Automatic cleaning machine for workpieces

A technology for automatic cleaning machines and workpieces, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of unguaranteed cleaning quality and high production costs, and achieve stable cleaning product quality. Stable parameters and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

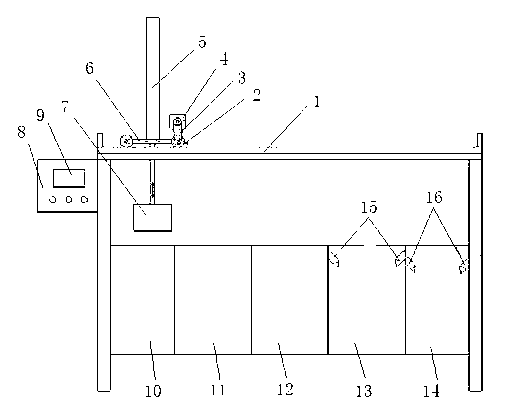

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] see figure 1 , an automatic workpiece cleaning machine is mainly composed of a truss type rack track 1, a trolley 6 with a gear type wheel 2, a hopper 7, a lifting cylinder 5, a servo motor 4 and a programmable logic controller 8 with a parameter setting touch screen 9 , the rack track 1 is placed horizontally above the cleaning tank, the cleaning tank has a pickling tank 10, an ultrasonic clear water tank 11, an alkaline water tank 12, a tap water tank 13 and a hot air tank 14, and the tap water tank 13 is provided with a tap water spray pipe 15, The hot air blowing pipe 16 is arranged in the hot air groove 14, the trolley 6 moves on the gear track 1 through the gear wheel 2, the lifting cylinder 5 and the servo motor 4 are fixed on the trolley 6, and the hopper 7 for loading workpieces is suspended on the lifting cylinder 5. The servo motor 4 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com