Formula and production method of pharmaceutical neutral borosilicate glass tube

A technology of neutral borosilicate glass and its production method, which is applied in the field of production of glass pharmaceutical tubes, can solve the problems of high precipitation of alkali metals and delamination, and achieve high product quality, small footprint, control and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

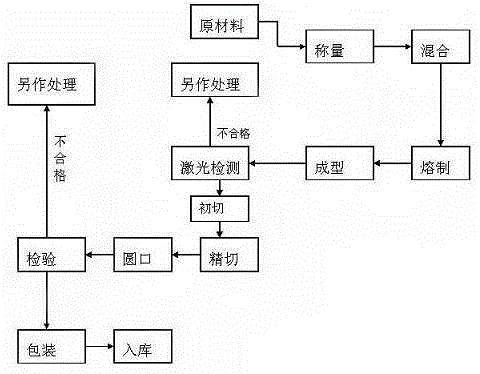

Method used

Image

Examples

Embodiment 1

[0047] A formulation of a neutral borosilicate glass medicinal tube, comprising the following components in parts by weight: 260 parts of quartz sand, 14 parts of lepidolite, 25 parts of aluminum hydroxide, 3 parts of fluorite, 80 parts of borax pentahydrate, and 4.5 parts of soda ash , 9 parts of sodium nitrate, 3 parts of potassium carbonate, 4.5 parts of barium carbonate, 4 parts of composite glass clarifying agent, and 120 parts of cullet; calculate the consumption of various raw materials according to the ratio, accurately weigh, and mix uniformly to form a batch. The uniformity of the batch is greater than 96%.

[0048] The composite glass clarifying agent is selected from YS-C type, produced by Jiangyin Inorganic Chemical Factory.

[0049] The expansion coefficient of cullet is 50-52, and the diameter is 10.0mm-35.0mm.

[0050] Put the prepared batch materials into the dodecagonal electric melting furnace. In the high-temperature melting furnace, it is necessary to go ...

Embodiment 2

[0053] A formulation of a neutral borosilicate glass medicinal tube, comprising the following components in parts by weight: 270 parts of quartz sand, 16 parts of lepidolite, 31 parts of aluminum hydroxide, 4 parts of fluorite, 93 parts of borax pentahydrate, and 5.2 parts of soda ash , 10.5 parts of sodium nitrate, 3.8 parts of potassium carbonate, 4.9 parts of barium carbonate, 4.5 parts of composite glass clarifying agent, and 130 parts of cullet; calculate the consumption of various raw materials according to the ratio, accurately weigh, and mix uniformly to form a batch. The uniformity of the batch is greater than 98%.

[0054] The composite glass clarifying agent is selected from YS-C type, produced by Jiangyin Inorganic Chemical Factory.

[0055] The expansion coefficient of cullet is 50-52, and the diameter is 10.0mm-35.0mm.

[0056] Put the prepared batch materials into the dodecagonal electric melting furnace. In the high-temperature melting furnace, it is necessary...

Embodiment 3

[0059] A formula for a neutral borosilicate glass medicinal tube, comprising the following components in parts by weight: 280 parts of quartz sand, 18 parts of lepidolite, 35 parts of aluminum hydroxide, 5 parts of fluorite, 100 parts of borax pentahydrate, and 6 parts of soda ash , 12 parts of sodium nitrate, 4.5 parts of potassium carbonate, 5.5 parts of barium carbonate, 5 parts of composite glass clarifying agent, and 140 parts of cullet; calculate the consumption of various raw materials according to the ratio, accurately weigh, and mix uniformly to form a batch. The uniformity of the batch is greater than 95%.

[0060] The composite glass clarifying agent is selected from YS-C type, produced by Jiangyin Inorganic Chemical Factory.

[0061] The expansion coefficient of cullet is 50-52, and the diameter is 10.0mm-35.0mm.

[0062] Put the prepared batch materials into the dodecagonal electric melting furnace. In the high-temperature melting furnace, it is necessary to go thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com