Automatic marble long hole water-free perforating machine

A marble and drilling machine technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of high scrap rate, low efficiency of marble drilling slender holes, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

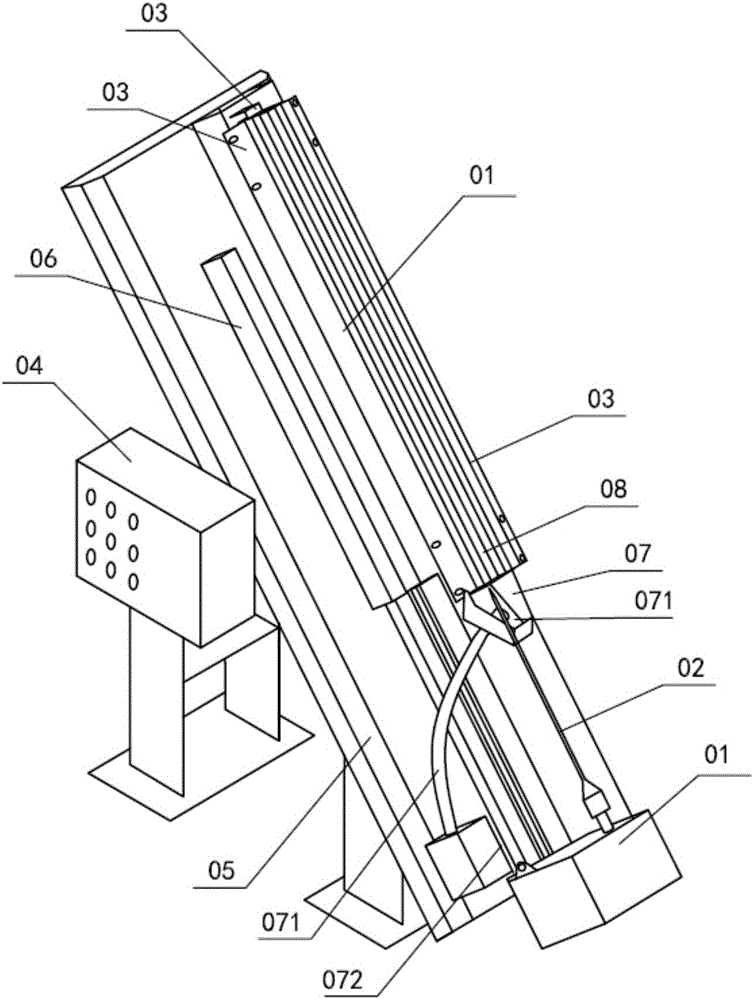

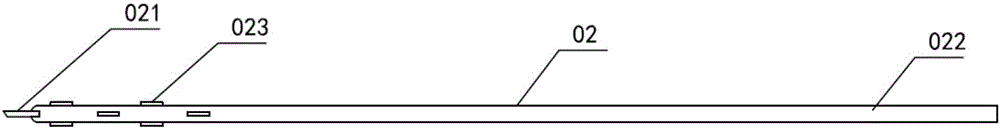

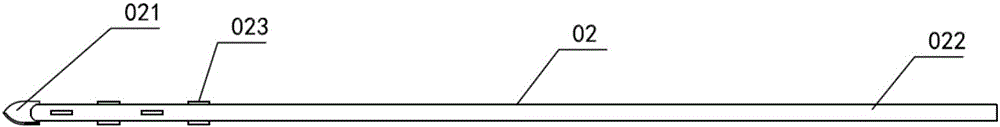

[0059] The structural diagram of the embodiment of the automatic punching machine of the present invention can be found in figure 1 , including a power head 01, a long-stem drill bit 02, a marble fixing device 03, a control device 04 and a frame 05, the power head 01, a marble fixing device 03 and a control device 04 are arranged on the frame 05, and the long-stem drill bit 02 includes a drill bit 021 And the drill rod 022, the drill rod 022 is installed on the power head 01, the drill bit 021 faces the marble fixture 03; the control device 04 controls the work of the long rod drill 02; the marble fixture 03 is a six-sided clamping fixture, through the six-sided clamp Tight fixture fastens marble 08 on the frame 05.

[0060] The drill bit 021 faces upwards, and the drill rod 022 forms a drill rod angle with the horizontal plane, and the drill rod angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com