Oriented high silicon steel strip and efficient annealing-mode preparation method thereof

A high-silicon steel and thin strip technology, applied in the field of metallurgy, can solve problems such as insufficient precipitation, large temperature difference between the inside and outside of the rolled annealed steel ring, and limited addition of grain boundary segregation elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] An oriented high-silicon steel thin strip, the composition of the thin strip is shown in Table 1 by weight percentage, and the balance is Fe and other unavoidable impurities.

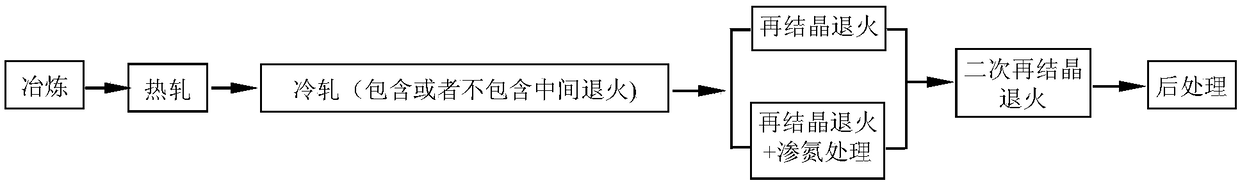

[0074] A method for preparing a high-efficiency annealing mode of an oriented high-silicon steel strip, comprising the steps of:

[0075] step 1:

[0076] Smelt according to the set composition of 9 groups of oriented high-silicon steel thin strips in Table 1, and die-cast into slabs at 1440-1600 °C;

[0077] Step 2:

[0078] Heating the slab to 1250°C for a holding time of 90 minutes; then performing hot rolling with a starting temperature of 1150°C and a final rolling temperature of 950°C to obtain a hot-rolled sheet with a thickness of 2.2mm;

[0079] Step 3:

[0080] Pickling the hot-rolled plate to remove the oxide layer;

[0081] Step 4:

[0082] The hot-rolled plate after pickling is rolled by the second cold rolling method, the first rolling reduction rate is 70%, the rolling tempera...

Embodiment 2

[0094] An oriented high-silicon steel thin strip, the thin strip composition by weight percentage is: Si: 4.5%, C: 0.05%, Als: 0.03%, N: 0.006%, Mn: 0.08%, Cu: 0.5%, S : 0.007%, Nb: 0.15%, V: 0.005%, Sn: 0.06%, Mo: 0.05%, Cr: 0.1%, and the balance is Fe and other unavoidable impurities.

[0095] A method for preparing a high-efficiency annealing mode of an oriented high-silicon steel strip, comprising the steps of:

[0096] step 1:

[0097] Smelted according to the set composition of oriented high-silicon steel thin strip, molded into slab at 1500℃;

[0098] Step 2:

[0099] Heating the slab to 1280°C for a holding time of 30 minutes; then performing hot rolling at a starting temperature of 1200°C and a final rolling temperature of 1050°C to obtain a hot-rolled sheet with a thickness of 3 mm;

[0100] Step 3:

[0101] The hot-rolled sheet is subjected to normalization treatment, the temperature during the normalization treatment is 800°C, the time is 600min, and then water...

Embodiment 3

[0112] An oriented high-silicon steel thin strip, the composition of the thin strip by weight percentage is: Si: 7.0%, C: 0.1%, Als: 0.05%, N: 0.003%, Mn: 0.1%, Cu: 0.5%, S : 0.035%, Nb: 0.4%, V: 0.1%, Mo: 1.0%, Cr: 1.0%, B: 0.5%, and the balance is Fe and other unavoidable impurities.

[0113] A method for preparing a high-efficiency annealing mode of an oriented high-silicon steel strip, comprising the steps of:

[0114] step 1:

[0115] Smelted according to the set composition of oriented high-silicon steel thin strip, and molded into slabs at 1440°C;

[0116] Step 2:

[0117] Heating the slab to 1200°C for a holding time of 120 minutes; then performing hot rolling at a starting temperature of 1120°C and a final rolling temperature of 900°C to obtain a hot-rolled sheet with a thickness of 1.5mm;

[0118] Step 3:

[0119] The hot-rolled sheet is subjected to normalization treatment, the temperature during the normalization treatment is 1200°C, the time is 1min, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com