Novel carbon fiber composite electric heating film and preparation method thereof

A carbon fiber and electric heating film technology, applied in the field of new carbon fiber composite electric heating film and its preparation, can solve the problems of polluted environment, difficult to measure heat supply, short service life, etc., and achieve the effects of simple preparation process, less energy loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

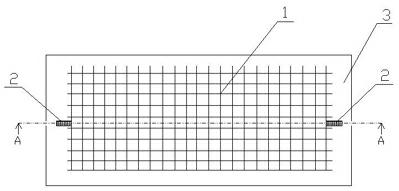

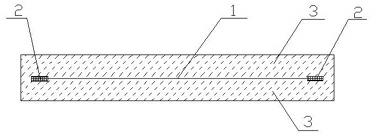

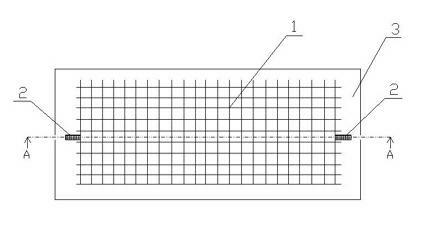

Image

Examples

Embodiment 1

[0022] The novel carbon fiber composite electrothermal film of this embodiment uses a carbon fiber weaving machine to weave polyacrylonitrile-based carbon fibers into a network structure layer, and connects metal electrodes at both ends; 3 N 4 The modified polycarbonate (PC) is melted, and the melted liquid is coated with a network structure layer by a film coating machine; after coating, it is solidified and shaped by a molding machine, and then dried by a dryer, which can be A new type of carbon fiber composite electrothermal film with a length of 560 mm, a width of 400 mm and a thickness of 0.7 mm was prepared.

[0023] The insulating and thermally conductive plastic used in this embodiment is Si 3 N 4 Modified polycarbonate, the composition of the insulating and heat-conducting plastic is as follows (by weight):

[0024] Polycarbonate 48%

[0026] E-glass fiber 10%

[0027] Silane coupling agent 1%

[0028] Vinyl silicone oil 1%

...

Embodiment 2

[0034] The new carbon fiber composite electric heating film of this embodiment uses a carbon fiber weaving machine to weave polyacrylonitrile-based carbon fibers into a network structure layer, and connects metal electrodes at both ends; uses a hot melt machine to modify the insulating and heat-conducting plastic film, namely MgO The polyphenylene sulfide (PPS) is melted, and the molten liquid is coated with the mesh structure layer by a coating machine; after coating, it is shaped by a molding machine, and then dried by a dryer, and a length of 550mm can be obtained. , a new type of carbon fiber composite electric heating film with a width of 200mm and a thickness of 0.7mm.

[0035] The insulating and heat-conducting plastic used in this embodiment is MgO-modified polyphenylene sulfide, and the composition of the insulating and heat-conducting plastic is as follows (by weight):

[0036] Polyphenylene sulfide 20%

[0038] E-glass fiber 5%

[003...

Embodiment 3

[0048] The novel carbon fiber composite electrothermal film of this embodiment uses a carbon fiber braiding machine to weave polyacrylonitrile-based carbon fibers into a network structure layer, and connects metal electrodes at both ends; 2 o 3 The modified polycarbonate (PC) is melted, and the molten liquid is coated with a network structure layer by a film coating machine; after coating, it is shaped by a molding machine, and then dried by a dryer to obtain A new type of carbon fiber composite electric heating film with a length of 550mm, a width of 400mm, and a thickness of 0.7mm.

[0049] The insulating and thermally conductive plastic used in this embodiment is Al 2o 3 Modified polycarbonate, the composition of the insulating and heat-conducting plastic is as follows (by weight):

[0050] Polycarbonate 52%

[0051] Alumina 35%

[0052] E-glass fiber 10%

[0053] Silane coupling agent 1%

[0054] Modified Ethylene Bis Fatty Acid Amide 1%

[0055] Stearate 1%

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com