Multiclamp type stretch forming machine

A stretch forming, clamp-type technology, applied in the field of mechanical engineering, can solve the problems of uneven distribution of tensile stress and tensile strain of the sheet, reduced material utilization, no mold attachment, etc., to improve material utilization and forming quality, The distribution of tensile stress and tensile strain is uniform, and the effect of good workpiece forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

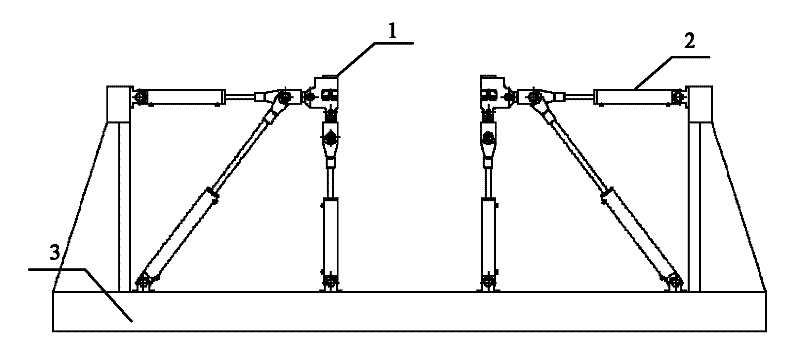

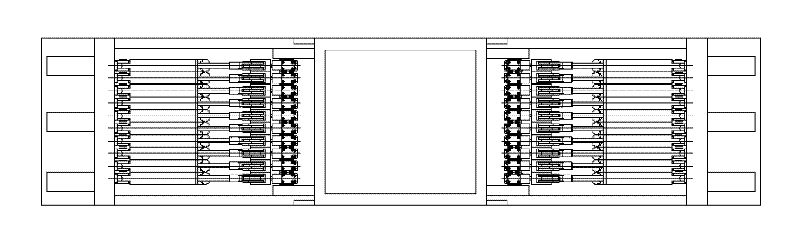

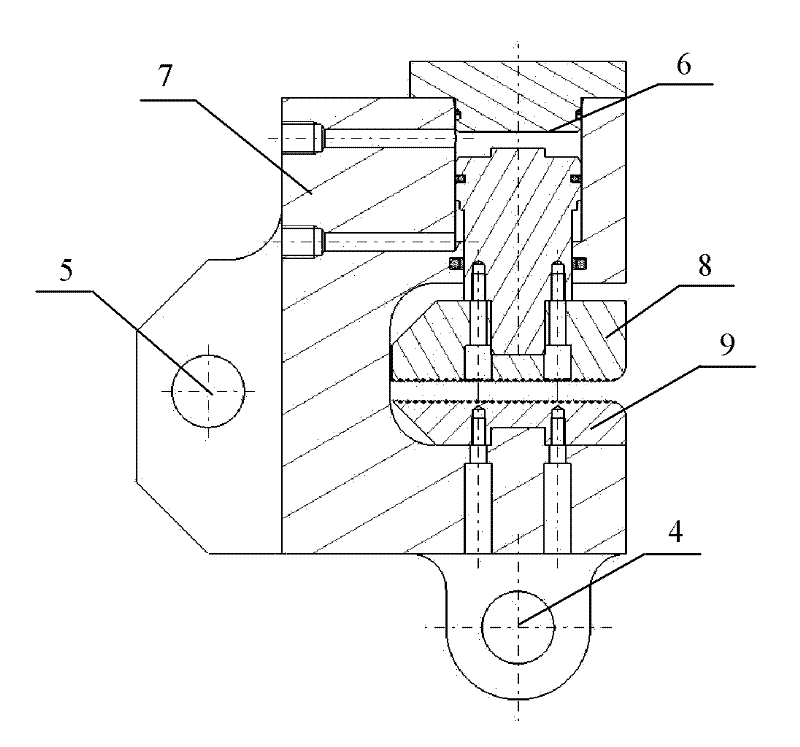

[0024] The multi-clamp stretch forming machine of the present invention is mainly composed of a clamping mechanism 1, a pulling mechanism 2 and a frame 3; a row of multiple clamping mechanisms 1 are respectively arranged on both sides of the frame 3, and each clamping mechanism The mechanism 1 is respectively provided with a lower connecting hole 4 and a rear connecting hole 5, and each connecting hole is connected with the pulling mechanism 2 through a pin shaft or a universal joint. When the pulling mechanism 2 connected with the clamping mechanism adopts three hydraulic cylinders, the lower connection hole 4 of the clamping mechanism 1 is connected with the vertically arranged pulling mechanism 2 through a universal joint; the rear part of the clamping mechanism 1 The connecting hole 5 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com