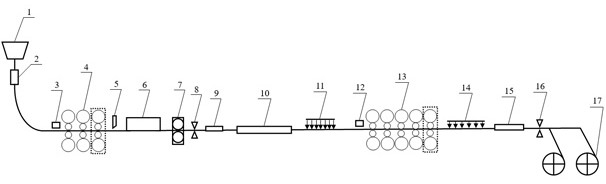

Multi-mode energy-saving hot-rolled strip steel production line and using method thereof

A hot-rolled strip steel, energy-saving technology, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of full-line shutdown and high energy consumption per ton of steel, and achieve CO2 emission reduction, energy consumption reduction, Effect of reducing CO2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The chemical composition and mass percentage of low carbon steel: C: 0.01%, Si: 0.52%, Mn: 0.31%, P: 0.012%, S: 0.002%, N: 0.005%, the rest is Fe and unavoidable of impurities.

[0083] Austenitic steel, using single billet rolling mode;

[0084] Production Process:

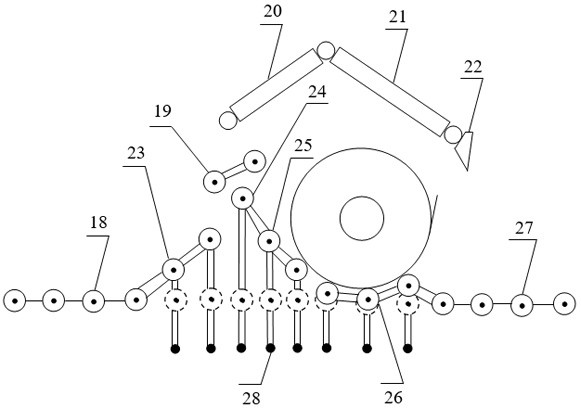

[0085] The thickness range of the continuous casting slab is 131mm, and the range of continuous casting casting speed is 6.8m / min; the first high-pressure water descaling is performed on the slab, and the pressure of the descaling water is 49MPa; the rough rolling mill 4 composed of 3 stands is used for descaling Rough rolling, the thickness of the intermediate billet outlet is 4mm; the single billet rolling mode is adopted: the billet is cut into short billets of 23 tons; in this mode, the mobile hot coil box 7 starts the lifting rod 28 of the lifting hydraulic device , so that the deflection roller 23, the forming roller 25, and the push roller 26 rise to a certain height, the lifting hydraulic device ...

Embodiment 2

[0087] The chemical composition and mass percentage of low carbon steel: C: 0.07%, Si: 0.05%, Mn: 0.54%, P: 0.011%, S: 0.005%, N: 0.006%, the rest is Fe and unavoidable of impurities.

[0088] Austenitic steel, using continuous rolling mode;

[0089] Production Process:

[0090] The thickness range of the continuous casting slab is 147mm, and the continuous casting speed range is 8.1m / min; the first high-pressure water descaling is carried out on the slab, and the descaling water pressure is 52MPa; the rough rolling mill 4 composed of 3 stands is used to carry out Rough rolling, the thickness of the intermediate billet exit is 11mm; in this production mode, the mobile hot coil box 7 makes the deflection roller 23, the forming roller 25, and the pushing roller 26 fall to the other parts are on the same horizontal line ( figure 2dotted line position), the lifting hydraulic device stops running, and the strip is directly emptied through the mobile hot coil box 7 to enter the ...

Embodiment 3

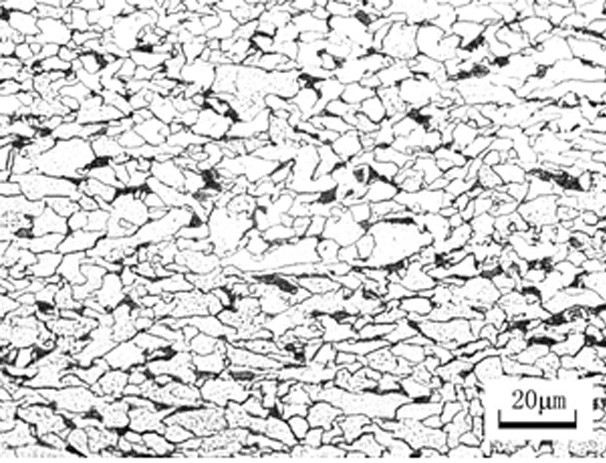

[0092] The chemical composition and mass percentage of medium carbon steel: C: 0.27%, Si: 0.83%, Mn: 1.2%, P: 0.015%, S: 0.003%, N: 0.004%, the rest is Fe and unavoidable of impurities.

[0093] Ferritic steel, using single billet rolling mode;

[0094] Production Process:

[0095] The thickness range of the continuous casting slab is 152mm, and the range of continuous casting casting speed is 7.7m / min; the first high-pressure water descaling is performed on the slab, and the descaling water pressure is 50MPa; the rough rolling mill 4 composed of 2 stands is used for Rough rolling, the thickness of the intermediate billet outlet is 27mm; the single billet rolling mode is adopted: the cast billet is cut into short billets of 35 tons; in this mode, the mobile hot coil box 7 activates the lifting rod 28 of the lifting hydraulic device , so that the deflection roller 23, the forming roller 25, and the push roller 26 rise to a certain height, the lifting hydraulic device stops ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com