An open profile expansion mold

A technology of bulging and mould, which is applied in the field of bulging molds for open profiles, can solve the problems that cannot meet the needs of bulging of open profiles, cannot guarantee the uniformity of tensile stress, and cannot be closed in the length direction of profiles, etc., and achieves a wide range of workpiece size changes , Uniform tensile stress and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

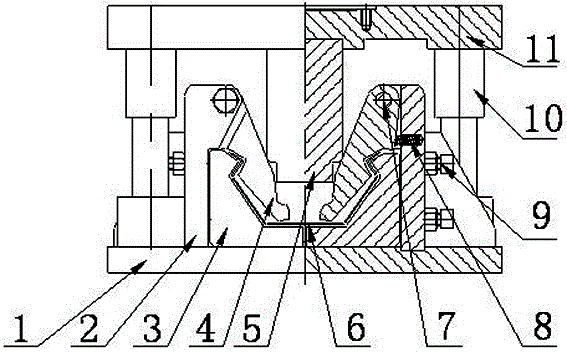

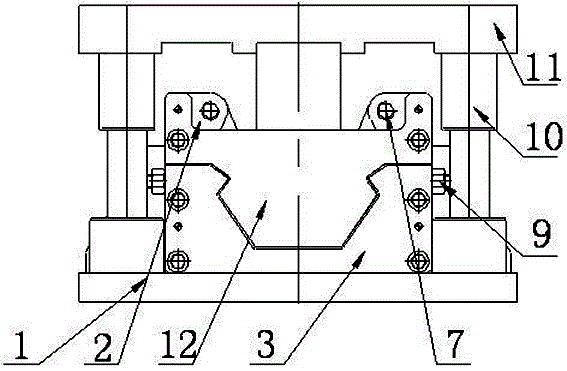

[0016] Such as figure 1 Shown, a kind of opening profile expansion mold, it comprises base 1, wallboard 2, die 3, side inner mold 4, punch 5, rotary pin 7, return spring 8 and die adjustment screw 9, die 3 Installed on the base 1, the wallboard 2 is installed on the base 1, and the wallboard 2 is located on both sides of the die 3. In this embodiment, the die 3 is divided into left and right pieces, and the wallboard 2 is installed with The die adjustment screw 9, the die adjustment screw 9 can adjust the distance between the left and right blocks of the die 3, in the present embodiment, the wallboard 2 is equipped with a feed die 12, and the side inner die 4 passes through The rotary pin 7 is installed on the wall panel 2, the side inner mold 4 can rotate around the rotary pin 7 to compress and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com