Wind air engine and automobile

An engine and power technology, applied in the field of machinery, can solve problems such as lack of driving speed, and achieve the effect of shortening the injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

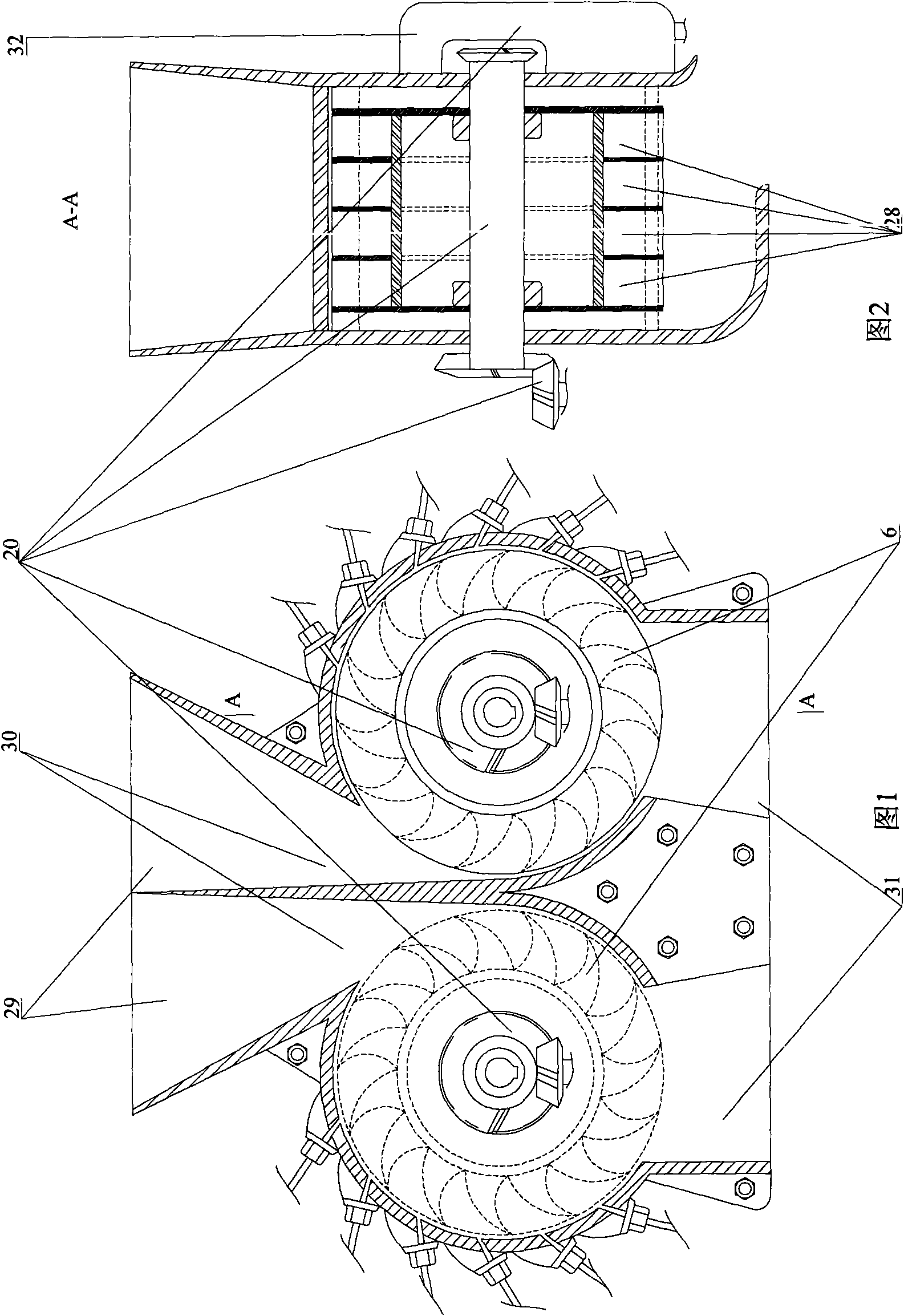

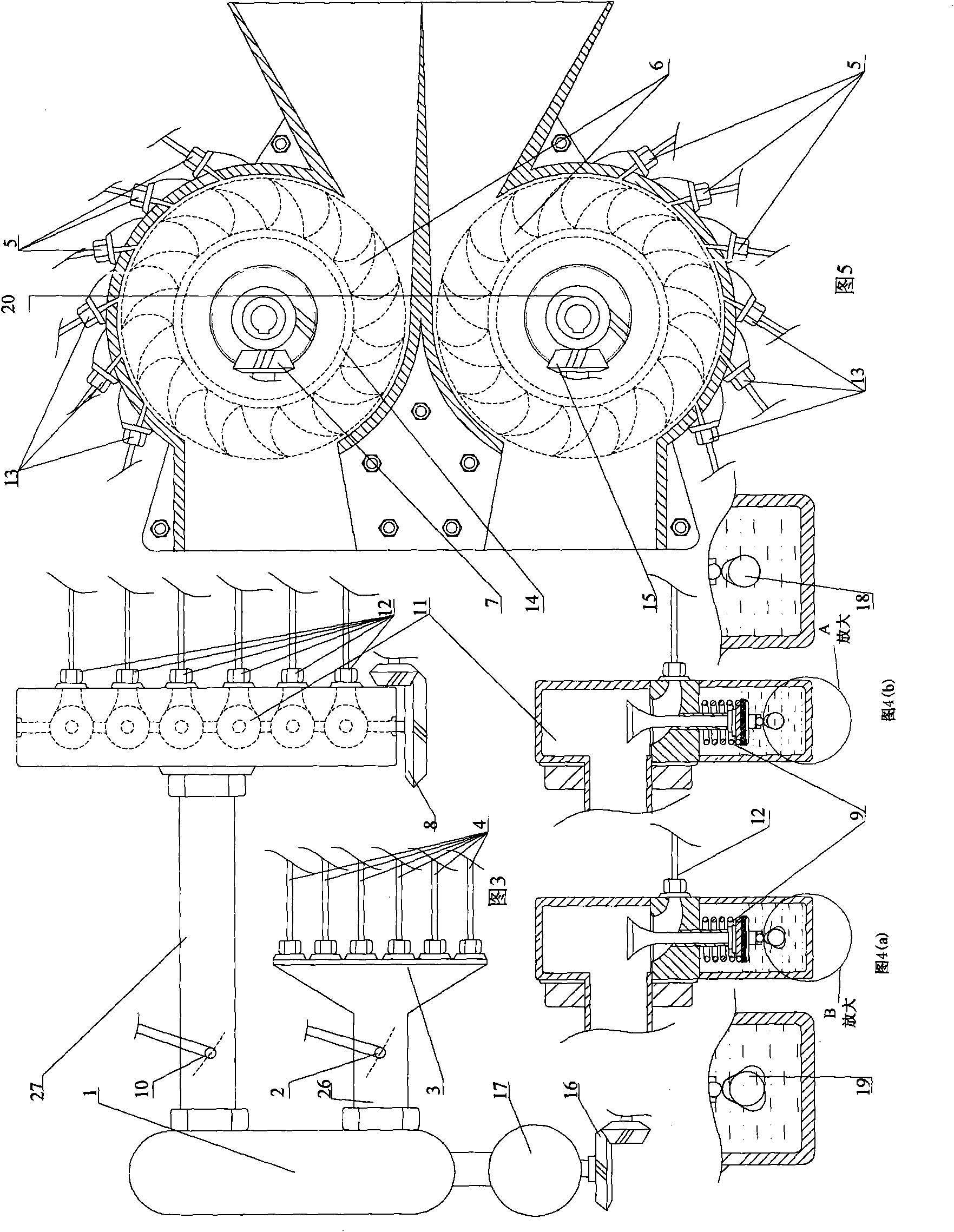

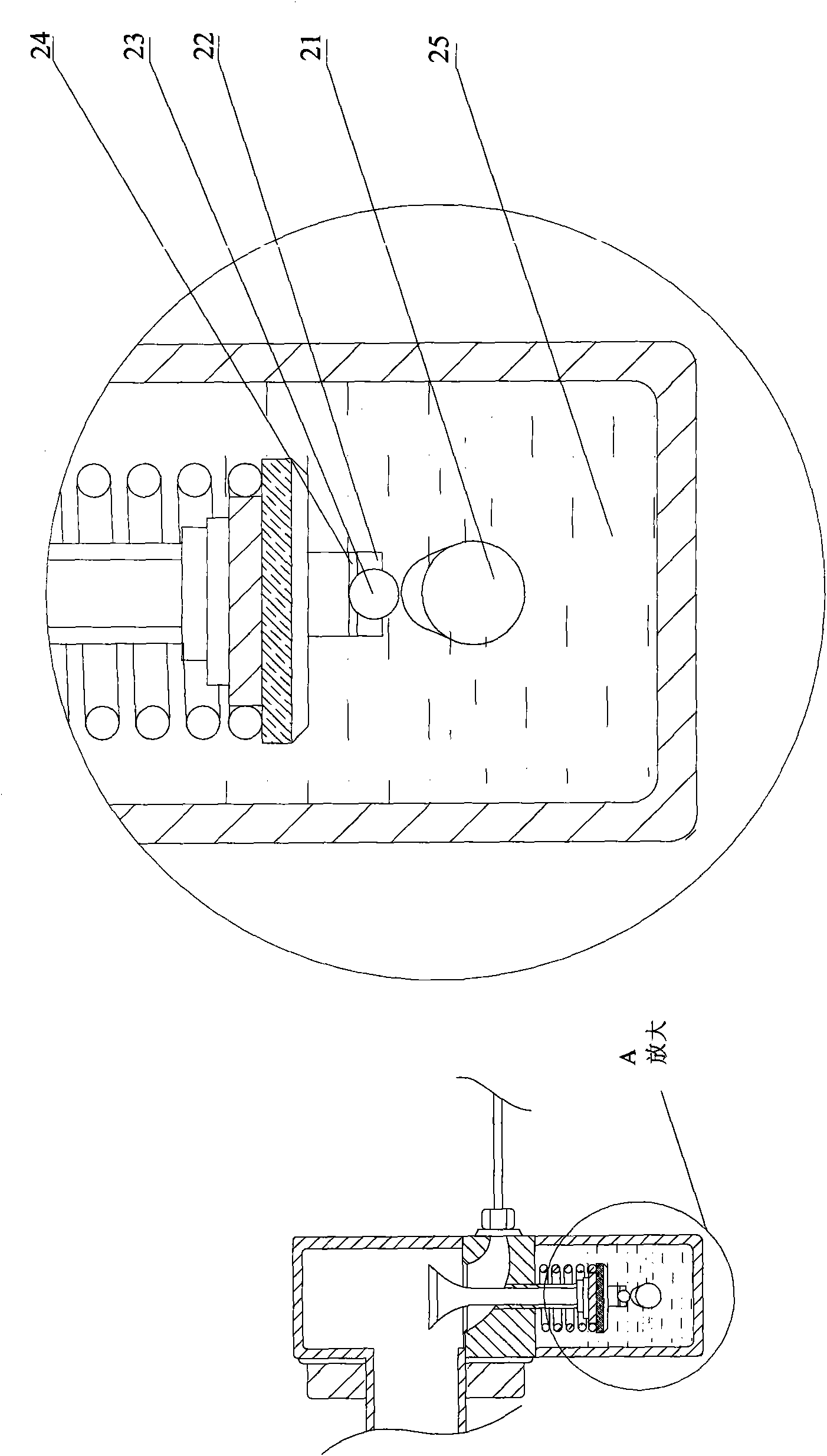

[0041]In the figure, wind engine is made up of following mechanism and system: wind engine 20 is made up of the outer port 29 of directional cylindrical air inlet, the inner mouth 30 of directional cylindrical air inlet, impeller chamber 28, impeller 6, impeller flywheel 14. The left impeller main shaft auxiliary power bevel gear 7, the right impeller main shaft auxiliary power bevel gear 15, the central main power output gearbox 32 and the air outlet 31 and other mechanisms; the wind engine high-pressure gas regeneration reserve supply system includes: storage Gas tank 1, high-pressure air compressor 17, transmission bevel gear 16 connected to high-pressure air compressor, etc.; wind engine starting acceleration jet system, including: central controllable high-pressure gas starting accelerator 2, distributor 3, connecting distributor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com