Patents

Literature

90results about How to "Realize flexible control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

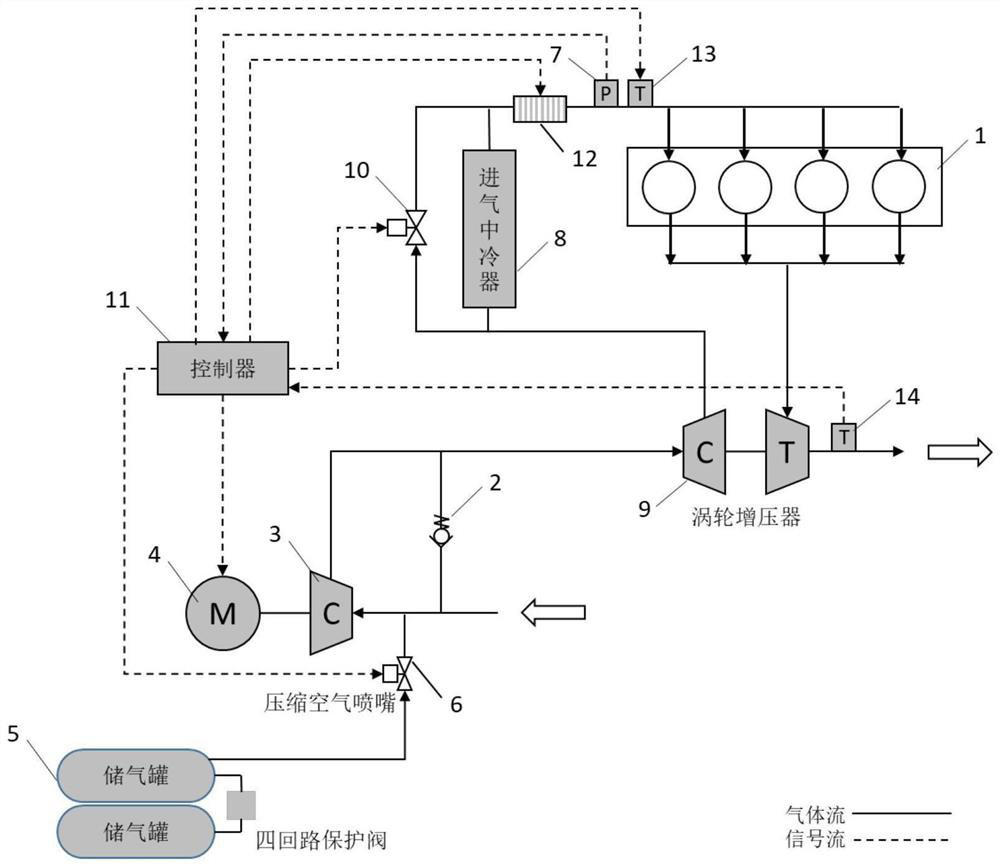

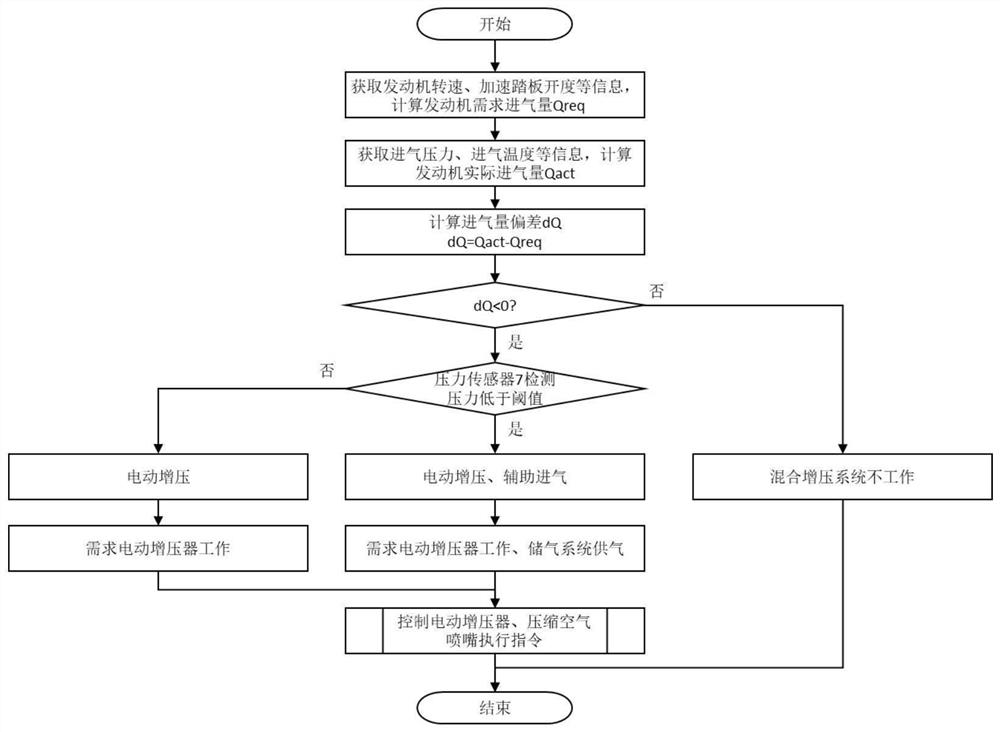

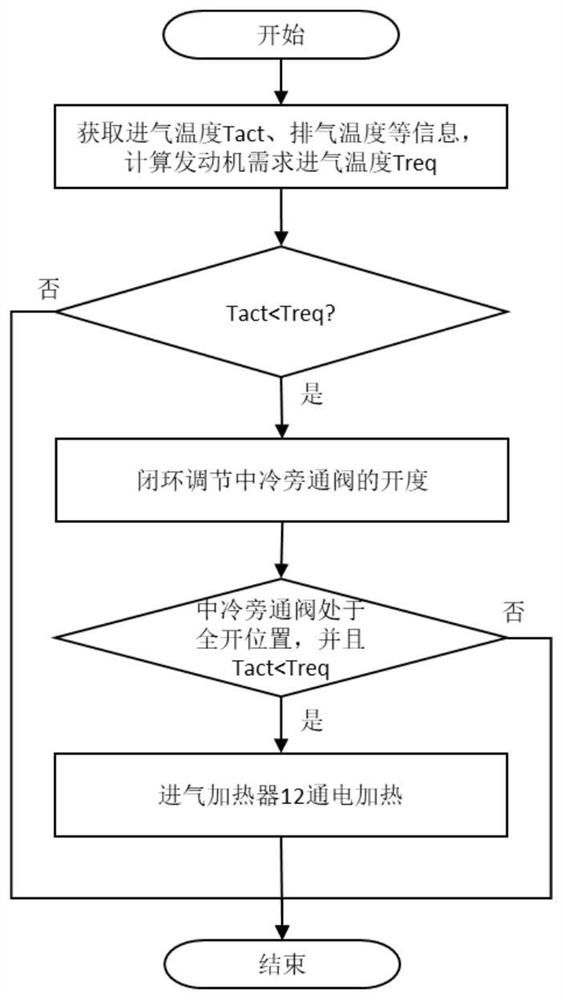

Multi-stage supercharging flexible air system with electric supercharging function for engine

ActiveCN112211717AIncrease intake air temperatureEmission reductionInternal combustion piston enginesEngine componentsIntercoolerMotronic

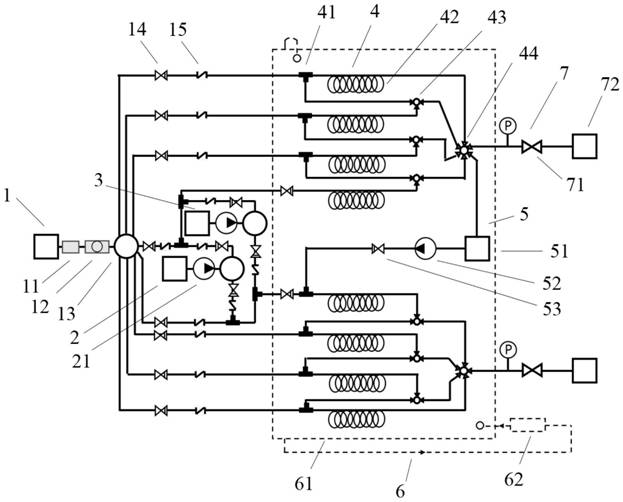

The invention provides a multi-stage supercharging flexible air system with an electric supercharging function for an engine. The multistage supercharging flexible air system involves an electric supercharger, the engine, a turbocharger, an air storage tank and a controller, wherein an air inlet communicates with the air inlet end of a first air compressor of the electric supercharger through a pipeline, the air inlet communicates with the air inlet end of a second air compressor of the turbocharger through a pipeline, and a one-way valve is arranged on the pipeline; the air outlet end of thefirst air compressor communicates with the air inlet end of the second air compressor through a pipeline; the air outlet end of the second air compressor communicates with an air inlet pipe of the engine through a pipeline via an air inlet intercooler and an air inlet heater; an air outlet pipe of the engine communicates with a turbine air inlet end of the turbocharger; the output end of the controller is electrically connected with a motor of the electric supercharger; the motor is used for driving the first gas compressor to operate; and a turbine of the turbocharger drives the second air compressor to operate through exhaust energy of the air outlet pipe of the engine.

Owner:DONGFENG COMML VEHICLE CO LTD

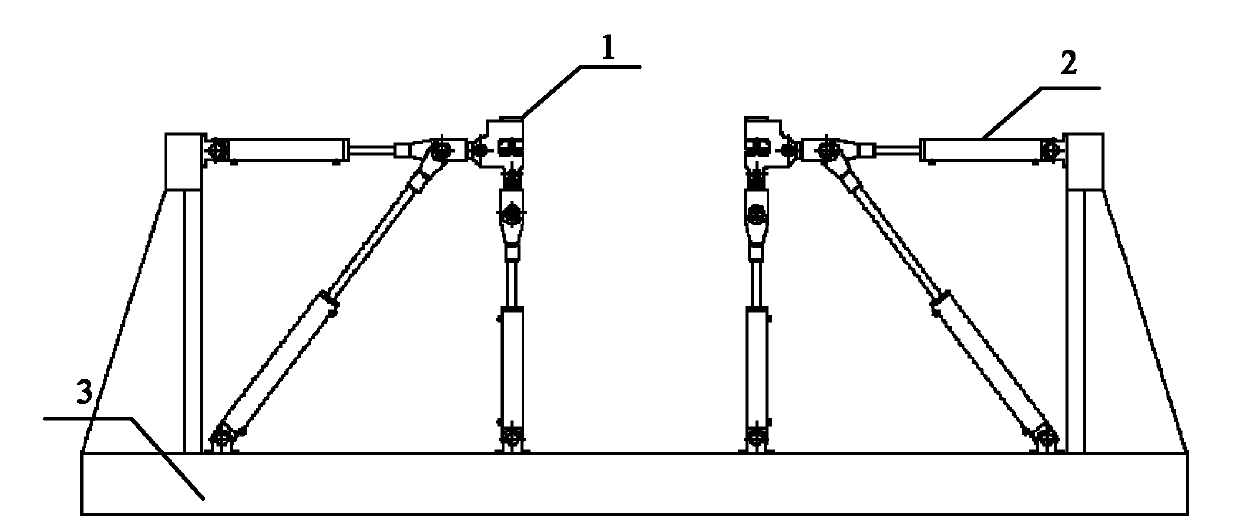

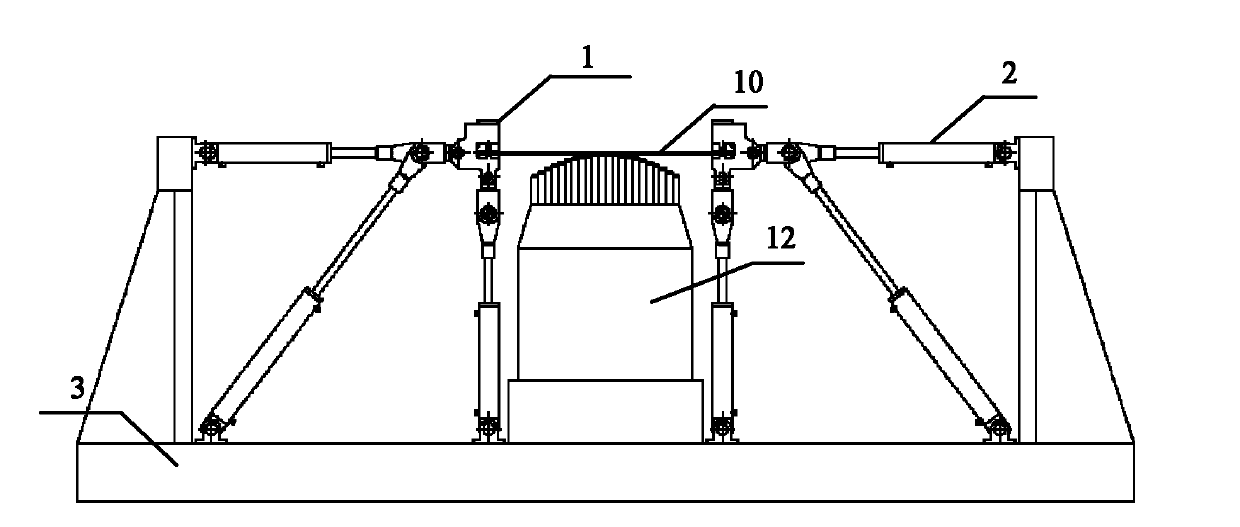

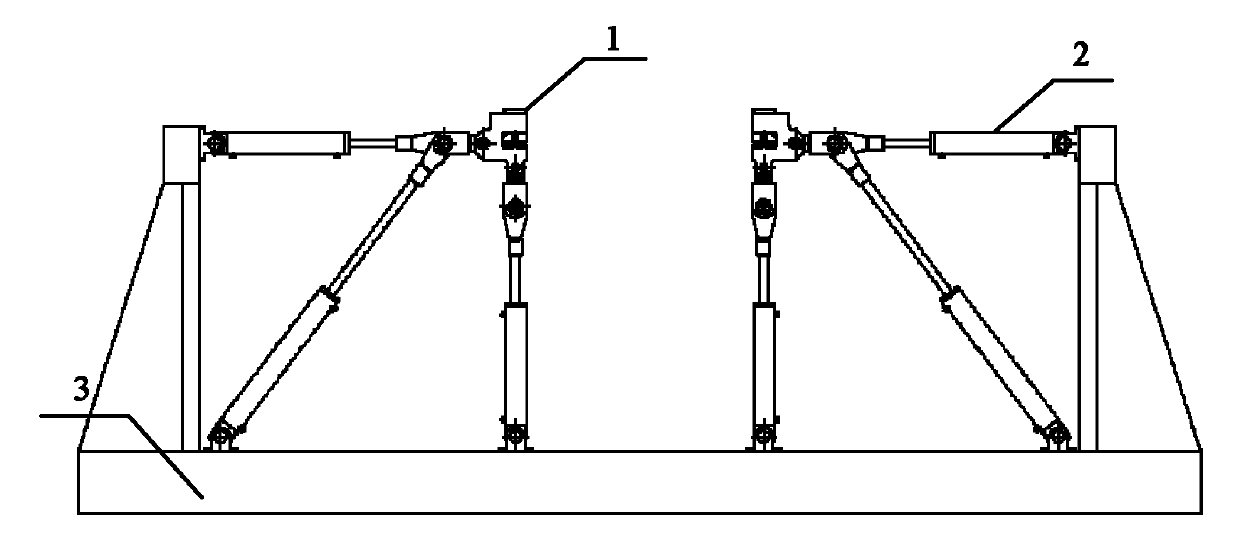

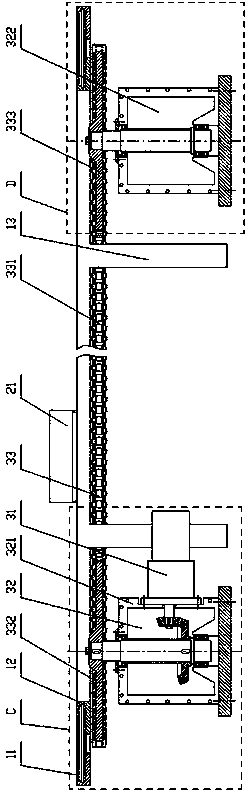

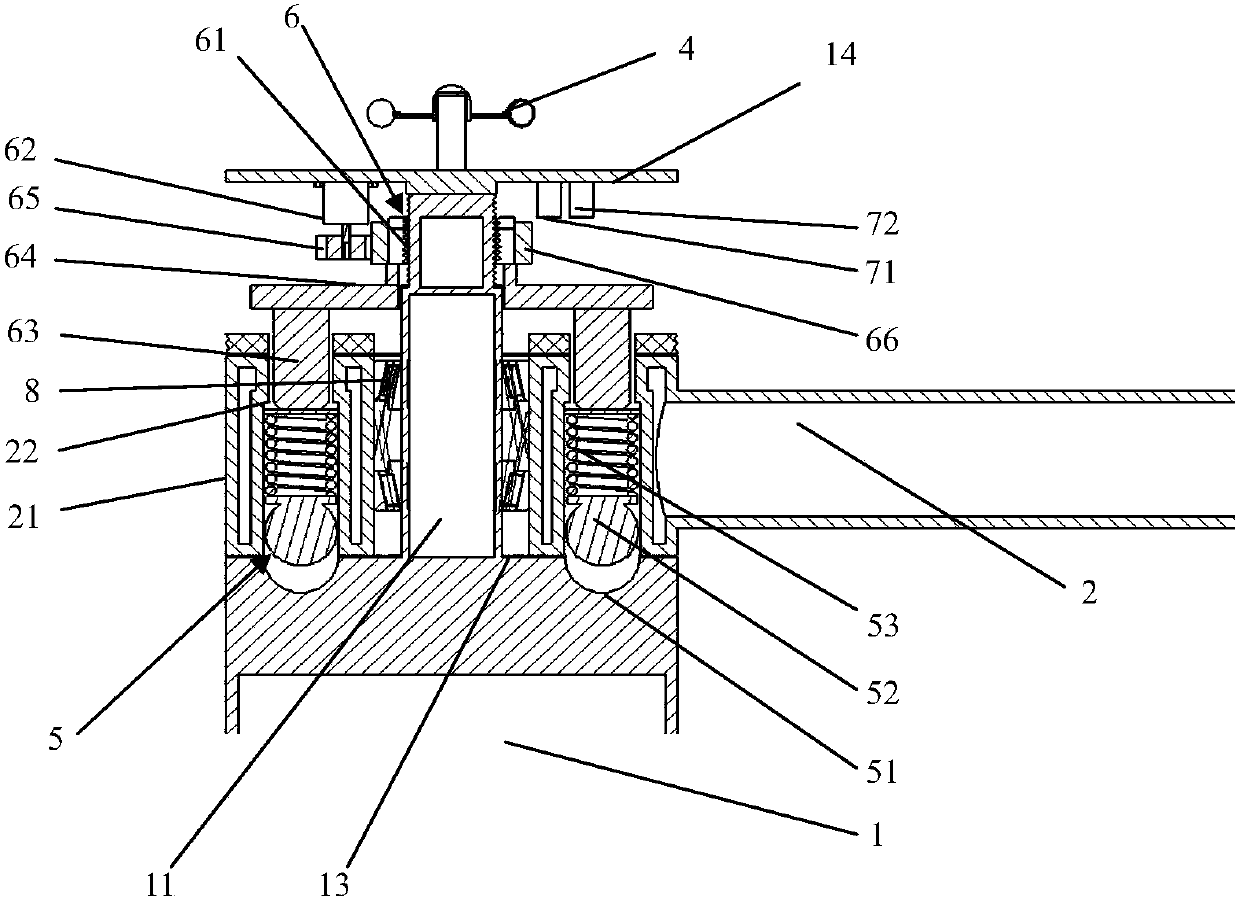

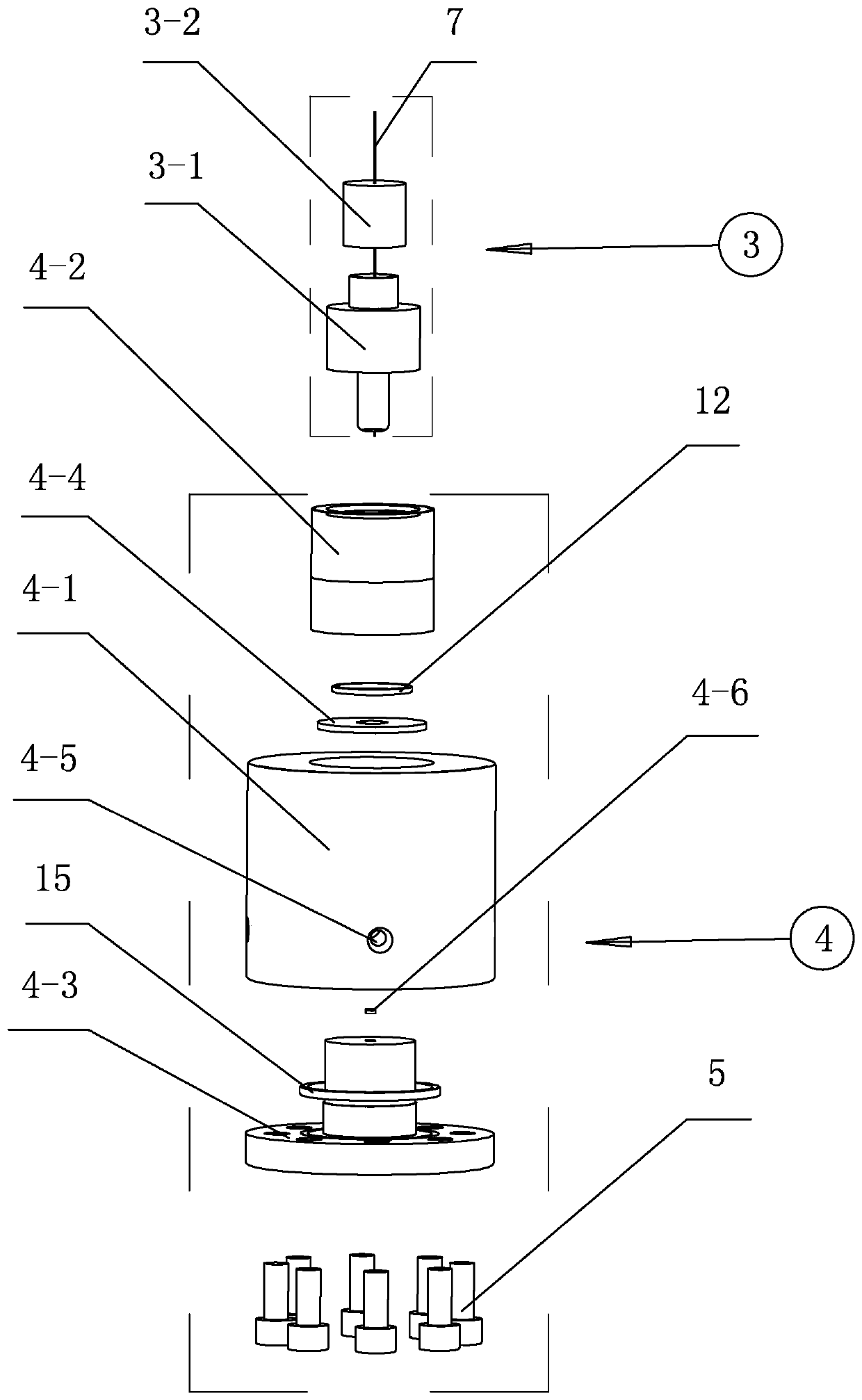

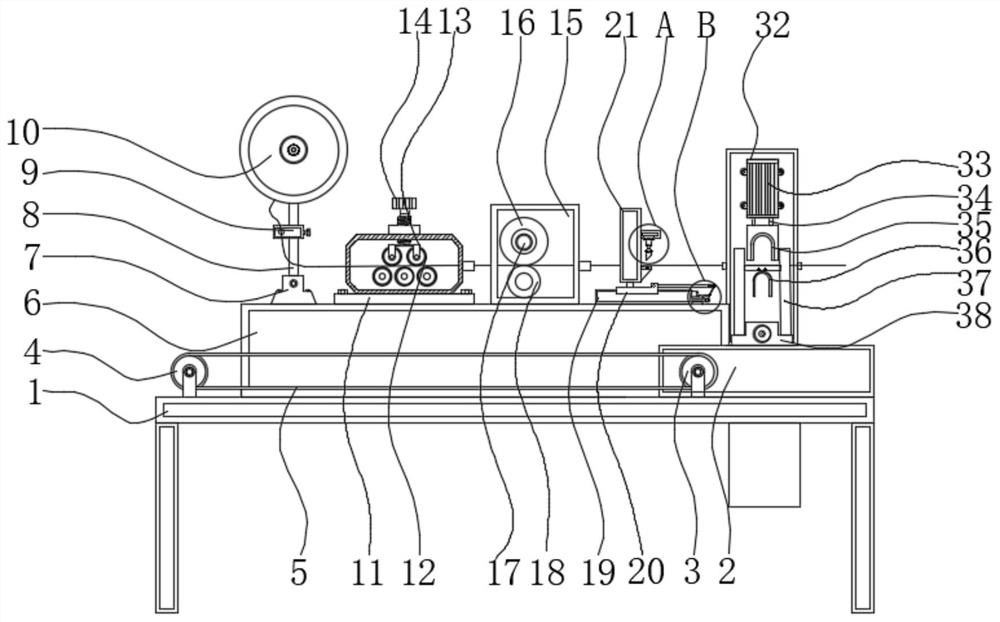

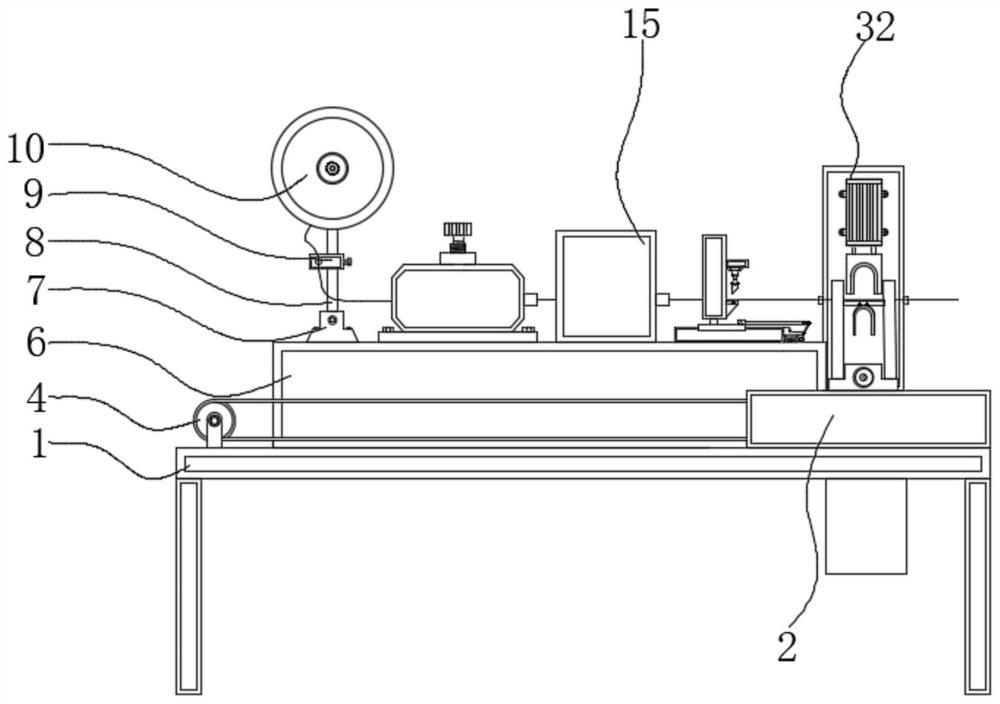

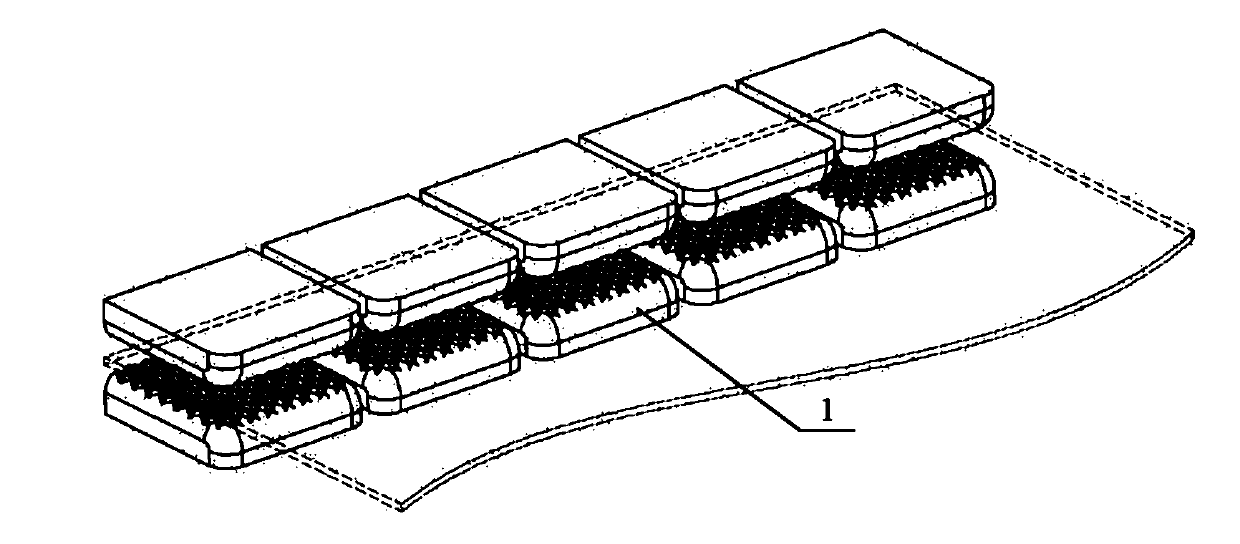

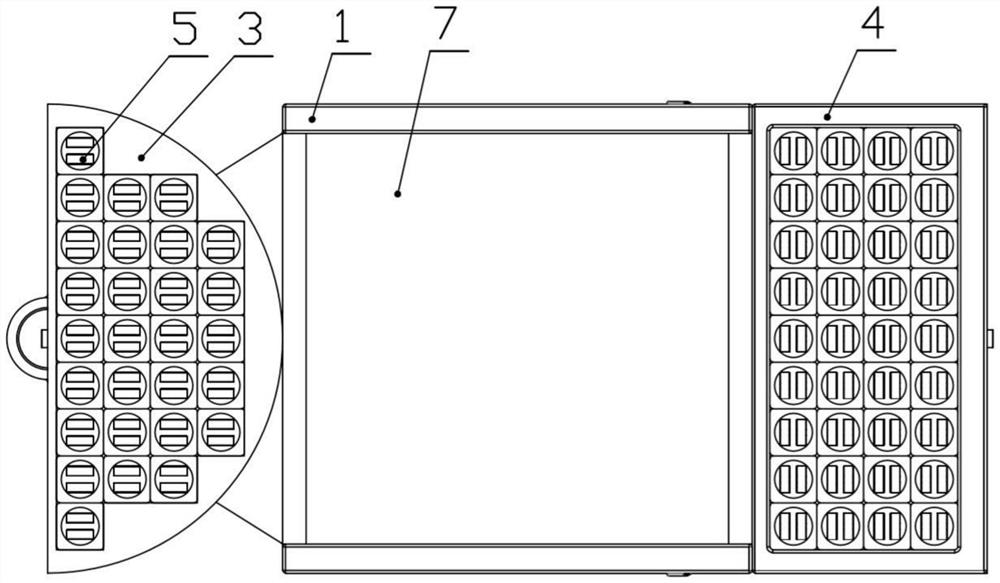

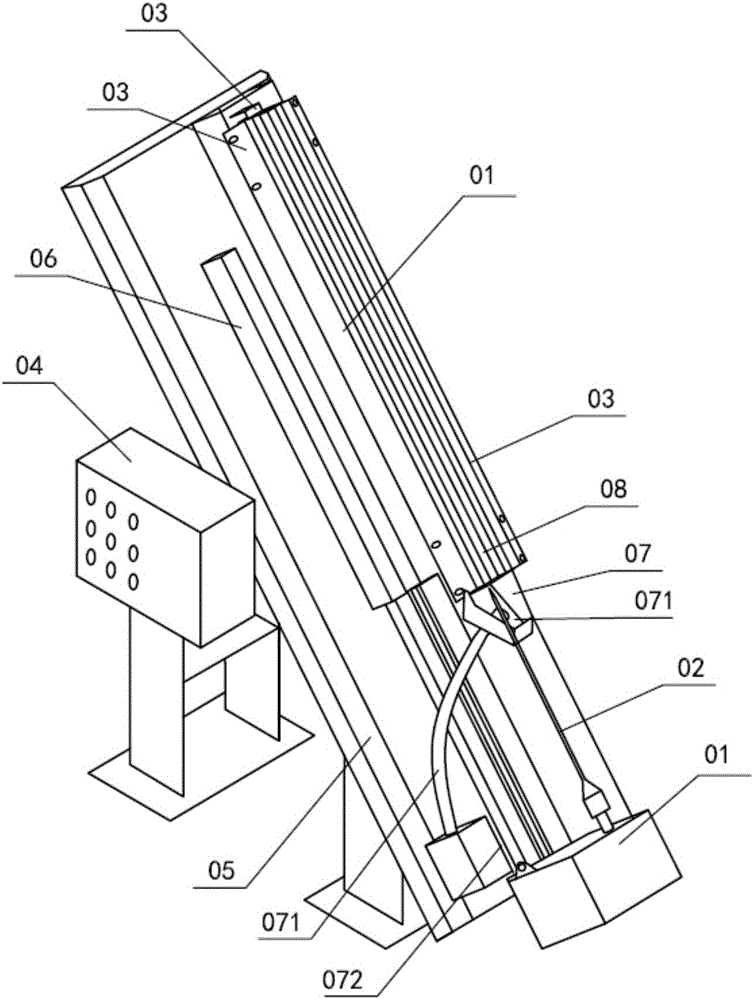

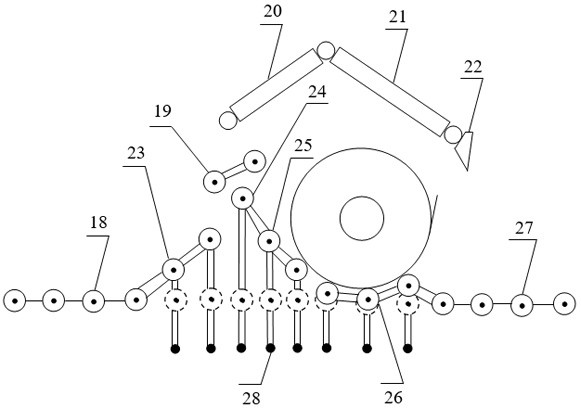

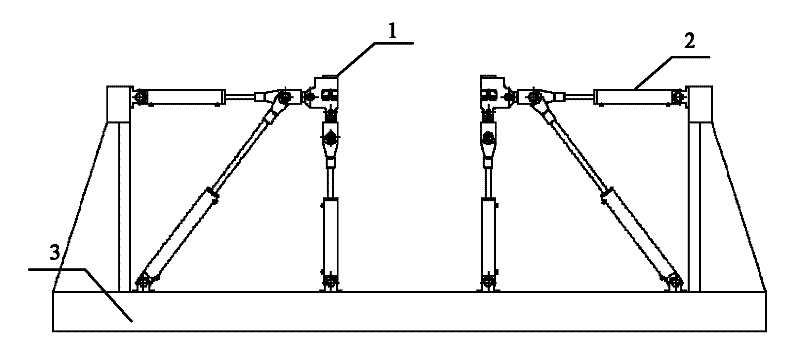

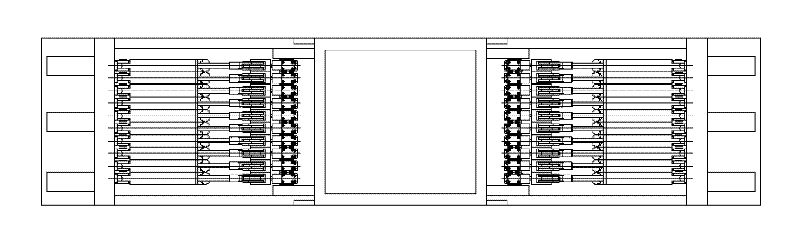

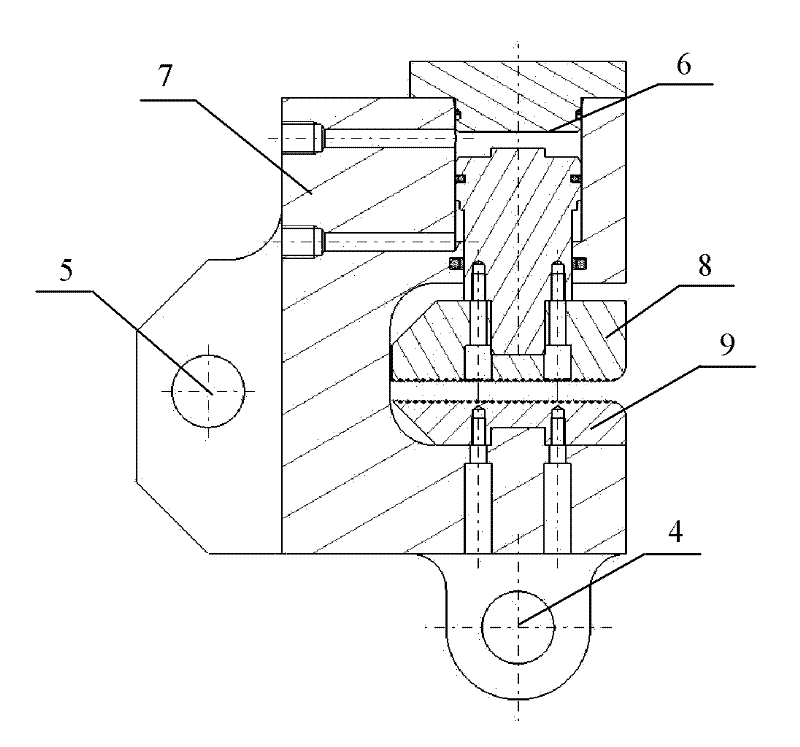

Multiclamp type stretch forming machine

The invention discloses a multiclamp type stretch forming machine and relates to plastic processing equipment for curve forming of plates, belonging to the field of mechanical engineering. The machine mainly comprises clamping mechanisms (1), a stretching mechanism (2) and a stand (3), wherein a row of clamping mechanisms (1) are respectively distributed at both sides of the stand (3); each clamping mechanisms (1) is provided with a lower connecting hole (4) and a rear connecting hole (5); and all the connecting holes are respectively connected with the stretching mechanism (2) by pin shafts or cardan joints. The machine can realize the flexible control of a plurality of clamps, ensure that a workpiece is more easily attached to a die in the stretching process, obviously improve the material utilization ratio of the workpiece and obtain higher workpiece forming effect.

Owner:长春瑞光科技有限公司

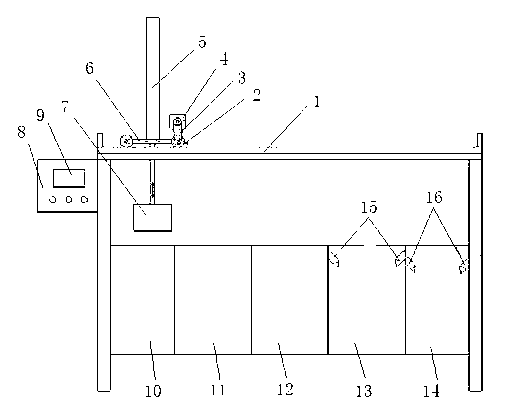

Automatic cleaning machine for workpieces

InactiveCN103302047AQuality improvementRealize automatic controlCleaning using liquidsControl theory

The invention discloses an automatic cleaning machine for workpieces. The automatic cleaning machine mainly comprises a truss type rack track, a trolley, a hopper, a lifting air cylinder and a servo motor, wherein wheels of the trolley are gear type wheels; the rack track is transversely arranged above a rinse tank; the trolley moves on the rack track through the gear type wheels; the lifting air cylinder and the servo motor are fixed on the trolley; the hopper loading the workpieces is suspended on the lifting air cylinder; the air cylinder is arranged perpendicular to the rinse tank, so that the workpiece hopper can move vertically; and the servo motor drives the trolley to locate and move through a synchronous belt. The automatic cleaning machine for the workpieces is simple in structure and low in cost, realizes the effects of high automation degree and controllable washing quality, and improves the production efficiency greatly.

Owner:ZHENJIANG DONGYI MACHINERY

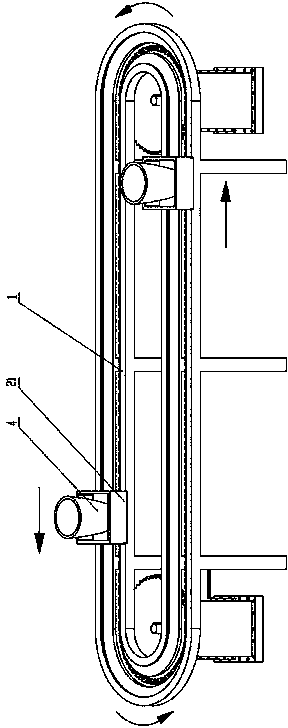

Flexile annular conveying device

ActiveCN103662616ARealize transmissionIncrease or decrease quantityConveyorsWorking environmentChain link

A flexible annular conveying device comprises a guide rail frame assembly (1), one or more self-adaptive guide material containing cart assemblies (2) and a power and transmission assembly (3). The self-adaptive guide material containing cart assemblies (2) are embedded into deep groove guide rails (14) of the guide rail frame assembly (1) through guide wheels (223) and connected with a chain (331) in the power and transmission assembly (3) through fixing connectors (213). Through the adoption of the technology, production materials can be conveyed efficiently, accurately and continuously, the flexible annular conveying device can well adapt to different work environments and conditions, material conveying work efficiency is effectively improved, and material conveying quality is guaranteed.

Owner:江苏宇腾物流有限公司

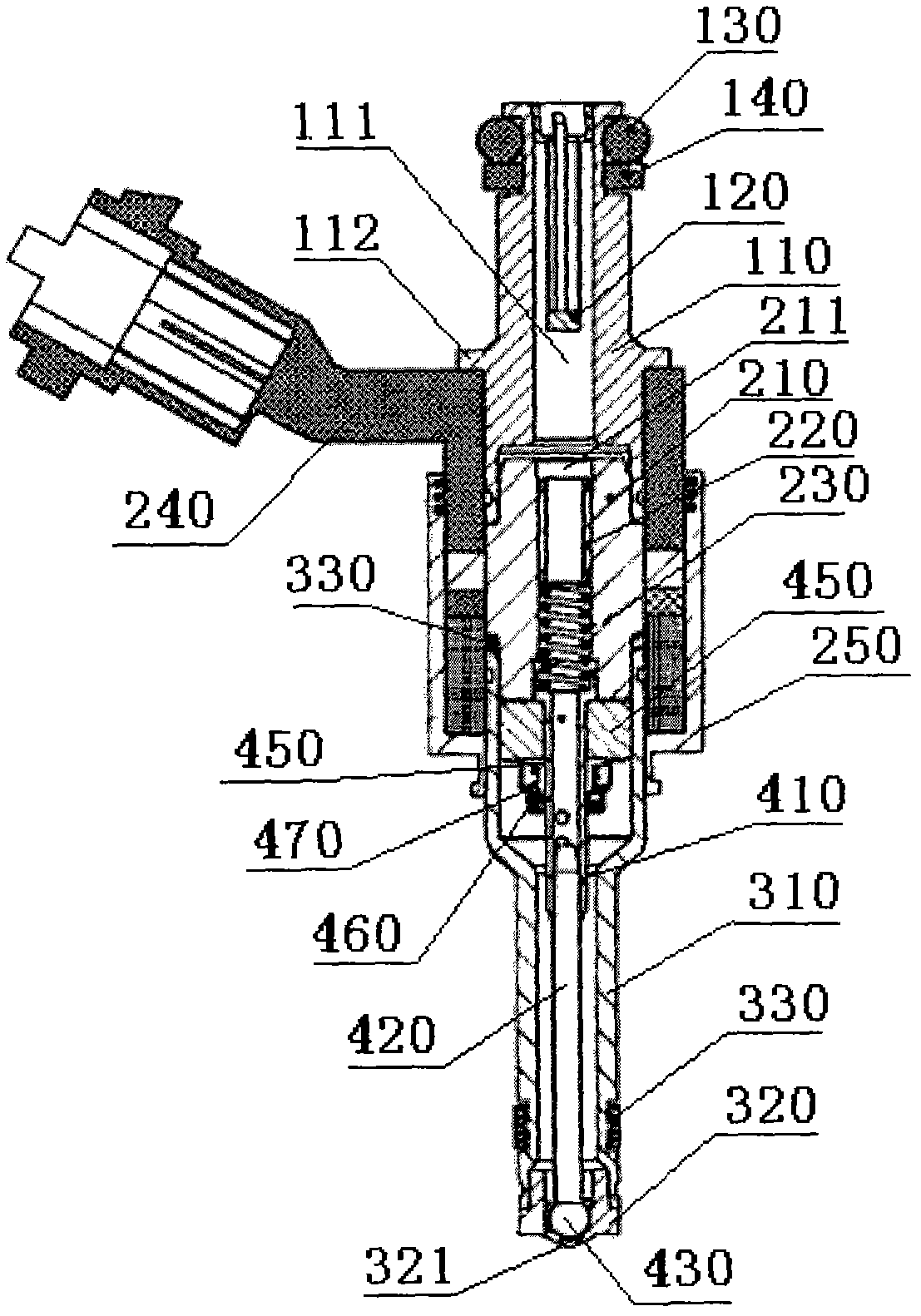

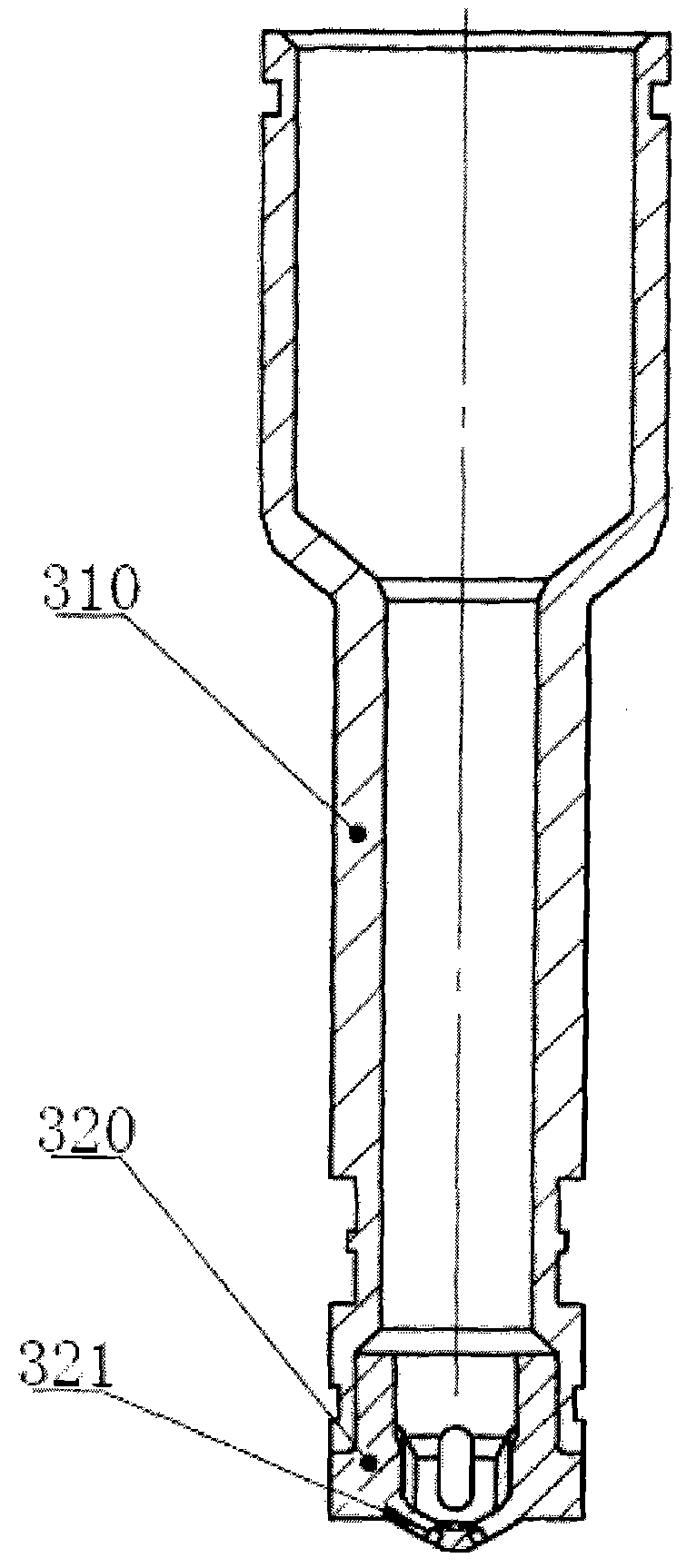

Gasoline direct spray oil sprayer

ActiveCN102003317APromote atomizationSimple enoughFuel injection apparatusMachines/enginesCombustion chamberSolenoid valve

The invention discloses a gasoline direct spray oil sprayer, which is arranged in a combustion chamber directly. The gasoline direct spray oil sprayer comprises an oil sprayer assembly, a needle valve component and an oil nozzle matching part, wherein the oil sprayer assembly comprises an oil filter component and a solenoid valve component; the needle valve component is arranged in the oil nozzle matching part; the solenoid valve component comprises an iron core, an electromagnet, a spring and a spring upper base, wherein the upper part of the iron core is connected with the oil filter component and the lower part of the iron core is connected with the oil nozzle matching part; the electromagnet is inserted from the small end of the oil nozzle matching part and is connected with the oil filter component; an axial inner bore serving as an oil duct is formed in the iron core; the spring upper base and the spring are arranged in the axial inner bore; the upper end of the spring is butted against the spring upper base, and the lower end of the spring is butted against the needle valve component; and an adjusting cushion block for adjusting the stroke of the needle valve component is arranged between the oil nozzle matching part and the iron core. The gasoline direct spray oil sprayer has good atomizing performance, simple structure, and low machining difficulty, can accurately control the oil spray amount, and is convenient to assembly.

Owner:NANYUE FUEL INJECTION SYST CO LTD

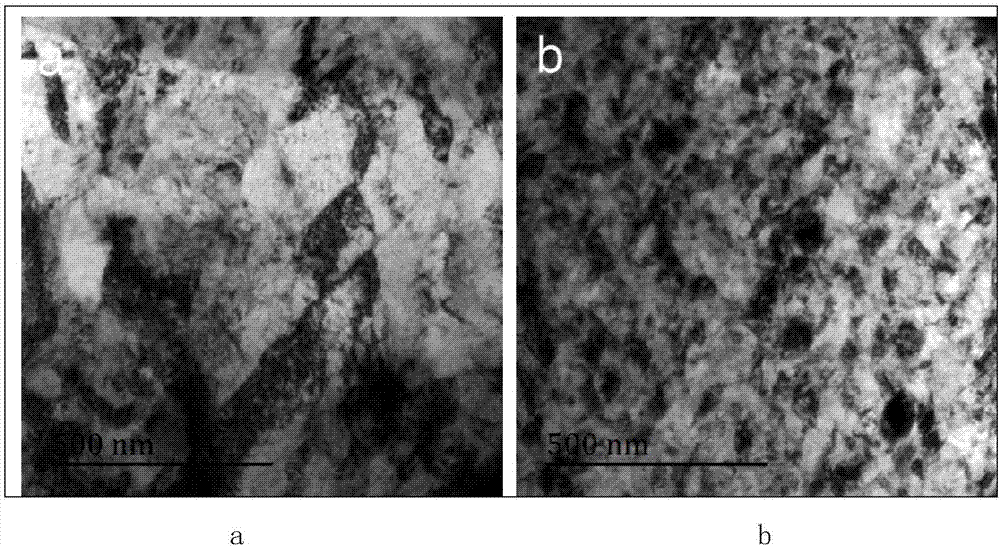

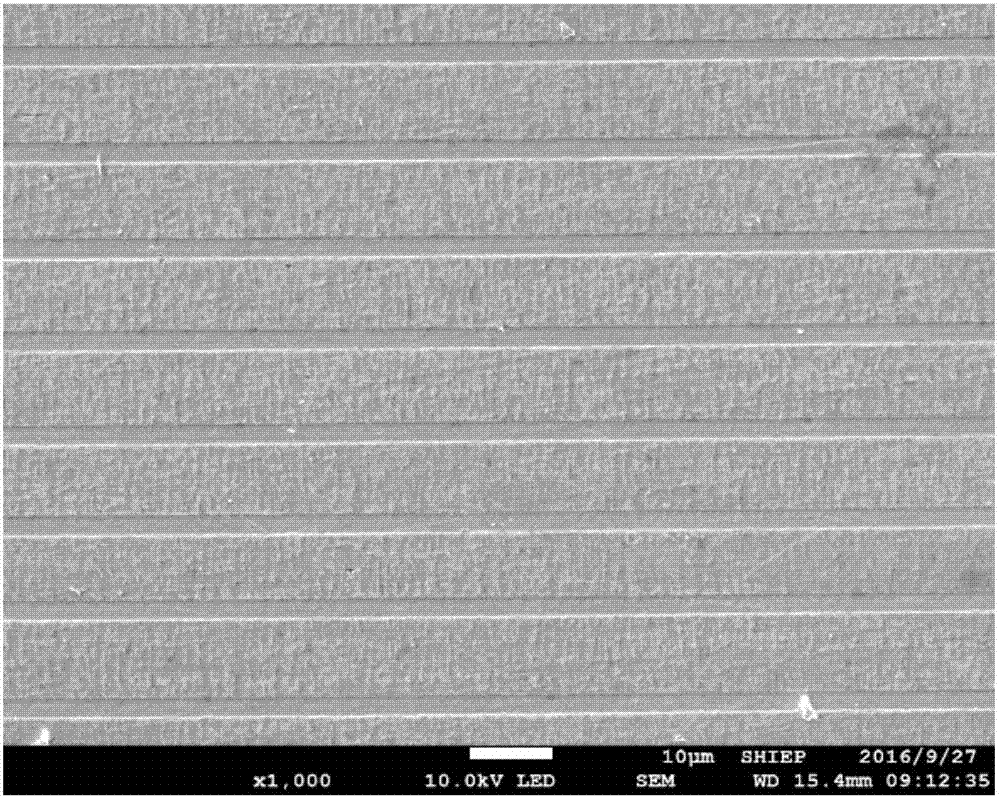

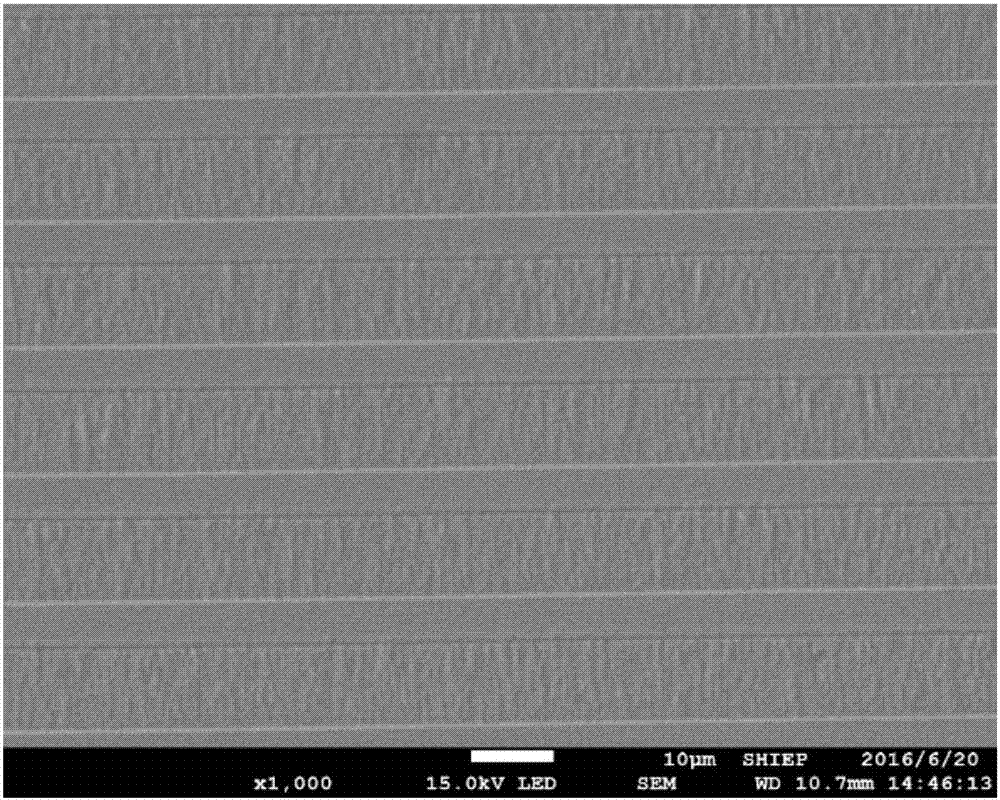

Preparation method of laminar composite nanostructured nickel

ActiveCN106929888AImprove mechanical propertiesMeeting high demands on mechanical propertiesMetallic materialsLayer thickness

The invention discloses a preparation method of laminar composite nanostructured nickel. A pretreated ordinary carton steel workpiece and a pure nickel plate are put in electrolyte consisting of 200-300 g of nickel sulfate, 30-40 g of nickel chloride, 30-40 g of boric acid, 2-8 g of sodium citrate, 2 g of composite additive and the balance of distilled water; the ordinary carbon steel workpiece, serving as a cathode, and the pure nickel plate, serving as an anode, are respectively connected with a negative pole and a positive pole of a direct-current voltage stabilization and current stabilization power supply; and circular alternating electrodeposition is performed by adopting two different current densities and the laminar composite nanostructured nickel alternately combined by two different grain layers is obtained. The preparation method realizes flexible control over the grain size and the layer thickness ratio of each single layer of the laminar composite nanostructured nickel plating layer through controlling two current densities and the deposition times under the two current densities. The prepared laminar composite nanostructured nickel is excellent in mechanical characteristic, can be used for a reinforced coating layer of a metal material, or serves as a high-performance structural material.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

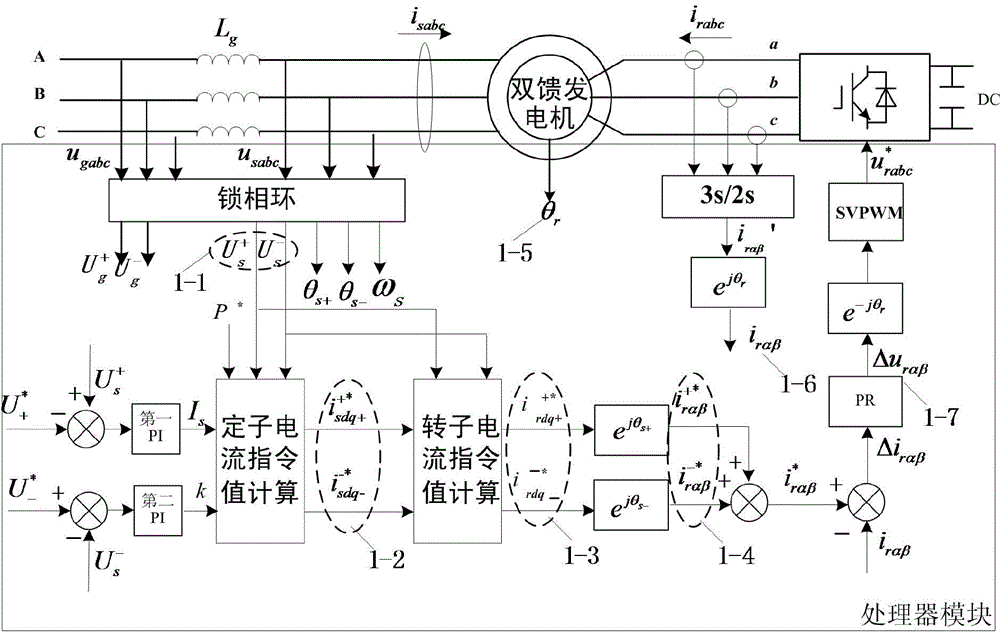

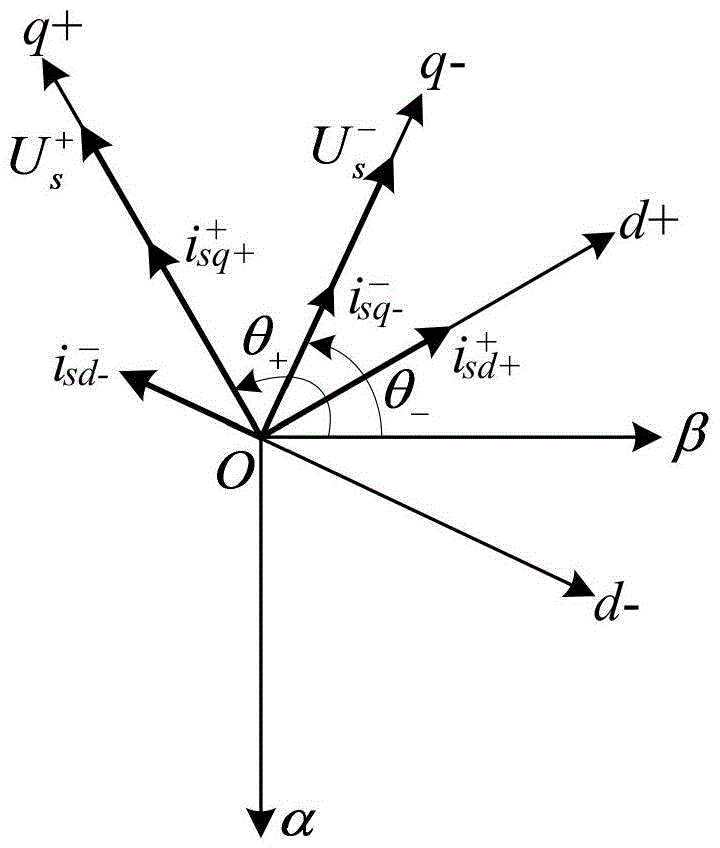

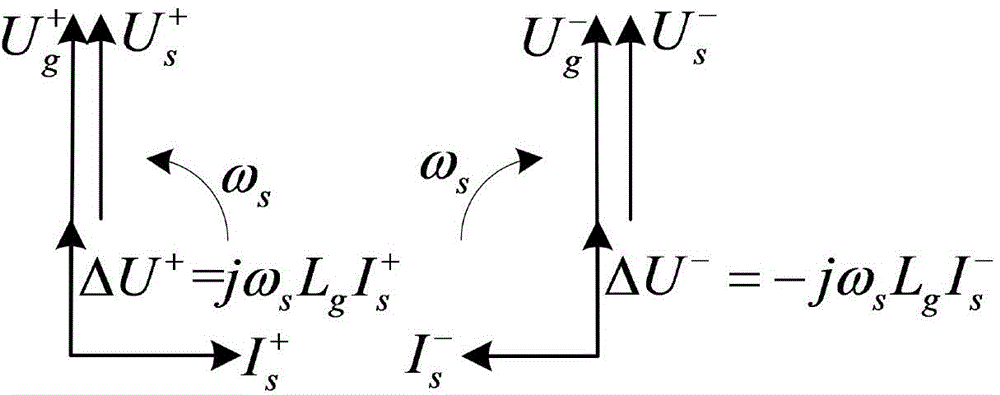

Method for reactive power control of voltage unbalance sudden rise of double-feed wind generator set power network

ActiveCN104538978AAchieve asymmetry controlReduce voltageReactive power adjustment/elimination/compensationReactive power compensationPower flowTerminal voltage

The invention discloses a method for reactive power control of voltage unbalance sudden rise of a double-feed wind generator set power network. The method is characterized by comprising the following steps: 1, decoupling positive and negative sequences of the voltage of a stator of a double-feed motor; 2, calculating the reactive current of the stator; 3, calculating the proportion of positive sequence reactive power in total reactive power; 4, calculating and synthesizing a current instruction value of a rotor; and 5, performing closed-loop control on the current of the rotor. By adopting the method disclosed by the invention, the distribution of the stator current and positive and negative sequence reactive power can be controlled, thereby achieving a target of performing compound control on the degree of asymmetry of generator terminal voltage and reactive power ripple rejection.

Owner:HEFEI UNIV OF TECH

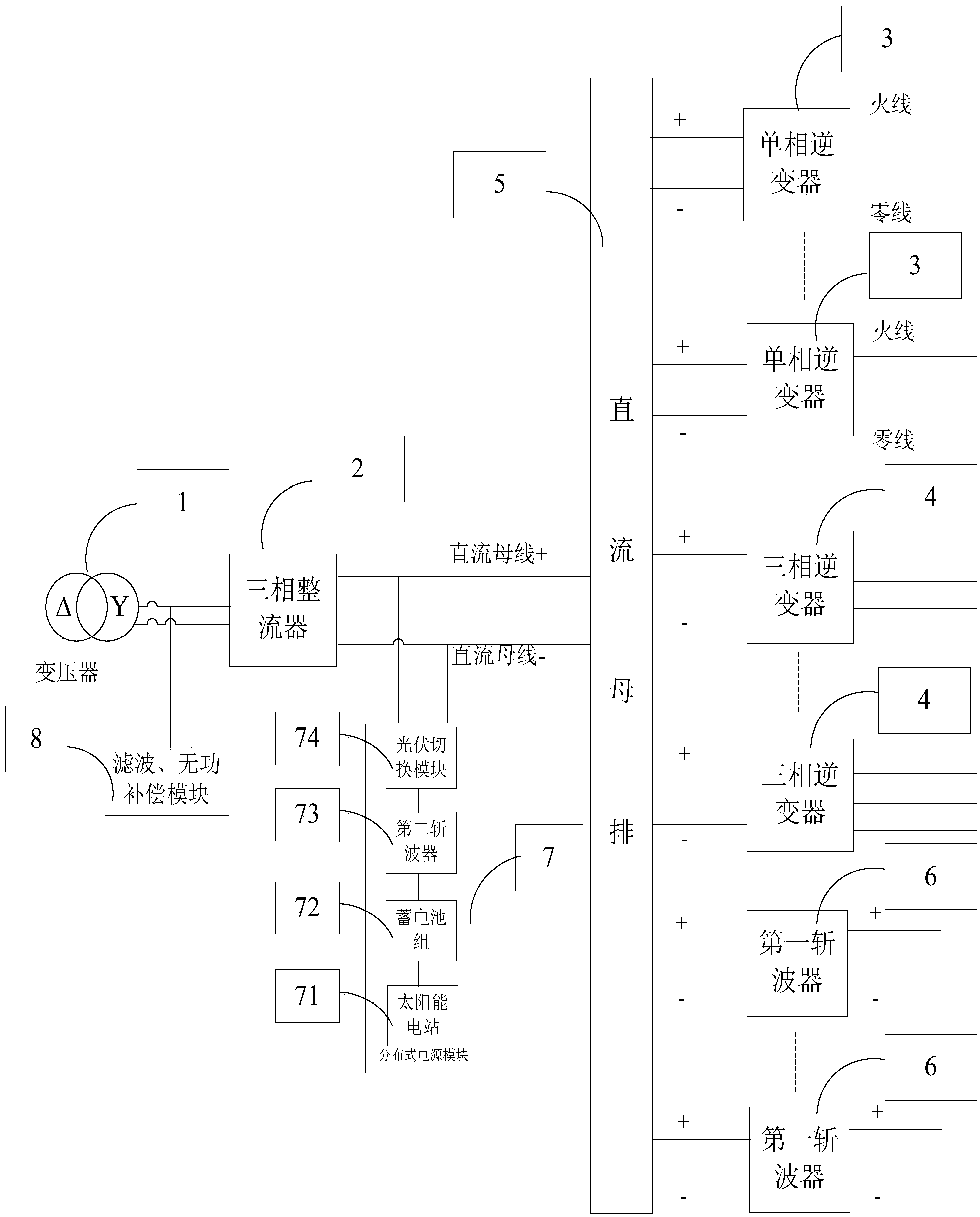

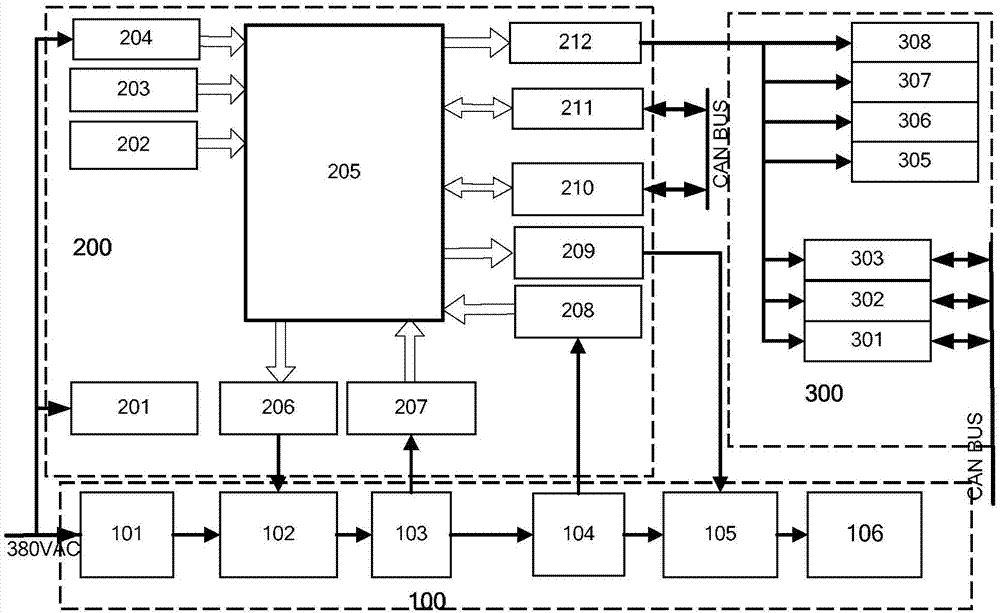

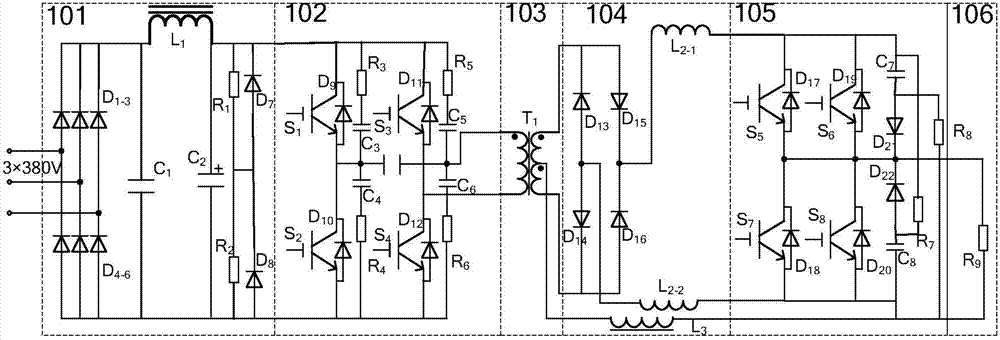

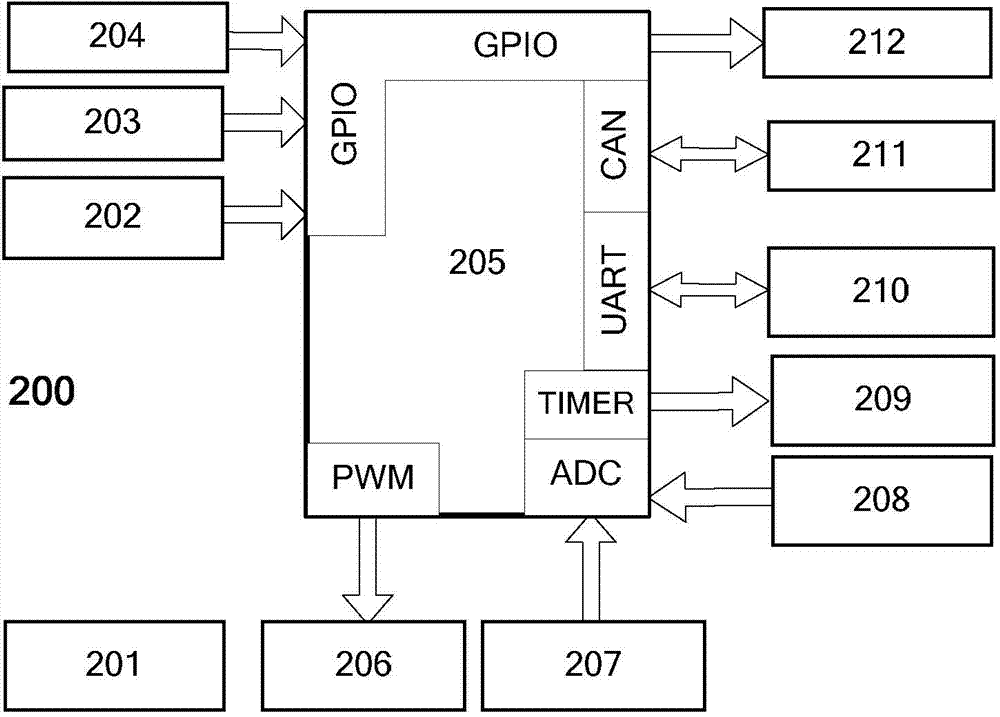

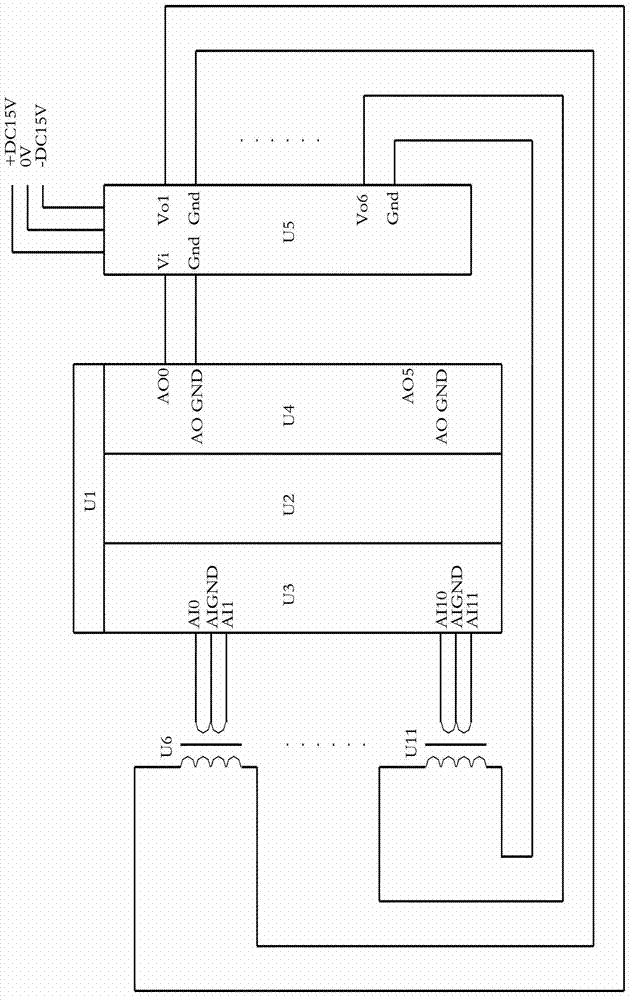

Intelligent power distribution and utilization flexible control system

ActiveCN103475032AModule division of labor is clearGuaranteed uptimeSingle network parallel feeding arrangementsPolyphase network asymmetry elimination/reductionPower qualityTransformer

The invention discloses an intelligent power distribution and utilization flexible control system. The intelligent power distribution and utilization flexible control system comprises a transformer, a three-phase rectifier, at least one single-phase inverter and at least one three-phase inverter. The three-phase rectifier converts a three-phase alternating current produced by the transformer into a direct current which is output to the inverters, the single-phase inverters convert the direct current into single-phase alternating currents with adjustable frequency and amplitude, and the three-phase inverters convert the direct current into three-phase alternating currents with adjustable frequency and amplitude. According to the intelligent power distribution and utilization flexible control system, the method that the three-phase alternating current is rectified and then inverted is adopted, the problem that a great deal of single-phase electric equipment is directly connected to a power supply grid to cause three-phase unbalance is solved, damage to power transmission and distribution equipment and the electric equipment is reduced, and reliability, economical efficiency and power quality of power supply are improved. Besides, the intelligent power distribution and utilization flexible control system achieves clear work division of modules, is easy to design, build and maintain, operates easily, and achieves convenient system expansion and upgrading.

Owner:STATE GRID CORP OF CHINA +1

All-digital variable polarity multifunctional square-wave pulse welding source

ActiveCN103658933ARealize flexible controlHigh control precisionArc welding apparatusFiltrationIntermediate frequency

The invention provides an all-digital variable polarity multifunctional square-wave pulse welding source, and relates to the technical field of welding equipment. The all-digital variable polarity multifunctional square-wave pulse welding source is characterized in that a main circuit and a control circuit are included; the main circuit comprises a rectification filtration module, a front stage inversion module, a medium frequency voltage transformation module, a rapid rectification filtration module and a rear stage inversion module which are sequentially connected; the rectification filtration module is connected with a three-phase AC input power source, and the rear stage inversion module is connected with an electric arc load; the front stage inversion module, the medium frequency voltage transformation module, the rapid rectification filtration module and the rear stage inversion module are all connected with the control circuit, so that power output is controlled by the control circuit. The five sorts of current waveforms, namely direct currents, direct current pulses, square waves, square wave pulses and pulse square waves can be output through the welding source, meanwhile, the main circuit of the welding source is of a double-inversion structure, and thus the good electric energy conversion efficiency and dynamic response performance can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

Strong-wind-self-protecting indicating plate and control method thereof

The invention discloses a strong-wind-self-protecting indicating plate and a control method thereof. The indicating plate comprises an upright column, a cross rod, an indicating plate body, a wind force or air velocity transducer, a connecting mechanism, a flexible unlocking mechanism and a control system, wherein a supporting seat is arranged on the upright column, and a shaft sleeve rotatably sleeving the supporting seat is arranged on the cross rod; the connecting mechanism is arranged between the upright column and the cross rod and comprises a rigid connection state and a flexible connection state which can be mutually switched; the flexible unlocking mechanism acts under the control of the control system, and thus, the connecting mechanism can be switched between the rigid connectionstate and the flexible connection state; the control system receives signals from the wind force or air velocity transducer and sends instructions to the flexible unlocking mechanism. The indicatingplate disclosed by the invention can be switched between rigid connection and flexible connection, and flexible unlocking is carried out when air velocity reaches a threshold value, so that a strong-wind-self-protecting function is achieved.

Owner:XIAMEN UNIV OF TECH

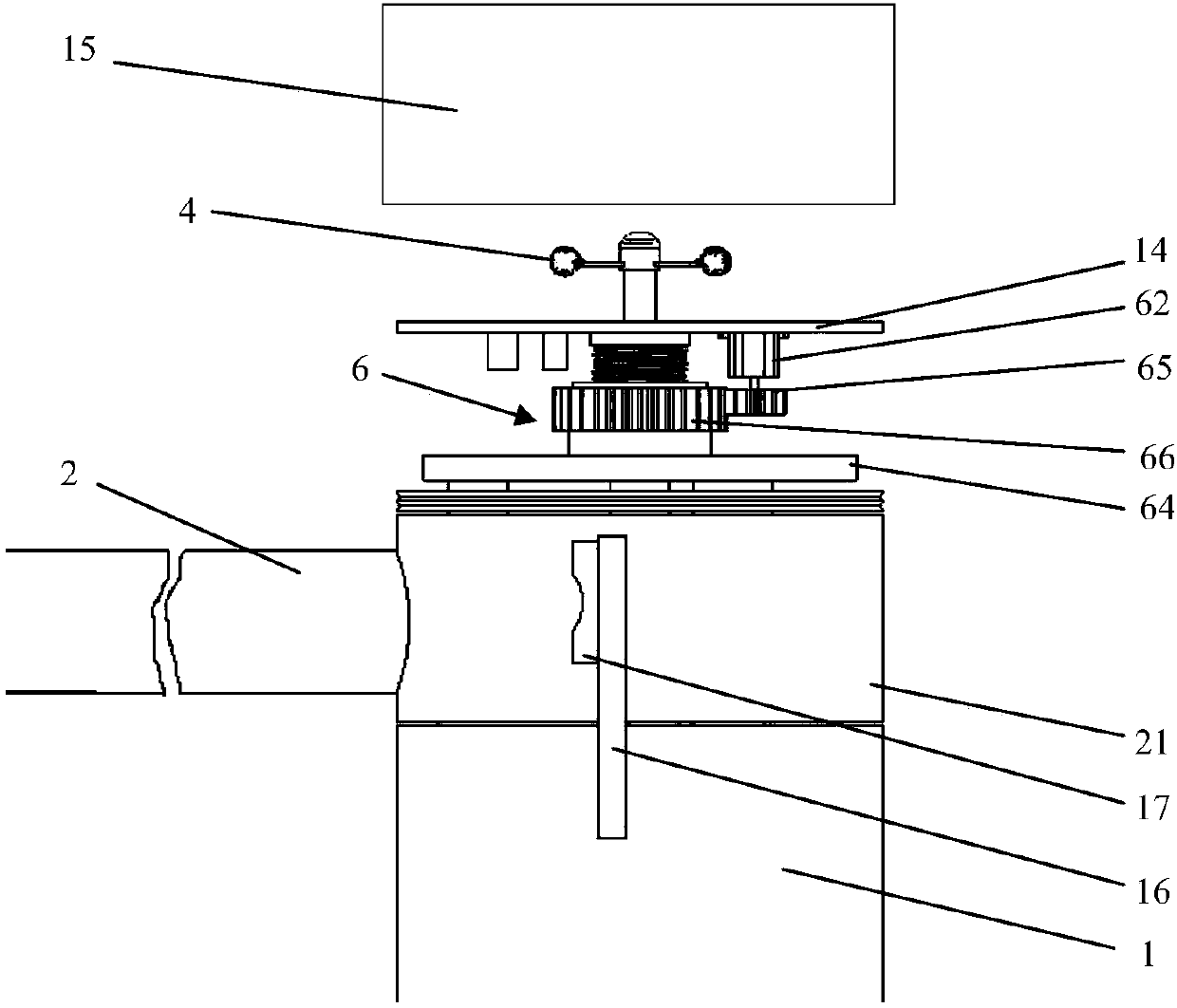

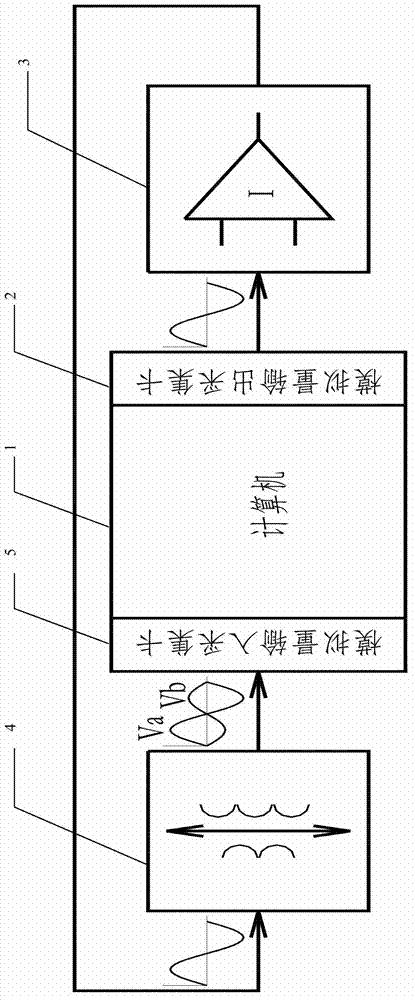

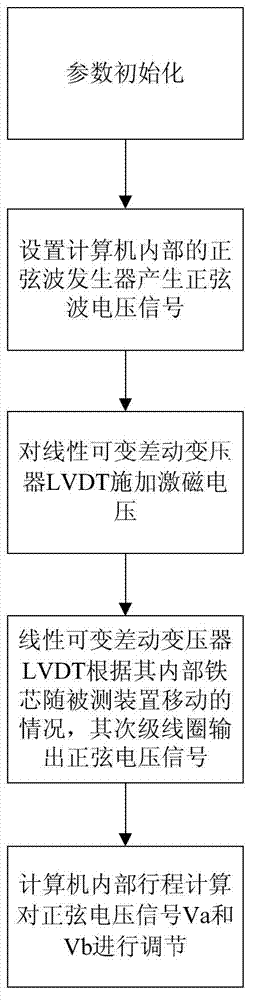

Demodulating device of linear variable differential transformer, and soft demodulating method thereof

ActiveCN102818513ARealize flexible controlLow maintenanceUsing electrical meansLinear variable differential transformerRisk stroke

The invention relates to a demodulating device of linear variable differential transformer, and a soft demodulating method thereof. The demodulating device comprises a computer for producing an excitation voltage signal and computing stroke of a measured device; an analog output acquisition card for providing a required excitation voltage signal to a LVDT (Linear Variable Differential Transformer); a sine wave power amplifier for amplifying the excitation voltage signal output by the analog output acquisition card; the LVDT for producing a sinusoidal voltage signal when the iron core follows the measured device to move back and forth; and an analog input acquisition card for collecting the sinusoidal voltage signal output by the LVDT. The demodulating device adopts the LVDT signal soft demodulating technology and corresponding hardware control software, so that the demodulating device adapts to the parameter variation of the LVDT. Therefore, the soft control of a test is realized, and the maintenance cost and the time for manufacturing the demodulating device are saved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

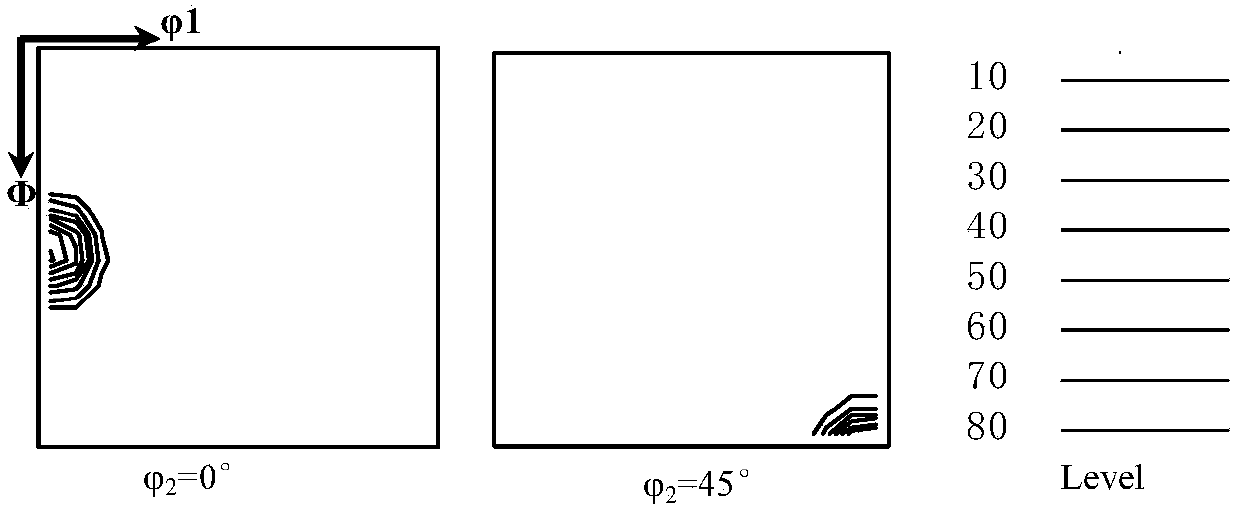

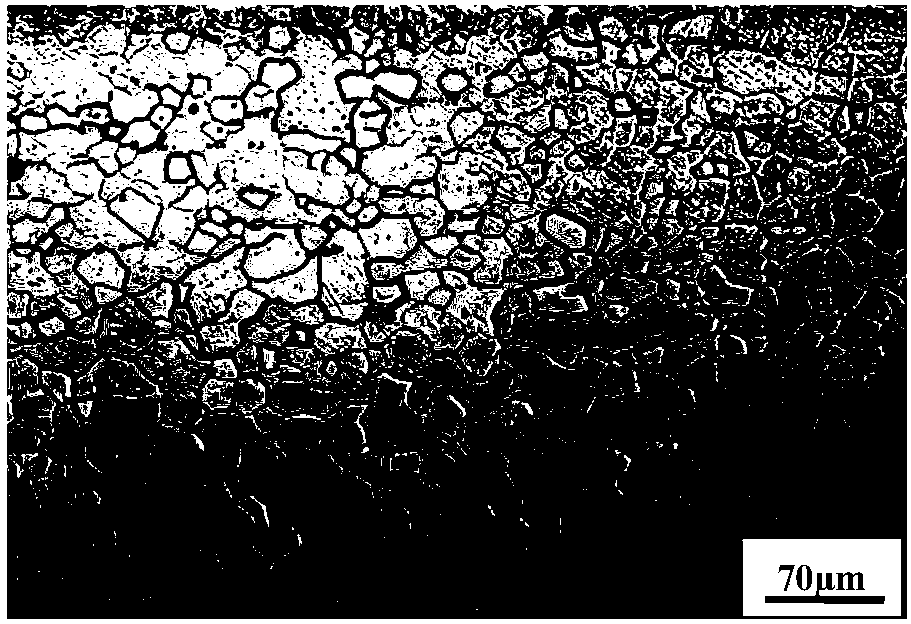

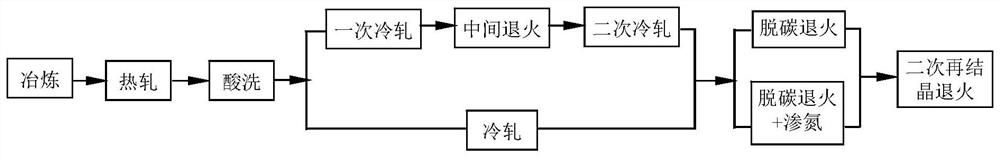

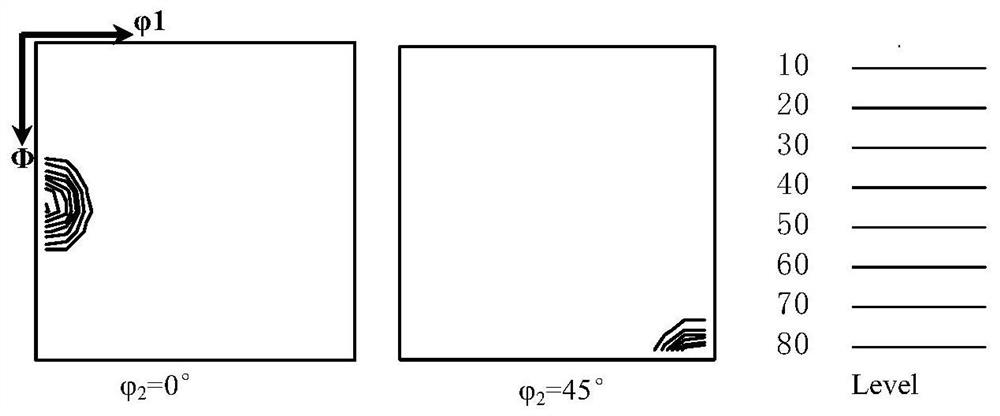

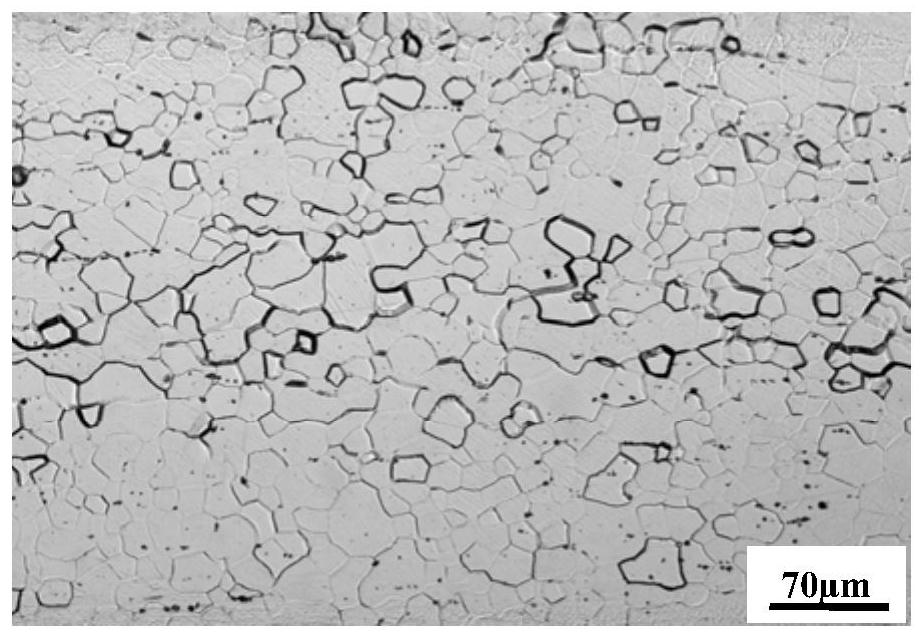

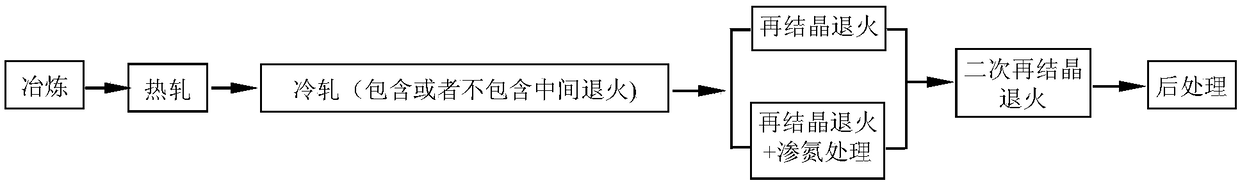

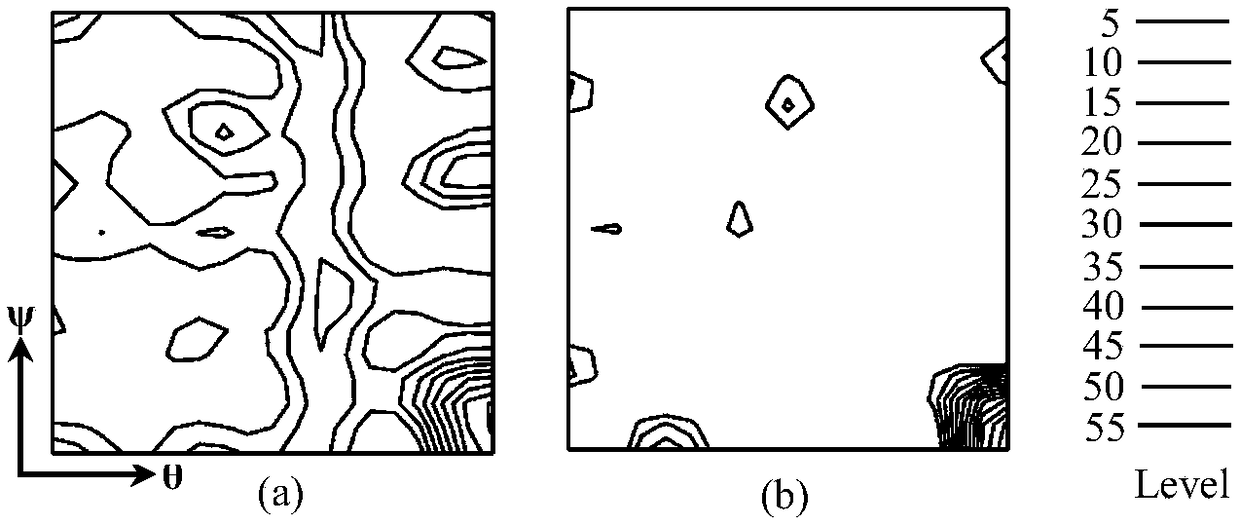

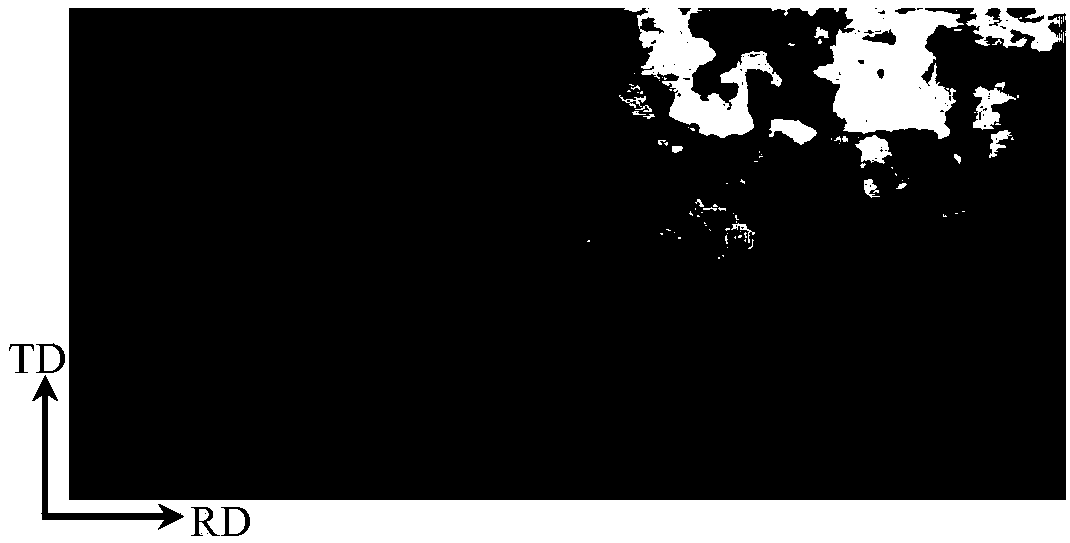

High magnetostriction coefficient Fe-Ga based thin strip and preparation method thereof

ActiveCN108251753ASimple and efficient scale preparationEfficient and stable preparationMagnetostrictive device manufacture/assemblySolid state diffusion coatingThin slabDie casting

The invention relates to a high magnetostriction coefficient Fe-Ga based thin strip and a preparation method thereof. According to the high magnetostriction coefficient Fe-Ga based thin strip and thepreparation method thereof, slabs of die casting, slab continuous casting, thin slab continuous casting and thin strip continuous casting are adopted, and simple and efficient scale production can berealized by using traditional rolling and annealing processes; an inhibitor system of low temperature intrinsic inhibitors and nitriding is established, and heat treatment and the rolling process arecontrolled to precipitate fine Cu2S, Nb(C,N) and V(C,N) or composite precipitates thereof as main intrinsic inhibitors; when the intrinsic inhibition is insufficient, nitriding is used for supplementing and forming nitrides such as AIN or BN before the secondary recrystallization annealing to achieve flexible control of the inhibition; cold rolling parameters are fine controlled to ensure primaryrecrystallization to obtain fine and uniform organizations and favorable textures, the coordinated matching of the organizations, the textures and the inhibitors before secondary recrystallization isachieved, and perfect and sharp secondary recrystallization of texture Goss ({110}(001)) is obtained. The magnetostriction coefficient (3 / 2) lambda s of a Fe-Ga based thin strip finished product is ashigh as 220-370ppm.

Owner:NORTHEASTERN UNIV

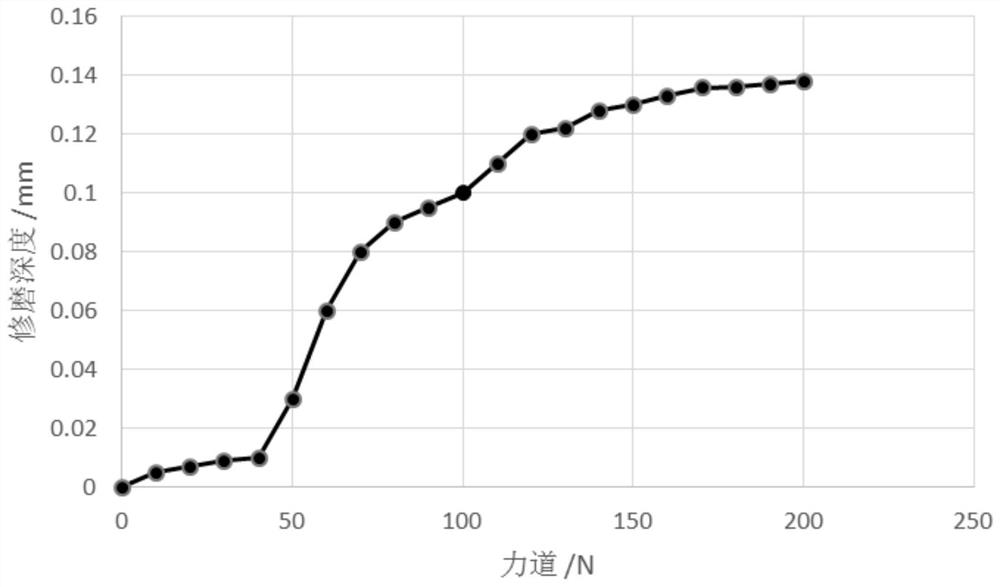

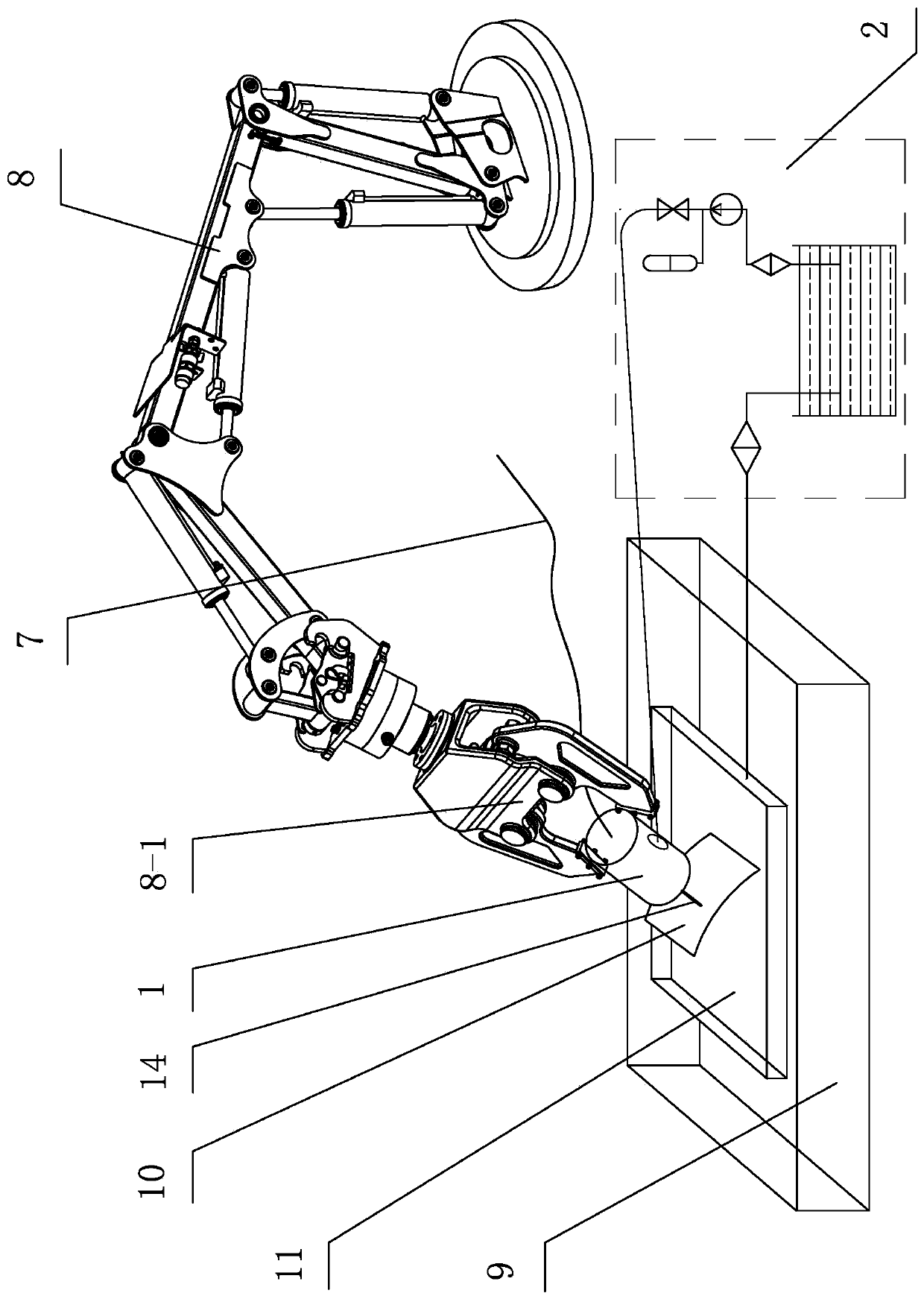

Robot flexible grinding method for surface defects of steel plate

InactiveCN112139857AAvoid secondary damageSmooth grindingGrinding feed controlAutomatic grinding controlSteel platesRobotic systems

The invention belongs to the technical field of metal surface grinding, and relates to a robot flexible grinding method for surface defects of a steel plate. A robot grinding system adopted by the method comprises a robot system and a flexible grinding system. The technical parameters such as The grinding track, the grinding rotating speed, the grinding force and the grinding frequency are effectively limited, flexible control over automatic grinding of a robot is achieved, secondary damage caused by rigid contact between machines and metal is avoided, the problems of uneven local ground edgesand the like are solved, automatic high-efficiency grinding is kept, and meanwhile the regular, attractive and smooth grinding effect is achieved.

Owner:沈阳东能科技有限公司

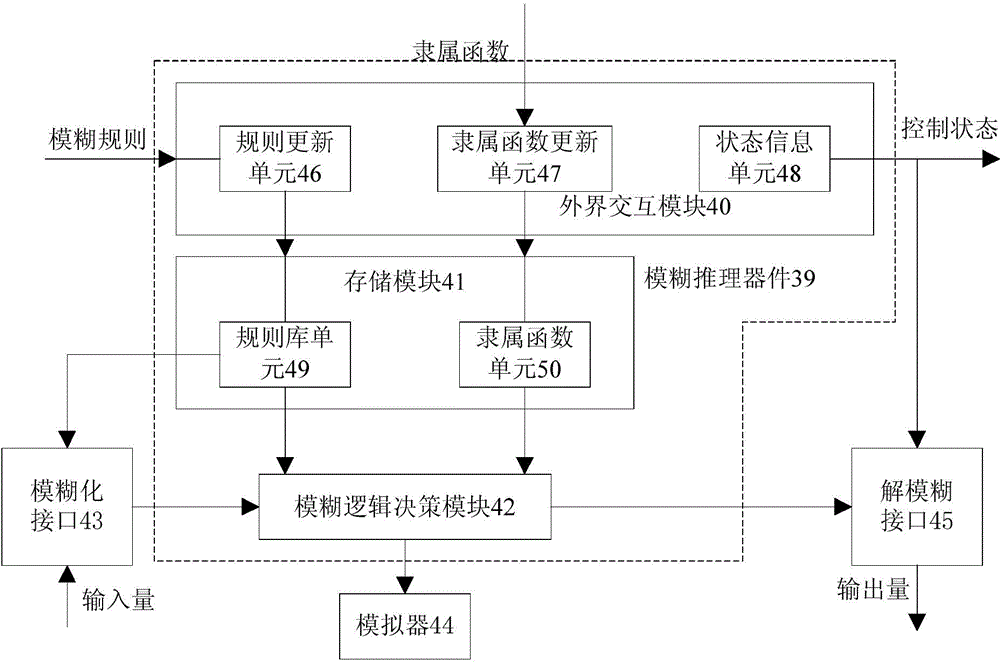

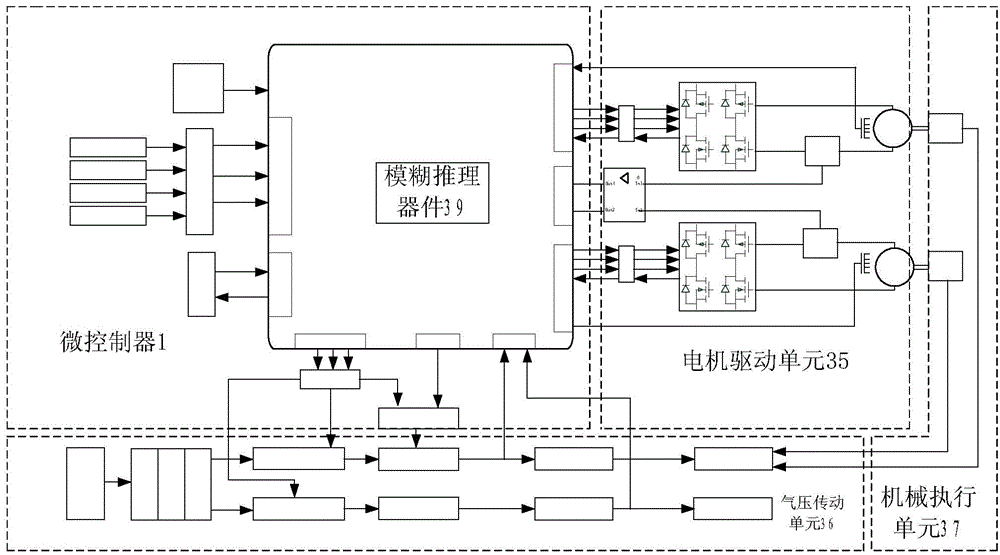

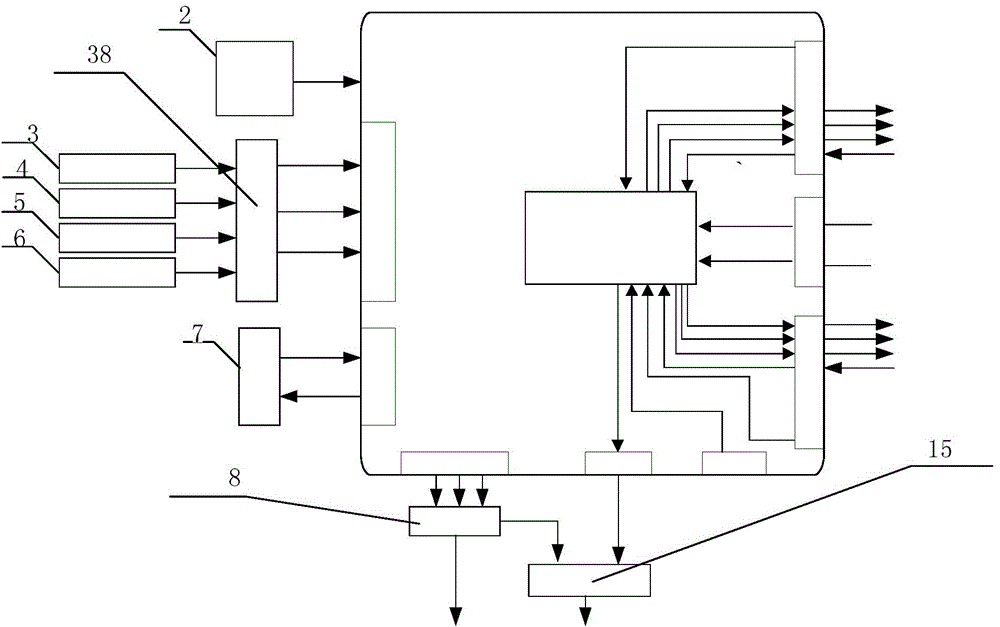

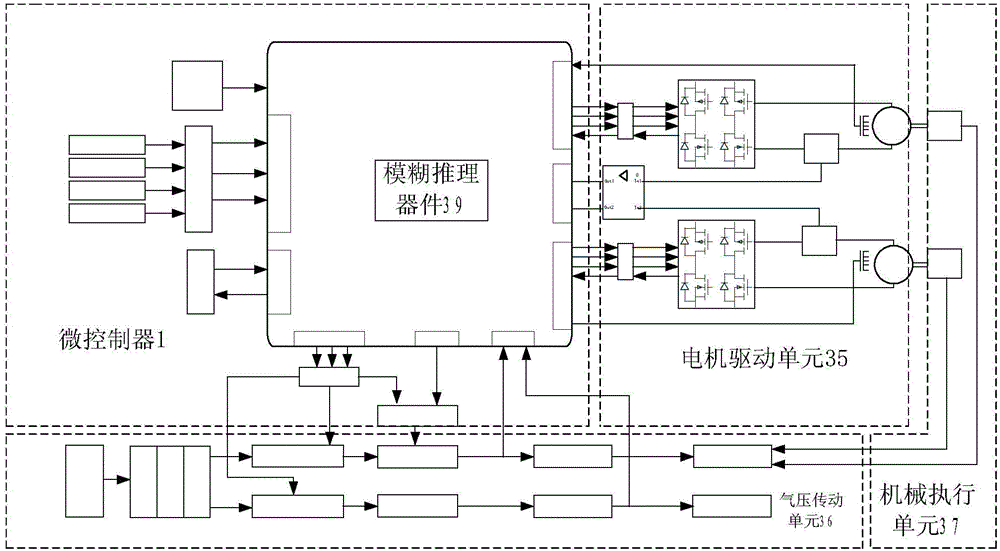

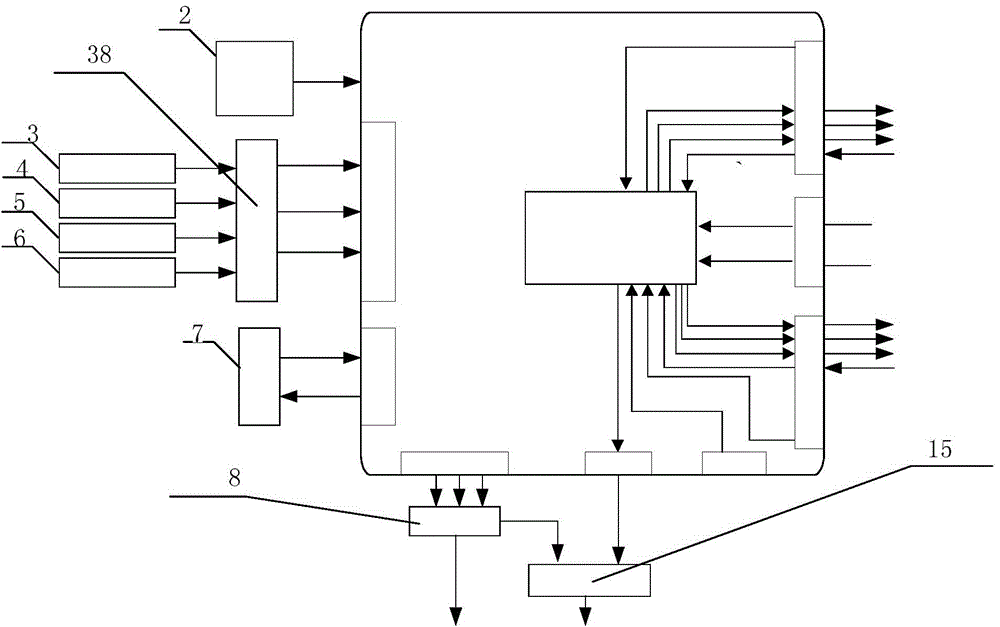

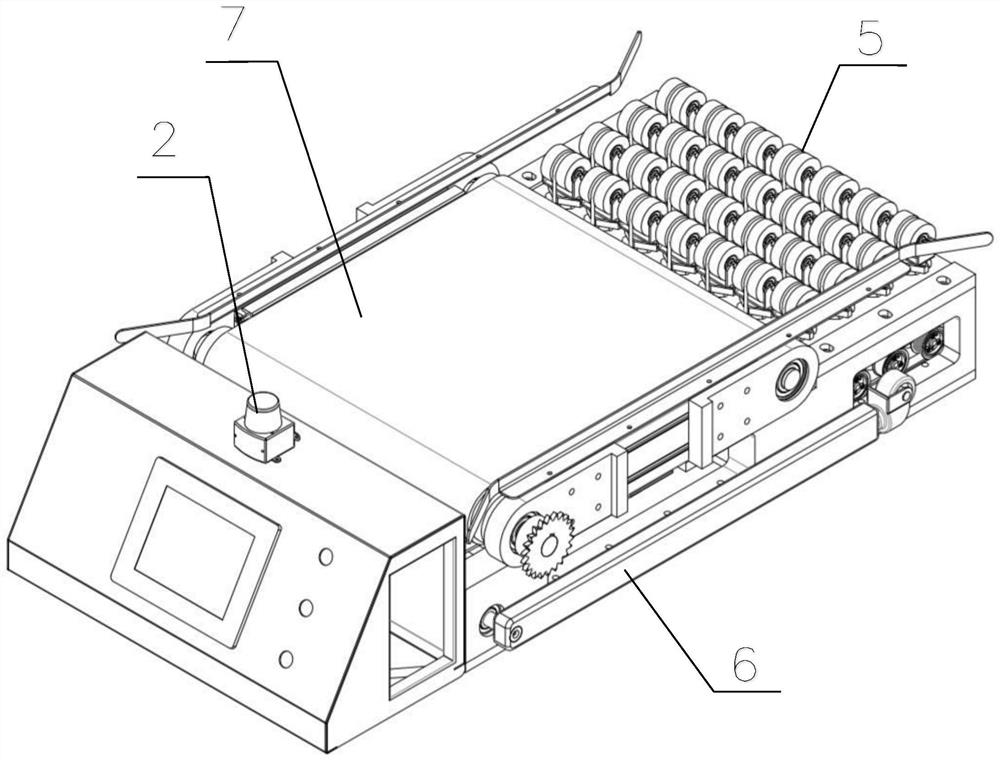

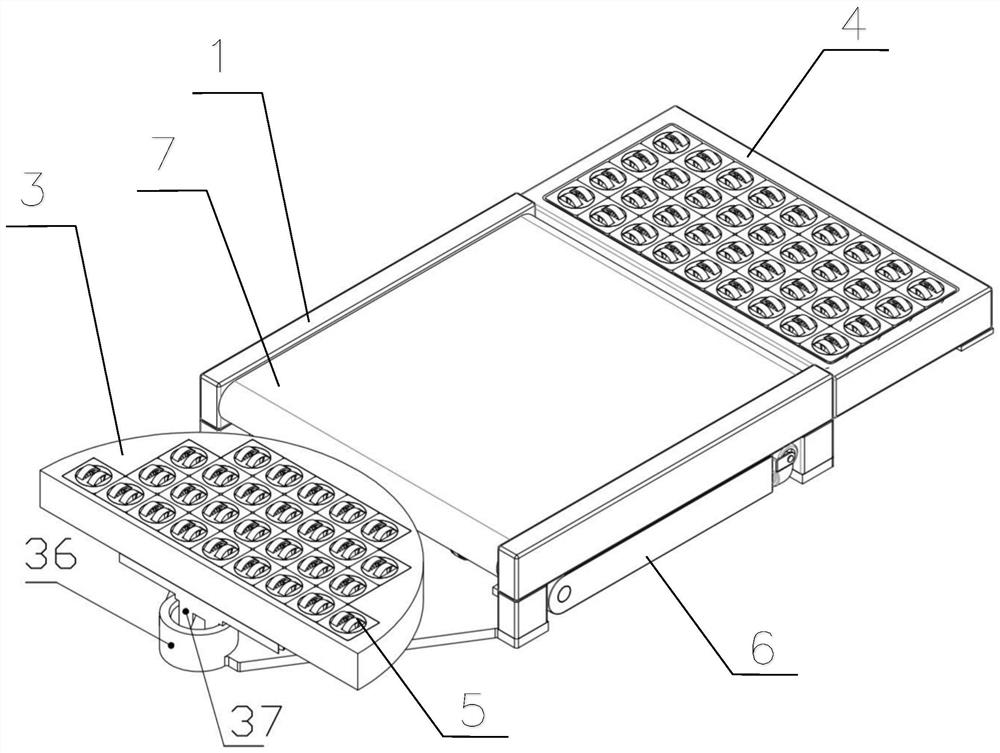

Fuzzy control system and realization method thereof for medical robot

ActiveCN104626162ARealize flexible controlReduce labor intensityProgramme-controlled manipulatorAdaptive controlDefuzzificationMedical robot

The invention relates to a fuzzy control system and a realization method thereof for a medical robot. The fuzzy control system and the realization method thereof for the medical robot comprises a fuzzy reasoning device which is arranged on a micro controller and a realization method of the fuzzy control system used for the medical robot, wherein the fuzzy reasoning device comprises an outside interaction module which is used for inputting fuzzy control rules, the outside interaction module is in communication connection with a storage module which is used for storing fuzzy models, the storage module is in communication connection with a fuzzy logic decision module which is used for establishing fuzzy models, the storage module and the fuzzy logic decision module are both in communication connection with a fuzzification interface which is used for inputting parameters, the fuzzy logic decision module is in communication connection with a simulator and a defuzzification interface which is used for outputting the parameters, and the defuzzification interface is in communication connection with the outside interaction module. By means of the fuzzy control system and the realization method thereof for the medical robot, the technological means of the outside interaction module, the storage module, the fuzzy logic decision module and the simulator is adopted, so that the medical robot has certain intelligence and assists a doctor to make a reasonable therapeutic schedule.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Flexible water-jet guided laser micro-machining system and method

PendingCN110883424ACompact designFlexible connectionLaser beam welding apparatusWater flowEngineering

The invention discloses a flexible water-jet guided laser micro-machining system and method. The flexible water-jet guided laser micro-machining system comprises an optical fiber transmission unit, aworkbench unit and a high-pressure liquid supply unit. The optical fiber coupling unit comprises an optical fiber fixing and switching module and a beam coupling transmission module. The beam couplingtransmission module comprises a coupling body, an upper pressure head and a lower nozzle holder. The end of a flexible optical fiber is fixed in a liquid cavity between the upper pressure head and the lower nozzle holder through the optical fiber fixing and switching module. A water inlet in the coupling body communicates with the liquid cavity. A nozzle block is arranged on the lower nozzle holder, and a spray hole in the nozzle block communicates with a nozzle on the lower nozzle holder. The coupling body is clamped on a manipulator of a robot. Stepless pressure-adjustable high-pressure water output by the high-pressure liquid supply unit is collected into the liquid cavity via water inlets to form a low-pressure stable water flow. The workbench unit comprises a three-axis linkage workbench. A clamping and fixing table board of workpieces is arranged on the workbench through a water tank. The flexible water-jet guided laser micro-machining system is simple, compact and flexible in structure, and multi-dimensional flexible micro-machining of the workpieces can be achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A kind of high magnetostriction coefficient Fe-ga based thin strip and its preparation method

ActiveCN108251753BEfficient and stable preparationIncrease productivityMagnetostrictive device manufacture/assemblySolid state diffusion coatingCrystallographyThin slab

The invention relates to a high magnetostriction coefficient Fe-Ga-based thin strip and a preparation method thereof. The invention adopts die casting, slab continuous casting, thin slab continuous casting and thin strip continuous casting slabs, and can carry out large-scale production simply and efficiently by using traditional rolling and annealing processes; establishes low-temperature inherent inhibitor + nitriding inhibition Agent system, control heat treatment and rolling process to precipitate fine Cu 2 S, Nb(C,N) and V(C,N) or their composite precipitates are used as the main intrinsic inhibitors. When the intrinsic inhibitory force is insufficient, nitriding is used to supplement the formation of nitrides such as AIN or BN before secondary recrystallization annealing. , to achieve flexible control of the suppression force; finely adjust the cold rolling parameters to ensure that the primary recrystallization obtains a fine and uniform structure and a favorable texture, and realize the coordination and matching of the structure, texture and inhibitor before the secondary recrystallization, and obtain a perfect and sharp Secondary recrystallization of Goss ({110}<001>) texture. The magnetostriction coefficient (3 / 2)λs of the finished Fe-Ga-based thin strip of the present invention is as high as 220-370ppm.

Owner:NORTHEASTERN UNIV LIAONING

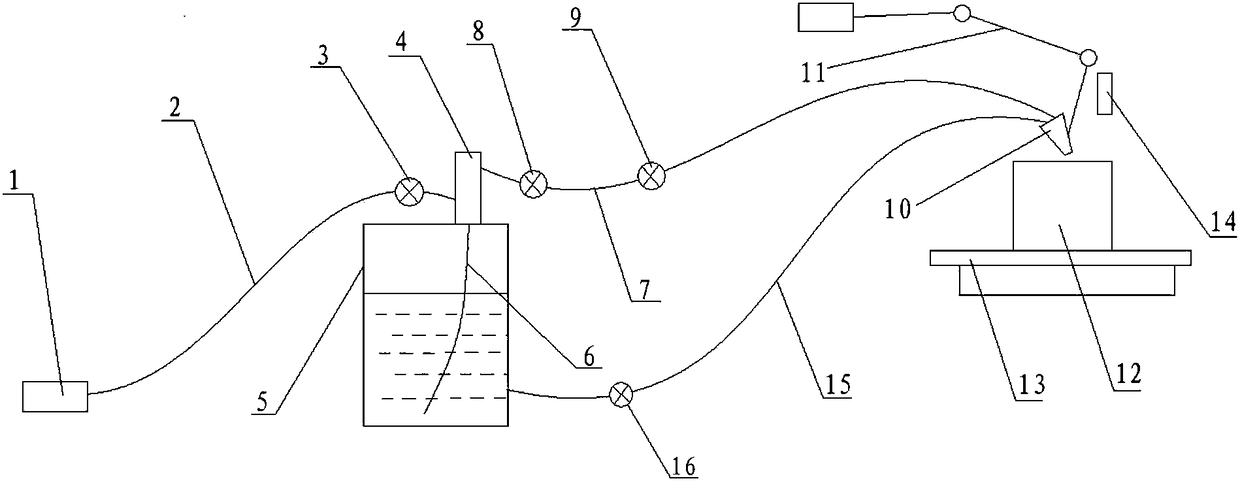

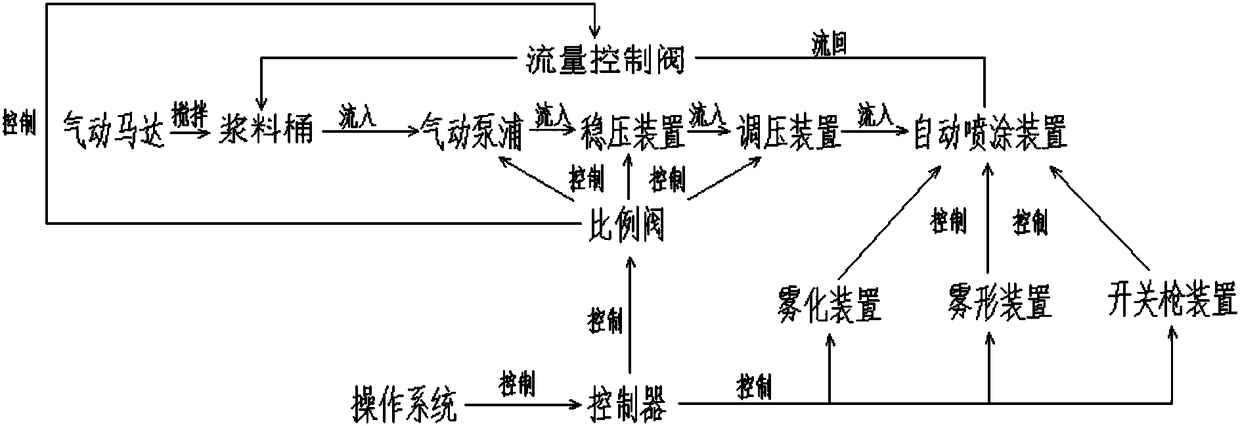

Automatic spraying system capable of stabilizing flow

InactiveCN108607713ARealize flexible controlGuaranteed uniformitySpraying apparatusInlet valveAir compressor

The invention discloses an automatic spraying system capable of stabilizing the flow. The automatic spraying system is characterized in that an air compressor is connected with an air inlet of a pneumatic slurry pump through an air inlet pipe and an air inlet valve, the pneumatic slurry pump is arranged on a slurry barrel, a feeding port of the pneumatic slurry pump is provided with a material guide pipe, and the material guide pipe extends into the slurry barrel; a discharging port of the pneumatic slurry pump is connected with a spray gun through a material conveying pipe, and a pressure stabilizing valve and a pressure regulating valve are arranged on the material conveying pipe; the spray gun is clamped at the top end of a mechanical arm, and the position and the spraying angle of thespray gun are adjusted through the mechanical arm; and a controller controls the flow pressure of the pneumatic slurry pump, the pressure stabilizing valve and the pressure regulating valve through aproportional valve, and is connected with the mechanical arm, the spray gun and a rotary heating platform. The automatic spraying system has the characteristics that the structure is simple, the operation is convenient and the control precision is high; and the slurry can be automatically sprayed and the flow of the slurry can be stable, and therefore the polycrystalline capacity is improved, thepolycrystalline cost is reduced, the automation degree is high, and the labor is saved.

Owner:镇江荣德新能源科技有限公司

Automatic strapping machine

PendingCN112093106AIncrease delivery speedImprove work efficiencyBinding material applicationBundling machine detailsStrappingMachine

The invention discloses an automatic strapping machine, and relates to the technical field of automatic strapping machines, in particular to an automatic strapping machine. The automatic strapping machine comprises a bottom plate and a fixing plate, wherein a placing plate is fixedly connected to the upper portion of the bottom plate, an auxiliary rotating wheel is movably connected in the placingplate, a main rotating wheel is arranged on the left side of the auxiliary rotating wheel in parallel, a belt is movably connected to the outer wall of the main rotating wheel, the fixing plate is located at the rear end of the belt, a mounting sleeve is movably connected to the upper portion of the fixing plate, a stand column is movably connected in the mounting sleeve, a wire fixing disc is movably connected to the outer wall of the stand column, and a rolling disc is perpendicularly arranged above the stand column. According to the automatic strapping machine, through cooperation of a steel wire conveying and correcting device, a bridge connecting plate conveying and positioning device, a steel wire automatic grabbing and knotting device and five machining procedures, the device can set different technological processes according to different bridge connecting plate specifications, flexible control over a whole system is achieved, and the robustness of equipment is enhanced.

Owner:山东英维思测控科技有限公司

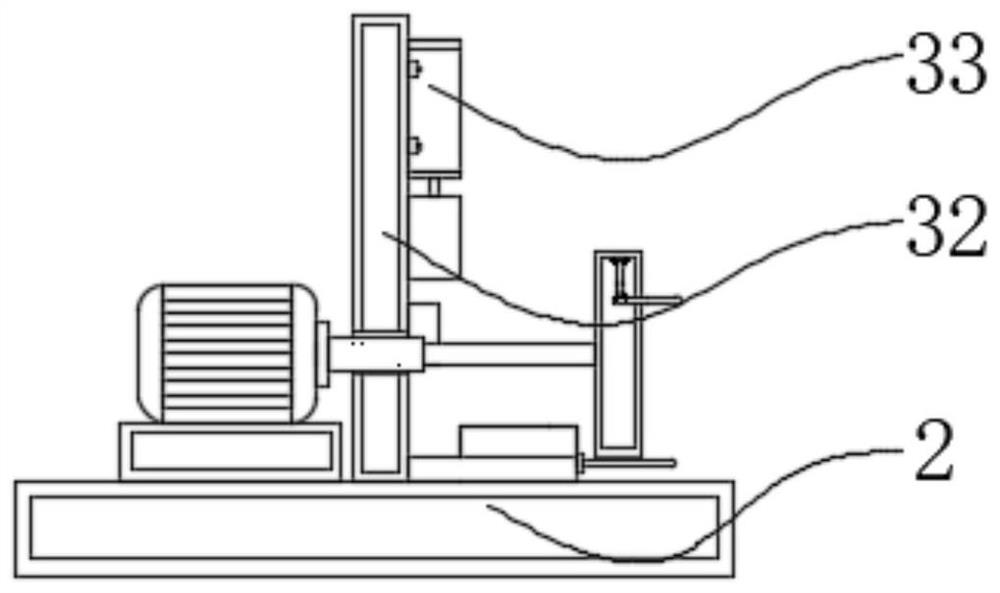

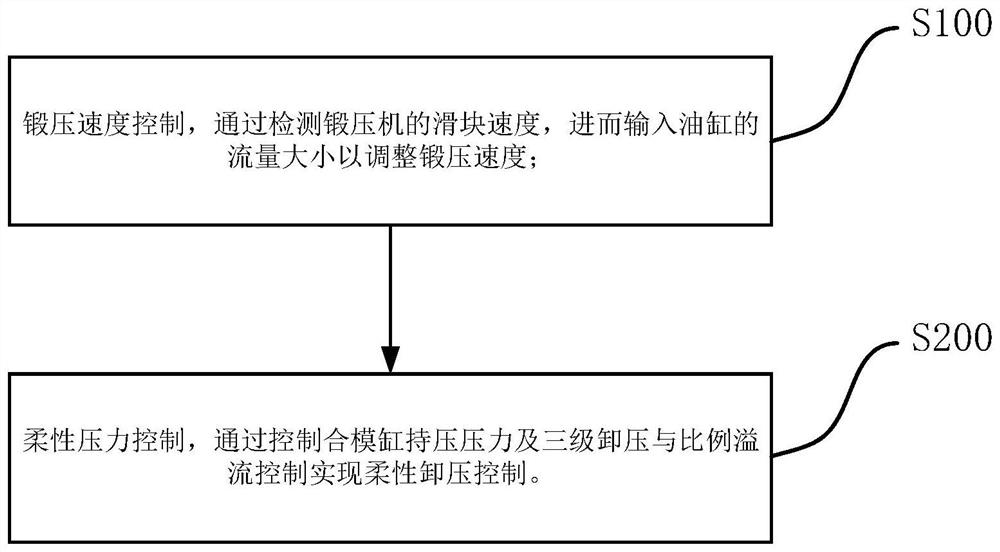

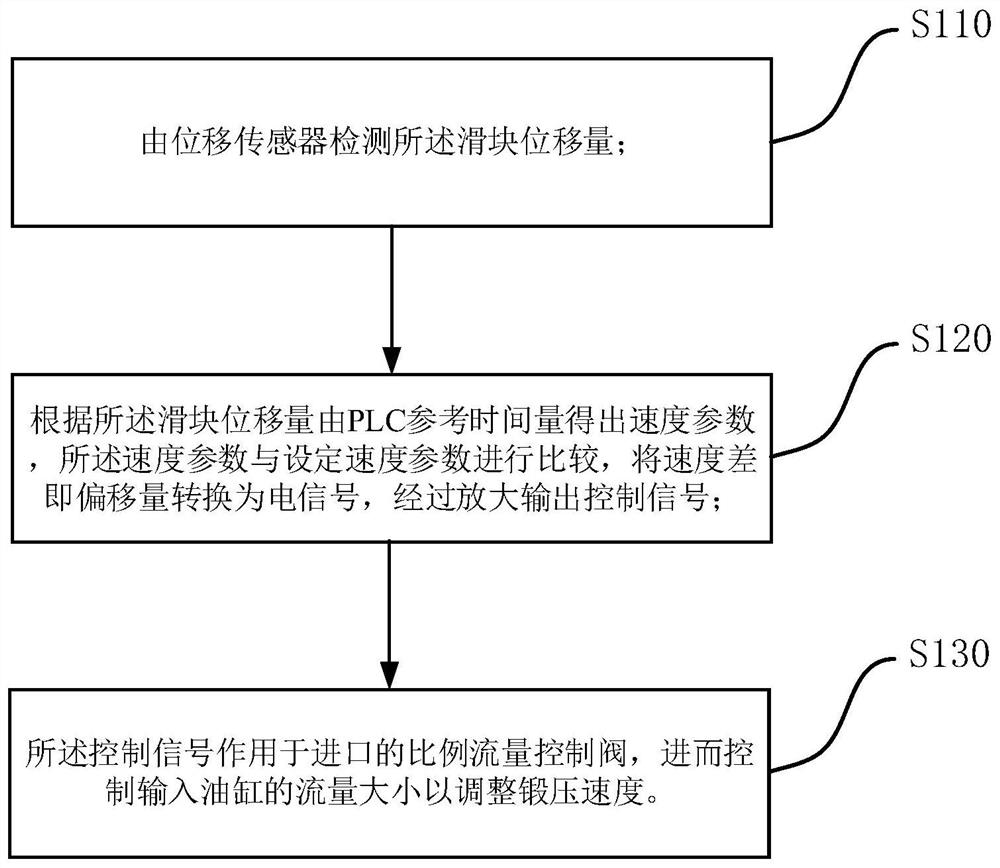

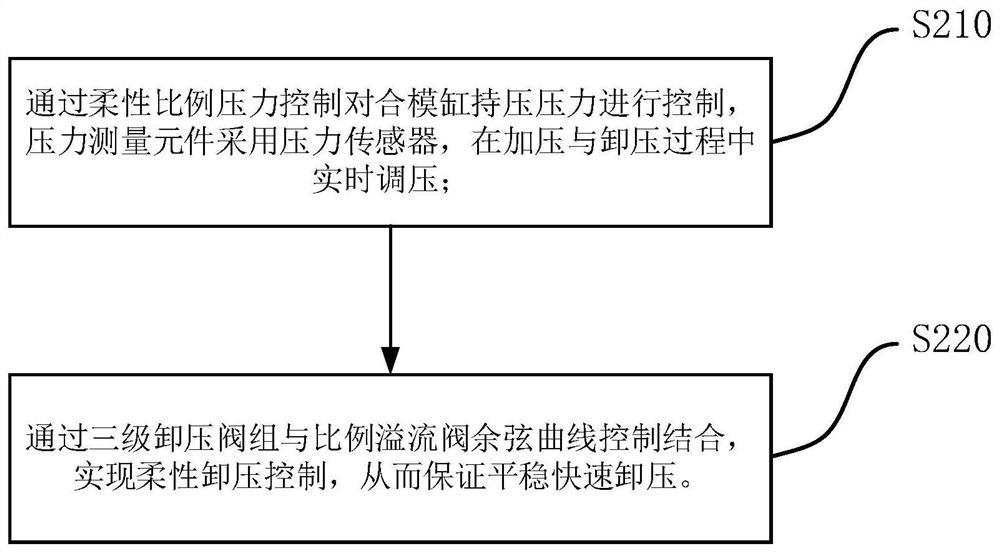

Flexible control method of forging press

PendingCN113351817ARealize flexible controlStable pressure reliefForging press drivesIndustrial engineeringPressure control

The invention discloses a flexible control method of a forging press, and belongs to the technical field of forging press control. The flexible control method of the forging press is characterized by comprising the following steps: S100, forging and pressing speed control: a forging and pressing speed is adjusted by detecting the speed of a sliding block of the forging press and further inputting the flow of an oil cylinder; and S200, flexible pressure control: flexible pressure relief control is realized by controlling the holding pressure of a die assembly cylinder of the forging press and controlling three-stage pressure relief and proportional overflow. By adopting the technical scheme, the invention provides the pressing speed control method based on an integral separation PID method; and the stroke of the sliding block is monitored in real time, and the flexible pressure relief control over the forging press is carried out by combining a three-level pressure relief valve group and a cosine curve control method of a proportional overflow valve according to the influence of an unloading process on the vehicle shape quality of wheels.

Owner:TIANJIN TIANDUAN PRESS CO LTD

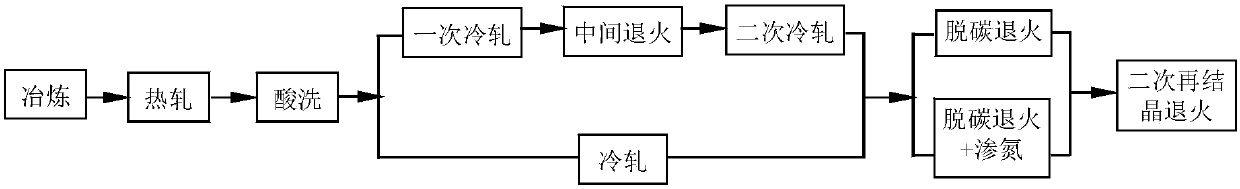

Oriented high silicon steel strip and efficient annealing-mode preparation method thereof

ActiveCN108823372ARealize flexible controlLow heating temperatureSolid state diffusion coatingFurnace typesThin sheetSilicon

An oriented high silicon steel strip and an efficient annealing-mode preparation method thereof belong to the technical field of metallurgy. The oriented high silicon steel strip comprises the following ingredients (by weight): 4.5-7.0% of Si, C being less than or equal to 0.1%, 0.005-0.05% of Als, 0.003-0.01% of N, 0.03-0.3% of Mn, Cu being less than or equal to 0.5%, 0.003-0.035% of S, 0.02-0.4%of Nb, 0.005-0.1% of V, and the balance Fe and impurities. The method comprises the following steps: casting according to the composition design to obtain a slab, hot-rolling, carrying out acid pickling, cold-rolling after acid pickling, carrying out decarburizing annealing on the slab, carrying out nitriding treatment, and finally carrying out secondary recrystallization annealing. By controlling an inhibitor system, the rolling technology and the annealing technology, short-process annealing-mode preparation of the oriented high silicon steel is realized, production efficiency is raised, production cost is reduced, and the product has excellent comprehensive performance and is thinner in thickness.

Owner:NORTHEASTERN UNIV

Method for preparing polyolefin through coordination polymerization in micro-reactor

ActiveCN111777700AImprove efficiencySolving Polymerization Reaction Residence Time ProblemsMicroreactorPolyolefin

The invention belongs to the technical field of polyolefin, and particularly relates to a method for preparing polyolefin through coordination polymerization in a micro-reactor. The method includes: letting an olefin monomer fluid, a main catalyst fluid and a cocatalyst fluid respectively enter the micro-reactor through shunting runners; arranging a micro-reaction runner of the micro-reactor in aconstant-temperature box and carrying out polymerization reaction; and collecting the polymerization liquid to obtain the polymer. According to the preparation method, the monomer and the catalyst canbe quickly mixed, the uniformity of a local reaction environment is controlled, and the problem of polymerization reaction retention time in the prior art is solved; the prepared polymerization product realizes excellent polymer performance and realizes high flux of polymerization. The olefin monomer concentration of the main reaction runner can be timely and effectively regulated, and the molecular structure and molecular weight of the polymerization product can be controlled. The micro-reactor polymerization technology provided by the invention is low in equipment investment, small in device size and safer and more flexible to operate; and the method is suitable for continuous production, small in amplification effect and suitable for industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

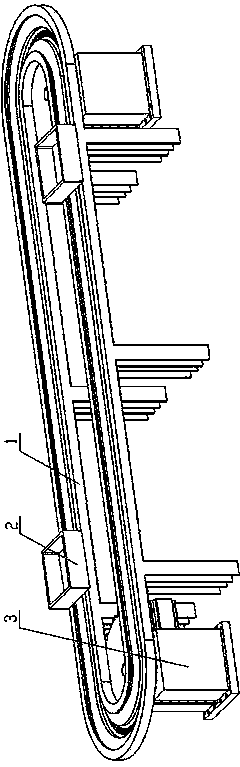

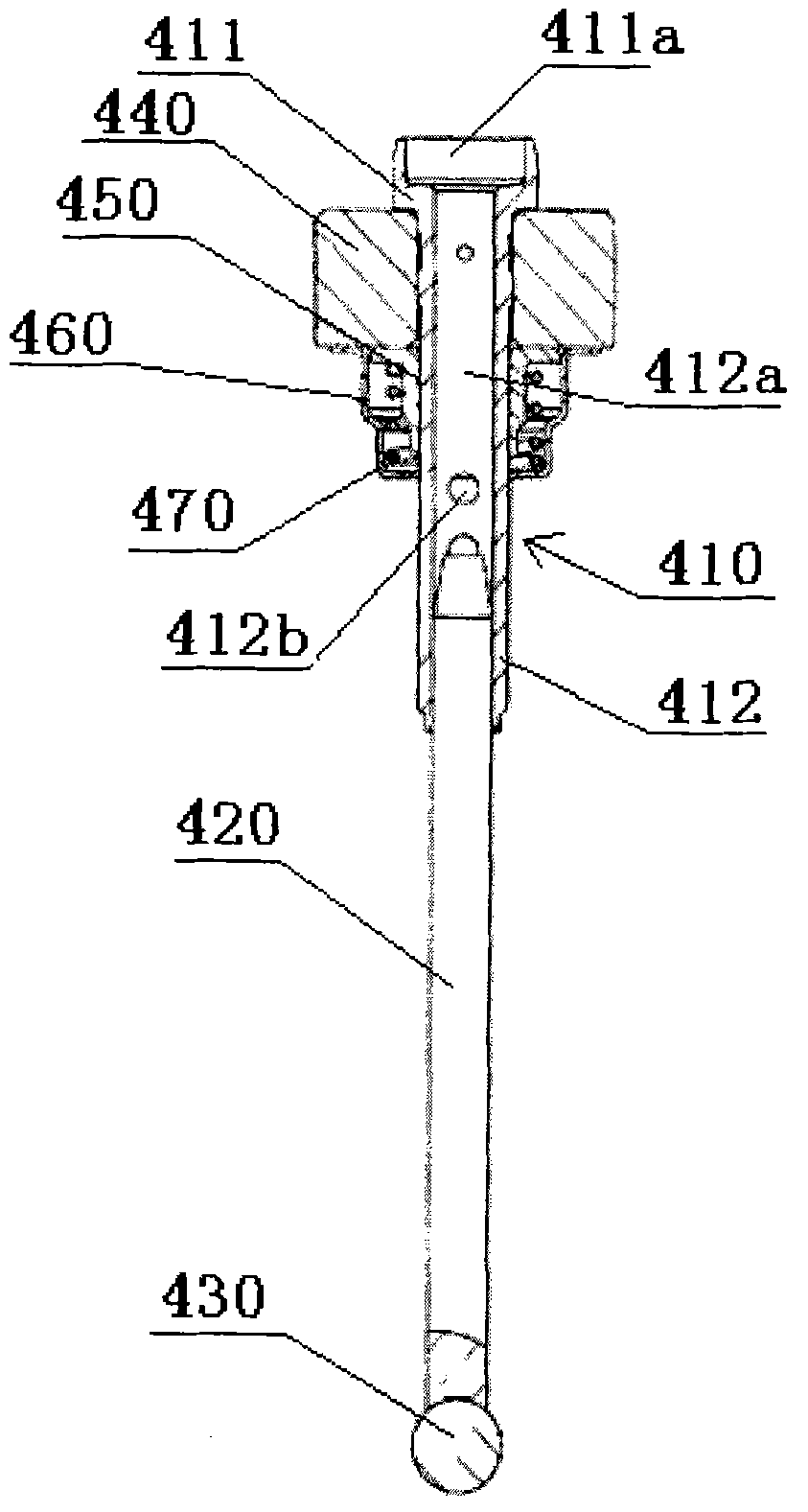

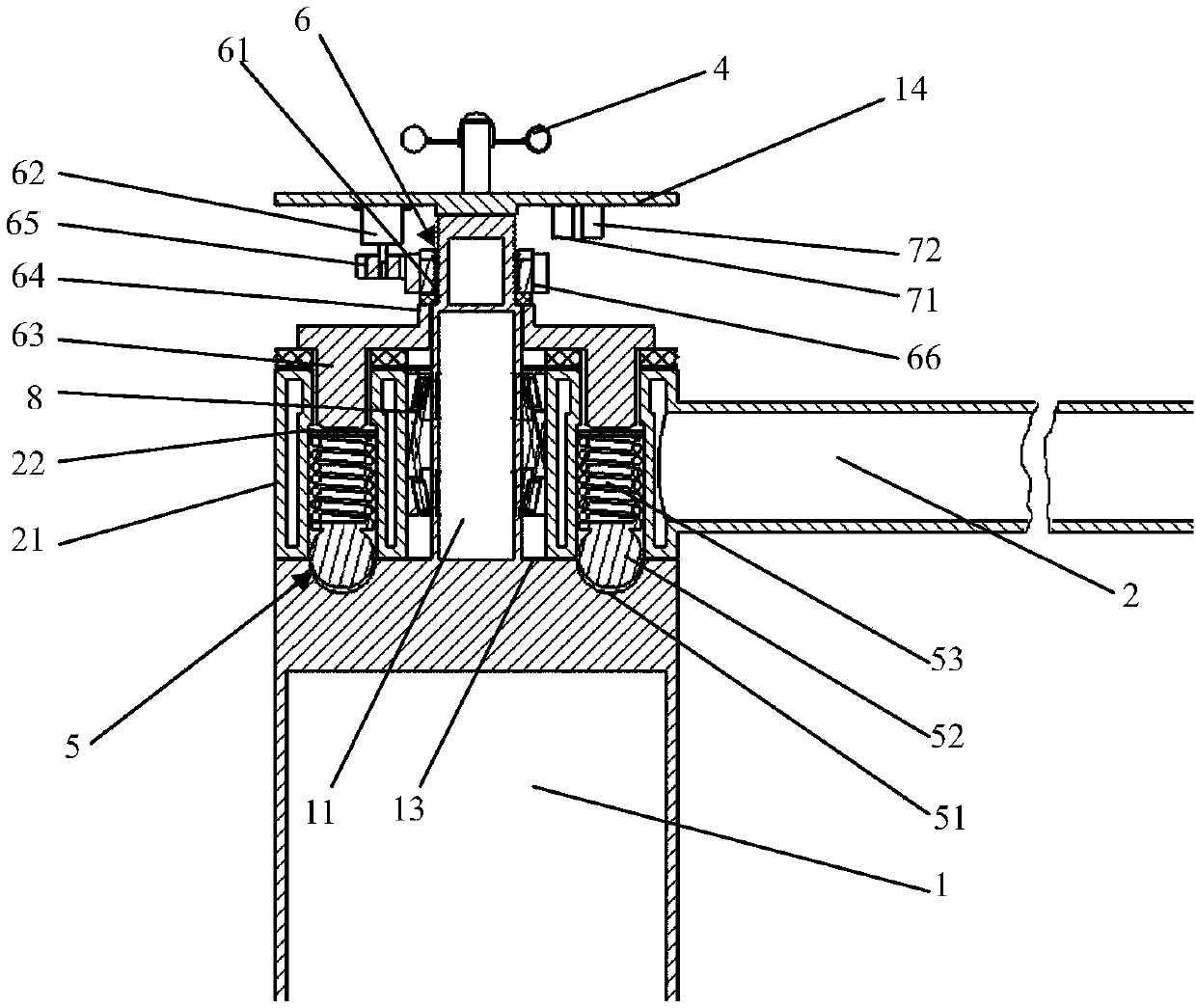

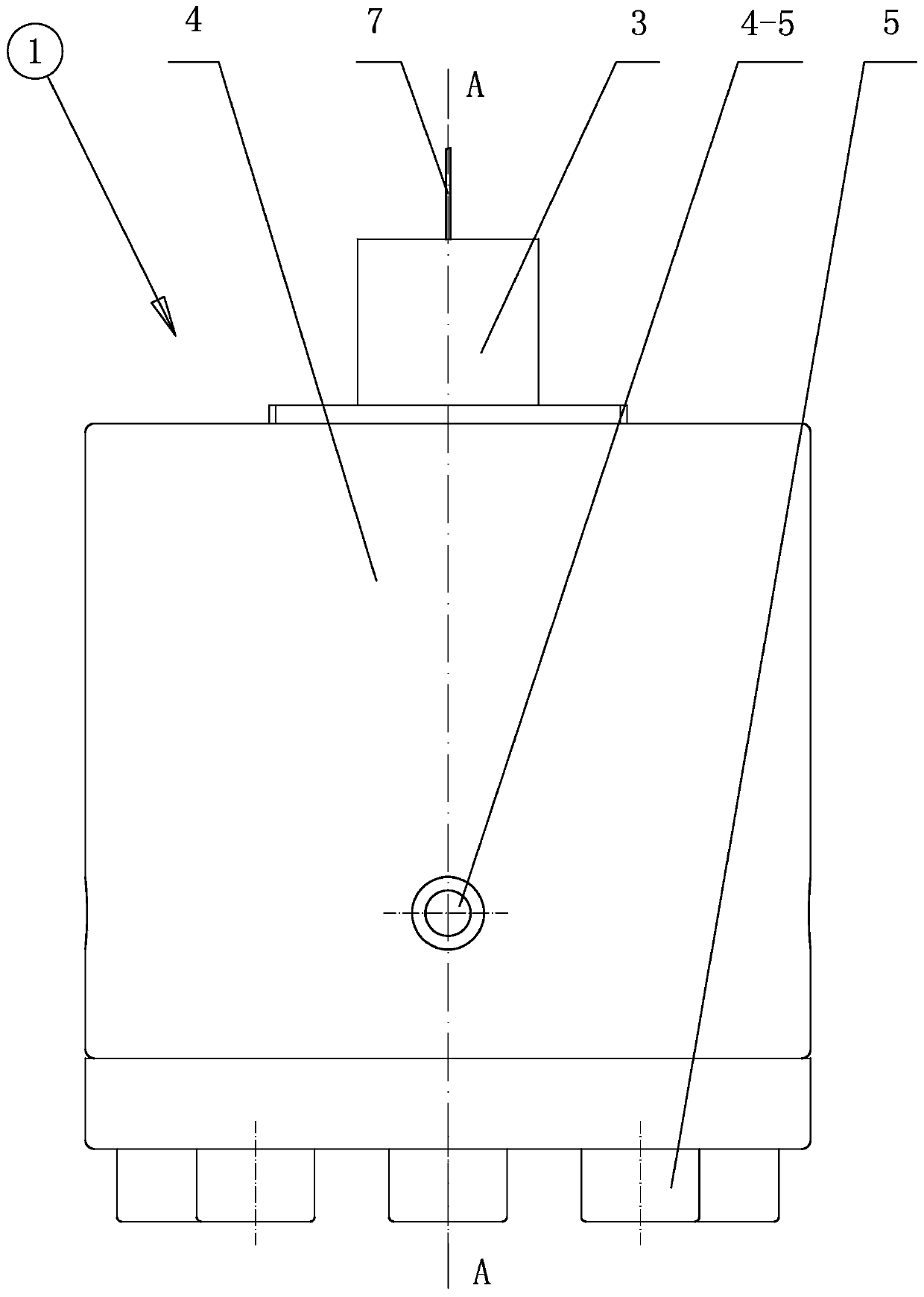

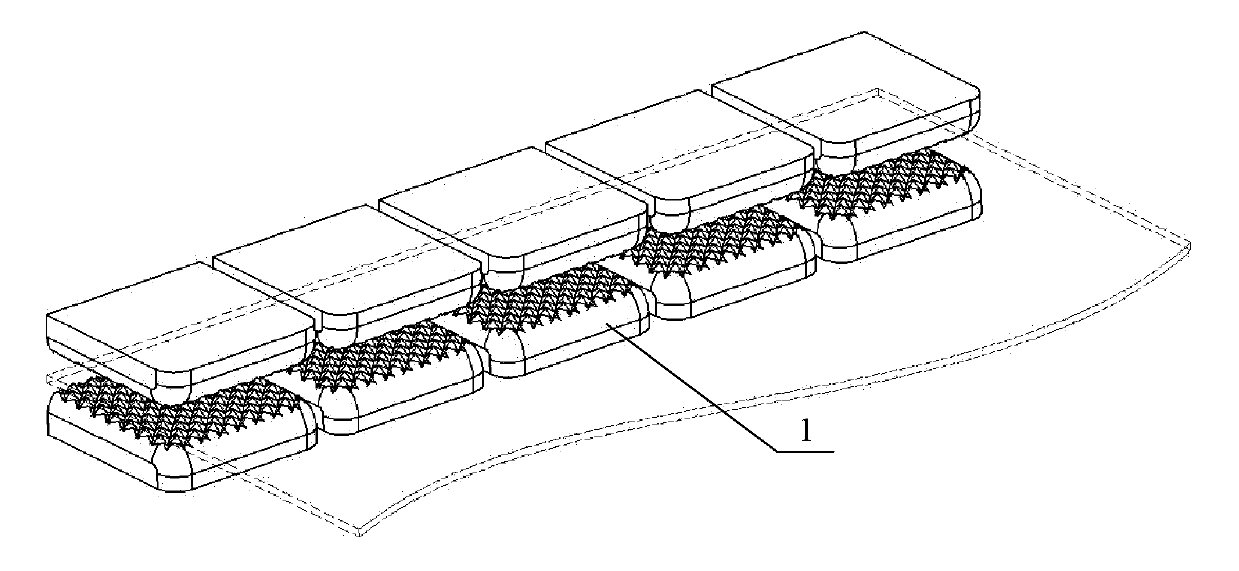

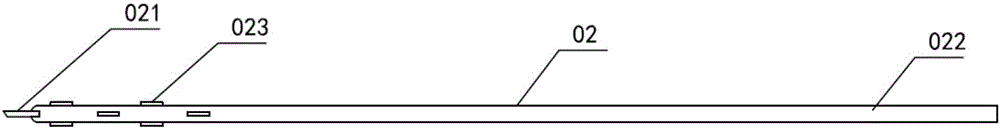

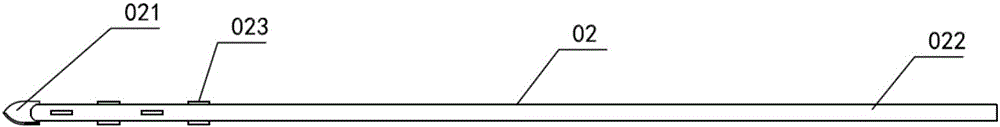

Material clamping block for multi-clamp type stretch forming machine

InactiveCN101947595ARealize flexible controlAchieving Stretch FormingEngineeringMechanical engineering

The invention discloses a material clamping block for a multi-clamp type stretch forming machine, relating to a plastic processing device for curve surface forming of sheet parts and belonging to the field of mechanical engineering. The material clamping block comprises two rows of multiple pairs, and the two rows are respectively arranged on the left side and the right side of the stretch forming machine. A gap is reserved between two adjacent material clamping blocks, a chine line and two angles on the front end of the material clamping face of each material clamping block are large rounded corners, and chine lines on the left end and the right end of the material clamping surface adjacent to other material clamping blocks are also provided with round corners. The design allows each material clamping block and a material clamping mechanism to passively produce unequal rotation, swinging or stretching to form arc or waveform linear parallelism, and the flexible control of multiple clamps of the stretch forming machine is realized; and the invention is beneficial to a workpiece to snuggle to a mold during stretching, the material utilization rate of the workpiece is obviously increased, and the stretching forming of a complex workpiece is realized.

Owner:JILIN UNIV

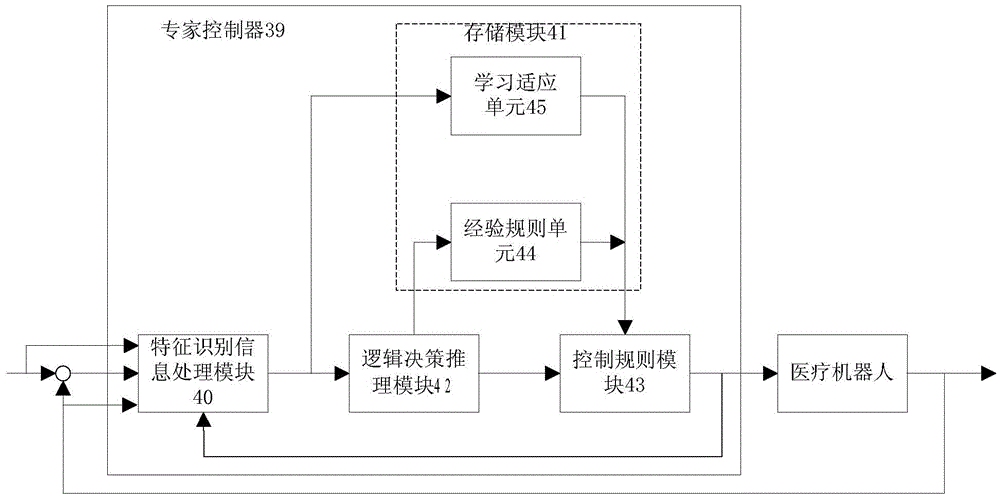

Expert control system for medical robot and implementation method thereof

ActiveCN104636583ATo achieve the purpose of precise treatmentRealize flexible controlProgramme-controlled manipulatorFractureInformation processingControl system

The invention relates to an expert control system for a medical robot and an implementation method thereof. The expert control system comprises an expert controller and is characterized in that the expert controller comprises a feature identifying information processing module connected with a storage module and a logic decision reasoning module through communication, the storage module is used for storing expert experience data, the logic decision reasoning module is used for determining an expert empirical model, the logic decision reasoning module is connected with a control rule module through communication, and the control rule module is connected with the medical robot through communication; the medical robot has certain expert intelligence and assists doctors in making reasonable treatment schemes, the ordinary doctors can have the diagnosis and treatment level of experts, and the purpose of conducting accurate treatment on patients is achieved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

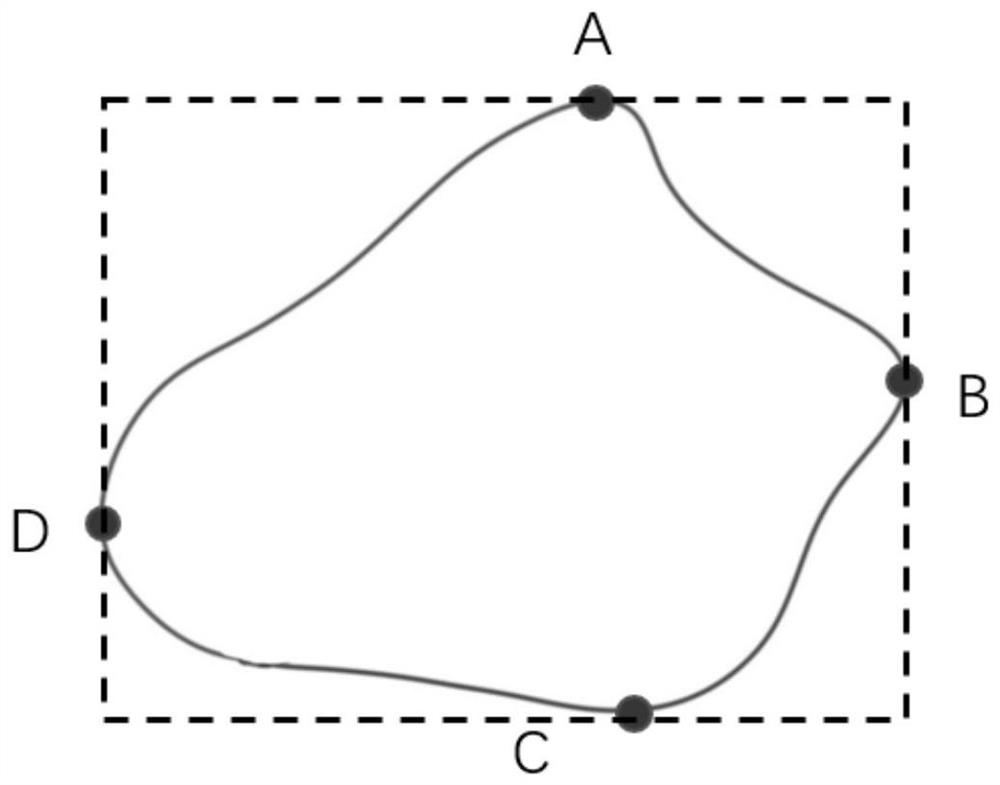

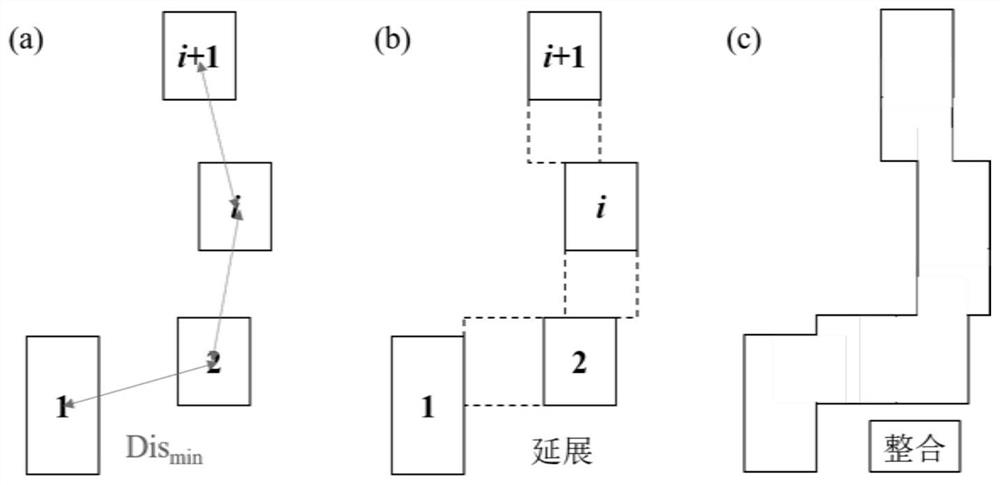

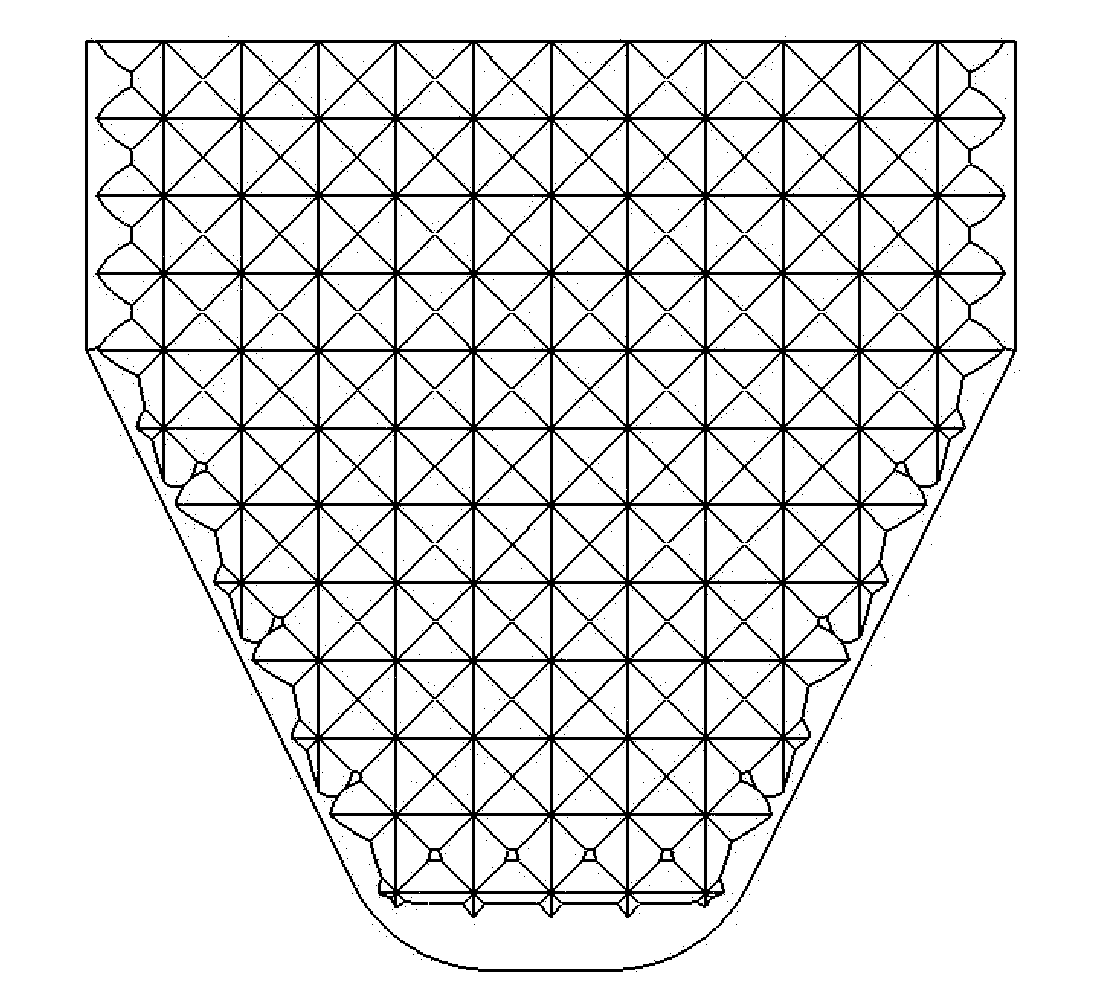

Flexible conveying belt and trajectory planning method thereof

ActiveCN111806997ARealize flexible controlRealize the purpose of flexible transportationControl devices for conveyorsSupporting framesControl engineeringTrajectory planning

The invention provides a flexible conveying belt and a trajectory planning method of the flexible conveying belt. The flexible conveying belt comprises flexible conveying units which can be intelligently controlled. After the flexible conveying units are connected in an end-to-end mode, a sensor arranged on one flexible conveying unit can detect a preset obstacle mark and a preset destination markso that the conveying length and the bending angle can be changed at any time according to the actual demand of the place, and the situation that objects arrive at the destination at the shortest distance as the objects bypass an obstacle can be guaranteed.

Owner:北京木跃智能科技有限公司

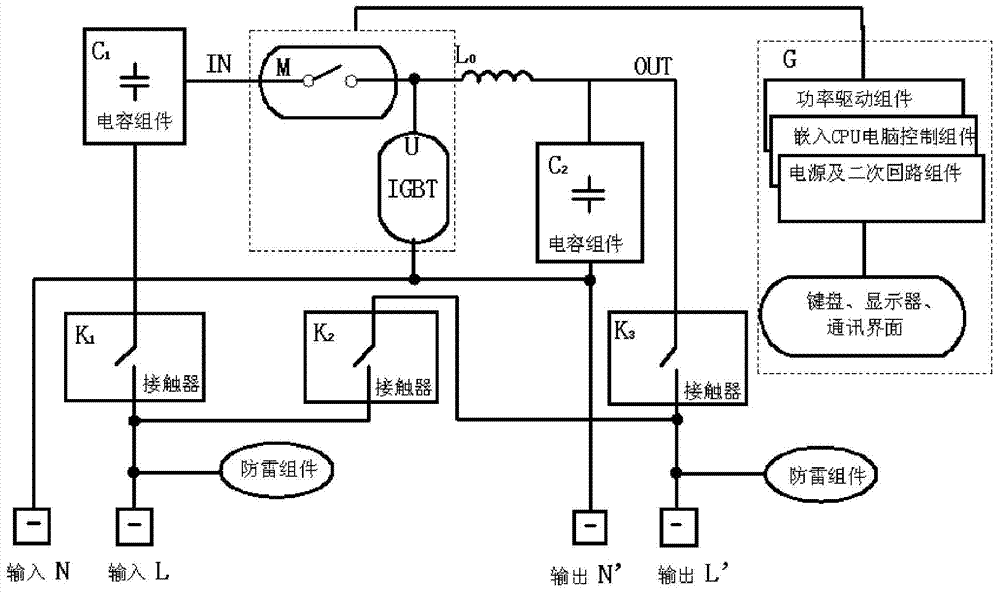

Novel voltage reduction energy saver based on 'AC-AC' chopping power electronic technology

InactiveCN104717791ASmooth Continuous AdjustmentRealize flexible controlElectric light circuit arrangementEnergy saving control techniquesCapacitanceLow-pass filter

The invention provides a novel voltage reduction energy saver based on an 'AC-AC' chopping power electronic technology. The novel voltage reduction energy saver comprises a null line input end, a phase line input end, a null line output end, a phase line output end, a first switch, a second switch, a third switch, a first capacitor assembly, a second capacitor assembly, a first high-frequency switch, a second high-frequency switch, an inductance coil and a controller. The first high-frequency switch and the second high-frequency switch are in series connection to constitute an 'AC-AC' chopper, the inductance coil and the second capacitor assembly are in series connection to constitute a low pass filter, and the 'AC-AC' chopper is connected. A standby circuit is further arranged between the phase line input end and the phase line output end. According to the technical scheme, line voltages can be adjusted smoothly and continuously, flexible control over a light source is achieved, when a chopping voltage reduction branch circuit in the circuit breaks down, the branch circuit only needs to be switched to a standby circuit, and accordingly the chopping voltage reduction branch circuit can be repaired in the state that an illuminating system works normally.

Owner:天津光通照明科技有限公司

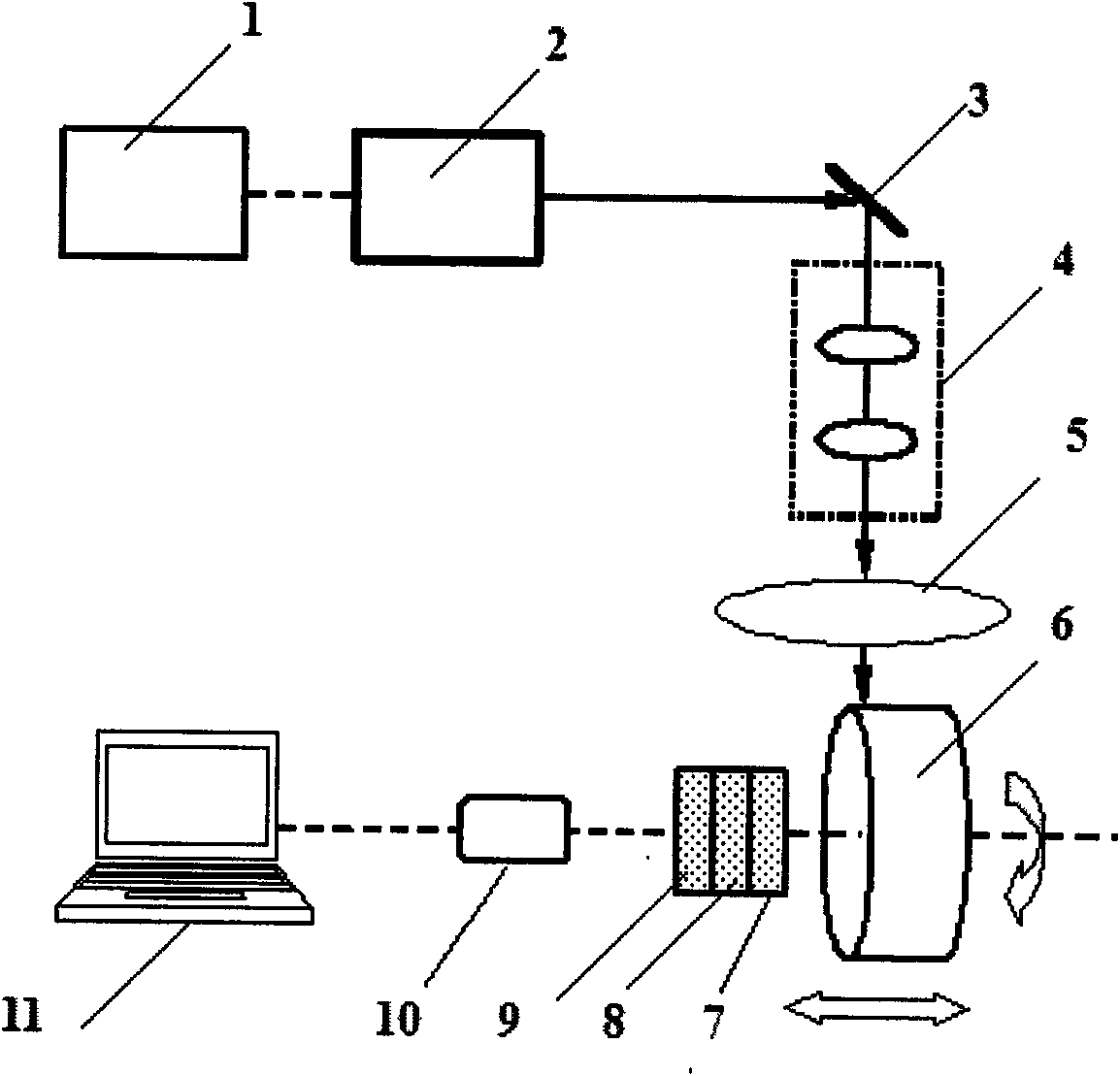

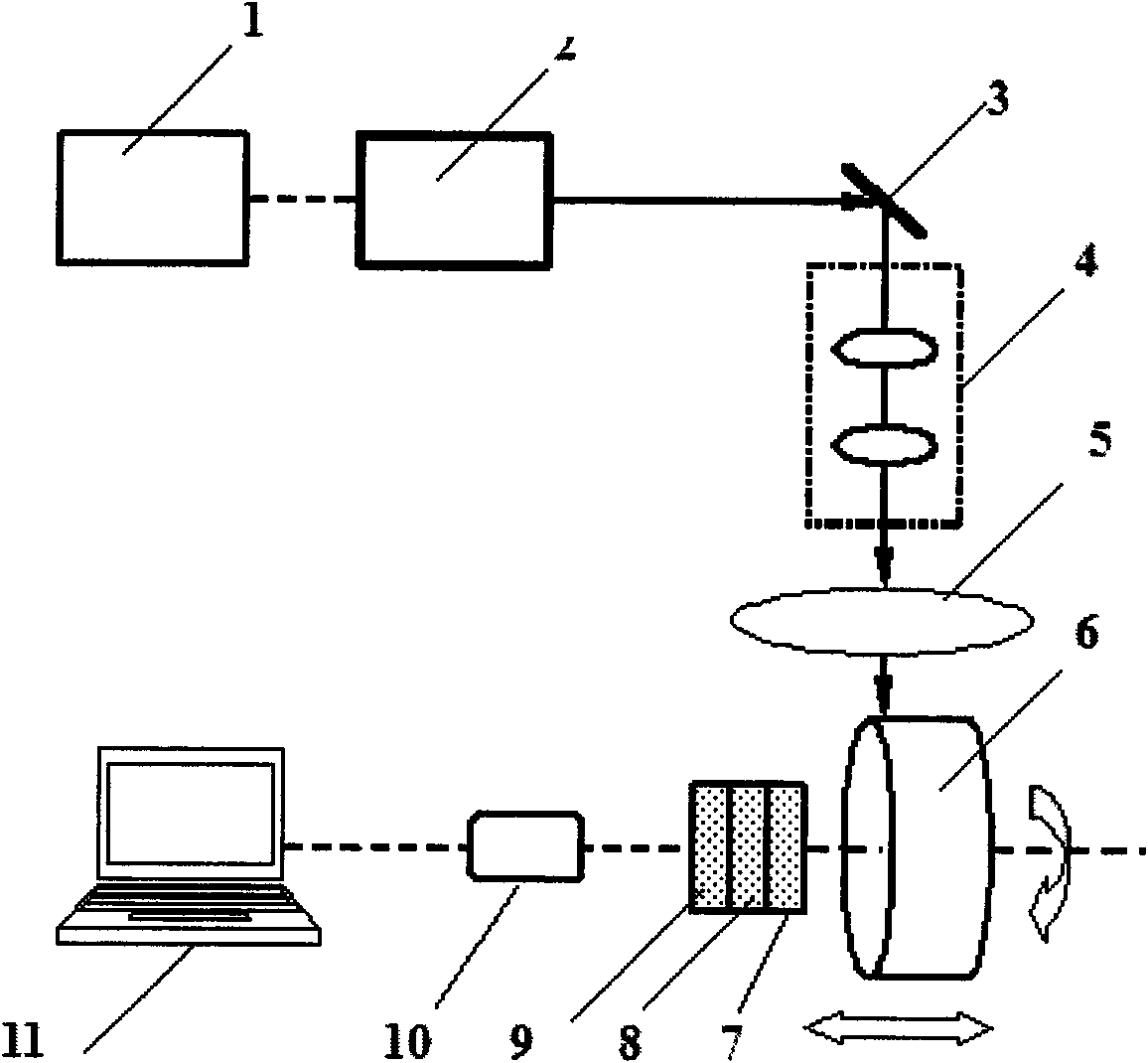

Method for processing antiwear texture of polyoxymethylene support ring

ActiveCN102172798AImprove machining accuracyEasy to processLaser beam welding apparatusSurface engineeringComputer control

The invention discloses a method for processing the antiwear texture of a polyoxymethylene support ring, which belongs to the technical field of surface engineering. A pulsed laser surface treatment device is adopted in the method and composed of a controller, a pulsed laser, a holophote, an extender lens, a focusing mirror, the polyoxymethylene support ring, a rotating table, an X-direction translational device, a Z-direction translational device, a stepping motor and a computer. The method comprises the steps: after the deoiling processing of the polyoxymethylene support ring, the polyoxymethylene support ring is installed on the rotating table, and the surface of the polyoxymethylene support ring is in the height range of texture processing by the adjustment of the Z-direction translational device; average laser power is adjusted in the range of texture processing, and the computer controls the scanning track of a laser focus on the surface of the polyoxymethylene support ring by controlling the X-direction translational device and the rotating table; and the pulsed laser surface treatment device is started to process the polyoxymethylene support ring. The invention has the advantages of high processing precision, convenience for processing, high efficiency, wide range of application, improvement of antiwear performance for the polyoxymethylene support ring and prolonging of service life of the polyoxymethylene support ring.

Owner:XUZHOU YONGJIA HYDRAULIC EQUIP

Automatic marble long hole water-free perforating machine

InactiveCN105922457ANormal workloadNormal working temperatureWorking accessoriesStone-like material working toolsDriving currentAutomatic control

The invention provides an automatic marble long hole water-free perforating machine which comprises a power head, a long rod drill, a marble fixing device, a control device and a machine frame. A drill body faces upwards; a drill rod included angle is formed between a drill rod and the horizontal plane and is an acute angle; the diameter of the drill body is larger than that of the drill rod; four pairs of drilling wings are arranged at the end, close to the drill body, of the drill rod; the control device comprises a cutting output control module and a drill body working control module; the cutting output control module is used for controlling the cutting output of the drill body to be smaller than or equal to the maximum cutting removal rate of the long rod drill; and the drill body working control module is used for controlling the drill body to work according to the drive current of the drill body or the pressure of the drill body. The drill body faces upwards and acts by utilization of gravity of cut stone chips; the diameter of the drill body is larger than that of the drill rod, the multiple pairs of drilling wings are arranged on the drill rod, and the technical problem that in the stone chip removal process, as the stone chips adhere to each other, stone chip removal is not smooth is avoided; and through the drill body working control module, the effect that in the cutting process, automatic control is achieved according to the characteristics of stone is achieved.

Owner:王军

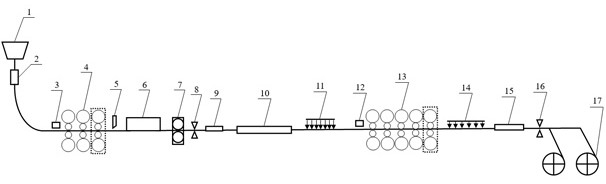

Multi-mode energy-saving hot-rolled strip steel production line and using method thereof

ActiveCN111842483AReduce energy consumptionImprove internal organizationWork treatment devicesMetal rolling arrangementsTundishScrap

The invention discloses a multi-mode energy-saving hot-rolled strip steel production line. The multi-mode energy-saving hot-rolled strip steel production line mainly involves a continuous casting tundish, a mold, a descaling machine 3, a roughing mill, a swing shear, an intermediate billet manipulator, a hot coil box, a rolling shear, a scrap steel removing device, a soaking pit furnace, an intermediate cooling device, a descaling machine 12, a finishing mill, a laminar cooling device, an induction soaking device, a flying shear and a recoiling machine, wherein the intermediate cooling deviceis arranged between the soaking pit furnace and the finishing mill, the scrap steel removing device is arranged behind the rolling shear, the scrap steel removing device do not communicate with the soaking pit furnace, the movable hot coil box is arranged between the intermediate billet manipulator and the rolling shear, and the induction soaking device is arranged between the laminar cooling device and the flying shear; and a using method comprises the following steps of smelting; casting into a blank; descaling for the first time; rough rolling; heating; cooling; descaling for the second time; finish rolling; cooling; electromagnetic induction heating; and coiling. The method not only has austenite rolling, but also can realize ferrite rolling, single-billet rolling and continuous rolling can be further achieved, and a product is uniform in mechanical property, low in comprehensive energy consumption and wide in thickness coverage range.

Owner:WUHAN UNIV OF SCI & TECH

Multiclamp type stretch forming machine

The invention discloses a multiclamp type stretch forming machine and relates to plastic processing equipment for curve forming of plates, belonging to the field of mechanical engineering. The machine mainly comprises clamping mechanisms (1), a stretching mechanism (2) and a stand (3), wherein a row of clamping mechanisms (1) are respectively distributed at both sides of the stand (3); each clamping mechanisms (1) is provided with a lower connecting hole (4) and a rear connecting hole (5); and all the connecting holes are respectively connected with the stretching mechanism (2) by pin shafts or cardan joints. The machine can realize the flexible control of a plurality of clamps, ensure that a workpiece is more easily attached to a die in the stretching process, obviously improve the material utilization ratio of the workpiece and obtain higher workpiece forming effect.

Owner:长春瑞光科技有限公司

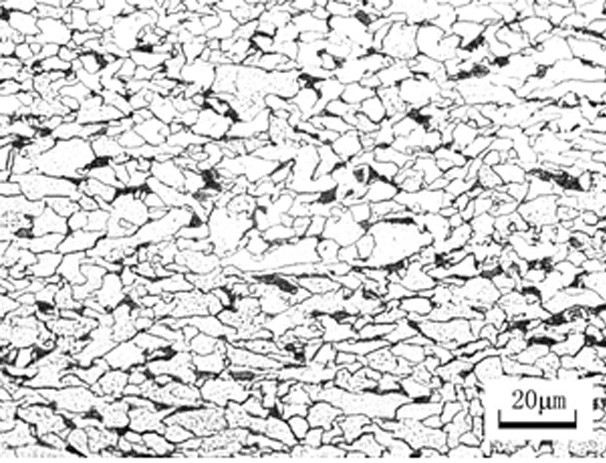

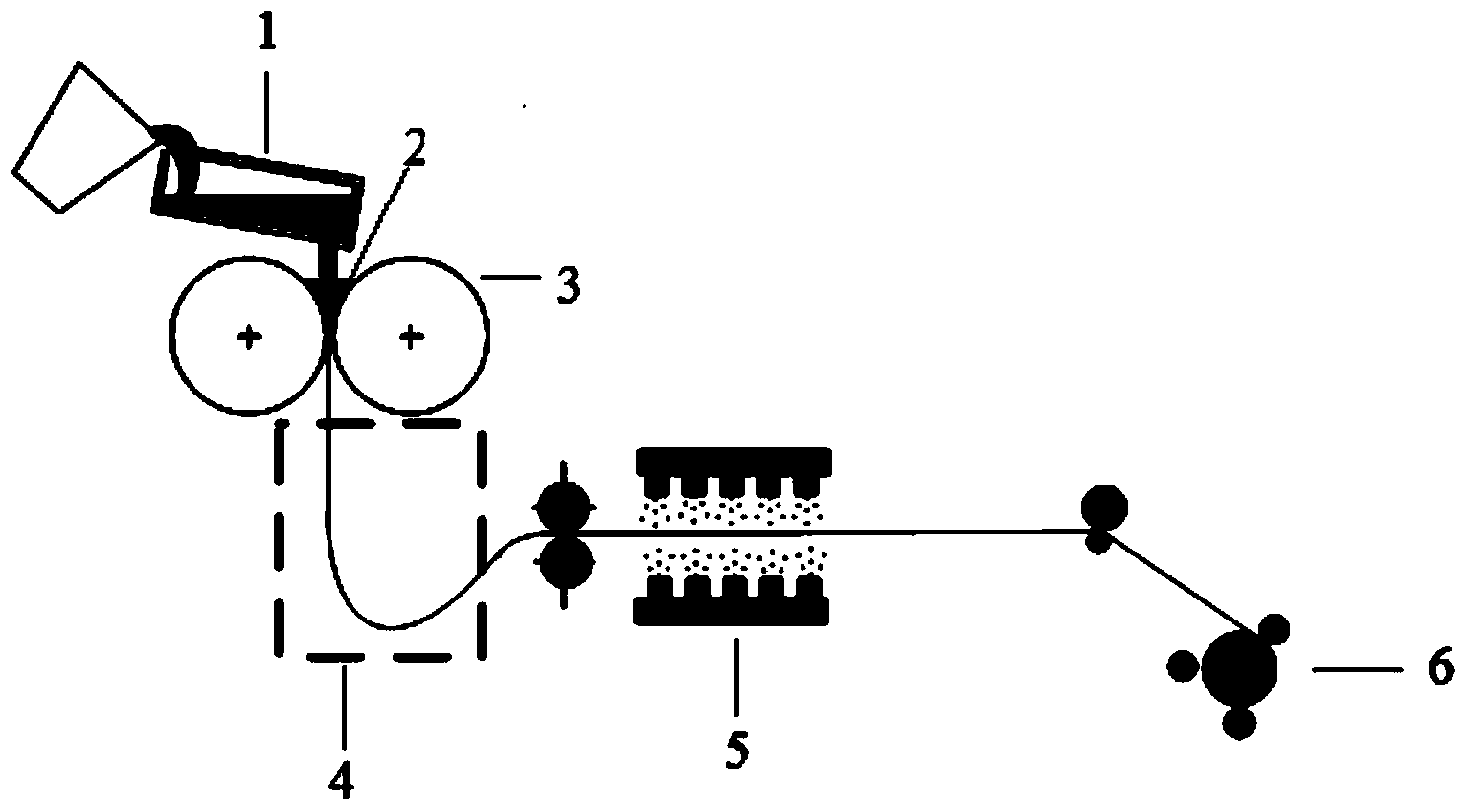

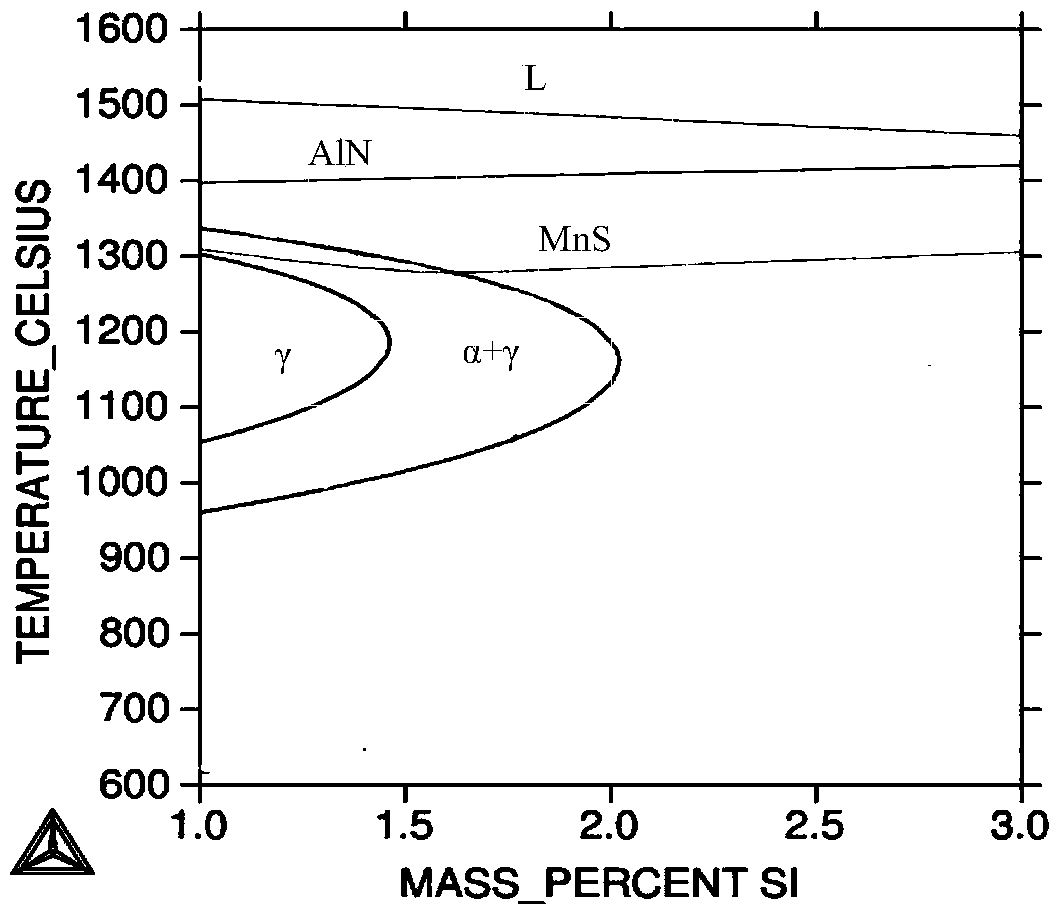

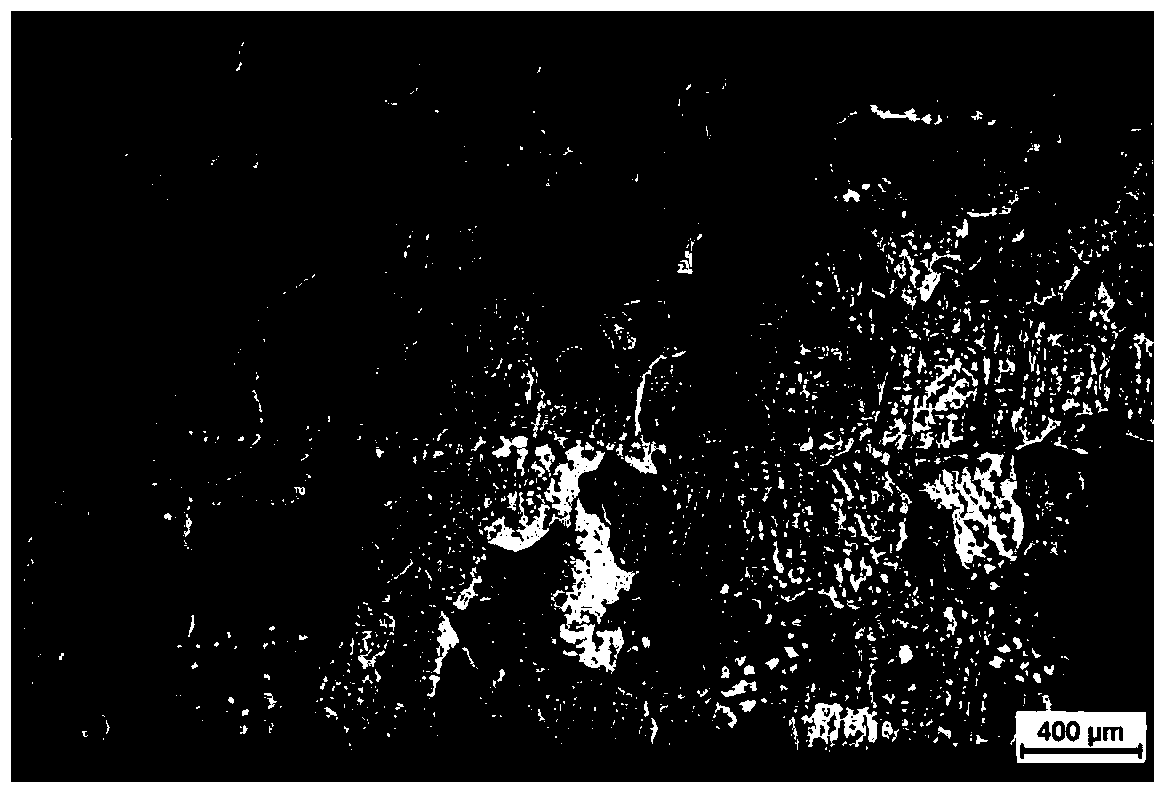

Method for controlling precipitates and impurities in twin-roll thin-strip casting process of non-oriented silicon steel

The invention belongs to the technical field of metallurgy, aims at the problem of not having a proper method for controlling precipitates and impurities in the process of producing non-oriented silicon steel in a twin-roll thin-strip casting manner, and provides a method for controlling the precipitates and impurities in the twin-roll strip casting process of non-oriented silicon steel. The method comprises the following steps of solidifying and forming molten non-oriented silicon steel by a twin-roll thin-strip casting machine so as to obtain cast strips with a thickness of 2.0-2.6 mm; taking the cast strips out of rolls, feeding the cast strips in a secondary cooling zone after casting, and slowly cooling the cast strips in a slow cooling chamber; feeding the cast strips into a tertiary cooling zone for fast cooling; cooling and coiling the cast strips which are subjected to the fast cooling by the tertiary cooling zone, and then obtaining non-oriented silicon steel cast strips. By utilization of the method, AlN precipitates in the cast strips reach a level of 0.5-2.0 microns, and the precipitation of MnS is obviously inhibited, so that the influence of the AlN and MnS precipitates on recrystallized grain growth and magnetic domain-wall movement is essentially eliminated, and a basis is laid for developing high-quality non-oriented silicon steel.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com