Method for controlling precipitates and impurities in twin-roll thin-strip casting process of non-oriented silicon steel

A technology of twin-roll strip continuous casting and oriented silicon steel, which is applied in the field of metallurgy to achieve the effects of increasing control means, eliminating annealing and recrystallization grain growth and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The chemical composition of experimental steel A is shown in Table 1. The molten steel was poured at a temperature of 1620°C, and poured from a tundish preheated to 1200°C into the molten pool composed of rotating steel rolls and side sealing plates of a twin-roll thin strip continuous casting machine. The speed is 50m / min, the strip temperature is 1422±2°C, and the thickness of the cast strip is 2.2-2.5mm; the cast strip enters the secondary cooling section, passes through the slow cooling chamber with a temperature of 800-850°C, and cools slowly for 15 seconds, the end temperature of the slow cooling section 1310~1320°C; after the high-temperature slow cooling, the cast strip immediately enters the third cooling section for rapid cooling, the cooling rate is 70°C / s, and the final cooling temperature is 800°C; the rapidly cooled cast strip is air-cooled to 400°C for coiling.

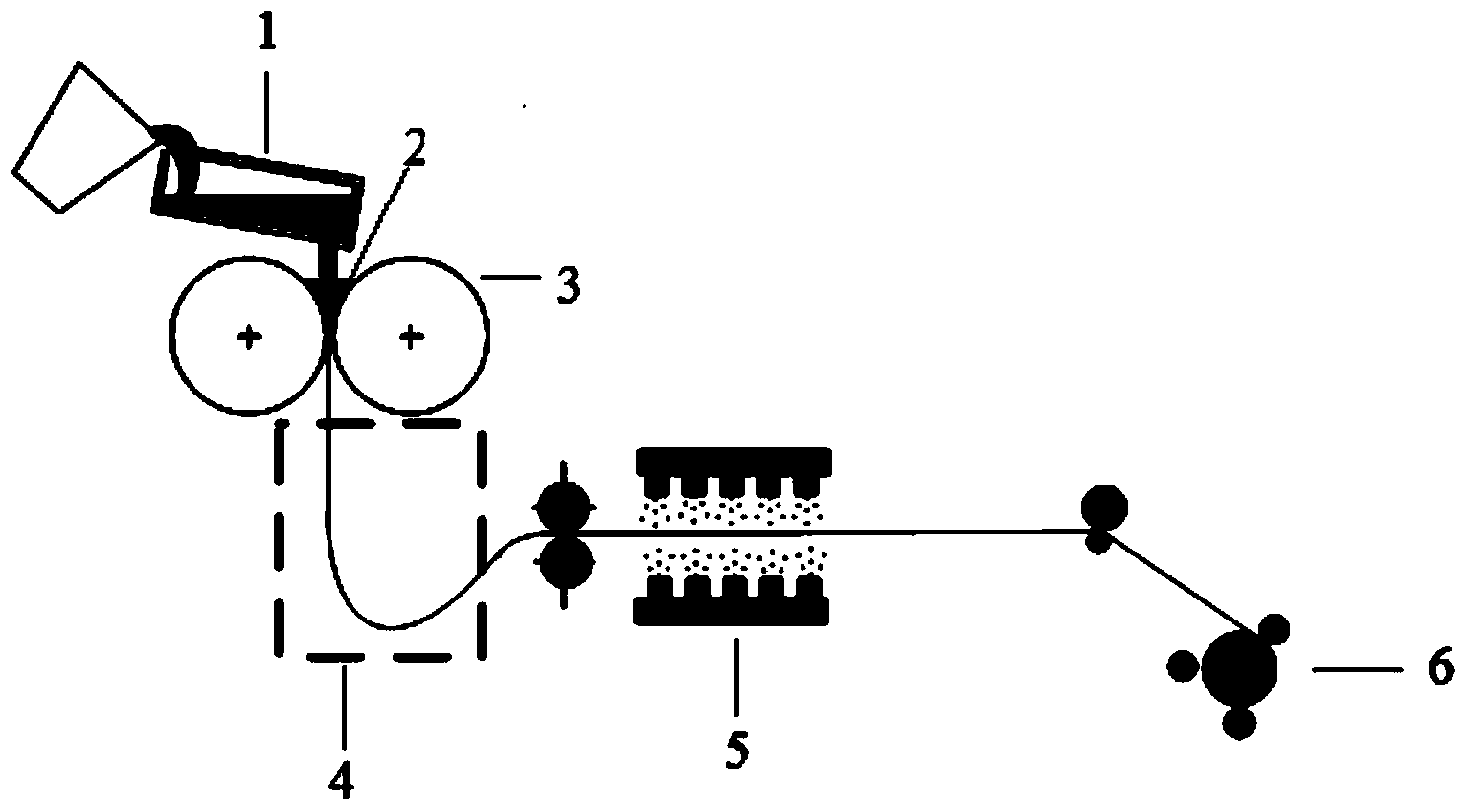

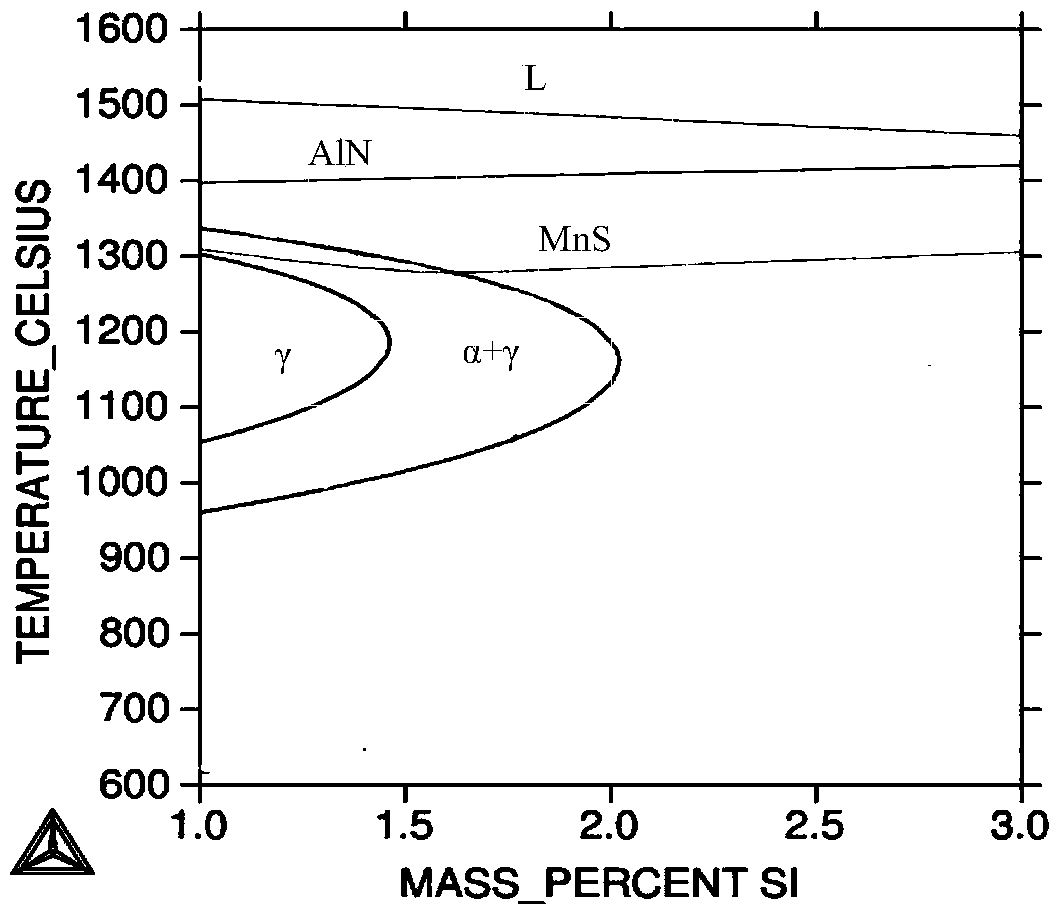

[0033] For the principle of casting and rolling process, see figure 1 , figure 2 The equili...

Embodiment 2

[0037] The chemical composition of experimental steel B is shown in Table 2. The molten steel was poured at a temperature of 1580°C, and poured from a tundish preheated to 1200°C into the molten pool composed of rotating steel rolls and side sealing plates of a twin-roll thin strip continuous casting machine. The speed is 60m / min, the strip temperature is 1380°C, and the thickness of the cast strip is 2.2-2.6mm; the cast strip enters the secondary cooling section and passes through the slow cooling chamber with a temperature of 850-900°C. After slow cooling for 10s, the end temperature of the slow cooling section is 1270- 1290°C; after the high-temperature slow cooling, the cast strip enters the third cooling section for rapid cooling, the cooling rate is 60°C / s, and the final cooling temperature is 780°C; the rapidly cooled cast strip is air-cooled to 500°C for coiling.

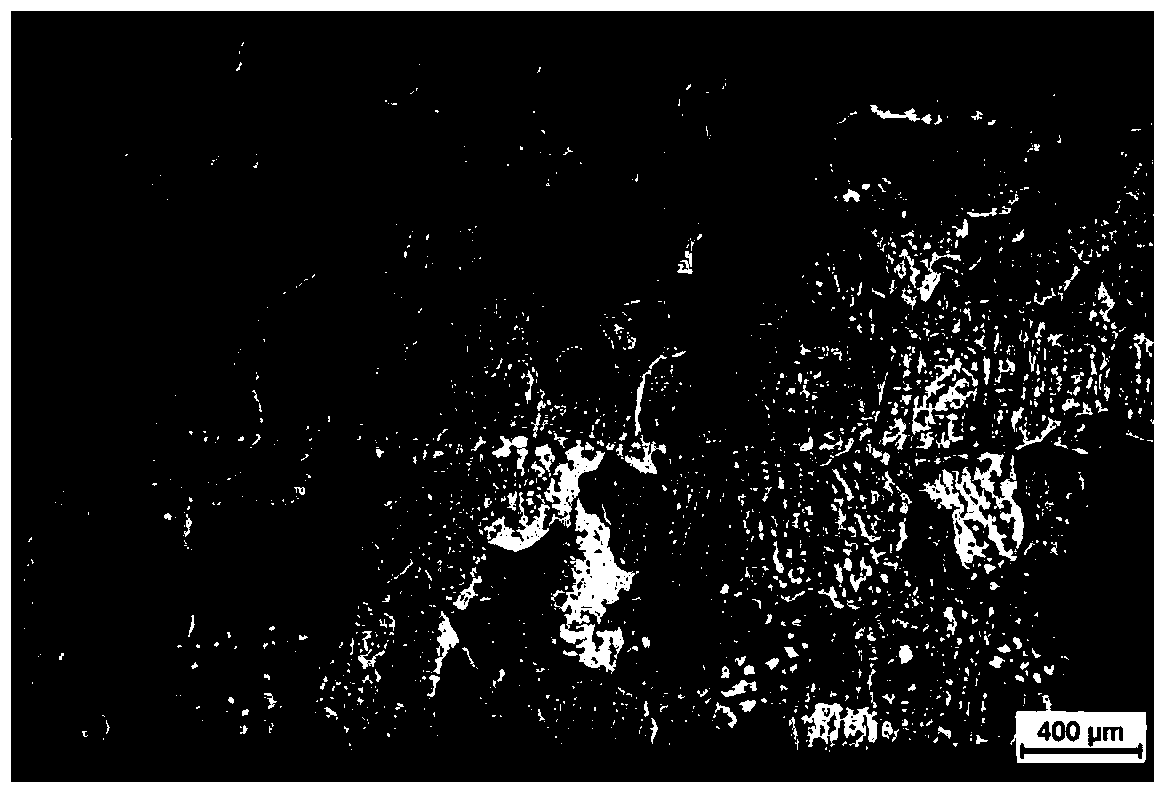

[0038] cast strip structure such as Figure 7As shown, AlN in the cast strip is precipitated alone, reach...

Embodiment 3

[0042] The chemical composition of experimental steel C is shown in Table 3. The pouring temperature is about 1540°C, and the tundish preheated to 1200°C is poured into the molten pool composed of rotating steel rolls and side sealing plates of the twin-roll thin strip continuous casting machine. The speed is 70m / min, the strip temperature is 1385°C, and the thickness of the cast strip is 2.0-2.4mm; the cast strip enters the secondary cooling section, passes through the slow cooling chamber with a temperature of 850-900°C, and after slow cooling for 12s, the end temperature of the slow cooling section is 1270~ 1280°C; after the high-temperature slow cooling, the cast strip enters the third cooling section for rapid cooling, the cooling rate is 50°C / s, and the final cooling temperature is 750°C; the rapidly cooled cast strip is air-cooled to 600°C for coiling.

[0043] cast strip structure such as Figure 9 As shown, AlN in the cast strip is precipitated alone, reaching the lev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com