Preparation method of high-crystallinity polyvinylidene fluoride (PVDF)

A technology of polyvinylidene fluoride and acrylic resin, which is applied in the field of preparation of high-performance organic functional materials, can solve the problems of high cost of copolymers, unsuitable for mass production, complicated process, etc., and achieve the effect of improving the crystallinity of β phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

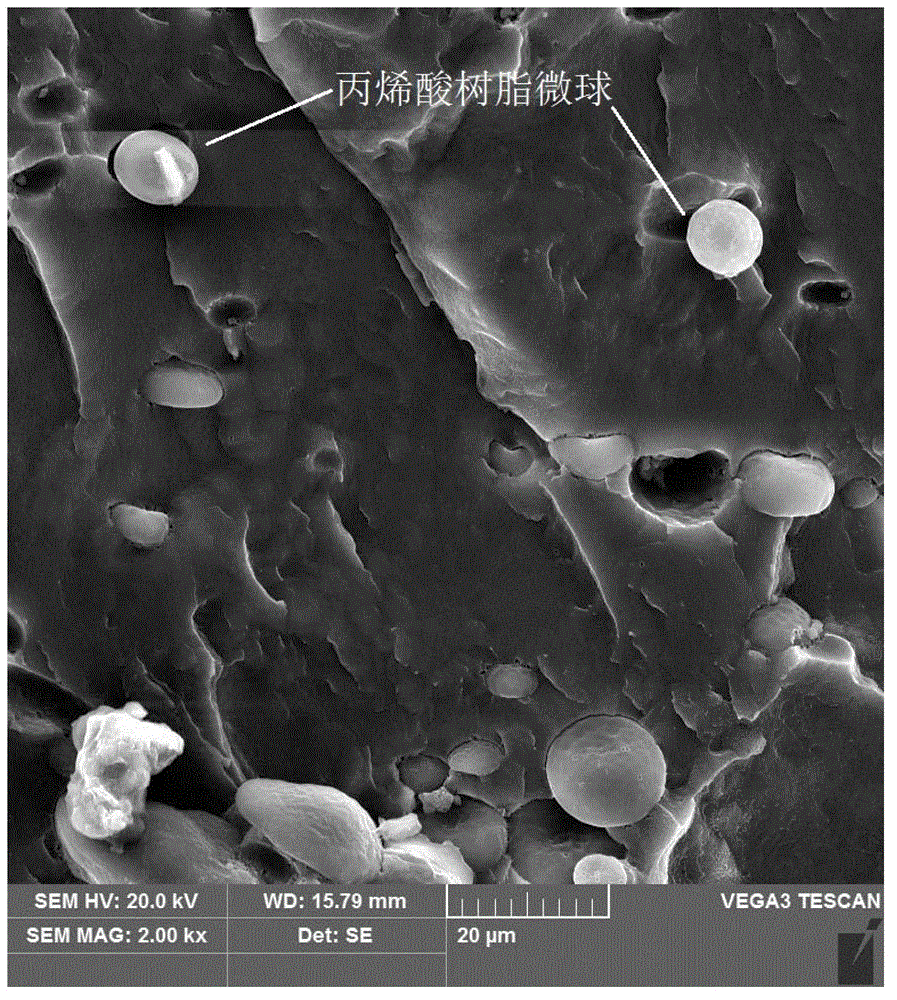

[0017] A kind of preparation method of high crystallinity polyvinylidene fluoride provided by the invention, its step comprises:

[0018] (1) PVDF and acrylic resin microsphere expansion agent are mixed in a mass ratio of 99:1 to 80:20, after which pure water is used as a medium for ball milling to uniformly mix PVDF and microspheres;

[0019] (2) drying at low temperature to obtain a uniform mixed powder of PVDF and thermally expandable microspheres;

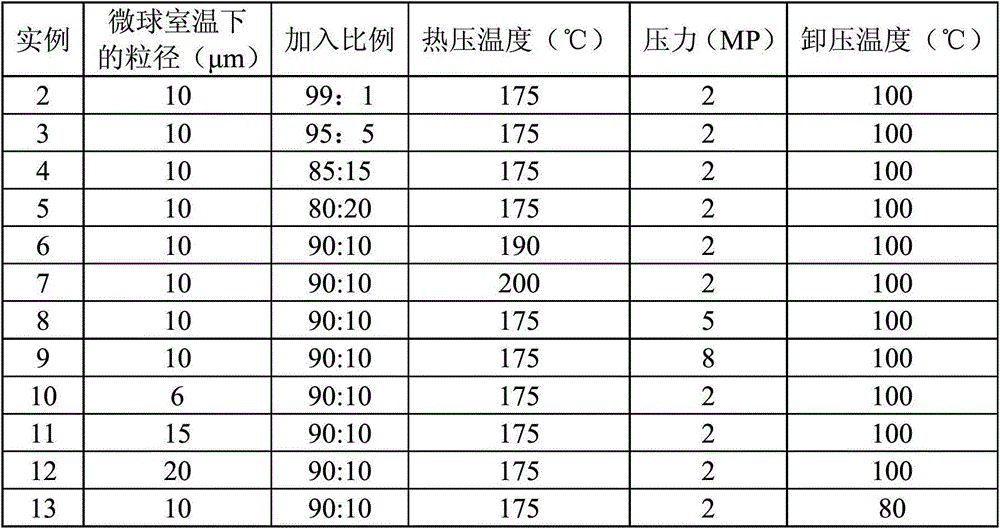

[0020] (3) Put the powder in a hot-press furnace for hot-pressing. Heat the powder to 175°C-200°C to melt the PVDF (at this temperature, the microspheres are still spherical solids). At the same time, apply a pressure of 2MPa to 8MPa in the axial direction;

[0021] (4) Keep the sample warm for 20 minutes, then cool down naturally;

[0022] (5) When the temperature drops to 100°C to 80°C, remove the pressure, and then cool the sample down to room temperature naturally;

[0023] (6) Grinding and cleaning the prepared PVDF sa...

example 1

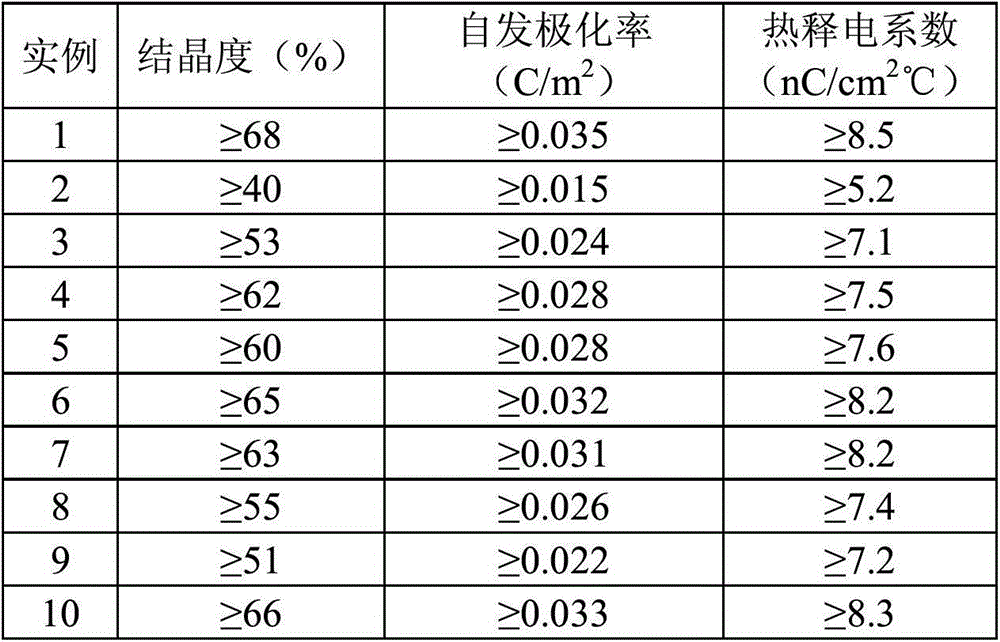

[0027] The acrylic resin microsphere expansion agent with a particle size of 10 μm at room temperature and PVDF were weighed according to a mass ratio of 90:10, and then ball milled with pure water as a medium to uniformly mix PVDF and microspheres. Dry the uniformly mixed slurry at 50° C. to obtain a uniformly mixed powder of PVDF and heat-expandable microspheres. The powder is placed in a hot-press furnace for hot pressing. Heat the powder to 175°C to melt the PVDF while applying a pressure of 2 MPa in the axial direction. The samples were incubated for 20 minutes, after which the temperature was naturally cooled. When the temperature dropped to 100°C, the pressure was released, and then the sample was naturally cooled to room temperature. The prepared PVDF samples were polished and cleaned.

[0028] Its performance is shown in Table 3.

example 2-5

[0030] Heat-expandable microspheres and PVDF are weighed according to mass ratios of 99:1, 95:5, 85:15 and 80:20. All the other are the same as example 1. The process parameters are shown in Table 2, and its performance is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com