Patents

Literature

36results about How to "Uniform tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

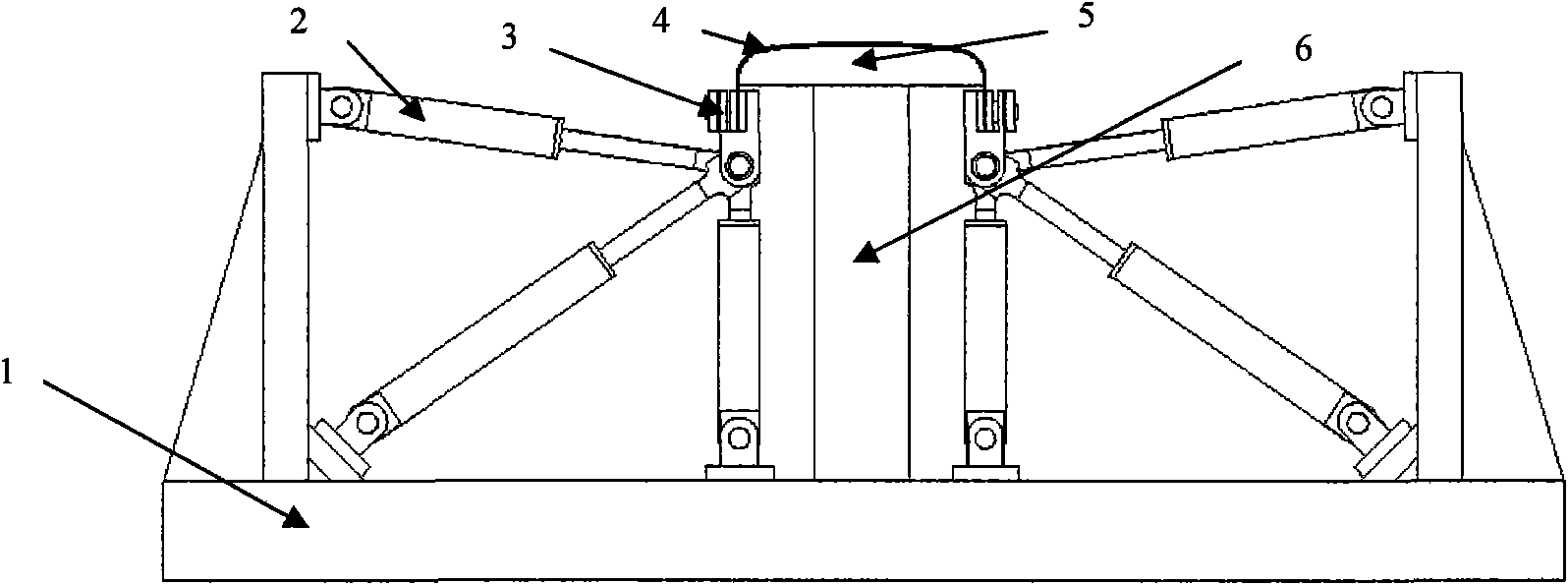

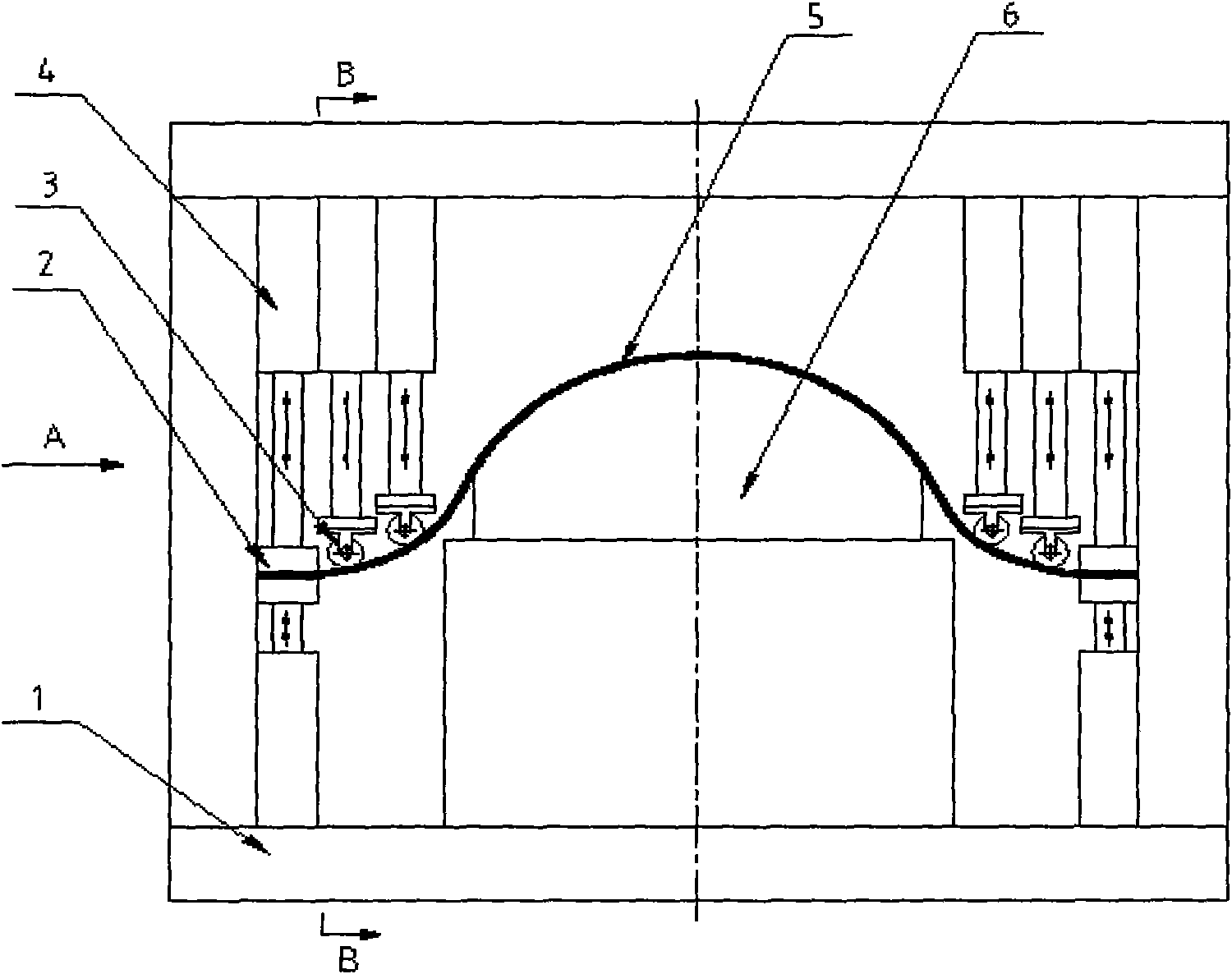

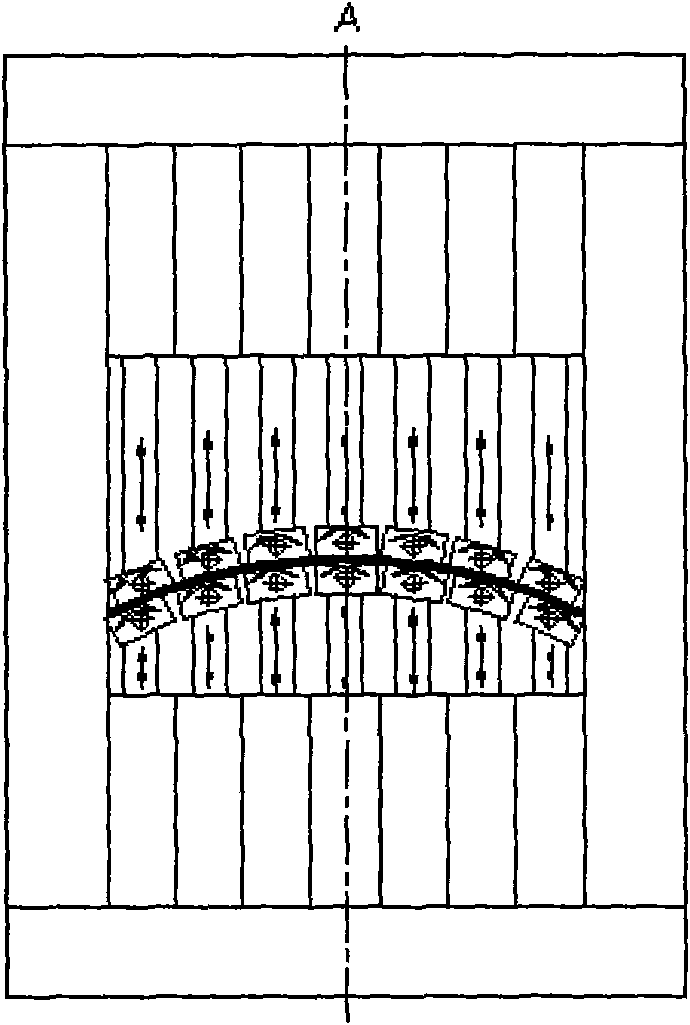

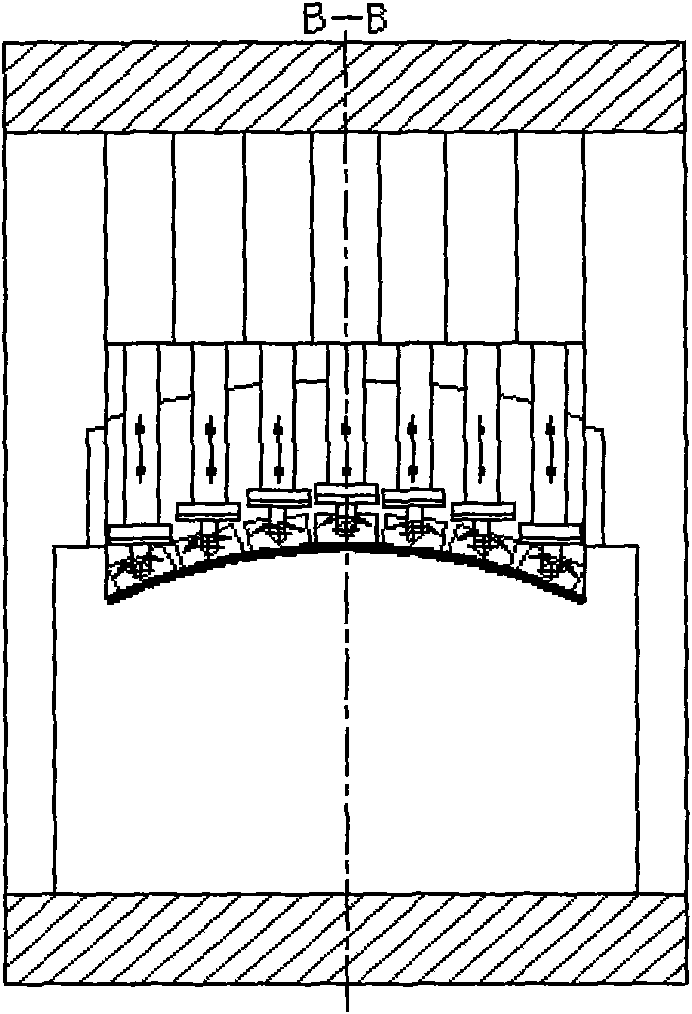

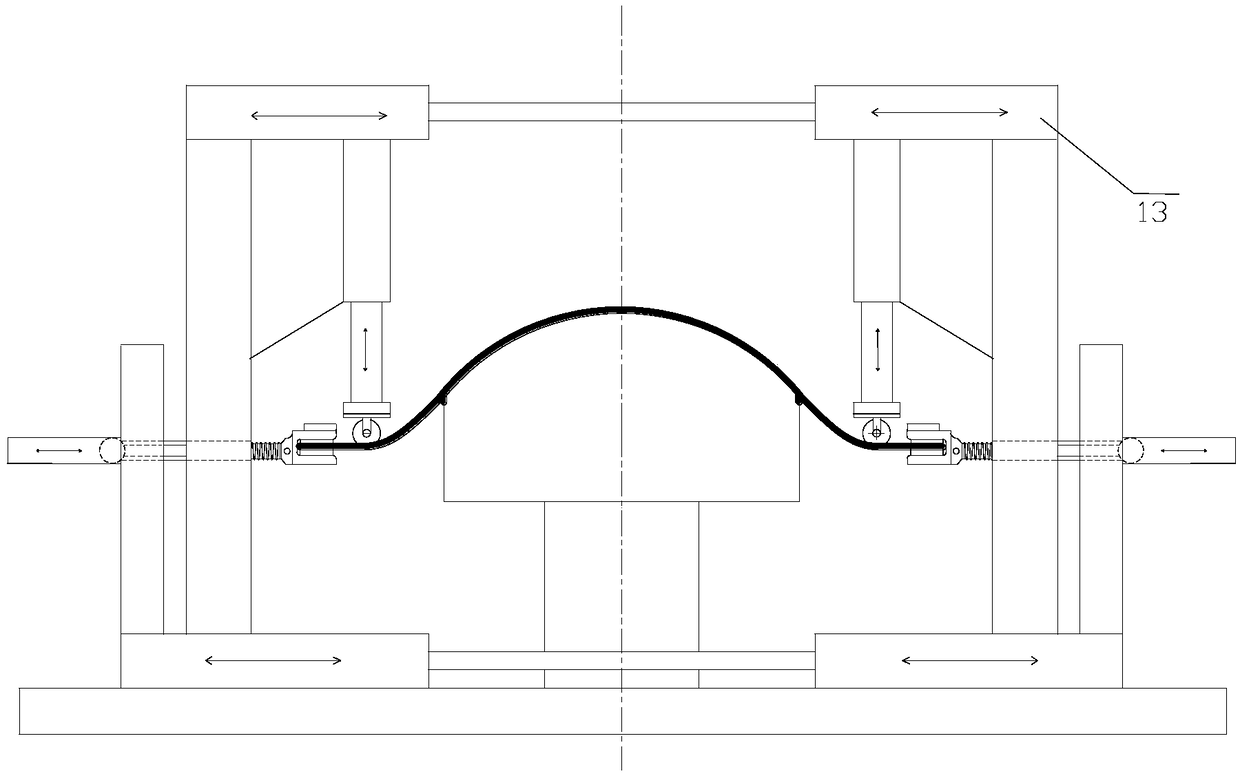

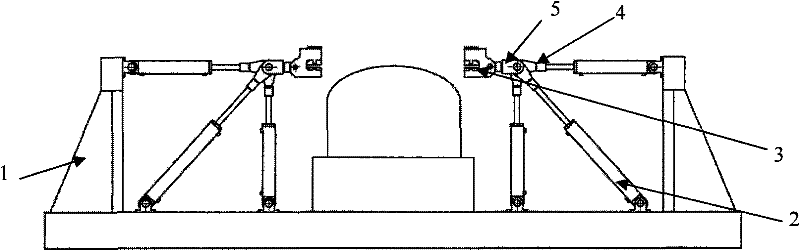

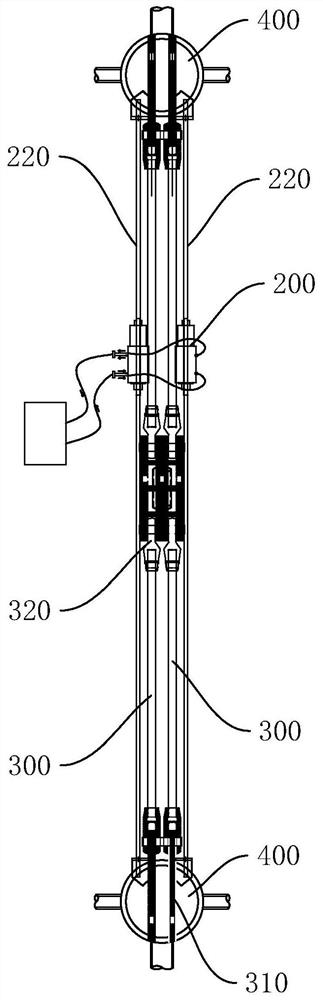

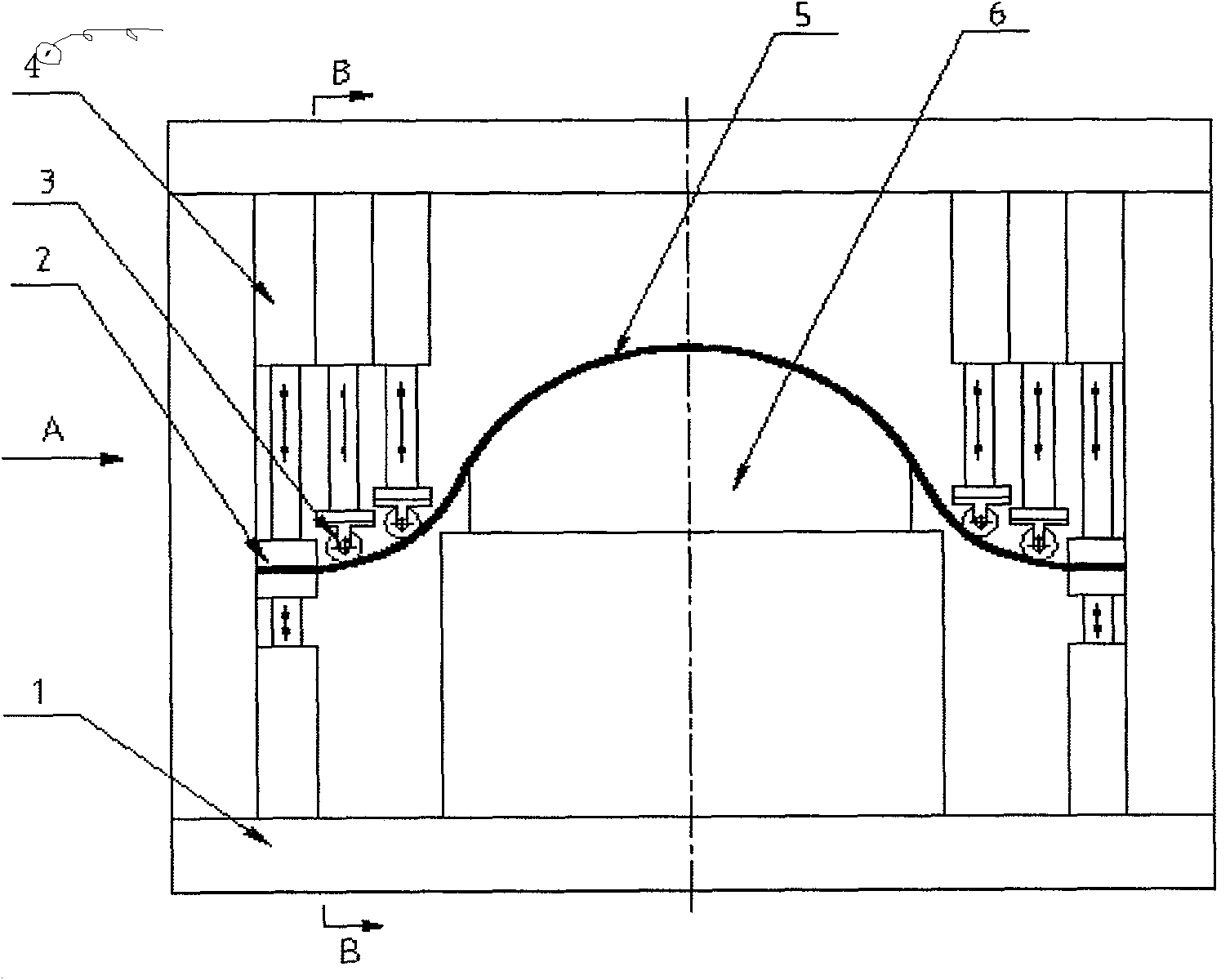

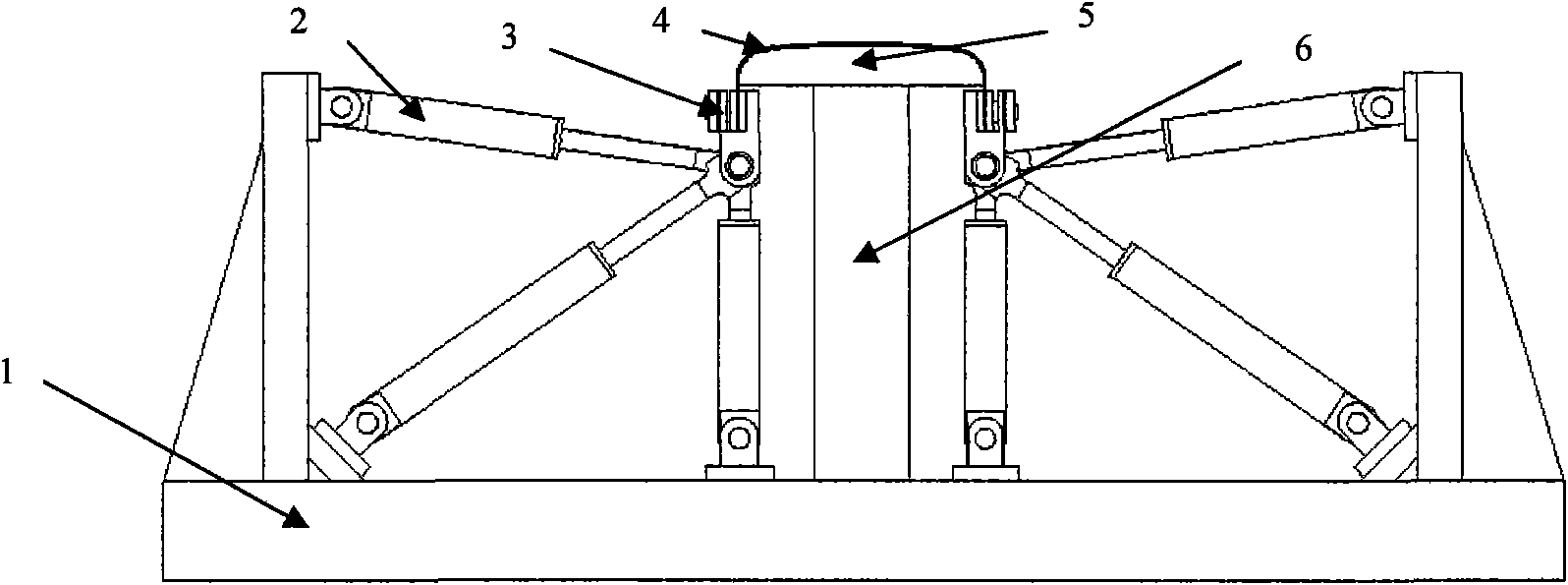

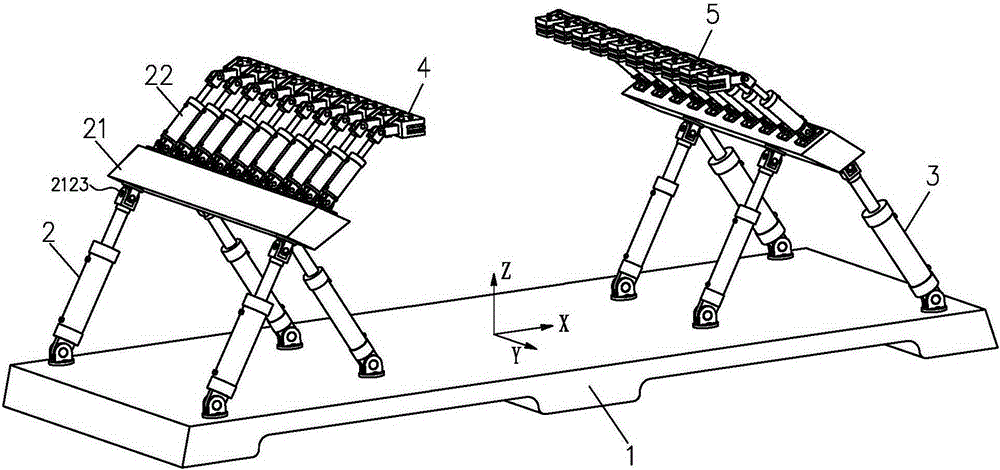

High-flexibility multi-head stretching machine

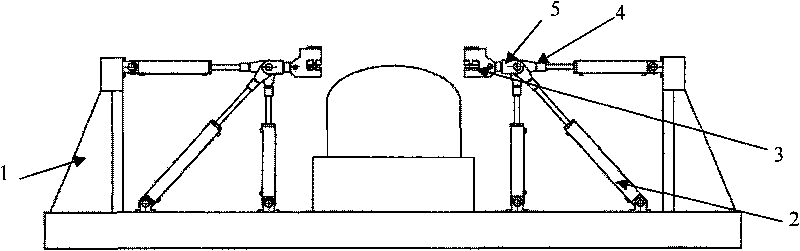

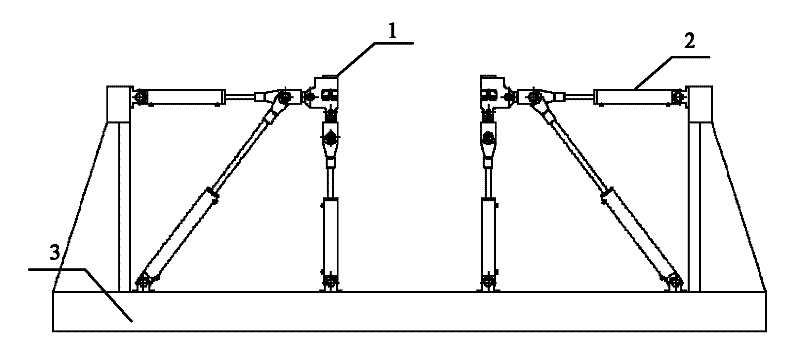

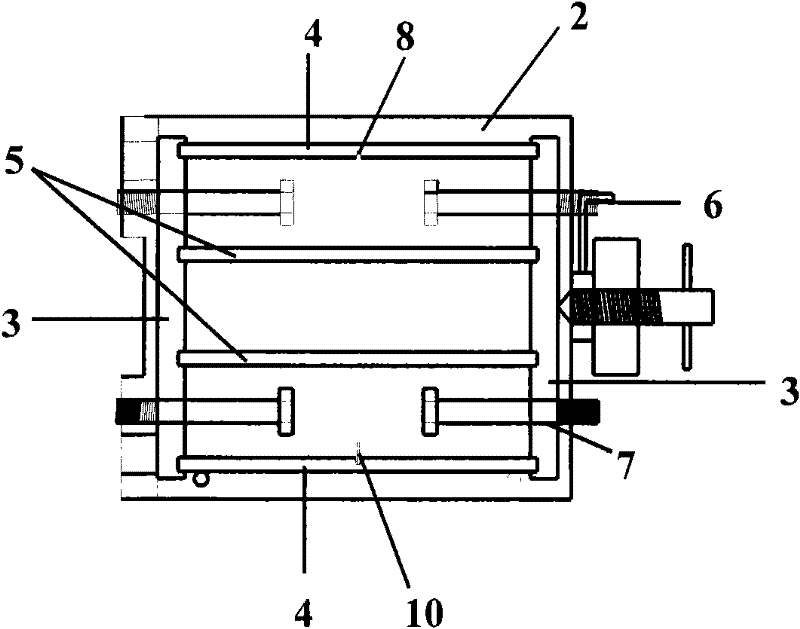

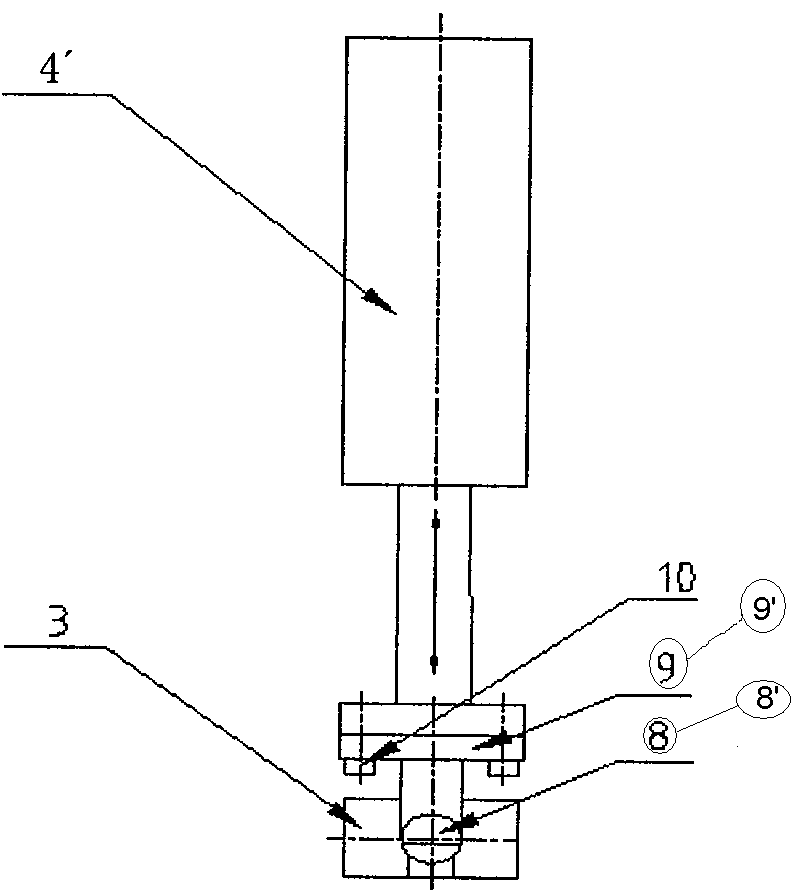

The invention discloses a high-flexibility multi-head stretching machine, which relates to plastic processing equipment for three-dimensional curved surface forming of sheet parts and belongs to the field of mechanical engineering. The machine aims to make the distribution of the pulling stress and the tension strain of stretched parts more trend to be uniform, improve the stretching quality and the utilization rate of materials, and realize the stretching of curvature parts with larger transverse curvature or certain wave. The machine mainly comprises a main frame (1), material pulling mechanisms, material clamping mechanisms (3) and universal mechanisms (5), wherein a row of a plurality of the material pulling mechanisms, the material clamping mechanisms (3) and the universal mechanisms (5) are arranged on both sides of the main frame (1) respectively; the material pulling mechanisms consist of three hydraulic cylinders (2) respectively, one of the hydraulic cylinders (2) is horizontally arranged, the other hydraulic cylinder (2) is vertically arranged, and the third hydraulic cylinder (2) are slantways arranged; and one end of each of the three hydraulic cylinders (2) is hinged with the main frame (1) respectively, while the other end is jointly connected with the universal mechanism (5) and the material clamping mechanism (3) through a hydraulic cylinder connection body (4) respectively.

Owner:JILIN UNIV

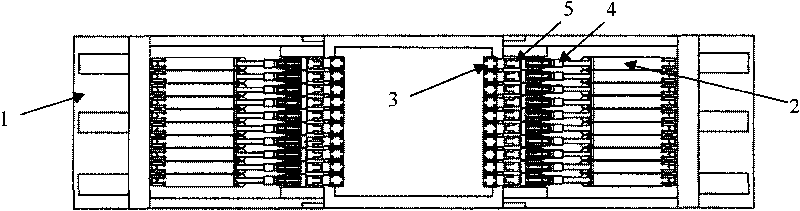

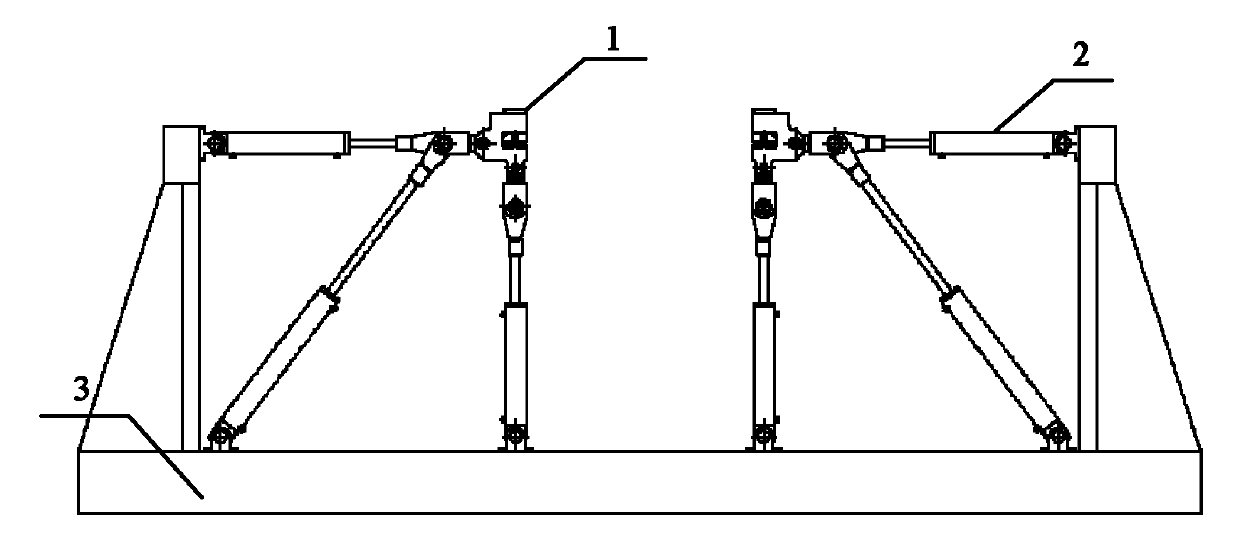

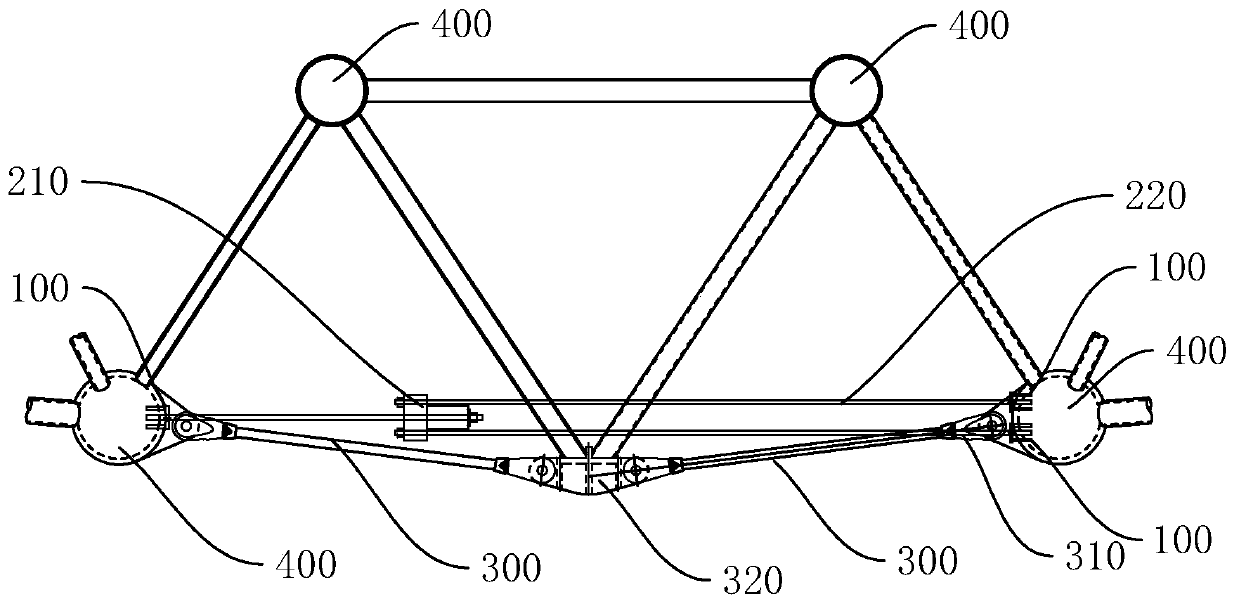

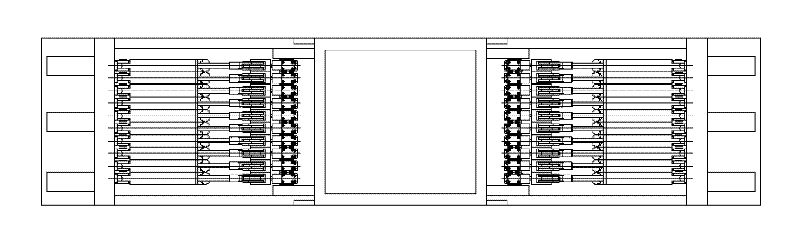

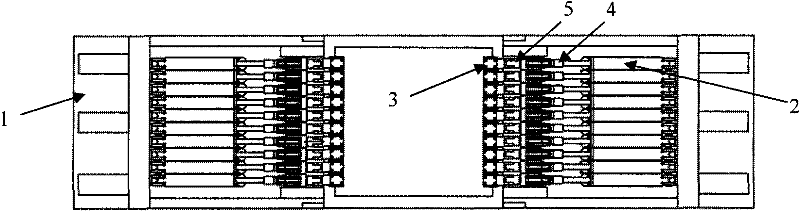

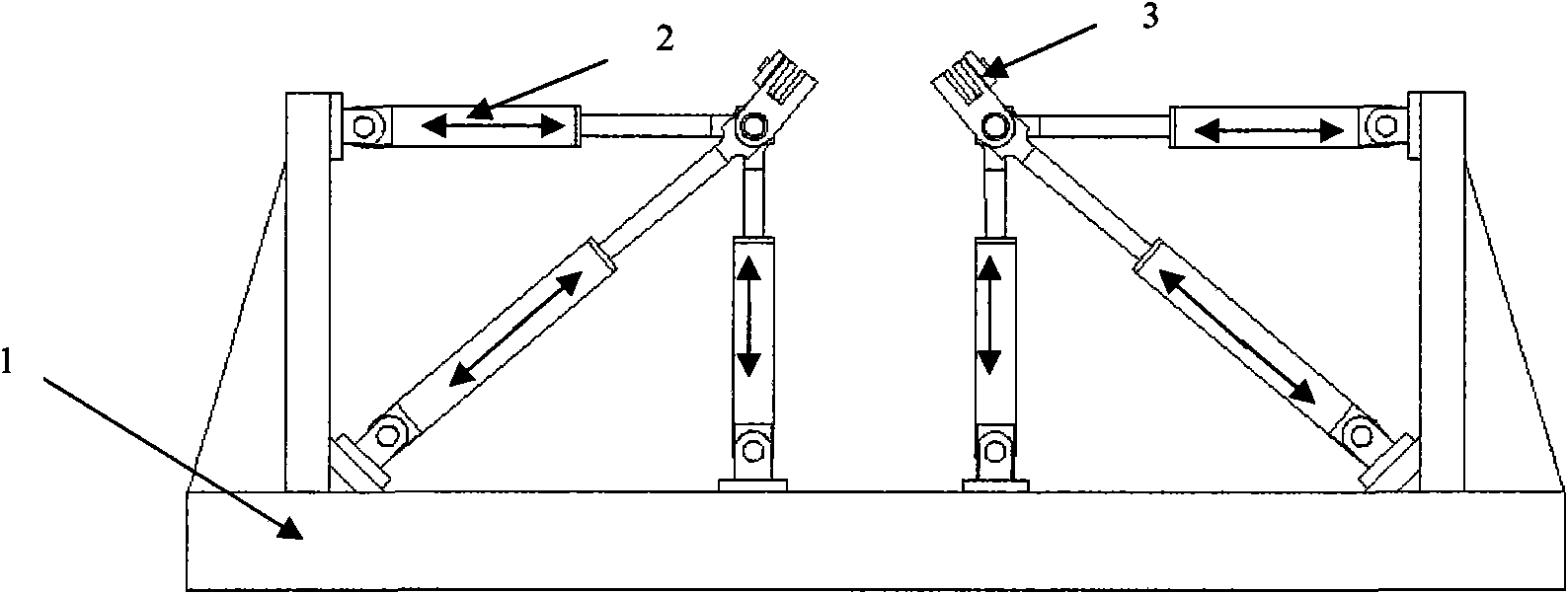

Multiclamp type stretch forming machine

The invention discloses a multiclamp type stretch forming machine and relates to plastic processing equipment for curve forming of plates, belonging to the field of mechanical engineering. The machine mainly comprises clamping mechanisms (1), a stretching mechanism (2) and a stand (3), wherein a row of clamping mechanisms (1) are respectively distributed at both sides of the stand (3); each clamping mechanisms (1) is provided with a lower connecting hole (4) and a rear connecting hole (5); and all the connecting holes are respectively connected with the stretching mechanism (2) by pin shafts or cardan joints. The machine can realize the flexible control of a plurality of clamps, ensure that a workpiece is more easily attached to a die in the stretching process, obviously improve the material utilization ratio of the workpiece and obtain higher workpiece forming effect.

Owner:长春瑞光科技有限公司

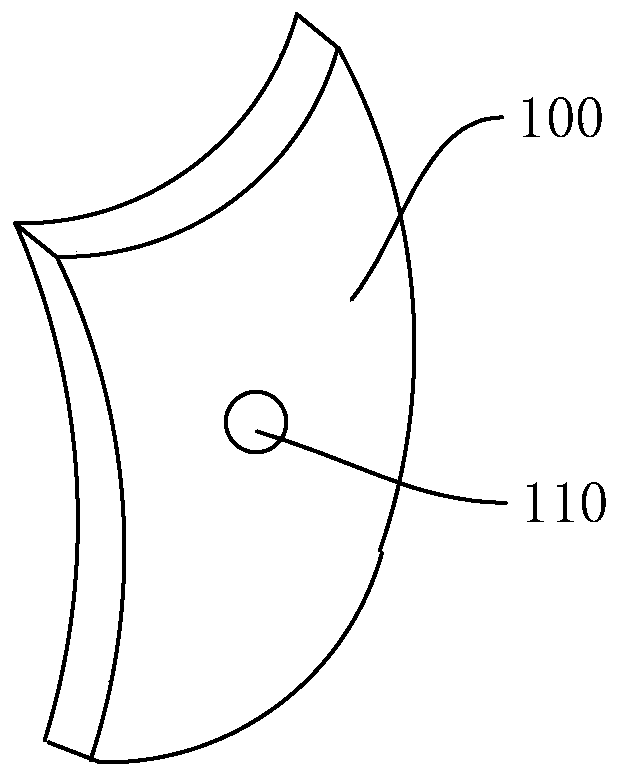

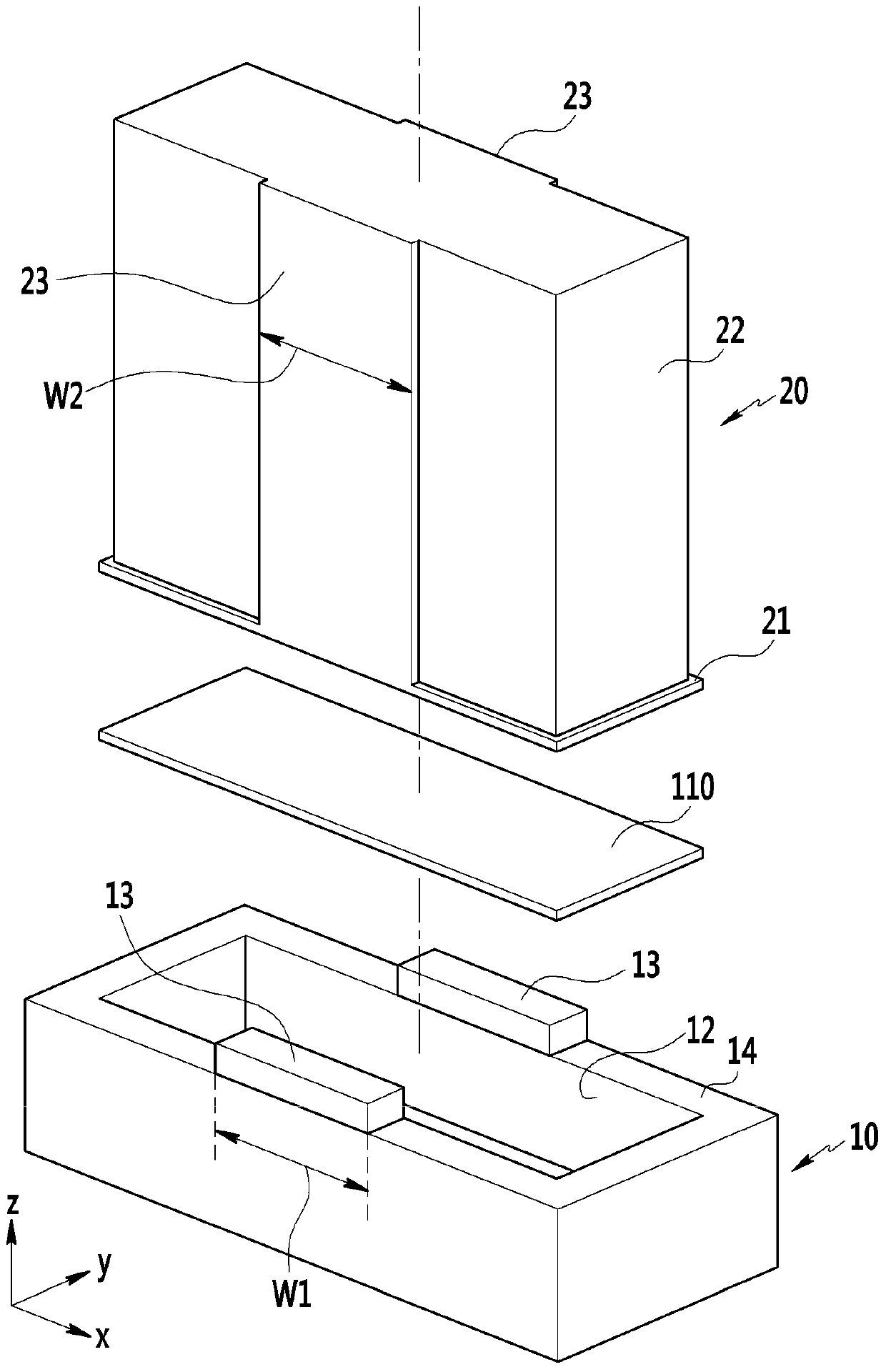

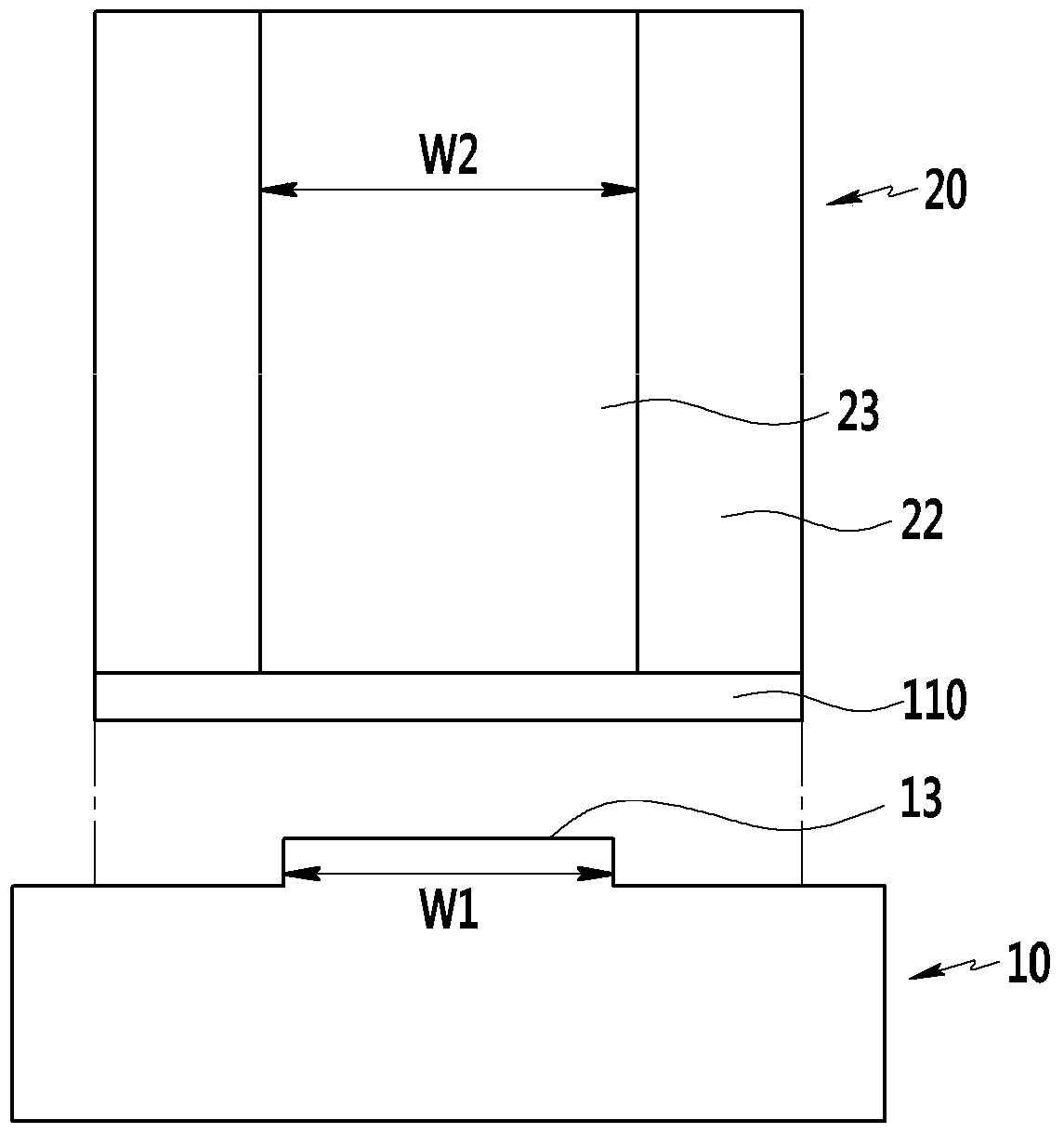

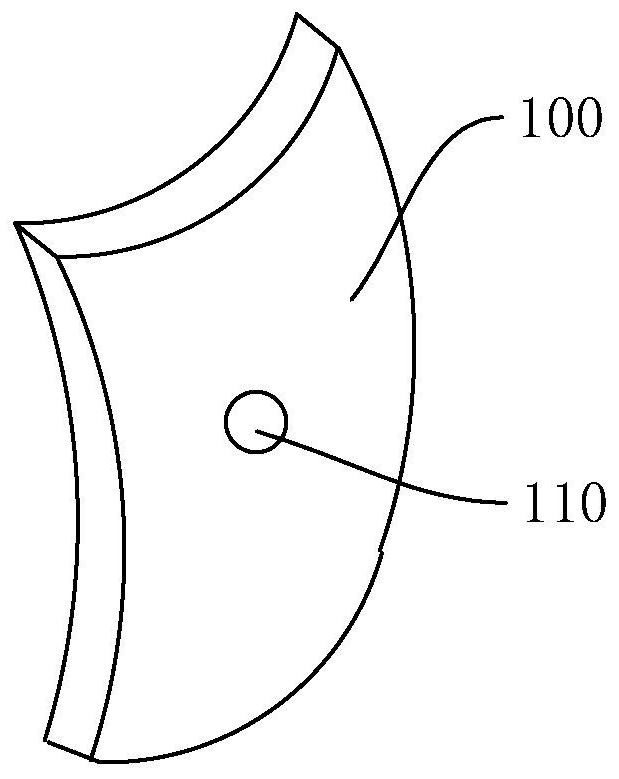

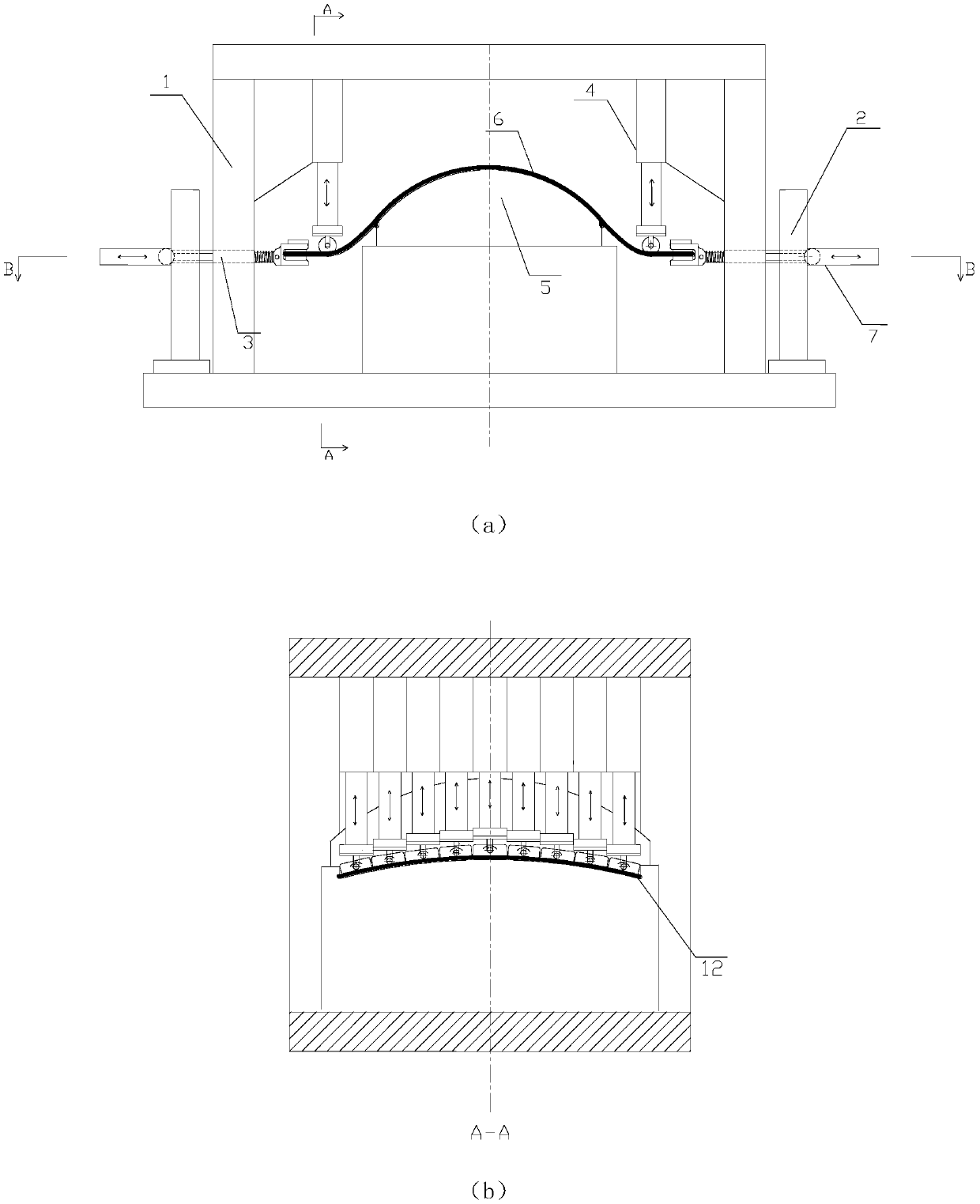

Plate stretch-forming machine

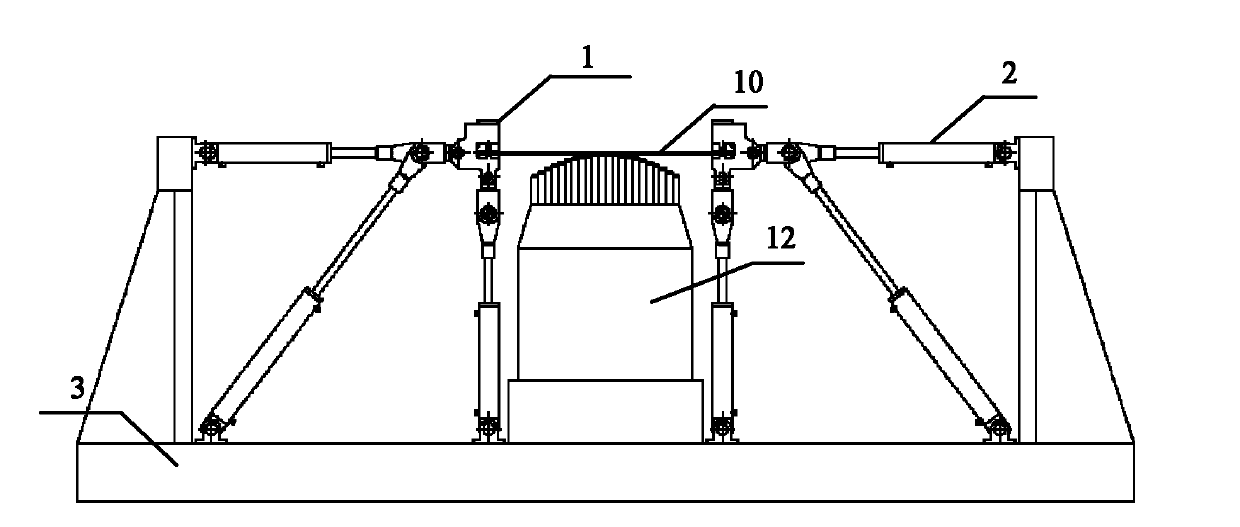

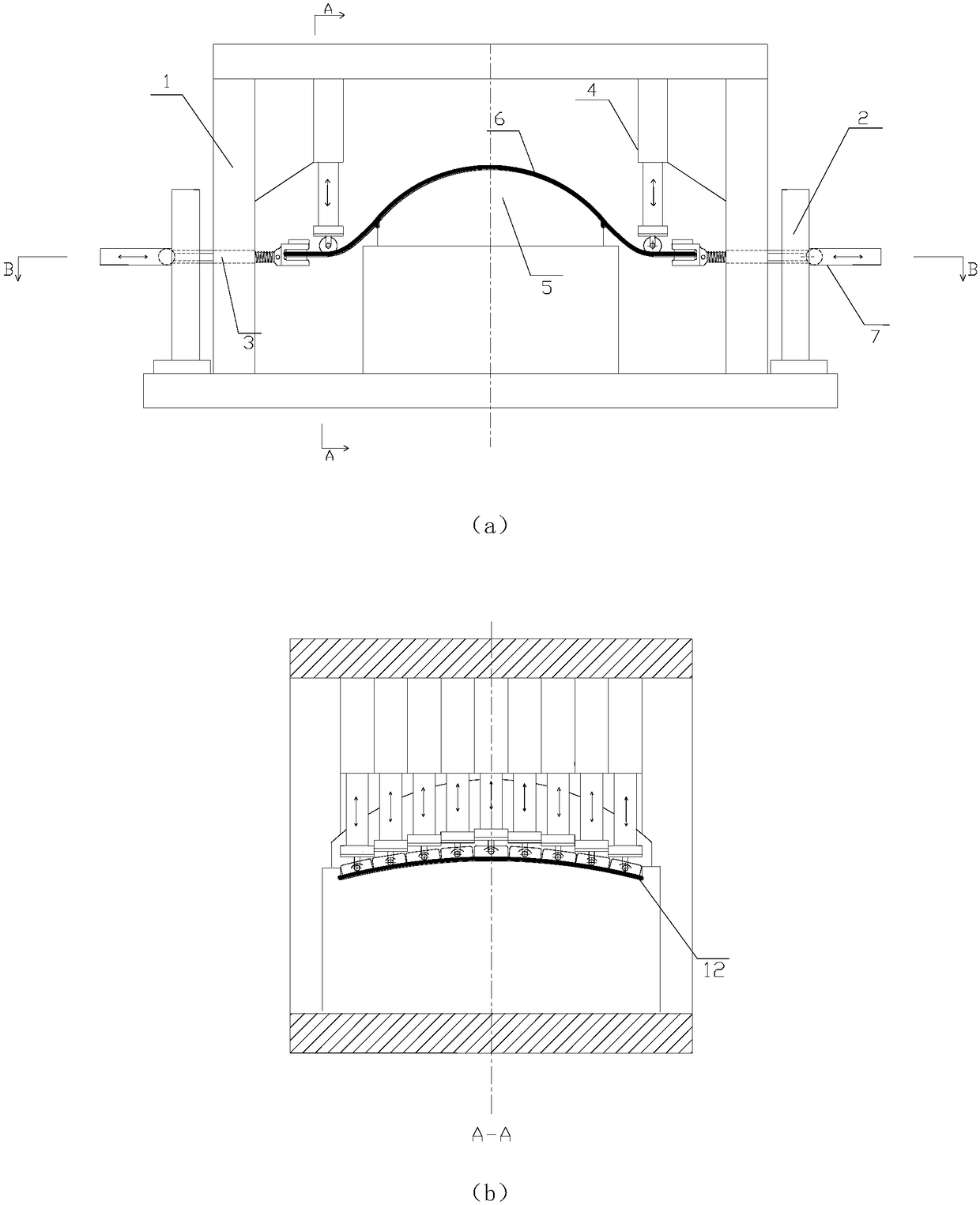

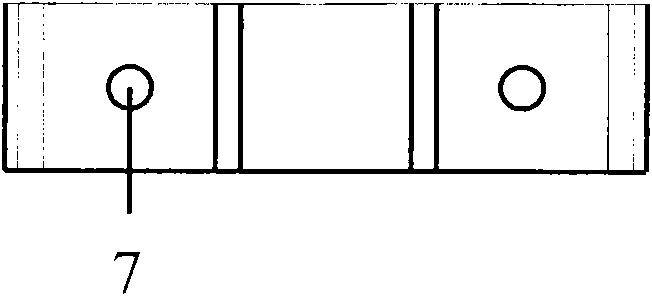

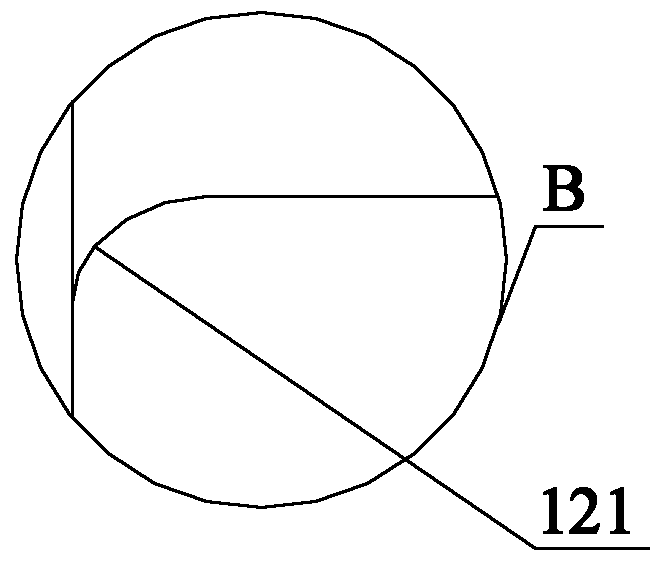

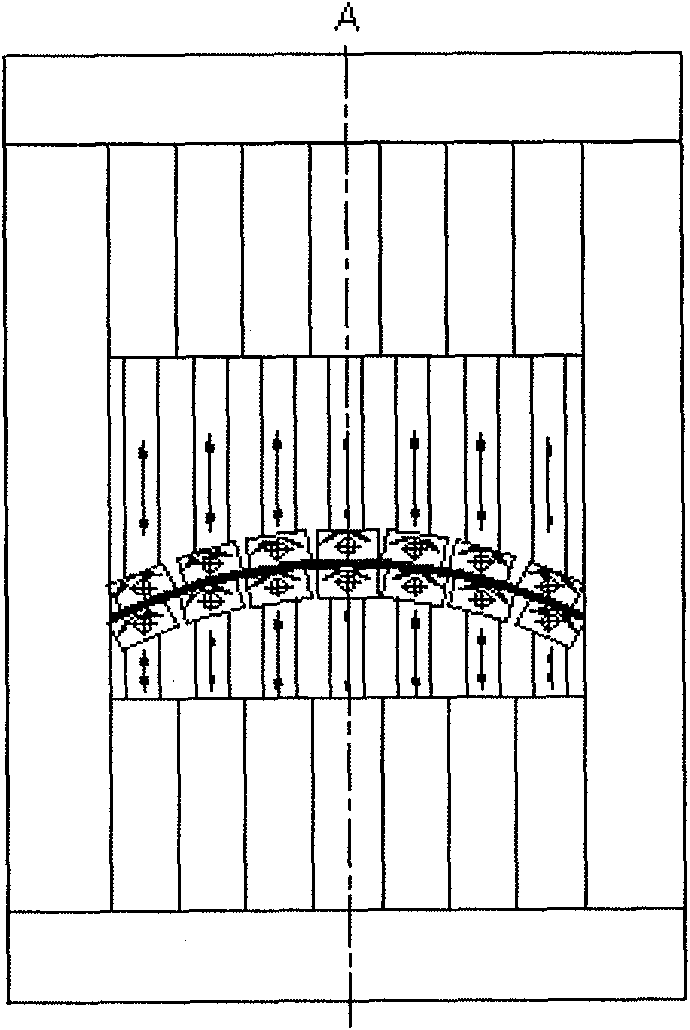

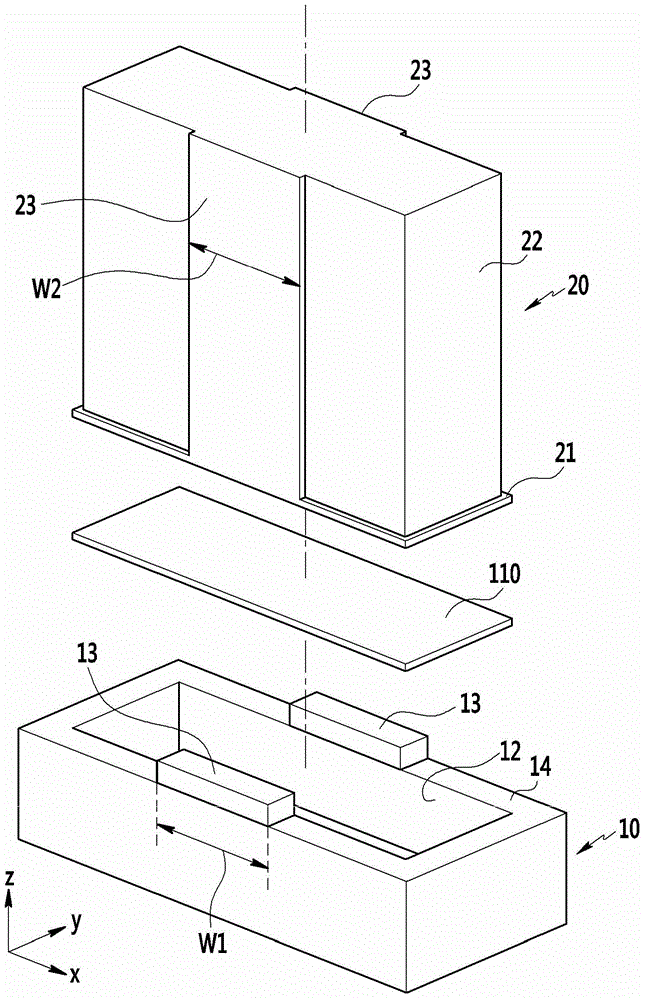

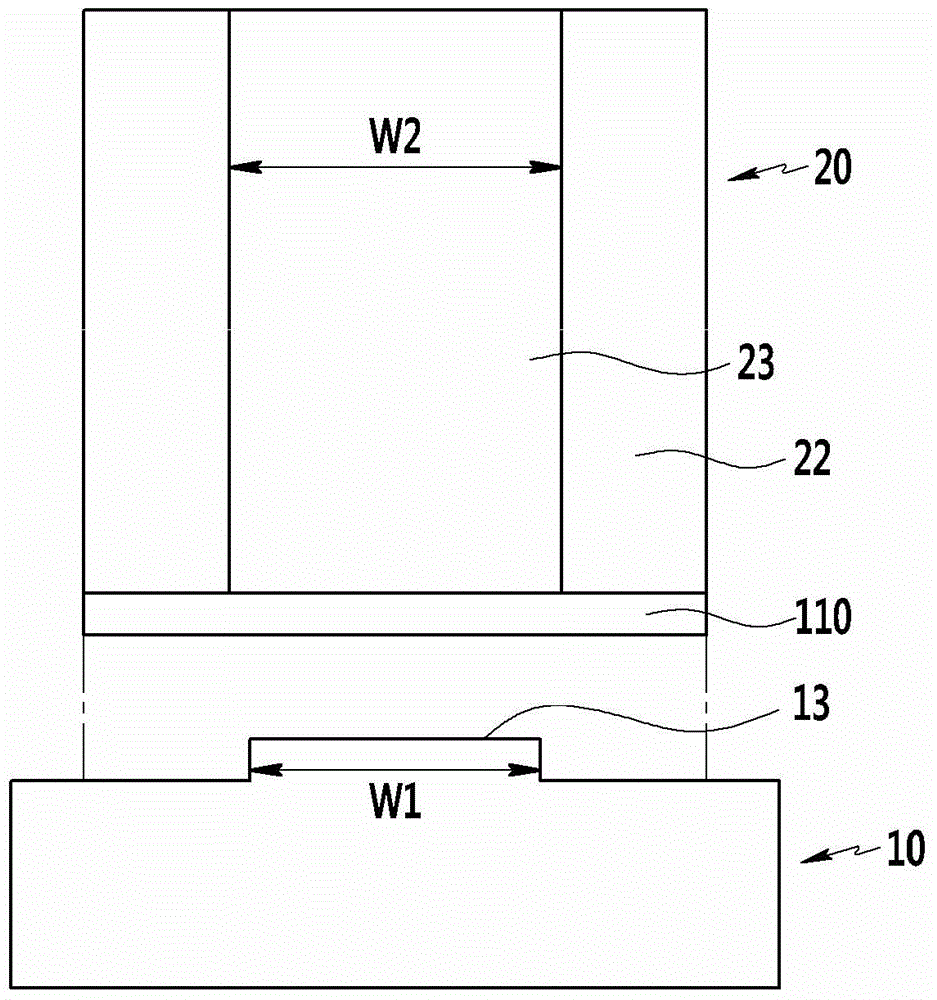

A plate stretch-forming machine of the invention relates to plastic processing equipments used for 3-D curved surface forming of plates and belongs to the mechanical engineering field. The machine aims at facilitating tensile stress and tensile strain distribution of stretch-forming parts to be even, realizing stretch-forming of curved parts with big curvature, improving stretch-forming quality and material utilization ratio and reducing manufacturing cost of stretch-forming devices. The machine mainly comprises a rack (1), a row of multiple material-pulling mechanisms and a row of multiple material-chucking mechanisms (3), which are arranged at the left and right sides of the rack (1) respectively; the material-pulling mechanism is formed by mutual hinge joint of three hydraulic cylinders (2), wherein, one of the three hydraulic cylinders (2) is horizontally arranged, one vertically arranged and one obliquely arranged; the material-chucking mechanism is mainly composed of a support (10), a material-chucking plate (11) and a small-stroke single-acting hydraulic cylinder (12).

Owner:JILIN UNIV

Sheet-stretching machine

The invention provides a sheet-stretching machine, relates to a plastic working device for the three-dimensional curved-surface forming of sheet workpieces, and belongs to the field of mechanical engineering. The invention aims to allow pulling pieces to tend to be uniform in the distribution of tensile stress and tension strain, realize the pulling of complex curved-surface workpieces, improve the forming quality of the pulling pieces, improve material utilization rate and reduce the cost for manufacturing pulling devices. This machine mainly comprises a frame (1), a left-side clamping mechanism, a right-side clamping mechanism and a down-pressing mechanism, wherein the frame (1) supports the left-side clamping mechanism, the right-side clamping mechanism and the down-pressing mechanism; each clamping mechanism is divided into an upper part and a lower part; each part has a plurality of clamping devices arranged in a row; and the down-pressing mechanism has a plurality of down-pressing devices arranged in a row or a plurality of rows.

Owner:JILIN UNIV

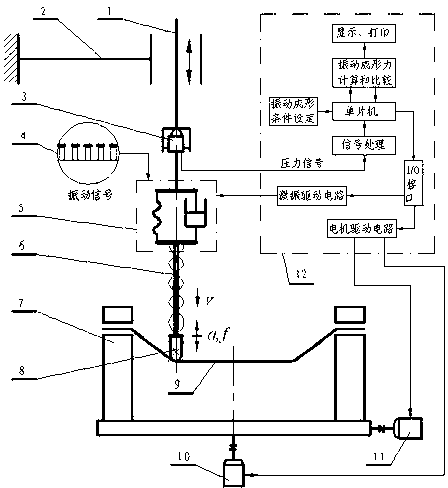

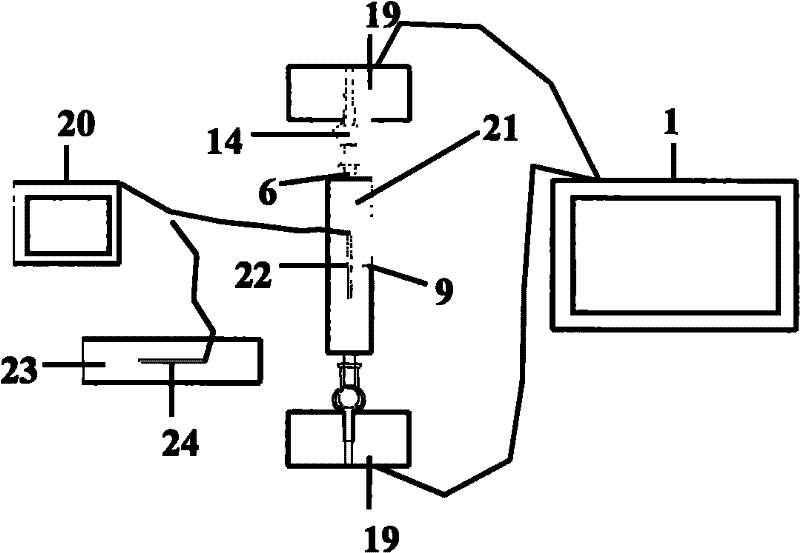

Single-point longitudinal vibration controllable progressive forming system for metal plate

InactiveCN103071726AImprove forming conditionsLighten or wrinkleLongitudinal vibrationParameter control

The invention discloses a single-point longitudinal vibration controllable progressive forming system for a metal plate. The main shaft of the single-point longitudinal vibration controllable progressive forming system for the metal plate is installed on a rack; a force sensor is installed on the shaft end of the main shaft; a vibration signal generator is connected with a vibration exciter; the vibration exciter is installed below the force sensor; a tool head is connected with the vibration exciter via a connecting rod; a workbench is installed just below the main shaft; the input end of a parameter controller is connected with the force sensor; and the output end of the parameter controller is respectively connected with the vibration frequency and amplitude control port of the vibration exciter as well as the X-shaft driving motor control port and the Y-shaft driving motor control port of the workbench. A single-point longitudinal vibration plasticity forming condition of the plate material is established by combining a forming technology parameter, a vibration mode parameter and a forming force parameter, and the parameter controller is used for monitoring and regulating the forming technology parameter and the vibration mode parameter in real time according to the plate material forming technology state and the vibration plasticity forming condition. The single-point longitudinal vibration controllable progressive forming system for the metal plate, which is disclosed by the invention, has the beneficial effects that the technical defects of single-point progressive forming can be overcome, the technology parameter and the vibration mode parameter can be monitored and regulated in real time according to the plate material vibration plasticity forming condition in the forming process, and efficient and precise progressive forming of the metal plate material can be realized.

Owner:JIANGXI UNIV OF SCI & TECH

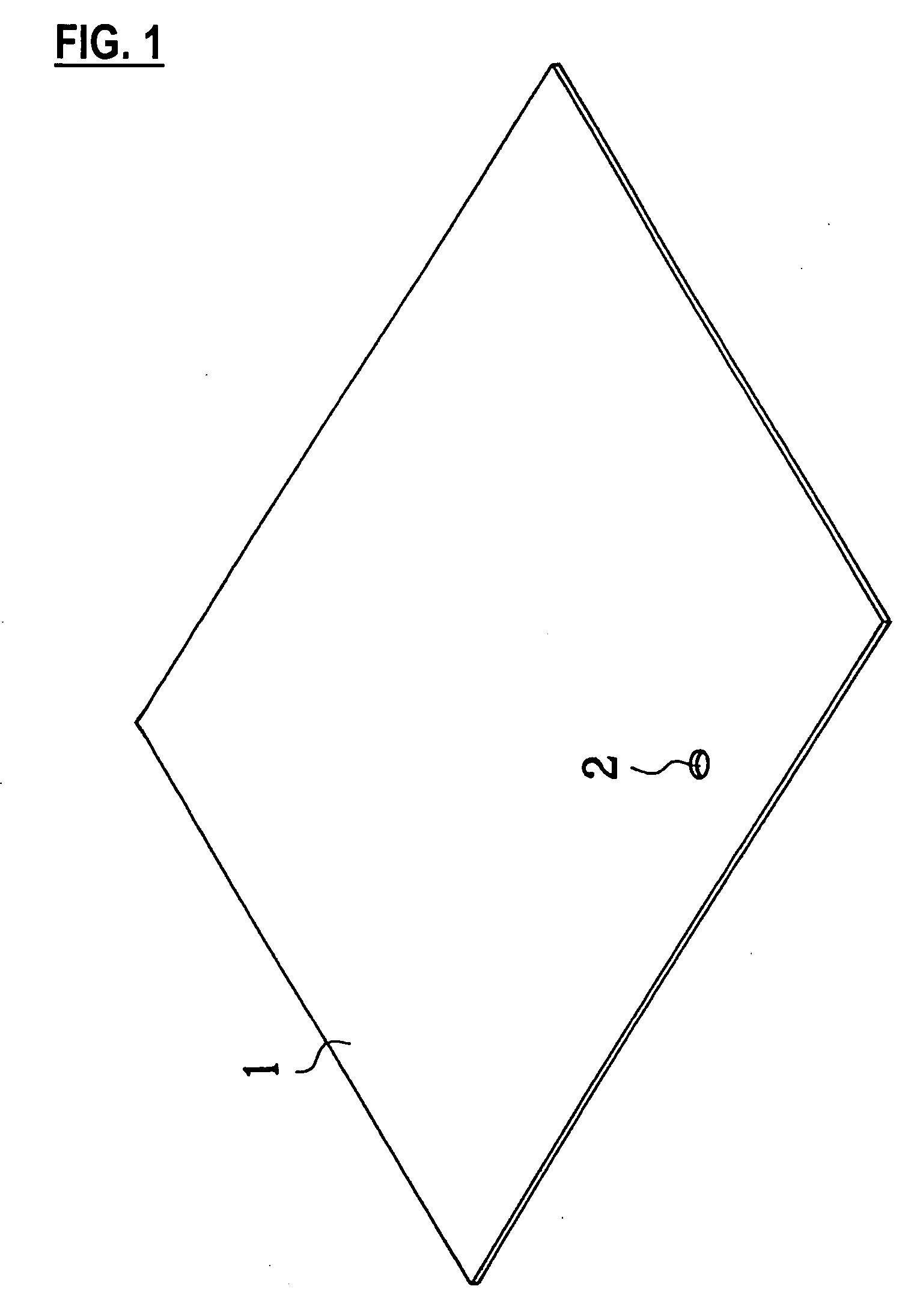

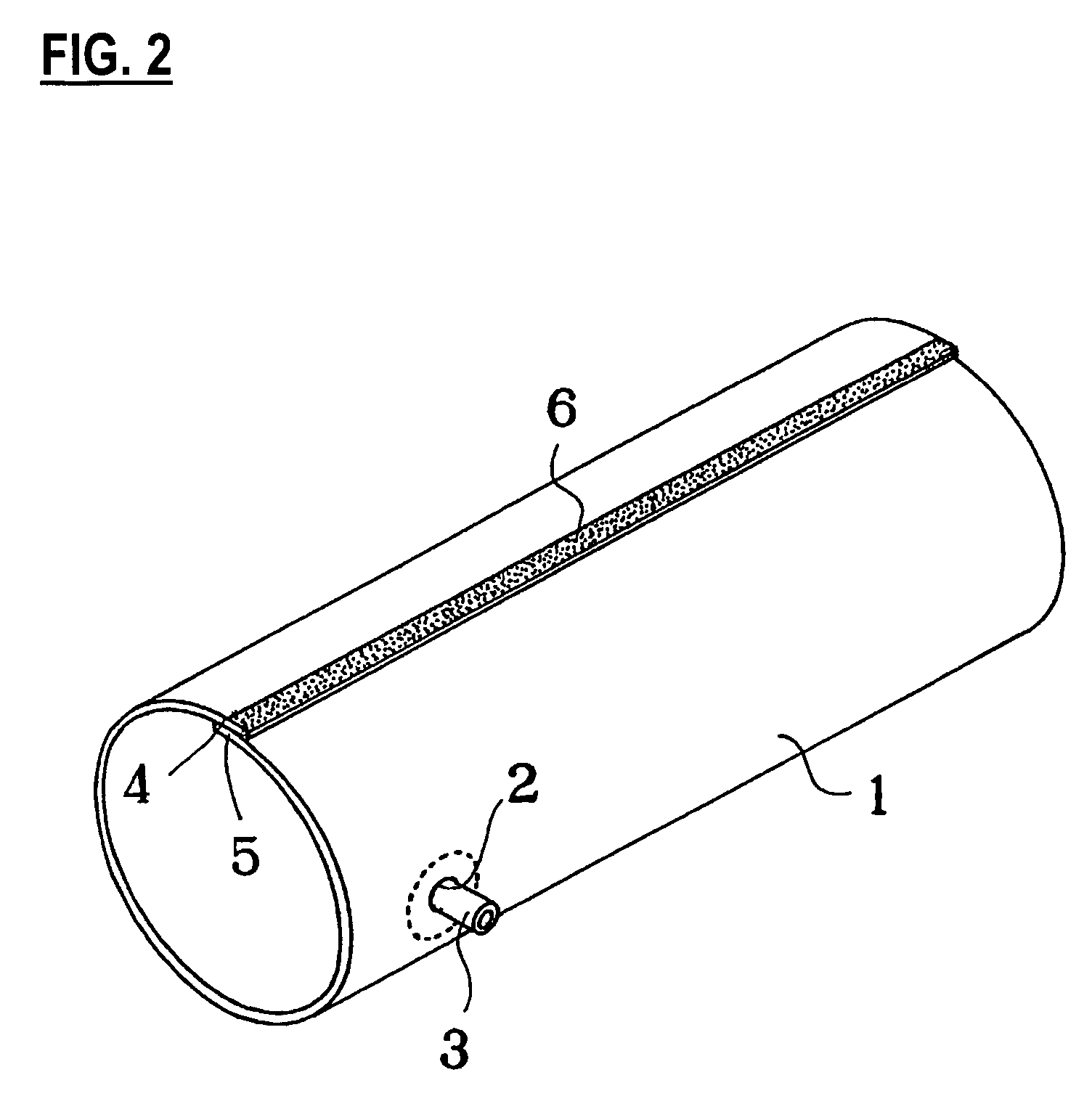

Producing method for air bag

InactiveUS20060027946A1Uniform tensile stressIncreased durabilityWood working apparatusCatheterEngineeringSheet material

Owner:TK INC CO

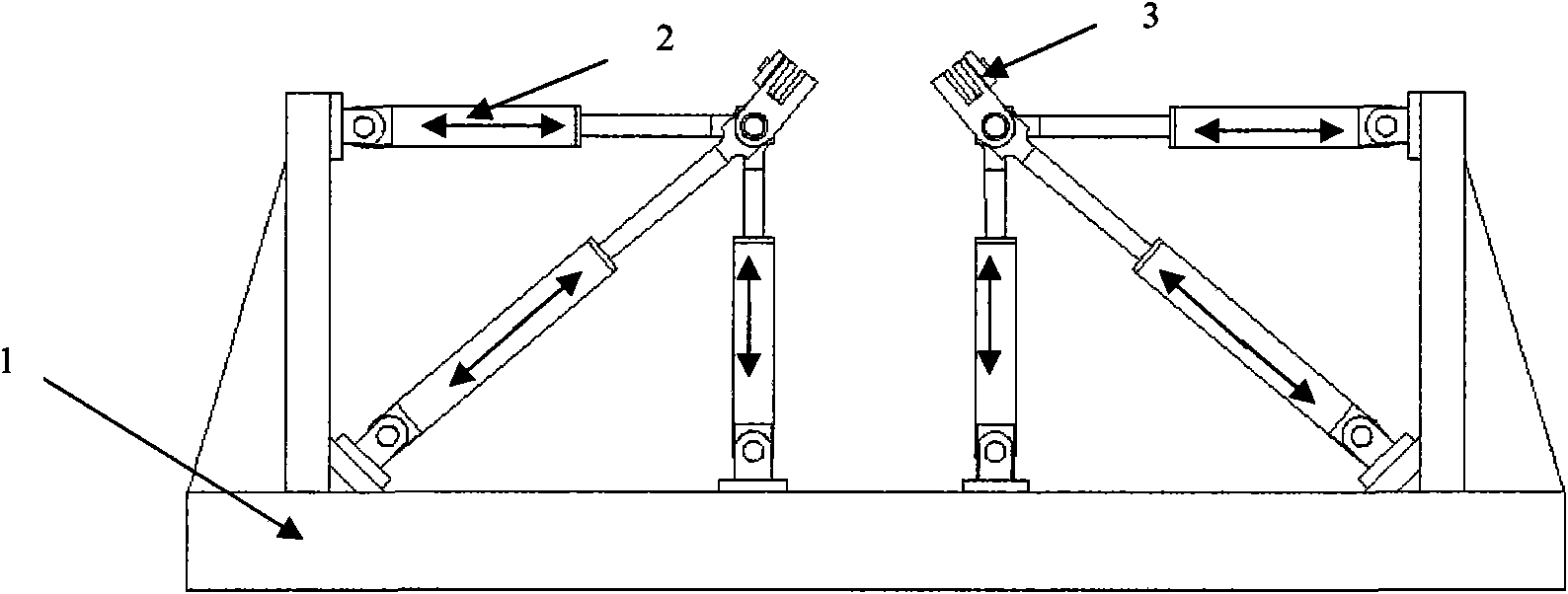

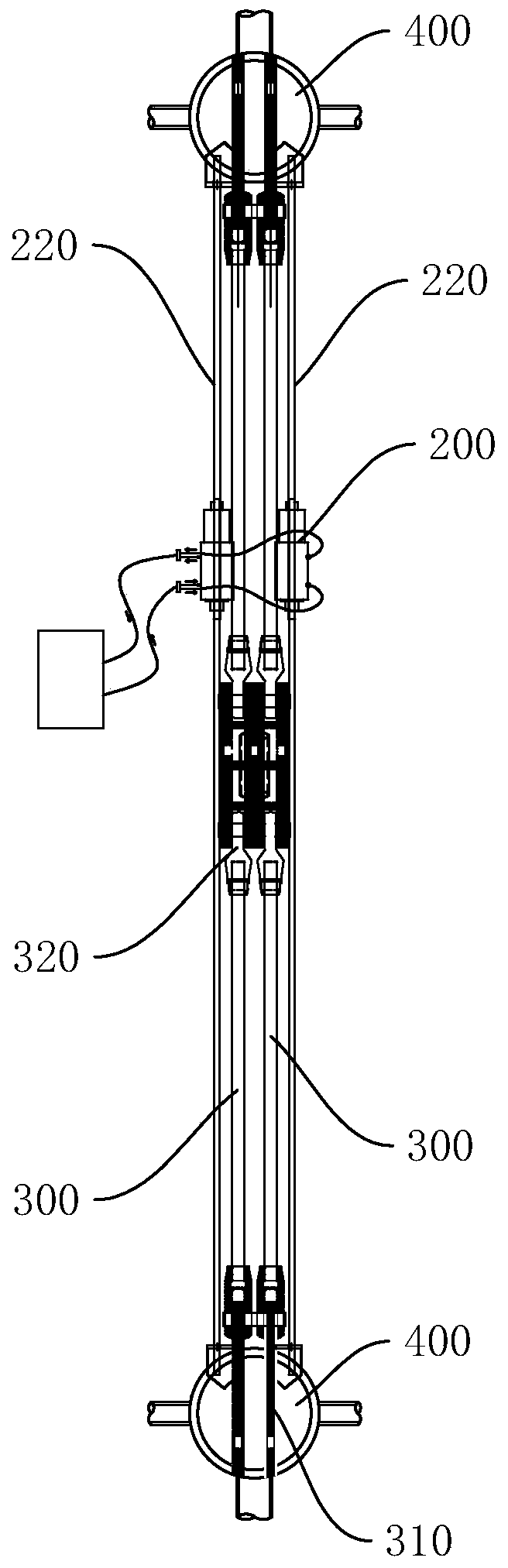

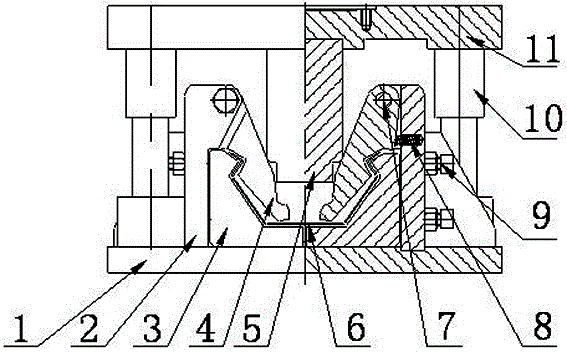

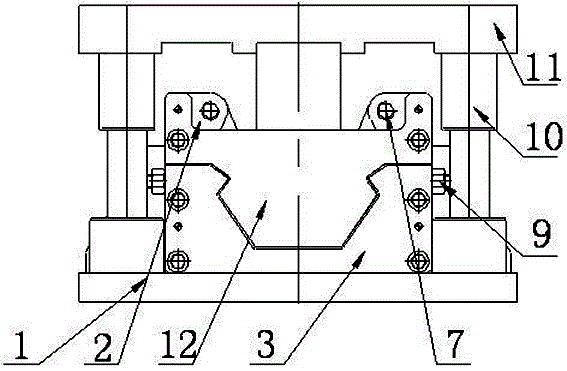

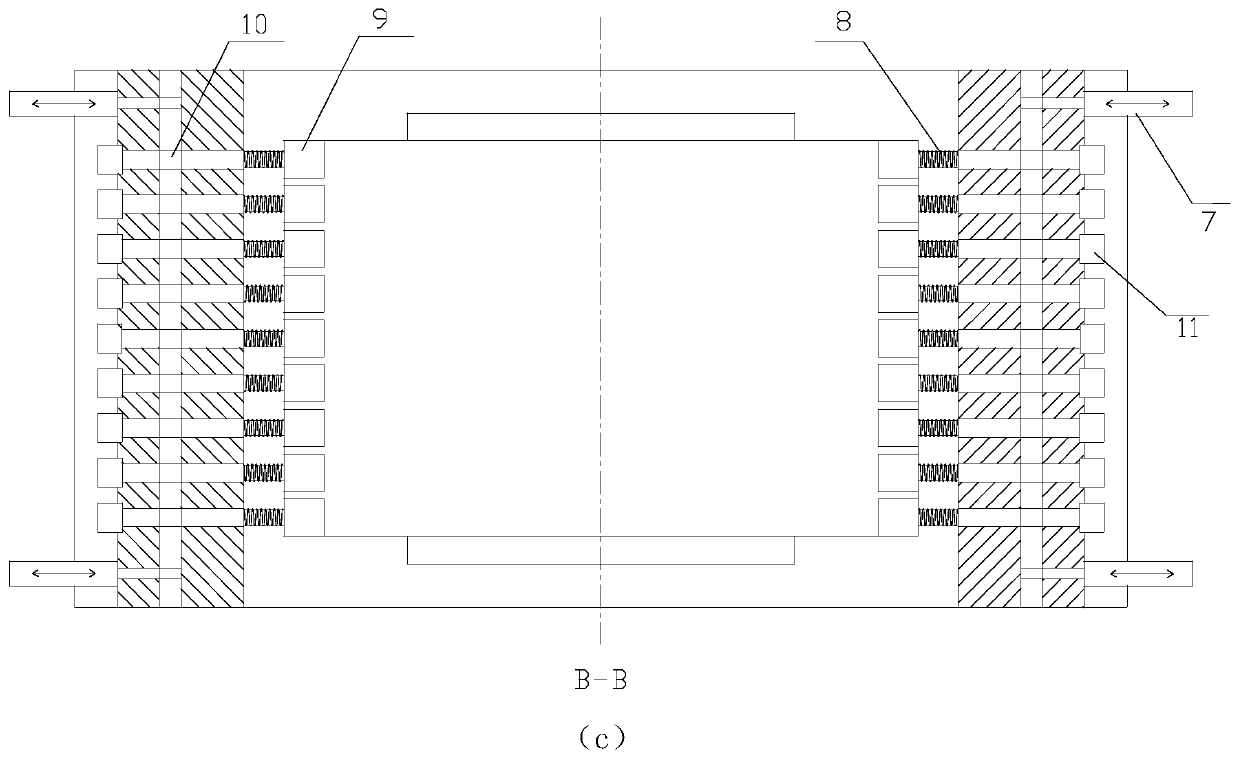

Stretching and pressing combined type plate stretch forming machine

ActiveCN108746332ASimplification of hydraulic control system and electrical control systemEasy to operate and maintainAircraft componentsMetal-working feeding devicesElectrical controlBending force

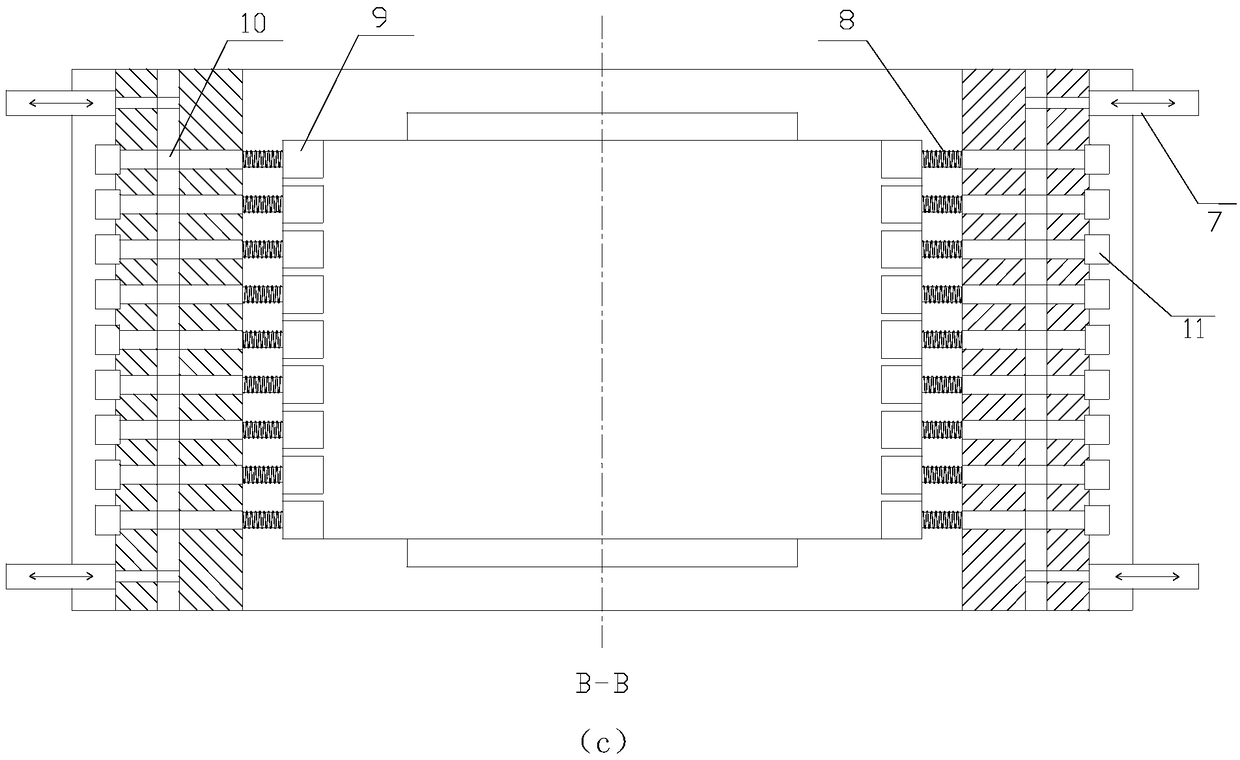

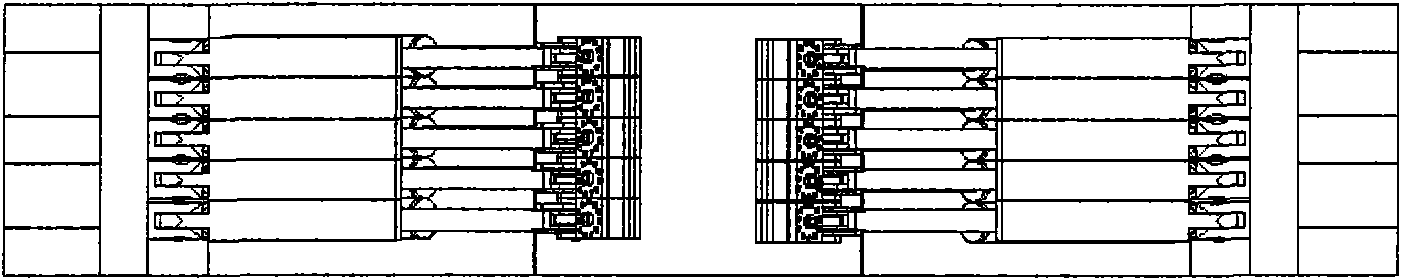

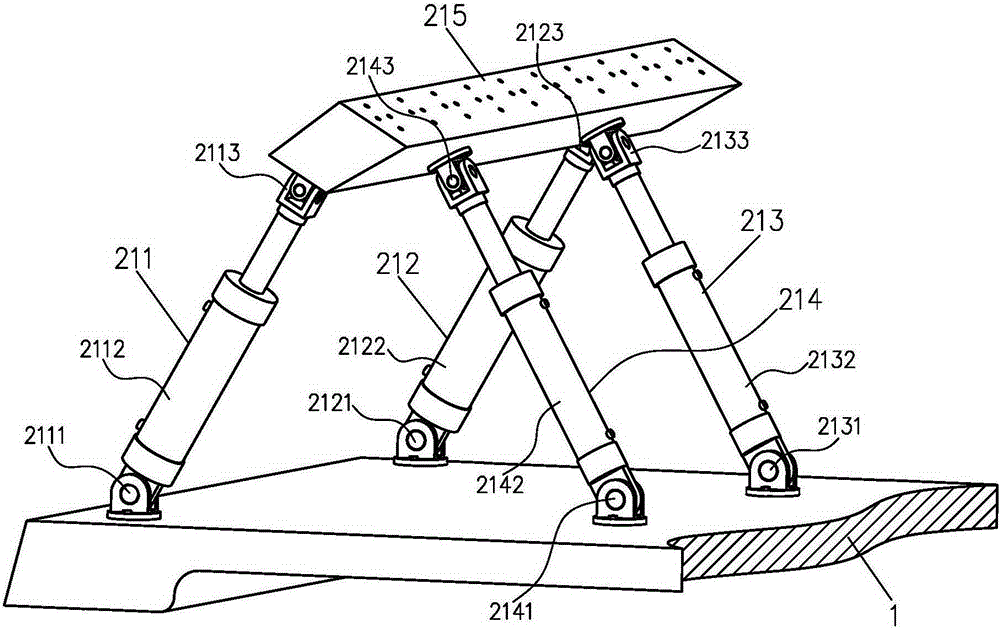

The invention discloses a stretching and pressing combined type plate stretch forming machine which is plastic working equipment for stretch forming of a plate type three-dimensional curved surface piece, and belongs to the field of mechanical engineering. A first object of the invention is to simplify hydraulic pressure of equipment and an electrical control system to lower the manufacturing cost; and a second object is to eliminate bending force on a plate when a vertical oil cylinder on a previous clamping device is loaded, so that pulling stress and strain of the stretch forming piece aredistributed more uniformly, and the shape stability and material utilization of the formed piece are improved. The stretch forming machine mainly consists of a rack, guide devices, downward pressing devices, clamping devices and horizontal prestretching devices (as shown in figures); the rack and the guide devices support the downward pressing devices, the clamping devices and the horizontal prestretching devices on the two sides; each clamping device consists of a plurality of clamping mechanisms; the downward pressing devices consists of a plurality of downward pushing mechanisms; the clamping mechanisms are arranged on the two sides of a mould in a row correspondingly; the downward pushing mechanisms are arranged on the two sides of the mould in a row correspondingly; and the horizontalprestretching devices consist of four hydraulic oil cylinders and universal joints and are arranged on the guide devices on the two sides.

Owner:JILIN UNIV

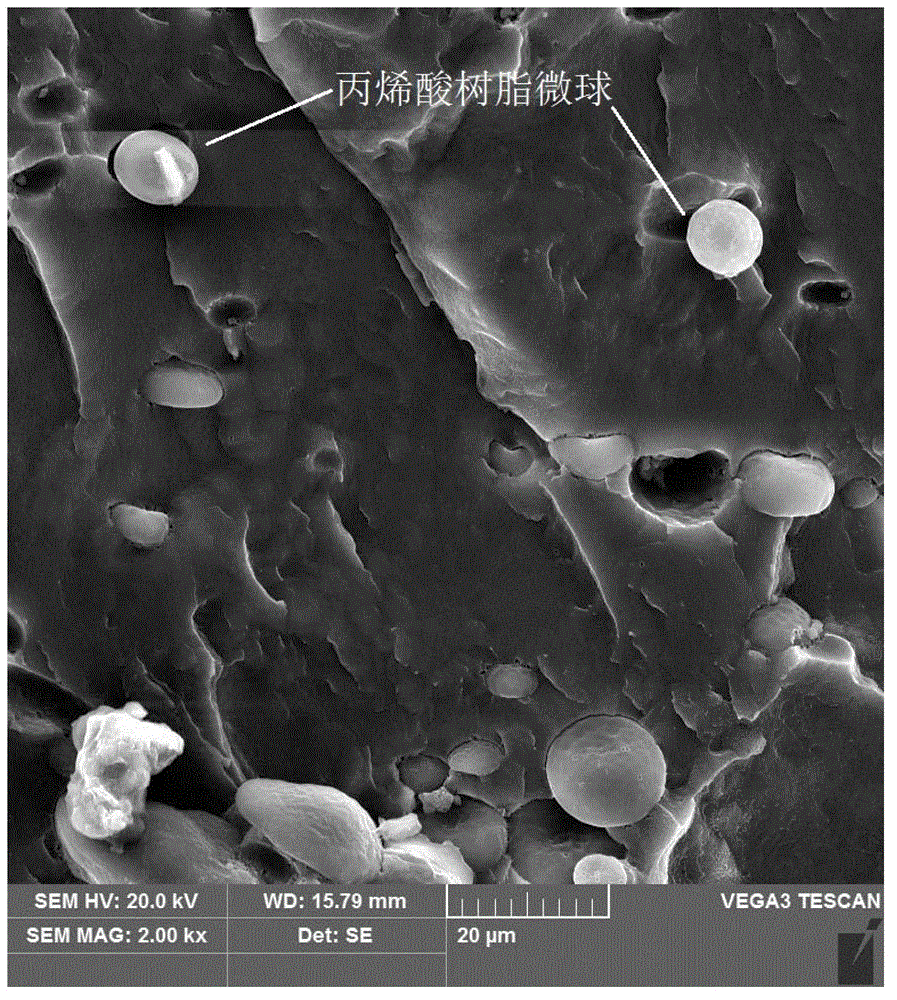

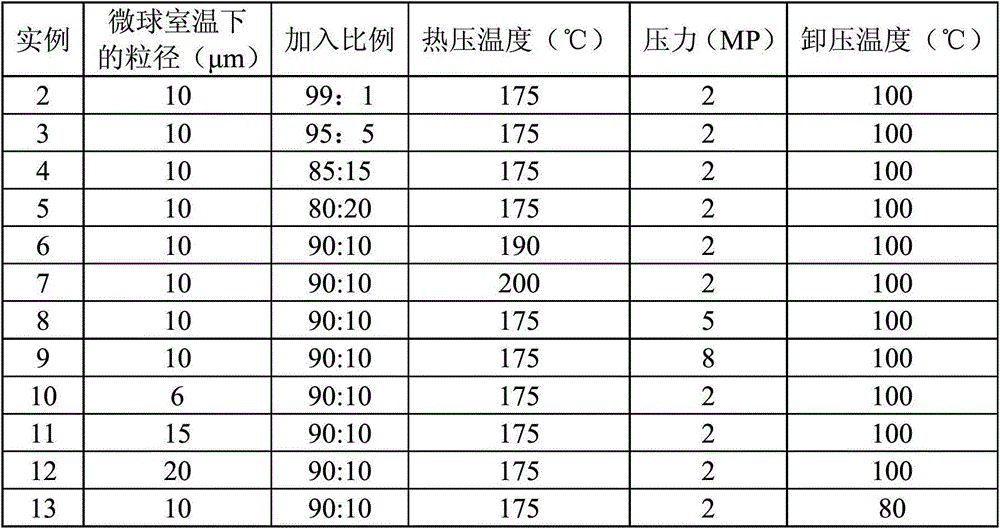

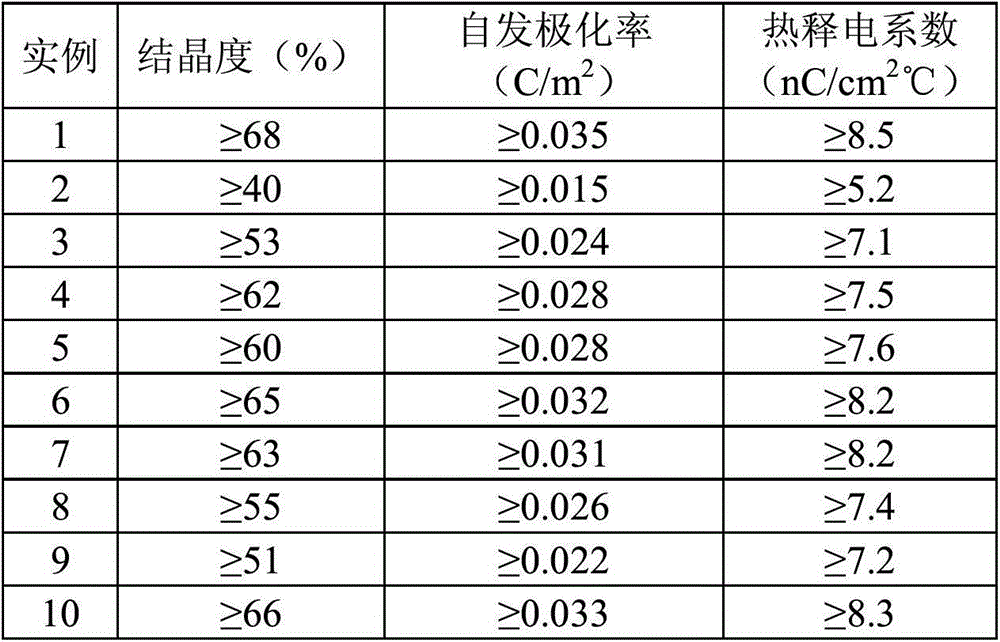

Preparation method of high-crystallinity polyvinylidene fluoride (PVDF)

The invention discloses a preparation method of high-crystallinity polyvinylidene fluoride (PVDF), which comprises the following steps: adding a microsphere expanding agent of which the thermal expansion coefficient is far higher than that of PVDF in the preparation of the PVDF material, wherein when the temperature rises from room temperature to the melting temperature of the PVDF, the microsphere sharply expands, and the volume of the microsphere is increased by about 10-20 times in comparison with the situation at room temperature; and then, cooling the PVDF from the melting temperature to room temperature to ensure that the PVDF is gradually solidified and crystallized, wherein in the cooling process, the microsphere sharply shrinks, so that uniform tensile stress can be formed in the PVDF in the solidification process, and the tensile stress can improve the crystallinity of a beta phase in the PVDF. For the PVDF prepared by the method, the crystallinity of the beta phase is obviously improved; and the pyroelectric property of the material is superior to that of the PVDF material prepared by a common method. The PVDF organic ferroelectric material prepared by the invention has high beta-phase crystallinity and spontaneous polarization rate and favorable pyroelectric property, and conforms to the use requirements of ferroelectric organic materials.

Owner:HUAZHONG UNIV OF SCI & TECH

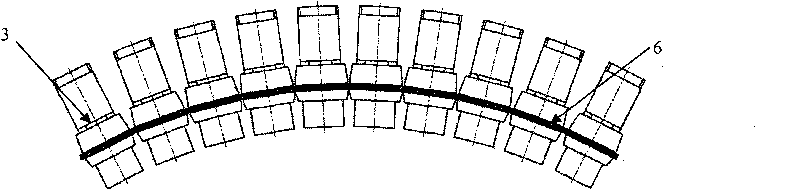

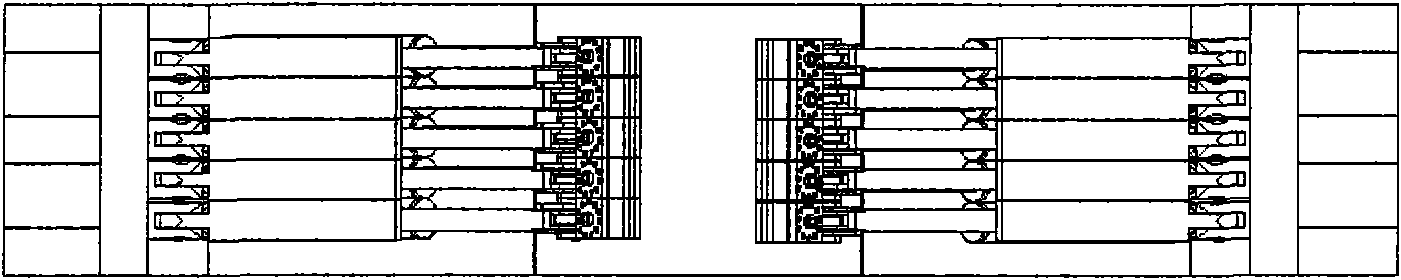

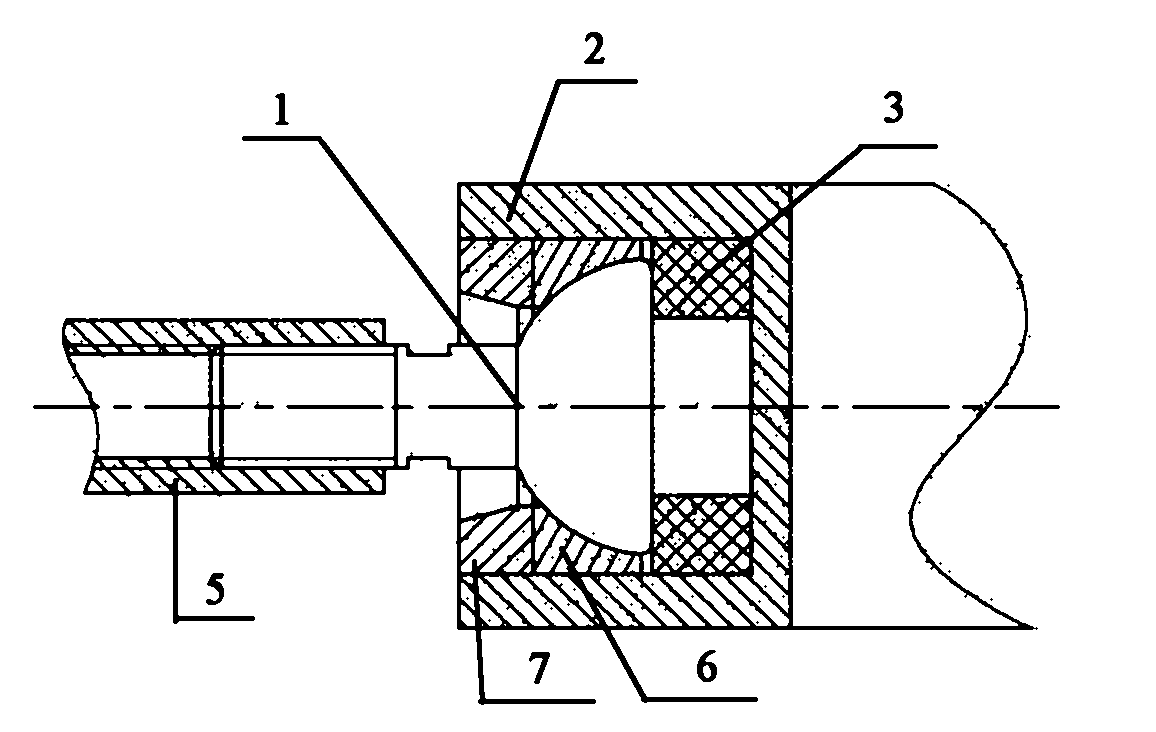

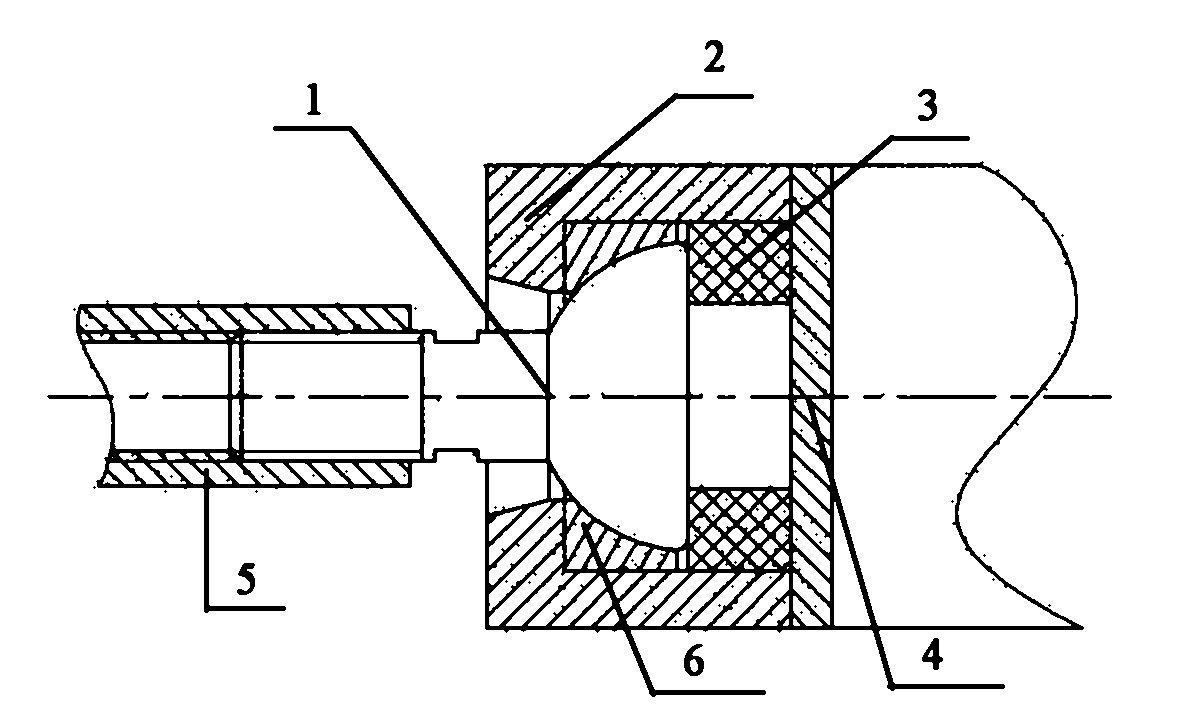

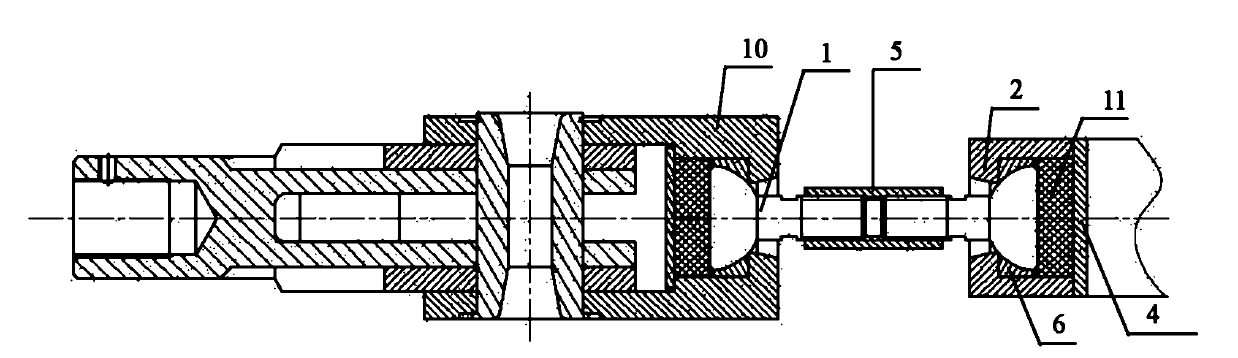

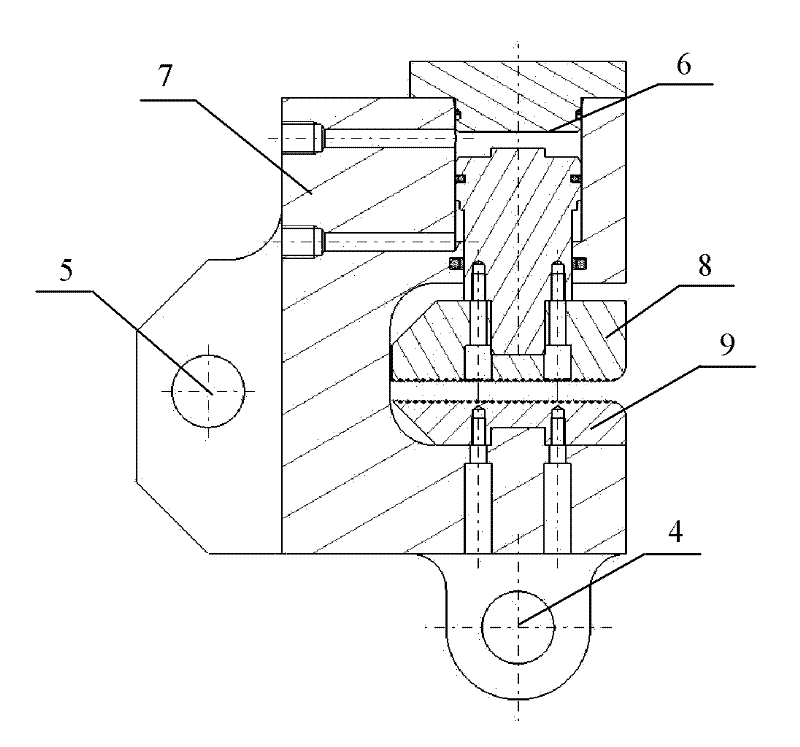

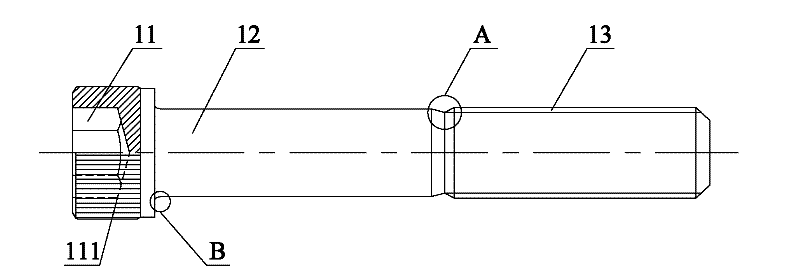

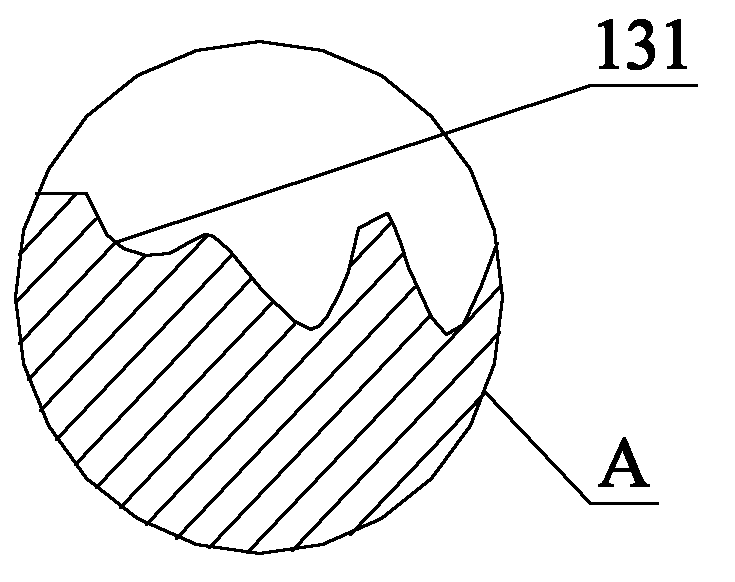

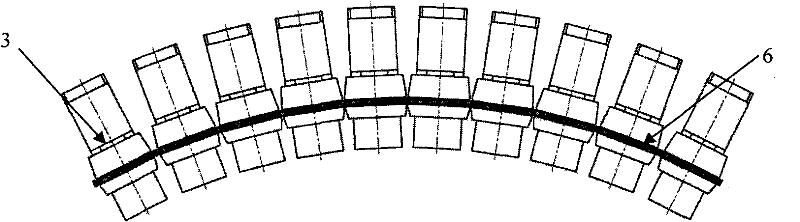

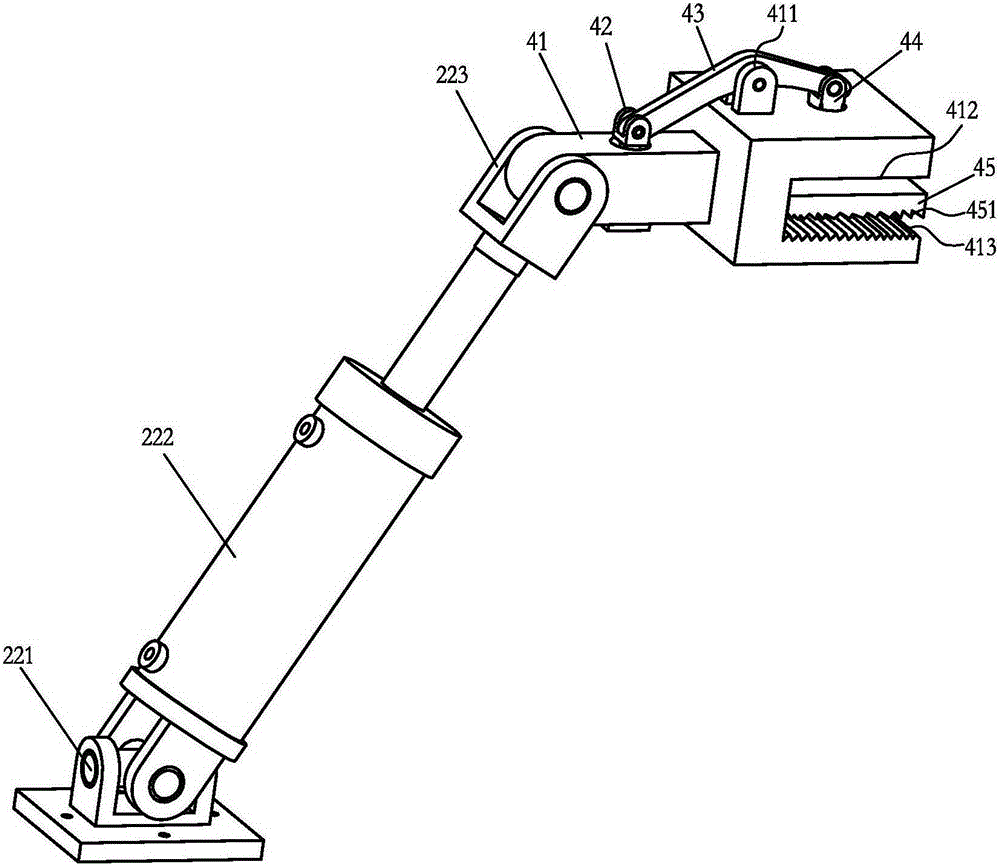

Universal pushing and pulling mechanism for stretch forming machine

ActiveCN101947594AIncrease freedomEasy to assembleMetal-working feeding devicesPositioning devicesEngineeringFree rotation

The invention discloses a universal pushing and pulling mechanism for a stretch forming machine, relates to a plastic processing device used for forming the curved surface of the sheet workpiece and belongs to the mechanical engineering field. The universal pushing and pulling mechanism mainly comprises a ball-end connection rod (1) and a connection body, wherein one end of the ball-end connection rod has a ball-shaped head, the other end is connected with the corresponding connection body through a screw thread or pin; and the ball-shaped head is hemispherical or spherical and is connected with a material-clamping frame (2) or a material-stripping mechanism connection body (10) directly or through a bearing bush (6) with a hemispherical pit. By using the universal pushing and pulling mechanism, the material-clamping mechanism can rotate and swing freely around the ball-shaped head of the ball-end connection rod and a plurality of material-clamping mechanisms in a row which are in a linear or arc arrangement can realize the flexible control of a plurality of clamps of the stretch forming machine; and the workpiece can snugglle closely to the mould during stretch forming, the material utilization rate of the workpiece can be obviously increased, the stretch forming of the workpiece with complicated curved surfaces can be realized, and the production demands of various workpieces can be met better.

Owner:JILIN UNIV

Sliding plate laser strengthening process for laser quenching on sliding plate surface

InactiveCN103602788AImprove deformationUniform tensile stressFurnace typesHeat treatment furnacesLaser quenchingHardness

The invention relates to a laser strengthening process of a sliding plate. The process comprises the following steps: A, conducting surface treatment on a sliding plate and detecting the sliding plate; B, coating a laser light absorption paint on both sides of the sliding plate; C, adjusting tool and optimizing process parameters according to the detection results, and fixing the slide plate on the tool; carrying out laser quenching on each region of the back side in a scattering manner, wherein the quenching region on the back side accounts for 1 / 3 to 2 / 5 of the total area of the back side; and carrying out laser quenching on the right side of the sliding plate in a scattering manner; and D, conducting detection. The laser strengthening process of the sliding plate can conveniently correct the deformation of the sliding plate, and the overall deformation of sliding plate with thickness of less than 50 mm can be effectively controlled within 0.5 mm and the sliding plate has a surface hardness of 52-56 HRC, so as to meet the usage requirements.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +1

Laser strengthening process for slide plate

InactiveCN103352105AImprove deformationUniform tensile stressHeat treatment process controlLaser quenchingHardness

The invention relates to a laser strengthening process for a slide plate. The process comprises the steps of: A. treating the slide plate surface, and detecting the slide plate; B. coating the front and back sides of the slide plate with a laser light absorption coating; C. adjusting a tool according to a detection result, optimizing technological parameters, and fixing the slide plate on the tool; firstly carrying out laser quenching on each region of the back side discretely, with the back side quenching region area accounting for 1 / 3-2 / 5 of the total area of the slide plate back side; then the discretely quenching the front side of the slide plate; and D. performing detection. The laser strengthening process for a slide plate can conveniently correct the deformation of the slide plate. The overall deformation of a slide plate with thickness of less than 50mm is effectively controlled within 0.5mm, and the surface hardness of the slide plate is 52-56HRC, thus meeting use requirements.

Owner:DANYANG HONGTU LASER TECH

Laser strengthening process for slide plate

InactiveCN103352105BImprove deformationUniform tensile stressHeat treatment process controlLaser quenchingLaser light

The invention relates to a laser strengthening process for a slide plate. The process comprises the steps of: A. treating the slide plate surface, and detecting the slide plate; B. coating the front and back sides of the slide plate with a laser light absorption coating; C. adjusting a tool according to a detection result, optimizing technological parameters, and fixing the slide plate on the tool; firstly carrying out laser quenching on each region of the back side discretely, with the back side quenching region area accounting for 1 / 3-2 / 5 of the total area of the slide plate back side; then the discretely quenching the front side of the slide plate; and D. performing detection. The laser strengthening process for a slide plate can conveniently correct the deformation of the slide plate. The overall deformation of a slide plate with thickness of less than 50mm is effectively controlled within 0.5mm, and the surface hardness of the slide plate is 52-56HRC, thus meeting use requirements.

Owner:DANYANG HONGTU LASER TECH

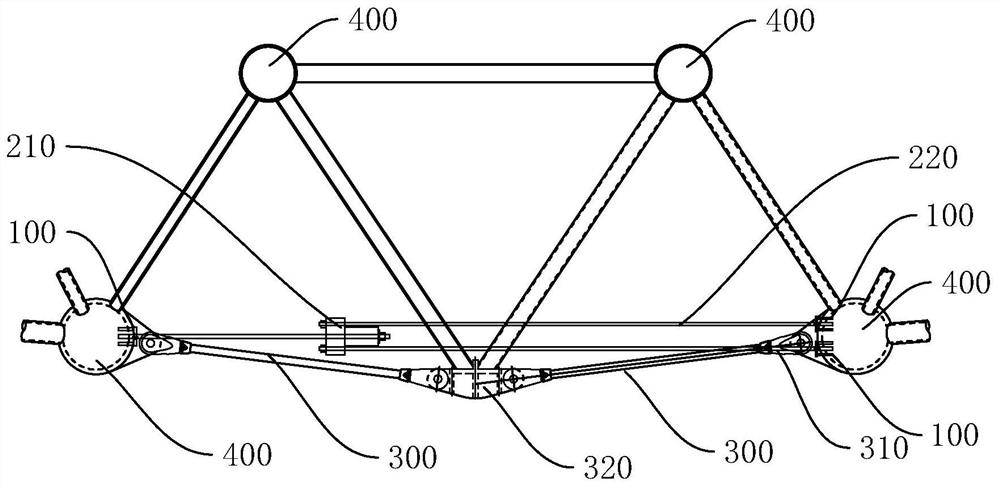

Net rack steel pull rod tensioning construction method and construction tool

ActiveCN111424989AUniform tensile stressReduce the degree of stress variationBuilding material handlingConstruction engineeringStructural engineering

The invention discloses a net rack steel pull rod tensioning construction method and construction tool. The net rack steel pull rod tensioning construction method comprises the steps that a tensioningtool is arranged on a net rack joint, and a tensioning device is installed on the tensioning tool; the two ends of a steel pull rod set are connected to the net rack joint; tensioning is conducted through the tensioning device till preset tensioning force is reached; and the tensioning device is dismounted. The net rack steel pull rod tensioning construction tool comprises a connecting body usedfor installing the tensioning device. When the tensioning device in the embodiment of the invention tensions a net rack, the steel pull rod set is also subjected to the tensioning force applied to thenet rack by the tensioning device and deforms, the tensioning force of the tensioning device is gradually transferred to the steel pull rod set, after tensioning of the net rack is completed and thetensioning device is dismounted, the degree of internal stress changes of the steel pull rod set after the tensioning device is dismounted is reduced, the tensioning tool on the net rack joint can also be applied to other construction processes after the tensioning device is dismounted, and universality and practicability are good.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

Multiclamp type stretch forming machine

The invention discloses a multiclamp type stretch forming machine and relates to plastic processing equipment for curve forming of plates, belonging to the field of mechanical engineering. The machine mainly comprises clamping mechanisms (1), a stretching mechanism (2) and a stand (3), wherein a row of clamping mechanisms (1) are respectively distributed at both sides of the stand (3); each clamping mechanisms (1) is provided with a lower connecting hole (4) and a rear connecting hole (5); and all the connecting holes are respectively connected with the stretching mechanism (2) by pin shafts or cardan joints. The machine can realize the flexible control of a plurality of clamps, ensure that a workpiece is more easily attached to a die in the stretching process, obviously improve the material utilization ratio of the workpiece and obtain higher workpiece forming effect.

Owner:长春瑞光科技有限公司

Mould for forming axial tensile-strength test piece of cement-based material and test method

InactiveCN101650283BMeasured axial tensile strengthThe test result is accurateMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementData acquisitionEngineering

The invention relates to a mould for forming an axial tensile-strength test piece of cement-based material and a test method, belonging to the field of building materials. The mould comprises a testing machine, a test piece forming mould, a test piece force-transfer device and a data acquisition device, wherein the test piece forming trial mould comprises a bottom plate, two end plates, two lateral plates and two intermediate plates; the two end plates and the two lateral plates are all arranged on the bottom plate, and a cavity is enclosed by the bottom plate, the end plates and the lateral plates; the two intermediate plates are also arranged on the bottom plate in parallel to the lateral plates and positioned in the cavity, and the cavity is divided into three parts by the two intermediate plates, wherein the parts at two sides are used for forming the test piece; bolt rods are embedded in two ends of the test piece, each bolt rod comprises a nail head, a smooth rod and a thread rod, wherein the nail head is embedded into the test piece, the smooth rod passes through the end plates, and thread rod straightly extends out of the end plates; the test piece force-transfer device selectively adopts a universal hinge, and the test piece is connected with the testing machine by the universal hinge; and the data acquisition device is used for acquiring experimental data. The invention can accurately and conveniently measure the axial tensile strength of the cement test piece, and is simple and practical.

Owner:BEIJING UNIV OF TECH

a bolt

InactiveCN102297188AHigh tensile strengthImprove fatigue lifeLoad modified fastenersScrewsEngineeringUltimate tensile strength

The invention discloses a bolt, which includes a nut and a screw rod. The outer circumferential surface of the screw rod has threads that match the nut; the end of the thread has a tooth mouth that engages with the nut, and the cross section of the tooth mouth is Oval. The threaded mouth with this kind of arc-shaped structure can significantly improve the bonding strength of the assembly structure after the threaded connection between the bolt and the nut, and reduce the tensile stress, shear force and other mechanical stresses that the tooth mouth is subjected to during use. The distribution is more uniform, so that the overall tensile strength of the bolt is correspondingly increased, and the overall fatigue life of the bolt is correspondingly extended.

Owner:SHANGHAI AUTOCRAFT

Laser strengthening process of sliding plate

The invention relates to a laser strengthening process of a sliding plate. The process comprises the following steps: A, conducting surface treatment on a sliding plate and detecting the sliding plate; B, coating a laser light absorption paint on both sides of the sliding plate; C, adjusting tool and optimizing process parameters according to the detection results, and fixing the slide plate on the tool; carrying out laser quenching on each region of the back side in a scattering manner, wherein the quenching area on the back side accounts for 1 / 3 to 2 / 5 of the total area of the back side; and carrying out laser quenching on the right side of the sliding plate in a scattering manner; and D, conducting detection. The laser strengthening process of the sliding plate can conveniently correct the deformation of the sliding plate, and the overall deformation of sliding plate with thickness of less than 50 mm can be effectively controlled within 0.5 mm and the sliding plate has a surface hardness of 52-56 HRC, so as to meet the usage requirements.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +1

Laser strengthening process of sliding plate

InactiveCN102676751BConvenient deformationImprove deformationHeat treatment process controlLaser lightHardness

The invention relates to a laser strengthening process of a sliding plate. The laser strengthening process of the sliding plate comprises the following steps: A, treating the surface of the sliding plate, and detecting the sliding plate; B, coating laser light absorbing coatings on the front surface and the back surface of the sliding plate; C, regulating a tool and optimizing process parameters according to a detection result, and fixing the sliding plate on the tool; firstly, performing laser quenching on various regions of the back surface discretely, wherein the area of the quenched region on the back surface accounts for 1 / 3-2 / 5 of the total area of the back surface of the sliding plate; and then performing laser quenching on the front surface of the sliding plate discretely; and D, detecting. The laser strengthening process of the sliding plate can correct deformation of the slide plate conveniently; the overall deformation of the sliding plate with a thickness of less than 50 mm is effectively controlled within 0.5 mm; and the surface hardness of the sliding plate is 52-56 HRC and meets the using requirement.

Owner:DANYANG HONGTU LASER TECH

High-flexibility multi-head stretching machine

The invention discloses a high-flexibility multi-head stretching machine, which relates to plastic processing equipment for three-dimensional curved surface forming of sheet parts and belongs to the field of mechanical engineering. The machine aims to make the distribution of the pulling stress and the tension strain of stretched parts more trend to be uniform, improve the stretching quality and the utilization rate of materials, and realize the stretching of curvature parts with larger transverse curvature or certain wave. The machine mainly comprises a main frame (1), material pulling mechanisms, material clamping mechanisms (3) and universal mechanisms (5), wherein a row of a plurality of the material pulling mechanisms, the material clamping mechanisms (3) and the universal mechanisms(5) are arranged on both sides of the main frame (1) respectively; the material pulling mechanisms consist of three hydraulic cylinders (2) respectively, one of the hydraulic cylinders (2) is horizontally arranged, the other hydraulic cylinder (2) is vertically arranged, and the third hydraulic cylinder (2) are slantways arranged; and one end of each of the three hydraulic cylinders (2) is hingedwith the main frame (1) respectively, while the other end is jointly connected with the universal mechanism (5) and the material clamping mechanism (3) through a hydraulic cylinder connection body (4) respectively.

Owner:JILIN UNIV

Reverse impact extrusion apparatus and method for manufacturing rechargeable battery casings

ActiveCN104795512BIncrease frictionUniform tensile stressShaping toolsExtrusion diesImpact extrusionManufacturing engineering

The invention discloses a reverse impact extrusion device and a manufacturing method for manufacturing rechargeable battery shells. A reverse impact pressing device according to an exemplary embodiment of the present invention includes a punch having a die-clamping portion protruding outward from each bottom side, and a die formed with a groove into which a tray is inserted. The walls are formed such that their central portion is higher than their side ends.

Owner:SAMSUNG SDI CO LTD

Tension construction method and construction tooling of grid steel tie rods

ActiveCN111424989BUniform tensile stressReduce the degree of stress variationBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a tensioning construction method and construction tooling of grid steel tie rods. The tensioning construction method of grid steel tie rods includes setting tensioning tools on grid nodes, installing tensioning equipment on the tensioning tools; The two ends of the tie rods are respectively connected to the nodes of the network frame; tensioning is carried out through the tensioning equipment until the preset tension is reached; the tensioning equipment is removed; the construction tooling for the tensioning of the steel tie rods of the network frame includes the connection for installing the tensioning equipment ontology. When the tensioning equipment in the embodiment of the present invention is stretching the network frame, the steel tie rod group is also subjected to the tension force applied by the tensioning device to the network frame and deformed, and the tension force of the tensioning device is gradually transferred to the steel tie rod group , after the unloading of the tensioning equipment is completed in the grid stretching, the degree of internal stress change of the steel tie rod group after the unloading of the tensioning equipment is reduced, and the tensioning tooling on the grid nodes can also be applied to other constructions after the unloading of the tensioning equipment Craftsmanship, versatility and practicability are good.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

Laser strengthening process for effective control of quenching deformation of sliding plate

InactiveCN103602789BImprove deformationUniform tensile stressFurnace typesHeat treatment furnacesLaser quenchingLaser light

The invention relates to a laser strengthening process of a sliding plate. The process comprises the following steps: A, conducting surface treatment on a sliding plate and detecting the sliding plate; B, coating a laser light absorption paint on both sides of the sliding plate; C, adjusting tool and optimizing process parameters according to the detection results, and fixing the slide plate on the tool; carrying out laser quenching on each region of the back side in a scattering manner, wherein the quenching area on the back side accounts for 1 / 3 to 2 / 5 of the total area of the back side; and carrying out laser quenching on the right side of the sliding plate in a scattering manner; and D, conducting detection. The laser strengthening process of the sliding plate can conveniently correct the deformation of the sliding plate, and the overall deformation of sliding plate with thickness of less than 50 mm can be effectively controlled within 0.5 mm and the sliding plate has a surface hardness of 52-56 HRC, so as to meet the usage requirements.

Owner:广州市朗丰流体机械有限公司

An open profile expansion mold

ActiveCN104624800BUniform tensile stressWide range of size variationsShaping toolsEngineeringMechanical engineering

The invention discloses an opening type sectional material expansion die which comprises a base (1), wallboards (2), a female die (3), side inner dies (4), male dies (5), rotation pins (7), reset springs (8) and female die adjusting screws (9). The female die (3) is installed on the base (1), the wallboards (2) are installed on the base (1) and are located on the two sides of the female die (3), the side inner dies (4) are installed on the wallboards (2) through the rotation pins (7) and can rotate around the rotation pins (7), the reset springs (8) are arranged in the wallboards (2), the male dies (5) are arranged on the inner sides of the side inner dies (4), and the female die (3) and the side inner dies (4) are matched to form a cavity. The opening type sectional material expansion die has the advantages that the opening type sectional material expansion die can be used for expanding processing of an opening sectional material, no dead angle exists when a workpiece is expanded by designing the tensile track into the combined motion of circulation motion and horizontal motion, and the opening type sectional material expansion die has the advantages of being simple in structure, reliable in clamping and the like.

Owner:四川省青神神力机械有限公司

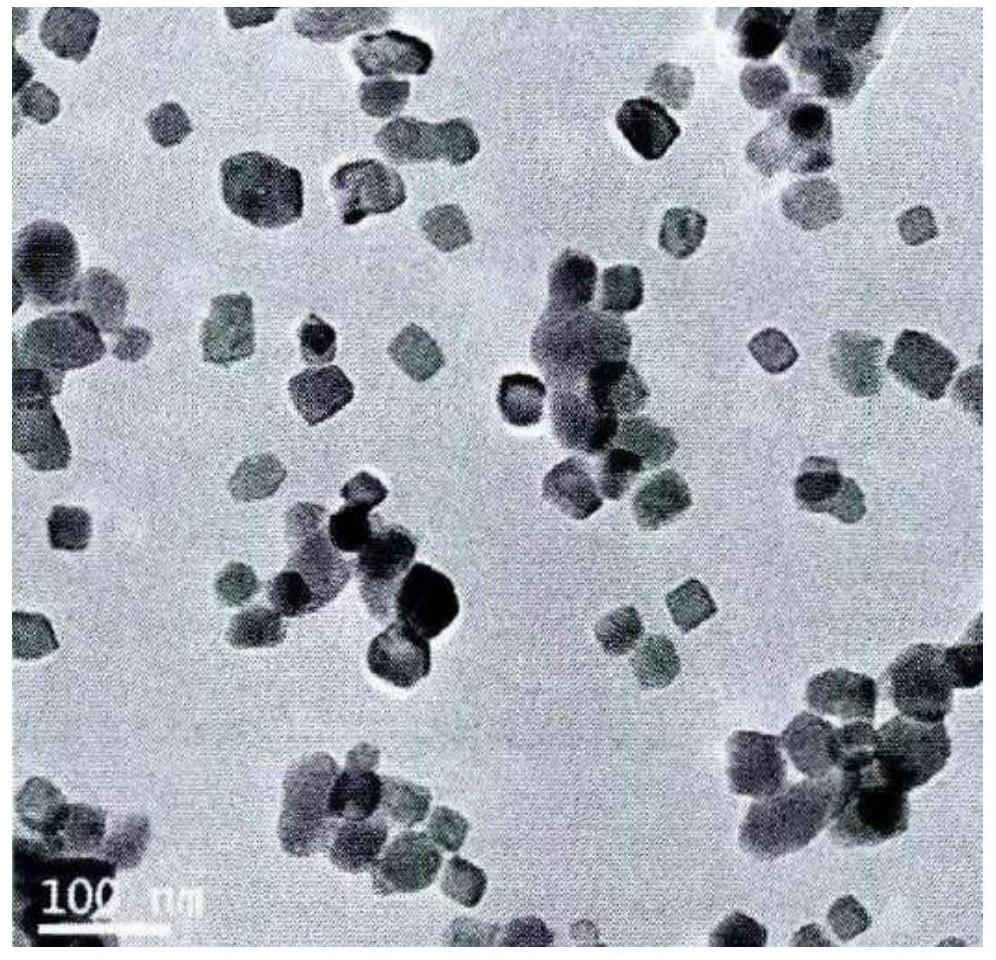

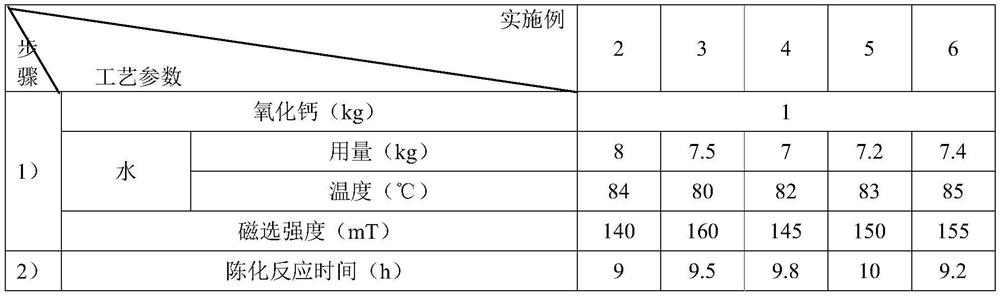

Preparation method of ultra-dispersed functional calcium carbonate

PendingCN114455622AStrong chelating abilityStrong specific surface areaCalcium/strontium/barium carbonatesNanotechnologyCalcium hydroxidePropanol

The invention provides a preparation method of ultra-dispersed functional calcium carbonate, and belongs to the technical field of nano material preparation, the preparation method comprises the following steps: carrying out digestion reaction on calcium oxide and water, carrying out magnetic separation enrichment on the obtained slurry through a magnetic separator, collecting the outflow calcium hydroxide slurry, and carrying out aging reaction, sieving and water addition dilution to prepare a calcium hydroxide suspension; 2-amino-2-methyl propanol is added into the calcium hydroxide suspension, carbon dioxide gas is introduced for a carbonization reaction, when the pH value of a reaction system is reduced to 6.5-7.0, the carbonization reaction is stopped, and obtained calcium carbonate slurry is dehydrated, dried, smashed and screened to obtain the ultra-dispersed functional calcium carbonate. The cubic ultra-dispersed functional calcium carbonate is prepared by adding the 2-amino-2-methyl propanol, and the cubic ultra-dispersed functional calcium carbonate is large in specific surface area, good in dispersity, not prone to agglomeration and low in oil absorption value.

Owner:河北立信新材料科技有限公司

Sheet-stretching machine

ActiveCN101559442BReduce manufacturing costUniform tensile stressTension stressMechanical engineering

The invention provides a sheet-stretching machine, relates to a plastic working device for the three-dimensional curved-surface forming of sheet workpieces, and belongs to the field of mechanical engineering. The invention aims to allow pulling pieces to tend to be uniform in the distribution of tensile stress and tension strain, realize the pulling of complex curved-surface workpieces, improve the forming quality of the pulling pieces, improve material utilization rate and reduce the cost for manufacturing pulling devices. This machine mainly comprises a frame (1), a left-side clamping mechanism, a right-side clamping mechanism and a down-pressing mechanism, wherein the frame (1) supports the left-side clamping mechanism, the right-side clamping mechanism and the down-pressing mechanism;each clamping mechanism is divided into an upper part and a lower part; each part has a plurality of clamping devices arranged in a row; and the down-pressing mechanism has a plurality of down-pressing devices arranged in a row or a plurality of rows.

Owner:JILIN UNIV

Plate stretch-forming machine

Owner:JILIN UNIV

A tension-compression composite plate stretch forming machine

ActiveCN108746332BRealize flexible formingReduce transition marginAircraft componentsMetal-working feeding devicesManufacturing cost reductionEngineering

The invention discloses a stretching and pressing combined type plate stretch forming machine which is plastic working equipment for stretch forming of a plate type three-dimensional curved surface piece, and belongs to the field of mechanical engineering. A first object of the invention is to simplify hydraulic pressure of equipment and an electrical control system to lower the manufacturing cost; and a second object is to eliminate bending force on a plate when a vertical oil cylinder on a previous clamping device is loaded, so that pulling stress and strain of the stretch forming piece aredistributed more uniformly, and the shape stability and material utilization of the formed piece are improved. The stretch forming machine mainly consists of a rack, guide devices, downward pressing devices, clamping devices and horizontal prestretching devices (as shown in figures); the rack and the guide devices support the downward pressing devices, the clamping devices and the horizontal prestretching devices on the two sides; each clamping device consists of a plurality of clamping mechanisms; the downward pressing devices consists of a plurality of downward pushing mechanisms; the clamping mechanisms are arranged on the two sides of a mould in a row correspondingly; the downward pushing mechanisms are arranged on the two sides of the mould in a row correspondingly; and the horizontalprestretching devices consist of four hydraulic oil cylinders and universal joints and are arranged on the guide devices on the two sides.

Owner:JILIN UNIV

Reverse impact extrusion device manufacturing rechargeable battery shell and manufacturing method

ActiveCN104795512AIncrease frictionUniform tensile stressShaping toolsExtrusion diesImpact extrusionManufacturing engineering

The invention discloses a reverse impact extrusion device manufacturing a rechargeable battery shell and a manufacturing method. The reverse impact extrusion device according to the example embodiment comprises a puncher pin with mold clamping parts protruding outward from bottom sides, and a die forming a tray inserted into a groove in the die. Walls are formed to enable central parts of the walls are higher than side ends of the walls.

Owner:SAMSUNG SDI CO LTD

Laser strengthening process of sliding plate

ActiveCN103602800AConvenient deformationImprove deformationFurnace typesHeat treatment furnacesLaser lightHardness

The invention relates to a laser strengthening process of a sliding plate. The process comprises the following steps: A, conducting surface treatment on a sliding plate and detecting the sliding plate; B, coating a laser light absorption paint on both sides of the sliding plate; C, adjusting tool and optimizing process parameters according to the detection results, and fixing the slide plate on the tool; carrying out laser quenching on each region of the back side in a scattering manner, wherein the quenching region on the back side accounts for 1 / 3 to 2 / 5 of the total area of the back side; and carrying out laser quenching on right side of the sliding plate in a scattering manner; and D, conducting detection. The laser strengthening process of the sliding plate can conveniently correct the deformation of the sliding plate, and the overall deformation of sliding plate with thickness of less than 50 mm can be effectively controlled within 0.5 mm and has a surface hardness of 52-56 HRC, so as to meet the usage requirements.

Owner:力量知识产权天津有限公司

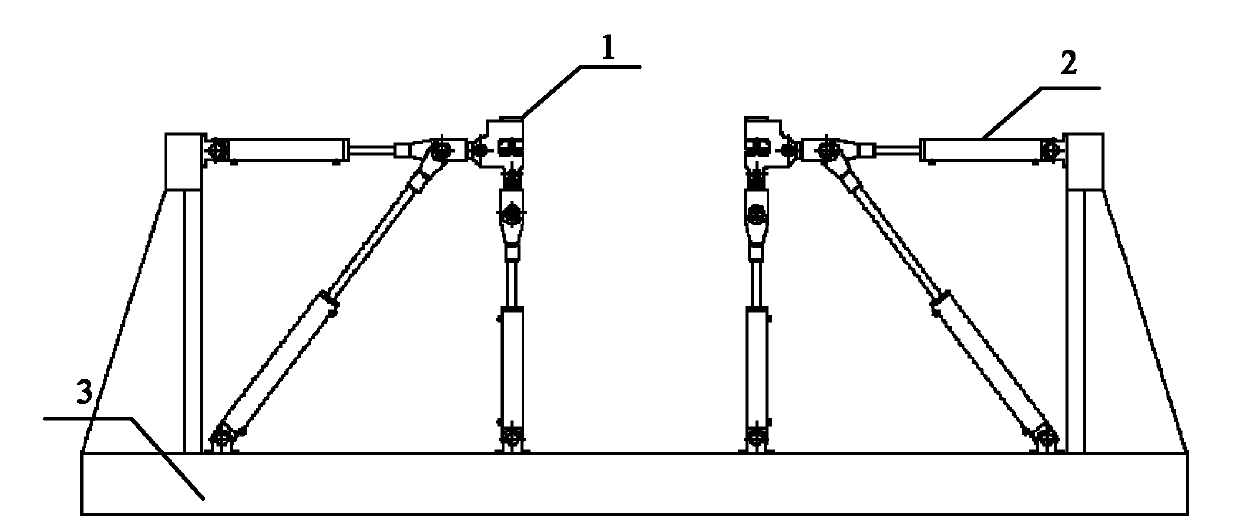

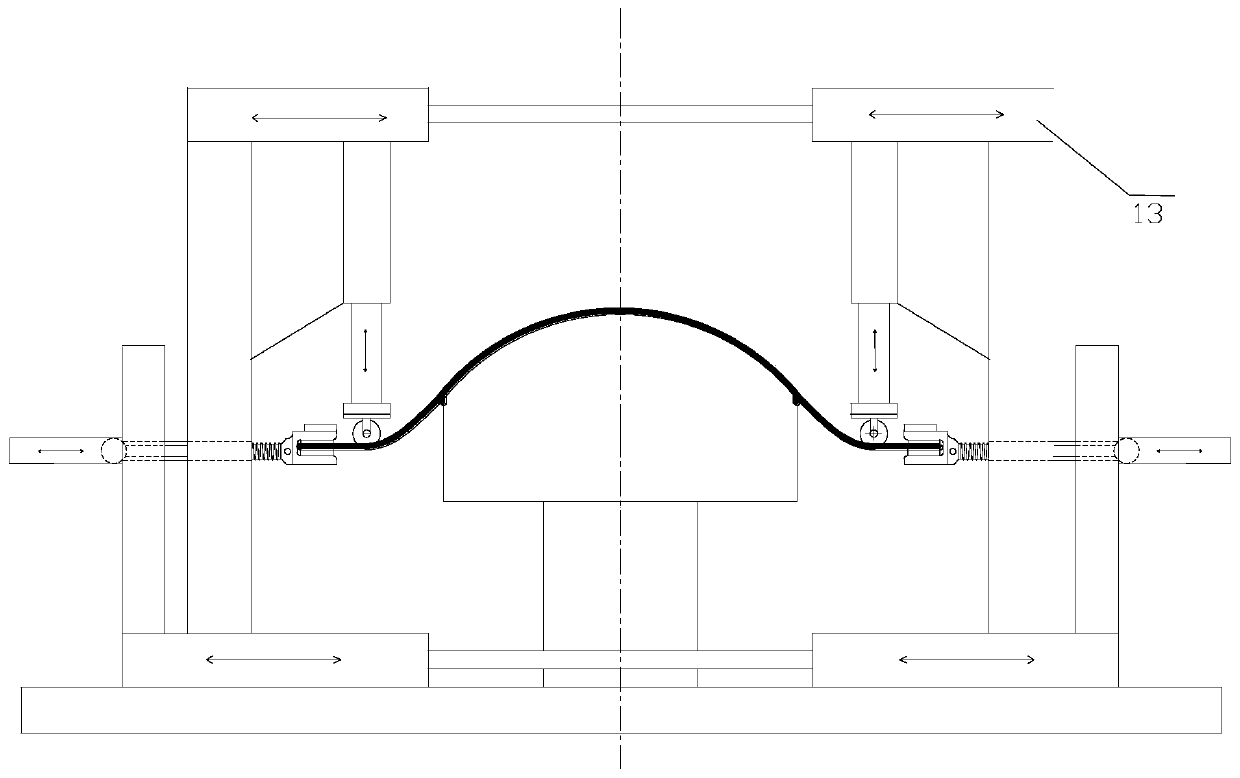

Four-degree-of-freedom hybrid multi-head flexible drawing machine

The invention discloses a four-degree-of-freedom series-parallel multi-point flexible shape pulling machine which is composed of a base, a left traction device, a right traction device, a left plate clamping mechanism and a right plate clamping mechanism. The bottom of the left traction device and the bottom of the right traction device are fixed to the base and used for supporting the left plate clamping mechanism and the right plate clamping mechanism respectively and are identical in structure and are four-degree-of-freedom series-parallel mechanisms of 4RPU-UPR structures. The left plate clamping mechanism and the right plate clamping mechanism which are used for clamping and fixing plates are also of the same structure. Compared with the prior art, the four-degree-of-freedom series-parallel mechanisms and layered adjustment and shape pulling work manners are adopted in the four-degree-of-freedom series-parallel multi-point flexible shape pulling machine, position points on shape pulling parts are easy to flexibly deform, the technology margin is reduced, and the forming quality and the utilization rate of materials are improved. The four-degree-of-freedom series-parallel multi-point flexible shape pulling machine not only is multiple in degree of freedom of motion and few in needed hydraulic cylinders but also has the advantages of being high in flexibility, easy to control, low in equipment manufacturing cost and the like.

Owner:ANHUI UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com