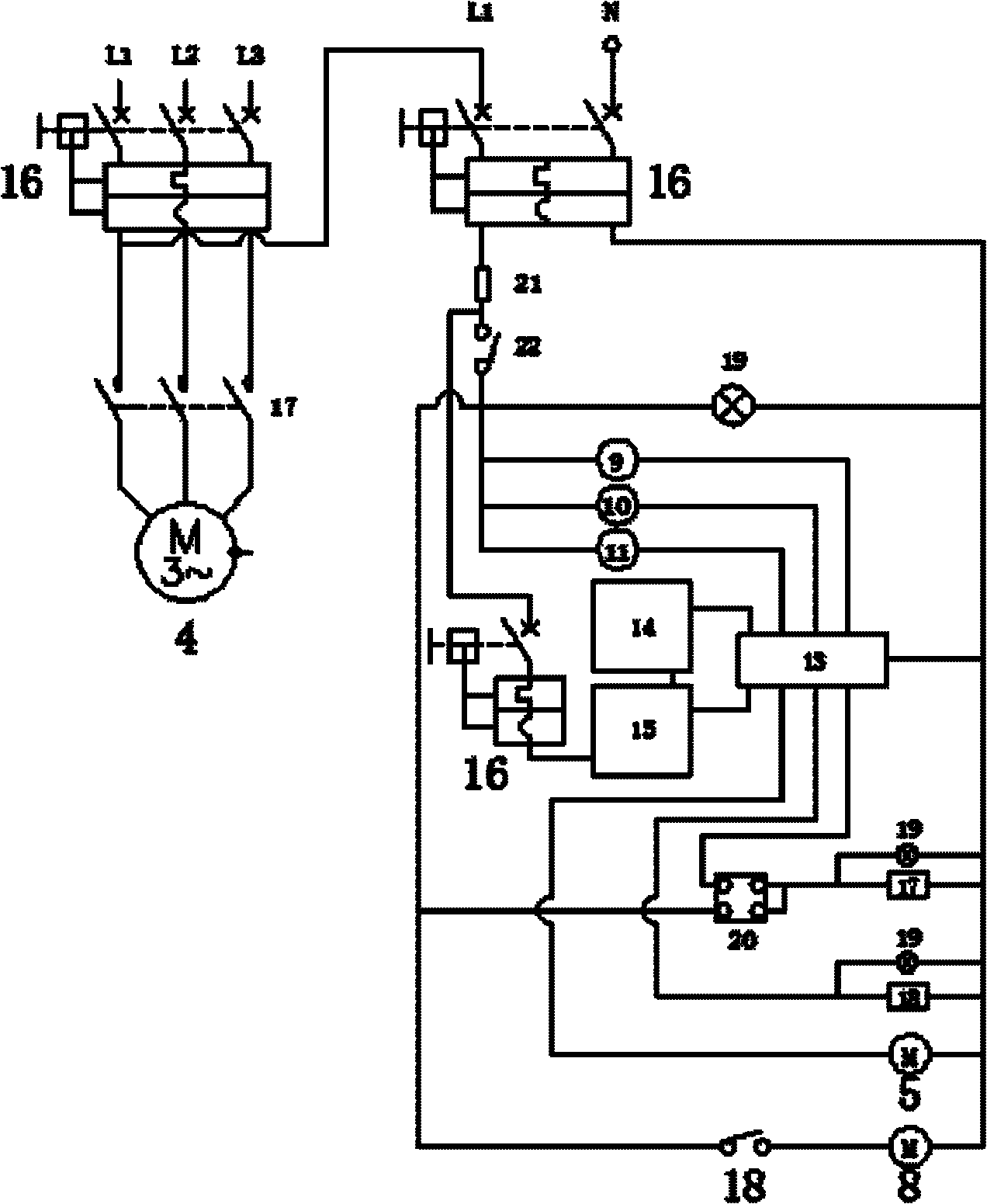

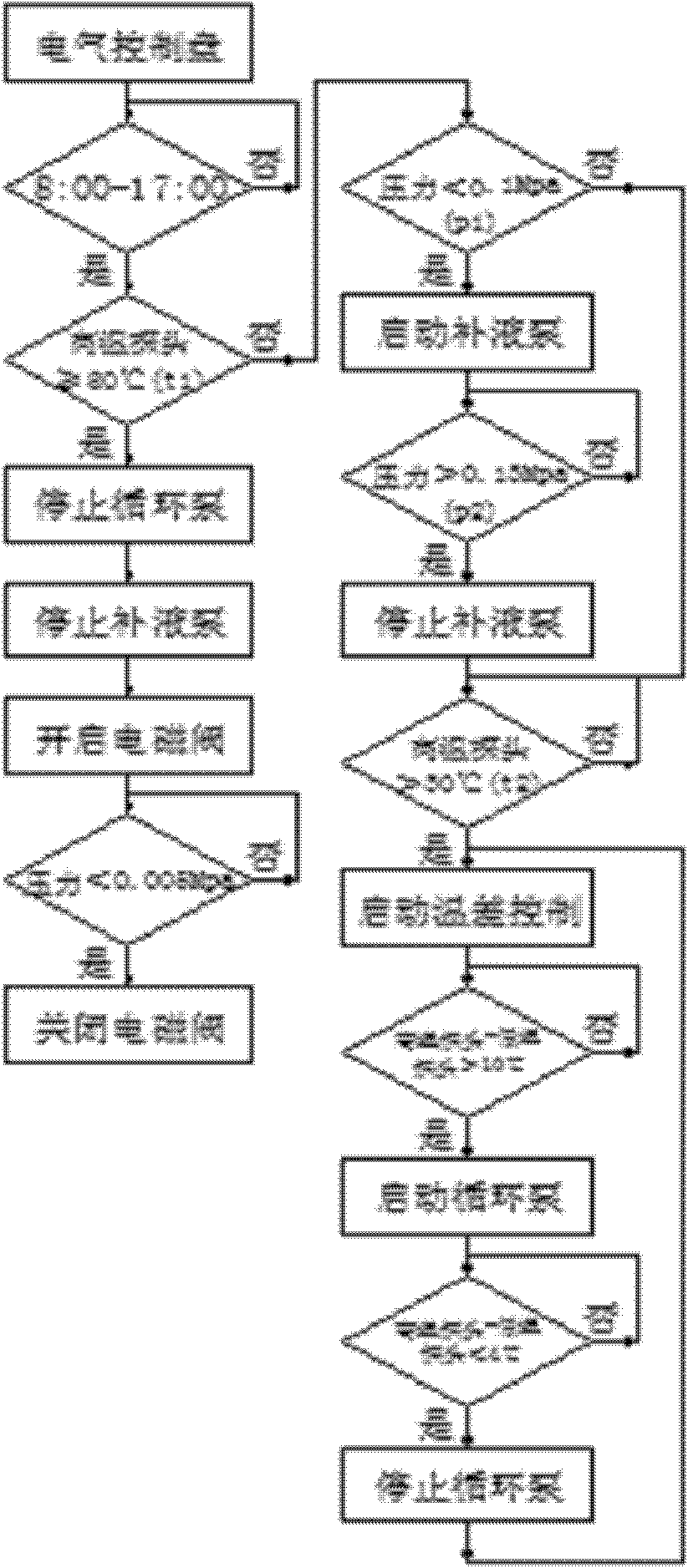

Solar water heating system and running method thereof

InactiveCN102155759ASolve the problem of overheatingSolve the phenomenon of overvoltageSolar heat devicesSpace heating and ventilation detailsSolar water heating systemSolar water

The invention relates to a solar water heating system. A high-temperature probe is arranged on the outlet of a flat-plate solar heat collector, and the outlet of the flat-plate solar heat collector is connected with the inlet of a liquid separation bag; the outlet of the liquid separation bag is connected with the inlets of solar water heater circulating pipes of users of each unit respectively; the outlets of the solar water heater circulating pipes are connected with an anti-freezing working medium return pipe; a solar water heater is placed in each user; a circulating pump is arranged at the high-end position of the tail end of the outlet of each of the circulating pipe; a pressure transducer is arranged on the outlet of the circulating pump; the pressure transducer is connected with the inlet of the flat-plate solar water heater, the outlet of a liquid compensation pump, the inlet of a safety valve and the inlet of an electromagnetic valve; a low-temperature probe is arranged at the low end of the anti-freezing working medium return pipe and connected with the inlet of the circulating pump; and electric control signals of the circulating pump, the liquid compensation pump, theelectromagnetic valve, the pressure transducer, the high-temperature probe and the low-temperature probe are connected with an electric control disc. In the solar water heating system, by using natural energy, the normal energy cost can be saved by 60 to 80 percent.

Owner:TIANJIN GUANGYI ENVIRONMENTAL PROTECTION TECH

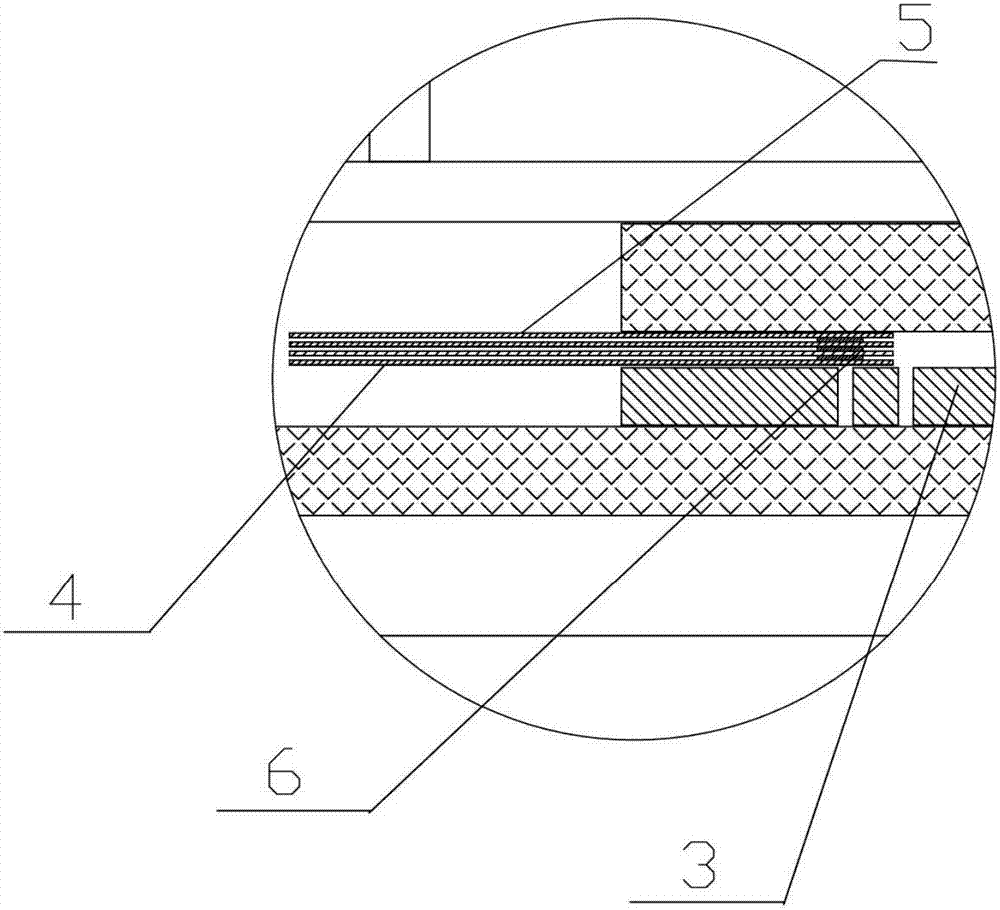

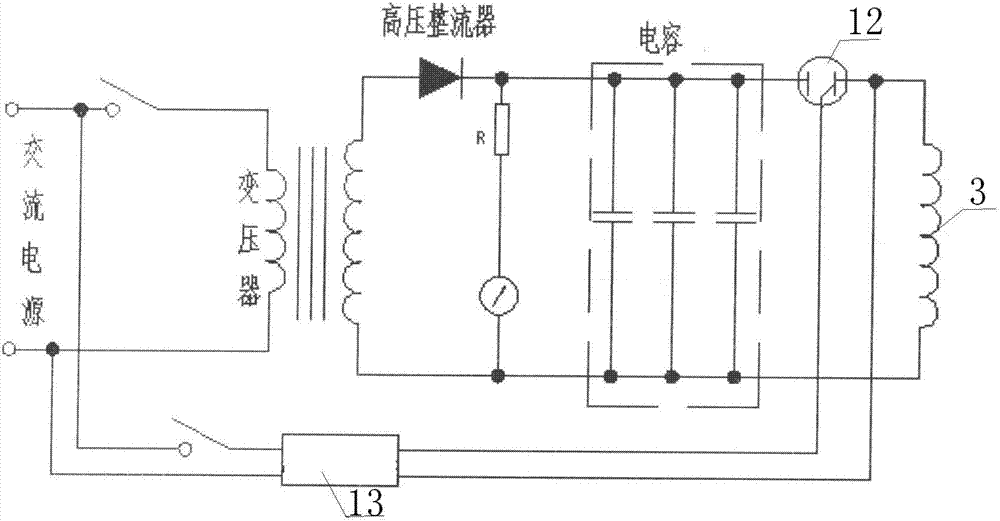

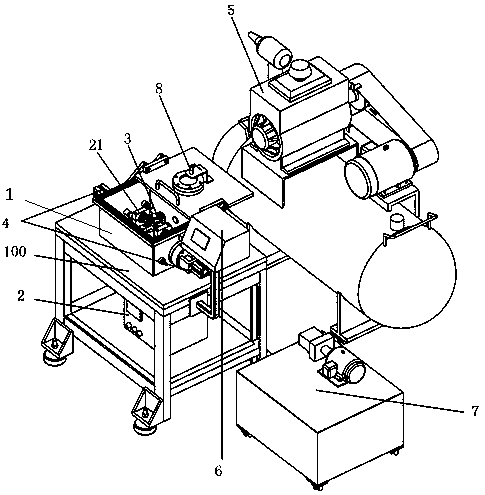

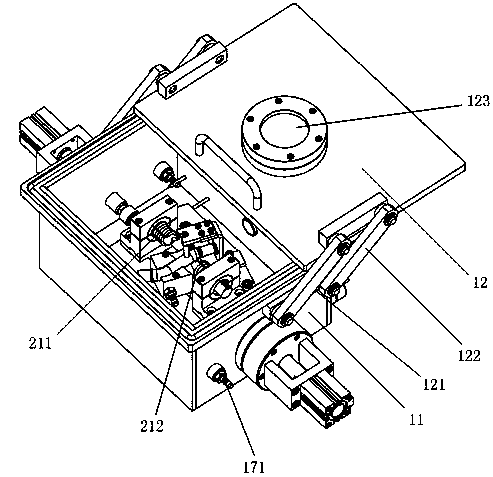

Electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs

InactiveCN107081513AReduce labor intensityIncrease productivityHigh frequency current welding apparatusWelding/soldering/cutting articlesCapacitanceElectrical battery

The invention discloses an electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs. The aluminum plate lugs and the copper pole lugs are fixed on a welding device; the welding device comprises a rack; a cushion plate is arranged on the rack; an electromagnetic coil is arranged on the cushion plate; welding areas of the multilayer aluminum plate lugs are placed on the electromagnetic coil; the copper pole lugs are placed on the upper portion of the aluminum plate lug at the uppermost layer; interval pieces are arranged between the welding areas of the aluminum plate lugs as well as the welding areas of the aluminum plate lugs and the copper pole lugs; the aluminum plate lugs and the copper pole lugs are fixed through a pressing plate; the electromagnetic coil is connected with a capacitance switch of a capacitance power supply device; the capacitance switch is controlled by a pulse generator to be switched on and switched off; and the pulse generator is started to charge a capacitor of the capacitance power supply device, when the charging voltage reaches the set value, the capacitance switch is turned on, and the capacitor quickly discharges, so that welding of the battery aluminum plate lugs and the copper pole lugs is achieved. The welding efficiency is improved, the welding quality is improved, energy consumption is reduced, auxiliary materials are not consumed, and energy saving and environmental friendliness are achieved.

Owner:INST OF OPTICAL MASCH CHONGQING CITY +1

Preparation method of environment-friendly wall surface sealing glue for building

ActiveCN104178061AImprove interface adhesionHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesBasementLayer interface

The invention discloses a preparation method of environment-friendly wall surface sealing glue for a building, relating to the technical field of building appliances. The preparation method comprises the steps of in a stirring tank A, dissolving PVA into water according to a proportion that 850kg of water is added in150kg of PVA, heating to 90 DEG C within about 1.5 hours while stirring, preserving the heat for half an hour, and then, cooling to 50 DEG C; in the stirring tank B, simultaneously and sufficiently dissolving boric acid and sodium benzoate in water; and in the stirring tank C, (1) adding 75-85% of water, (2) simultaneously pouring 10-15% of products in the stirring tank A and VAE into water, mixing and dissolving the products in the stirring tank A, VAE and water, and stirring for 30 minutes; and (3) pouring 0.025% of defoaming agents, 0.025% of emulsifiers and 0.2% of thickening agents at one step to dissolve, and uniformly stirring. By using the preparation method, the adhesive force of a smooth basement layer interface can be increased, the bonding strength is high, the cement galling process is firm and reliable, hollowing is avoided, and no waste gas, waste water and waste power consumption are generated in the production process.

Owner:山东韩师傅新材料有限公司

High-frequency brazing machine

ActiveCN104174960AImprove qualityReduce precisionHeating appliancesSoldering auxillary devicesEddy currentEngineering

The invention discloses a high-frequency brazing machine which comprises a worktable, a vacuum system component and a cooling component. A welding work box, a high-frequency generator, a programmed control device and a temperature detection component are arranged on the worktable, a work fixture and a high-frequency magnetic bar coil are arranged in the welding work box, the work fixture fixes a workpiece to be welded, a pneumatic drive workpiece is arranged at one end of the welding work box and connected with the work fixture and drives the work fixture to run, and the programmed control device is connected with the vacuum system component, the pneumatic drive workpiece, the high-frequency generator, the cooling component and the temperature detection component. By the mode, the high-frequency brazing machine realizes brazing by the aid of eddy current, safety can be guaranteed, and the high-frequency brazing machine is low in risk and cost, high in efficiency and fine in welding performance.

Owner:CHANGSHU JUNCHI SCI & TECH

Integrated momentum-exchange machine

InactiveCN1448622AReduce lossesStrong entrainmentExhaust apparatusSilencing apparatusMomentumControl theory

The present invention is one integrated moment exchanger for treating tail gas of motor vehicle. The integrated moment exchanger consists of 13 stages of main and auxiliary integrated exchangers connected parallelly, and each stage of exchanger has jetting reception tubes and diffusion tubes in the same number. The present invention can eliminate tail gas pollution radically, and may be used inreplacing available exhaust silencer system in motor vehicle.

Owner:张裕光 +2

Floating plate device for wave-collecting generating system

The invention discloses a floating plate device for a wave-collecting generating system, which includes a bracket and floating plates for collecting wave energy, wherein the floating plates includes a first floating plate and a second floating plate that are arranged in parallel; the first floating plate includes a first accommodating cavity facing to a wave guide surface; and the second floating plate includes a second accommodating cavity facing to the wave guide surface. The floating plate device is applied to the wave-collecting generating system, operates without noise, produces no waste gas, waste material, sewage and radiation, and therefore is the environment-friendly generating technology; and when typhoon approaches, the floating plates can rise up to be fastened to the shore or cliff, so as to avoid being damaged by billows.

Owner:浪能电力科研有限公司 +1

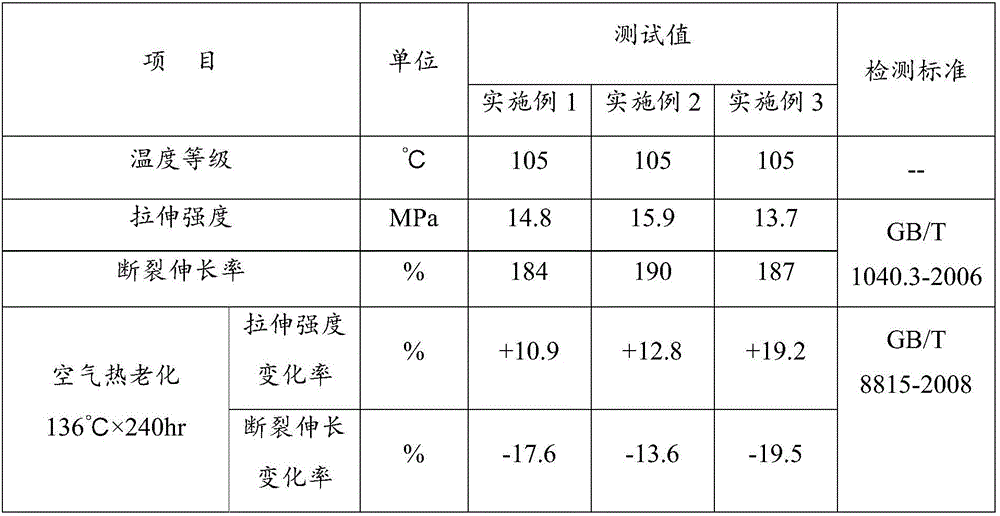

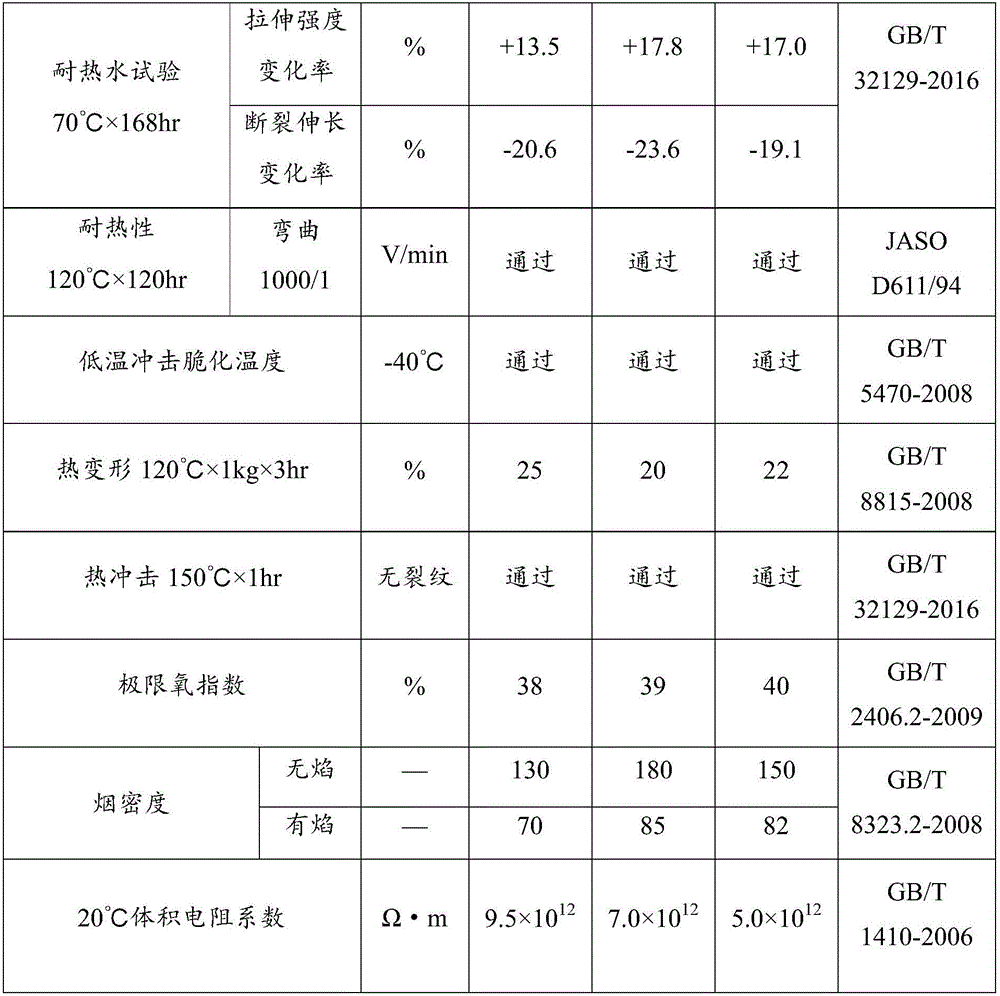

Halogen-free flame-retardant heat-resistant weather-resistant polypropylene nano composite insulating material for automobile wire and preparation method thereof

ActiveCN105219006AHigh strengthImprove wear resistancePlastic/resin/waxes insulatorsInsulated cablesPolypropyleneExtrusion Granulation

The invention relates to a halogen-free heat-resistant weather-resistant polypropylene nano composite insulating material for an automobile wire and a preparation method thereof. The composite insulating material is prepared from 50-60 parts of polypropylene nano compounds and 50-60 parts of halogen-free flame-retardant master batches. The polypropylene nano compounds are prepared from, by weight, 100 parts of polypropylene, 10-15 parts of polypropylene polar monomer grafts, 4.0-8.0 parts of nano inorganic compounds and the like. The halogen-free flame-retardant master batches are prepared from, by weight, 100 parts of organic hydroxide, 20-30 parts of carrier resin and the like. By the adoption of the binary technology, the polypropylene nano compounds and the halogen-free flame-retardant master batches high in flame-retardant agent content are prepared, the polypropylene nano compounds and the halogen-free flame-retardant master batches are mixed, extruded and granulated through a double-screw extruding machine, and the nano composite insulating material is obtained. The material is low in cost and environmentally friendly, integrates excellent physical and mechanical performance and electric performance and good extruding processability, is suitable for insulating processing of the automobile original wire, and can be used for insulating wrapping of communication cables, logging cables and oil-submerged pump cables.

Owner:TONGJI UNIV

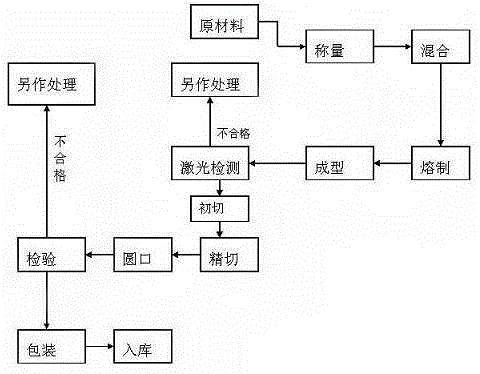

Formula and production method of pharmaceutical neutral borosilicate glass tube

The invention relates to a formula of a pharmaceutical neutral borosilicate glass tube. The pharmaceutical neutral borosilicate glass tube comprises components with the following parts by weight: 260 to 280 parts of quartz sand, 14 to 18 parts of lepidolite, 25 to 35 parts of aluminum hydroxide, 3 to 5 parts of fluorite, 80 to 100 parts of borax pentahydrate, 4.5 to 6 parts of sodium carbonate, 9 to 12 parts of sodium nitrate, 3 to 4.5 parts of potassium carbonate, 4.5 to 5.5 parts of barium carbonate, 4 to 5 parts of a compound glass clarifying agent, and 120 to 140 parts of cullet. The invention has the benefits that the product has higher chemical stability, heat stability and water resistance, so that the mechanical strength of the product is remarkably improved; through a production method of the neutral borosilicate glass tube, the product qualification rate reaches 90 percent, energy is saved, and pollution, waste gases and volatiles are eliminated.

Owner:山东康和医药包装材料科技有限公司

Flexible water-jet guided laser micro-machining system and method

PendingCN110883424ACompact designFlexible connectionLaser beam welding apparatusWater flowEngineering

The invention discloses a flexible water-jet guided laser micro-machining system and method. The flexible water-jet guided laser micro-machining system comprises an optical fiber transmission unit, aworkbench unit and a high-pressure liquid supply unit. The optical fiber coupling unit comprises an optical fiber fixing and switching module and a beam coupling transmission module. The beam couplingtransmission module comprises a coupling body, an upper pressure head and a lower nozzle holder. The end of a flexible optical fiber is fixed in a liquid cavity between the upper pressure head and the lower nozzle holder through the optical fiber fixing and switching module. A water inlet in the coupling body communicates with the liquid cavity. A nozzle block is arranged on the lower nozzle holder, and a spray hole in the nozzle block communicates with a nozzle on the lower nozzle holder. The coupling body is clamped on a manipulator of a robot. Stepless pressure-adjustable high-pressure water output by the high-pressure liquid supply unit is collected into the liquid cavity via water inlets to form a low-pressure stable water flow. The workbench unit comprises a three-axis linkage workbench. A clamping and fixing table board of workpieces is arranged on the workbench through a water tank. The flexible water-jet guided laser micro-machining system is simple, compact and flexible in structure, and multi-dimensional flexible micro-machining of the workpieces can be achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Polyolefin communication cable material used in rail transportation, and preparation method thereof

InactiveCN106519543AHigh strengthImprove wear resistancePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a polyolefin communication cable material used in rail transportation, and a preparation method thereof. The polyolefin communication cable material is composed of, by weight, 40 to 60 parts of ethylene-vinyl acetate copolymer, 40 to 60 parts of propylene-ethylene block copolymer, 10 to 20 parts of an interface compatilizer, 140 to 180 parts of a fire retardant, 1 to 2 parts of a composite antioxidant, 5 to 10 parts of an antiwear additive, 1 to 2 parts of an ultraviolet light absorber, 2 to 4 parts of a lubricating agent, 2 to 3 parts of a water resistance agent, and 1 to 2 parts of a metal deactivator. The polyolefin communication cable material is high in strength, and excellent in wear resistance; possesses petroleum butter resistance, environmental stress crack resistance, hydrophobicity performance, watertightness, weatherability, excellent physical and mechanical properties, electrical performance, and excellent extrusion processability; and is capable of resisting a temperature as high as 105 DEG C; the preparation method and formula are simple; no toxic substance or waste gas is generated in production process; the compatibility of the above ingredients is excellent, and processing fluidity is excellent; the flame resistance is capable of satisfying requirements in UL-94 V-0 vertical flame test; and oxygen index value is equal to or larger than 38%.

Owner:WUXI JAKE PLASTIC

Wind air engine and automobile

InactiveCN101550914ANo consumptionNo emissionsAuxillary drivesWind motor controlFumaroleHigh pressure

The present invention discloses a wind air engine, including an impeller chamber, impellers arranged in the impeller chamber, an exhaust outlet and an air jet system for jetting high pressure gas into the impeller chamber; the impeller chamber is provided with a fumarole for receiving the high pressure gas and an air inlet for receiving external windage airflow, the high pressure gas jetted by the fumarole is used to generate a main power, and the external windage airflow is used to generate an auxiliary power. The invention also discloses an automobile equipped with the wind air engine. The high pressure gas is taken as the power, there is non fuel-consumption, non exhaust gas and non hot gas discharge; the external windage airflow is received to drive the impellers to generate the auxiliary power, thus the external resistance force airflow when the automobile is running is translated into power slickly, it is capable of reducing energy resource consumption greatly, and improving a running speed of a power machine.

Owner:丛洋

Dry film developing solution for printed circuit board and preparation method of dry film developing solution

ActiveCN107340693AImprove stabilityReduce decomposition ratePhotosensitive material processingWater insolubleAgricultural engineering

The invention relates to the technical field of chemical engineering, in particular to a dry film developing solution for a printed circuit board and a preparation method of the dry film developing solution. The dry film developing solution for the printed circuit board, provided by the invention, is mainly prepared from potassium carbonate, sodium carbonate, sodium hypochlorite and water. The dry film developing solution for the printed circuit board, provided by the invention, has the advantages of high stability and low corrosion; meanwhile, the developing property of minute patterns can be maintained and fine patterns can be displayed; besides, residues and bubbles on a dry film can be reduced, so that the display quality of the patterns is ensured. Furthermore, the dry film developing solution for the printed circuit board, provided by the invention, has the advantages that the condition that water soluble organic polymer salts remained on the dry film are hard to clean can be prevented, the production of water insoluble polymers also can be prevented, and environmental pollution is reduced; the dry film developing solution is a green and environment-friendly dry film developing solution.

Owner:惠州威尔高电子有限公司

Production process of D-tryptophan

The invention discloses a production process of D-tryptophan. The production process comprises the following steps: dissolving medical-grade L-tryptophan; adding racemase to obtain a DL-tryptophan aqueous solution; and adding type-D acylase for resolution to directly obtain a product namely D-tryptophan. The production process disclosed by the invention is easily-available in raw materials, low in production cost, simple in process and mild in reaction condition, the yield reaches 90%, and the optical purity reaches 99%. The production process is mild in reaction, does not generate exhaust gas and wastewater, is not dangerous, can meet the requirements on current environmental protection and safety, and is green and safe in production, so that the D-tryptophan belongs to stage encouraged biological medicines.

Owner:南通荣泰生物科技有限公司

Cage type electric mini-tiller and application thereof

InactiveCN103797908AReduce volumeReduce weightTilling equipmentsAgricultural engineeringMotive power

The invention discloses a cage type electric mini-tiller. The cage type electric mini-tiller comprises a machine frame, a machine head, a power mechanism, a transmission mechanism and executing mechanisms. The executing mechanisms are symmetrically distributed at the two ends of the machine head. A tillage wheel axle is perpendicular to the upper surface of an outer shell, and the tillage wheel axle is fixed inside the outer shell through an upper end locating bearing of the tillage wheel axle and a lower end locating bearing of the tillage wheel axle. A tillage wheel axle chain wheel and a tillage wheel disk are coaxially connected, are fixed on the tillage wheel axle and can rotate freely. The tillage wheel axle chain wheel and a driving chain wheel are connected in a meshed mode through a transmission chain. The tillage wheel disk is placed outside the outer shell, and the tillage wheel disk is fixedly provided with a plurality of cylindrical tillage wheel teeth. The cage type electric mini-tiller has the advantages of being small in size, low in weight, low in noise, free of tail gas, suitable for tillage operations such as plowing and soil loosening in small land blocks and in a room, and the like.

Owner:东莞开拓机械制造有限公司 +1

Highly-absorbent negative-iron dust-free paper made with dry method and production process thereof

InactiveCN101519855AGuaranteed uniformityHigh tensile strengthNatural cellulose pulp/paperWood working apparatusFiberElectricity

The invention relates to a highly-absorbent negative-iron dust-free paper made with a dry method, which is made up of 60-90 percent of anhydrous wood pulp, 5-25 percent of super absorbent polymer (SAP) and 5-15 percent of negative-iron generation powder. The highly-absorbent negative-iron dust-free paper is made with a dry method comprising the steps of dispersing the napped wood pulp, mixing loose polyethylene chemical fiber with the napped wood pulp, spraying and jetting the mixed loose polyethylene chemical fiber and the napped wood pulp on the mesh belt of a paper making machine under vacuum condition, spraying and jetting the SAP and the negative-iron generation powder through a SAP metering and adding device to shape paper, forming the paper by a reheating prepressing roll, embossing and compacting the paper, spaying gel on the paper in an atomizing way, and drying the paper with hot blast. The highly-absorbent negative-iron dust-free paper made with a dry method can improve the menstrual blood absorbing and keeping capacity by 2 to 10 times, generate 1,500 to 4,500 negative irons and play the role of highly absorbing and keeping the menstrual blood, relieving uneasiness, killing bacteria, diminishing inflammation and improving health of women, is applicable to bedridden patients for an extended time, paper diapers, wet tissues, toilet wet paper, and the like and causes no sewage or waste gas when heated by electricity or heat-conducting oil in the production process.

Owner:杨建文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com