Method for processing antiwear texture of polyoxymethylene support ring

A processing method and technology for supporting rings, which are applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of easy wear and large friction coefficient, and achieve the effects of wide application range, high processing accuracy and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

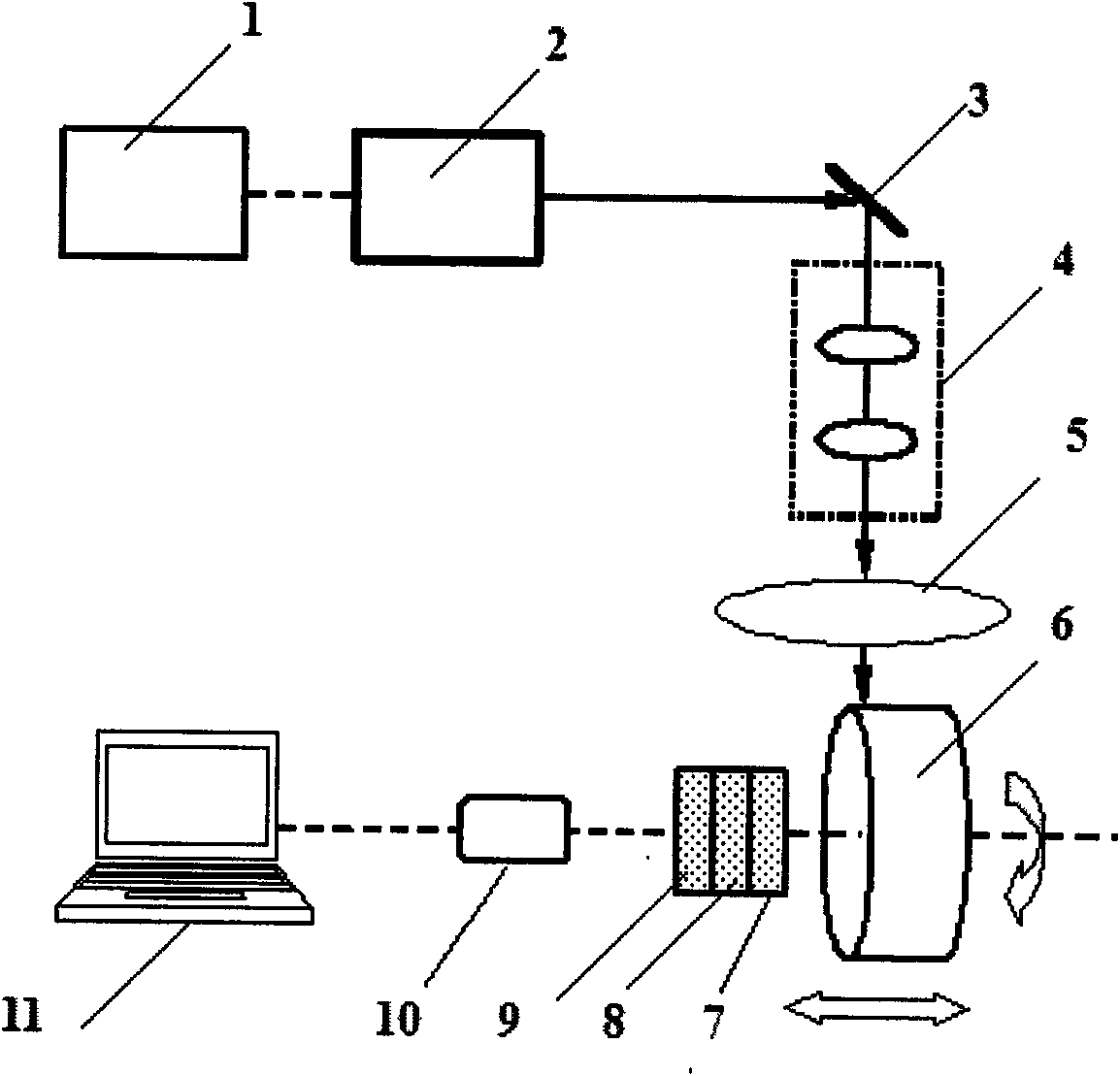

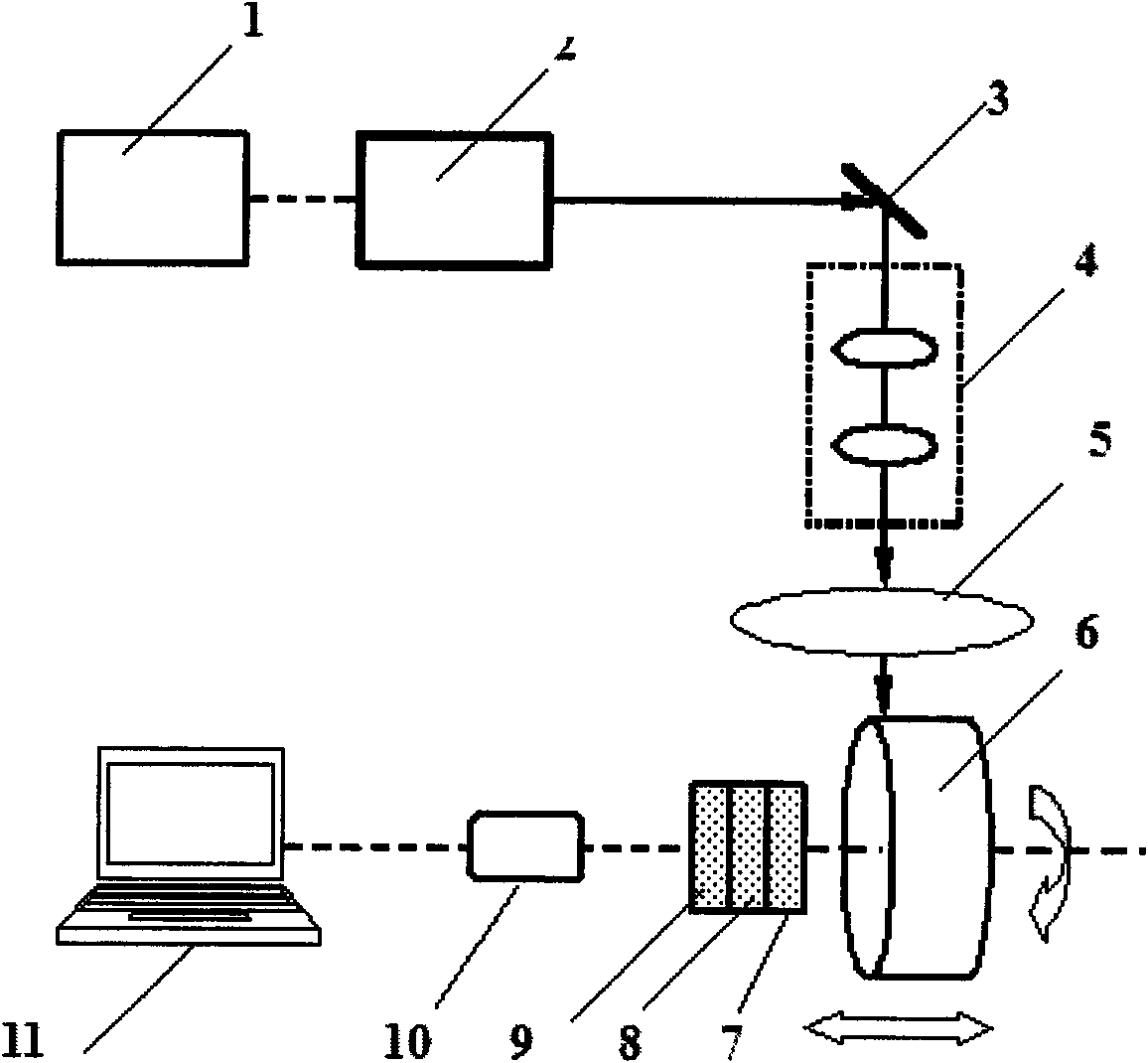

[0021] As shown in the accompanying drawings, the anti-wear texture processing method of polyoxymethylene support ring adopts a pulse laser surface treatment device. The pulse laser surface treatment device has a controller 1, and a pulse laser 2 connected to the controller 1. A total reflection mirror 3 is installed at the place, a beam expander 4 is installed under the total reflection mirror 3, a focusing mirror 5 is installed under the beam expander 4, a rotary table 7 is installed under the focusing mirror 5, and a X direction translation device 8, Z direction translation device 9 is installed on the X direction translation device 8; Rotary table 7, X direction translation device 8 and Z direction translation device 9 are each connected with a stepper motor 10; all stepper motors 10 are It is connected with the computer 11; the polyoxymethylene support ring is installed on the rotary table 7 during work. Among them: the controller 1 and the pulse laser 2 constitute a puls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com