Flexible water-jet guided laser micro-machining system and method

A flexible and micro-machining technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large overall structure and lack of processing flexibility, and achieve the effect of simple connection, less microcracks, and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

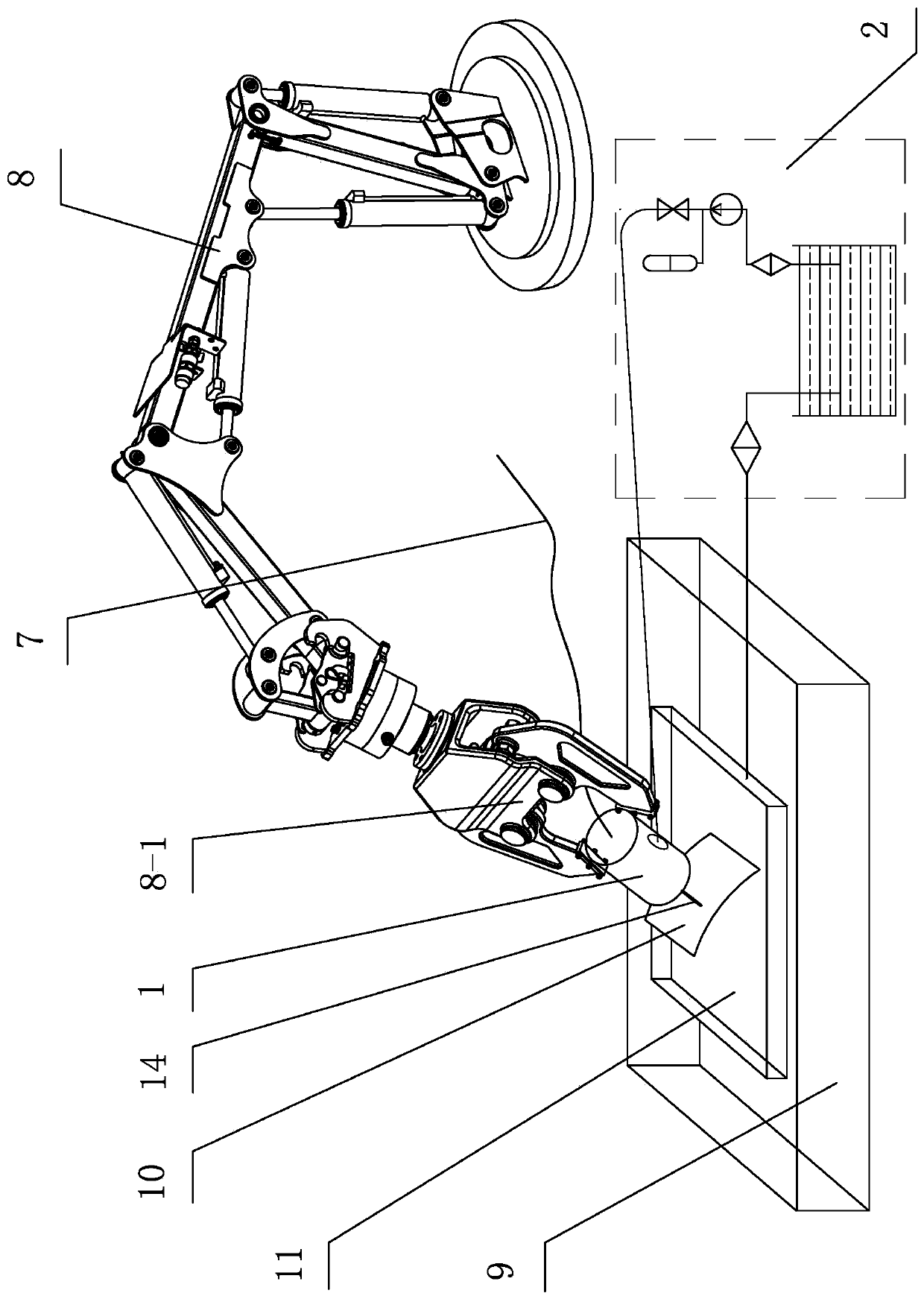

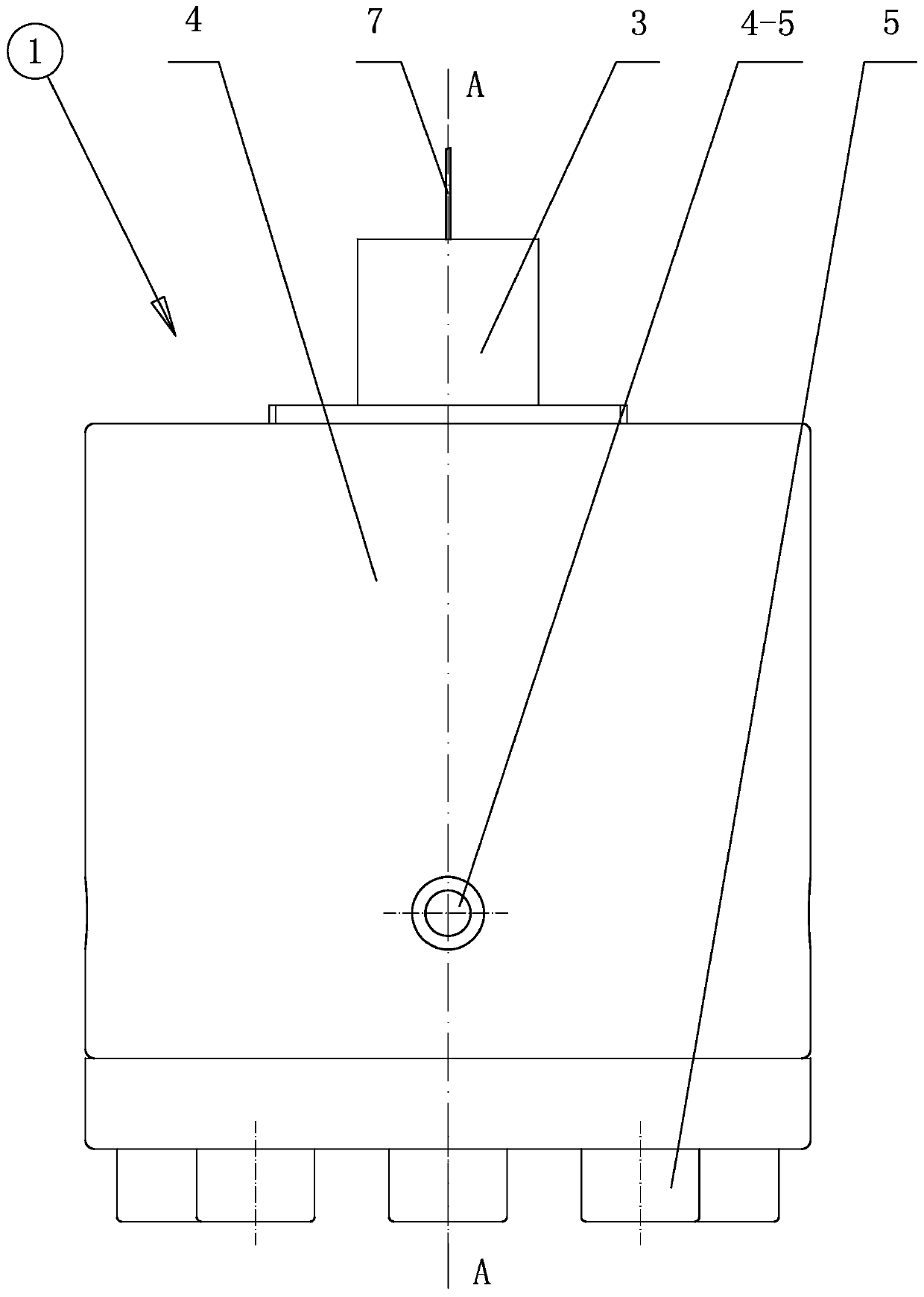

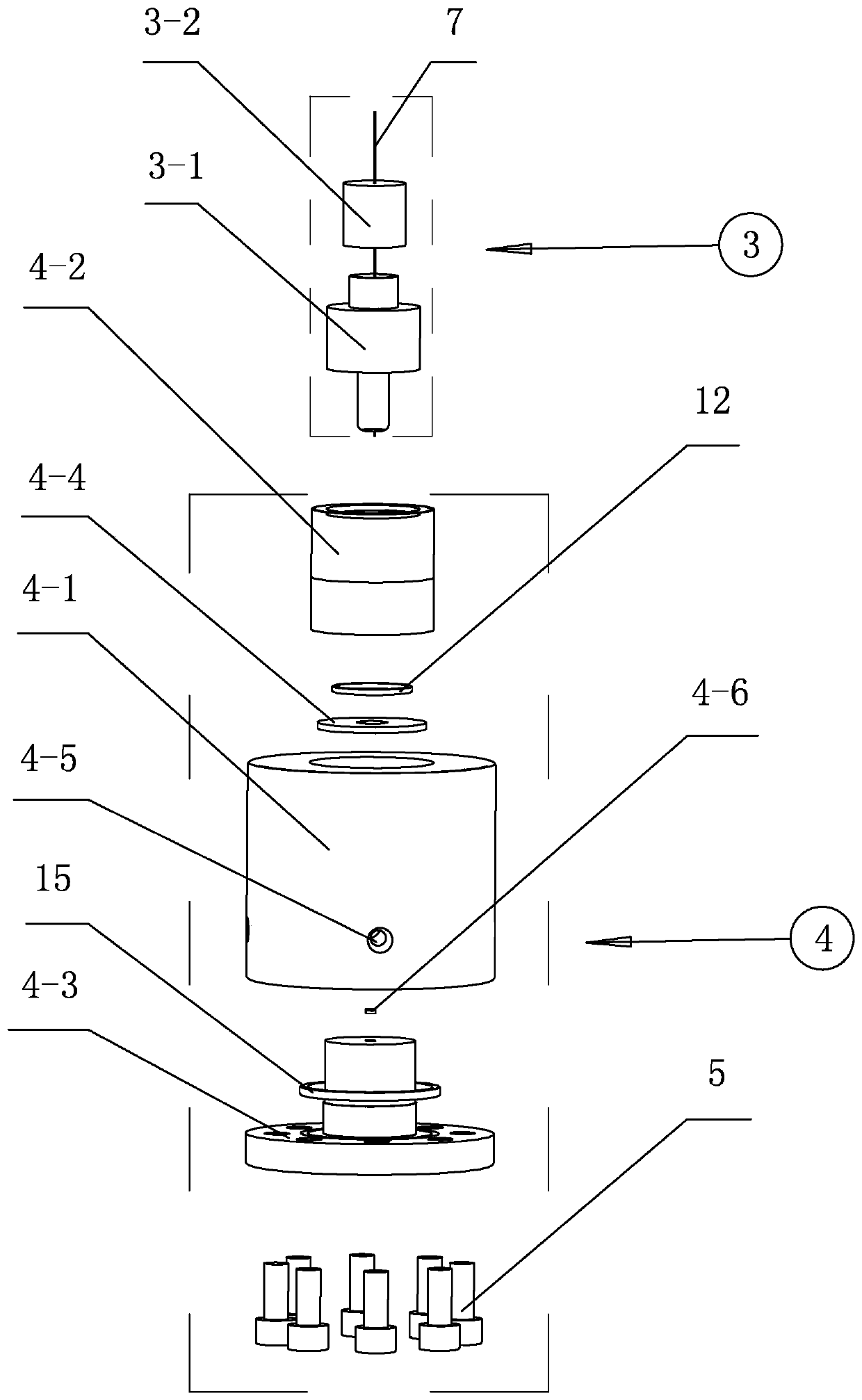

[0032] The water-conducting laser flexible micromachining system of the present invention includes a robot 8, an optical fiber transmission coupling unit 1, a workbench unit and a high-pressure liquid supply unit 2, and the robot 8, workbench unit and high-pressure liquid supply unit 2 are all existing Mature technology, the optical fiber transmission coupling unit 1 is the core of the present invention, including an assembled optical fiber fixed transfer module 3 and a beam coupling transmission module 4, such as figure 1 , figure 2 , image 3 shown.

[0033] The beam coupling transmission module 4 includes a coaxial coupling body 4-1, an upper pressure head 4-2, a pressure plate 4-4 and a lower nozzle seat 4-3, and a coaxial coupling body 4-1 is provided inside. Connected upper fine thread inner hole and lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com