Method for preparing polyolefin through coordination polymerization in micro-reactor

A technology of microreactor and coordination polymerization, which is applied in the field of polyolefins, can solve the problems of easy violent polymerization, failure to meet the gas-liquid phase coexistence requirements of olefin coordination polymerization, and difficult to achieve olefin polymerization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

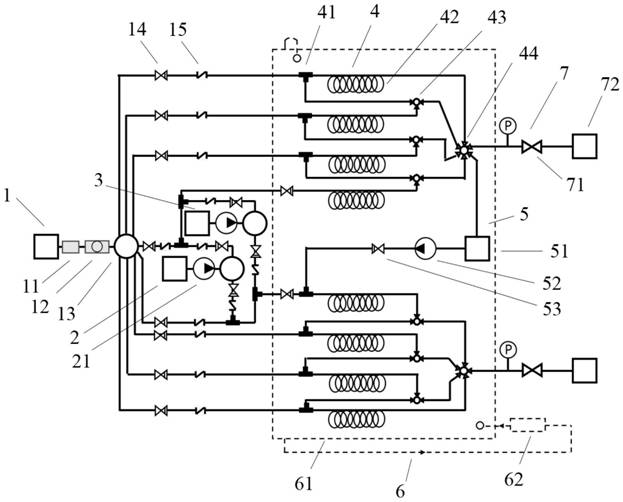

[0075]In this embodiment, the first feed module 1 includes a filter 11, a mass flow meter 12 and a splitter 13, which are gas olefin monomer feed ports.

[0076] (1) Ethylene monomer enters the micro-reaction channel through the filter 11 and the mass flow meter 12 of the first feeding module 1; The high-pressure constant-flow pump enters the flow channel of the microreactor; the fluid B is composed of biscyclopentadienyl zirconium dichloride and xylene at a concentration of 2.31×10 -2 mg / mL mixed; the cocatalyst fluid C enters the microreactor flow channel through the high-pressure constant flow pump 21 of the second feed module 2 at a flow rate of 0.5mL / min; the fluid C is made of MAO and xylene at a concentration of 9.16mg / mL mixed;

[0077] (2) The material of the micro-reaction channel used is stainless steel. The tube length of a single main reaction module is 8m, the outer diameter is 3.18mm, and the inner diameter is 2mm; The time is about 30 minutes;

[0078] (3) C...

Embodiment 2

[0093] In this embodiment, the first feed module 1 includes a filter 11, a mass flow meter 12 and a splitter 13, which are gas olefin monomer feed ports.

[0094] (1) Propylene monomer enters the micro-reaction channel through the filter 11 and the mass flow meter 12 of the first feed module 1; the main catalyst fluid B passes through the high pressure of the third feed module 3 at a flow rate of 0.5mL / min The constant flow pump enters the flow channel of the microreactor; the fluid B is made of TiCl 4 / Dimethyl phthalate / MgCl 2 It is mixed with solvent white oil at a concentration of 1.25mg / mL; the cocatalyst fluid C enters the microreactor flow channel through the high-pressure constant-flow pump 21 of the second feed module 2 at a flow rate of 0.5mL / min; the fluid C It is composed of triethylaluminum, external electron donor cyclohexylmethyldimethoxysilane, and n-heptane at a concentration of 6.25mg / mL and 60mg / mL;

[0095] (2) The material of the micro-reaction flow chan...

Embodiment 3

[0100] In this embodiment, the first feed module 1 includes a filter 11, a mass flow meter 12 and a splitter 13, which are gas olefin monomer feed ports.

[0101] (1) Propylene monomer enters the micro-reaction channel through the filter 11 and the mass flow meter 12 of the first feed module 1; the main catalyst fluid B passes through the high pressure of the third feed module 3 at a flow rate of 0.5mL / min The constant flow pump enters the flow channel of the microreactor; the fluid B is made of TiCl 4 / fluorene diether / MgCl 2 Mixed with white oil with a concentration of 1.25mg / mL; the cocatalyst fluid C enters the microreactor flow channel through the high-pressure constant-flow pump 21 of the second feed module 2 at a flow rate of 0.5mL / min; the fluid C is obtained by Triethylaluminum and comonomer undecenyl alcohol are mixed with n-heptane at concentrations of 6.25mg / mL and 9.4mg / mL, respectively;

[0102] (2) The material of the micro-reaction flow channel used is stainl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com