Preparation method of ultra-dispersed functional calcium carbonate

A functional calcium carbonate, ultra-dispersion technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of different effects, to achieve increased whiteness, increased toughness, The effect of low oil absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

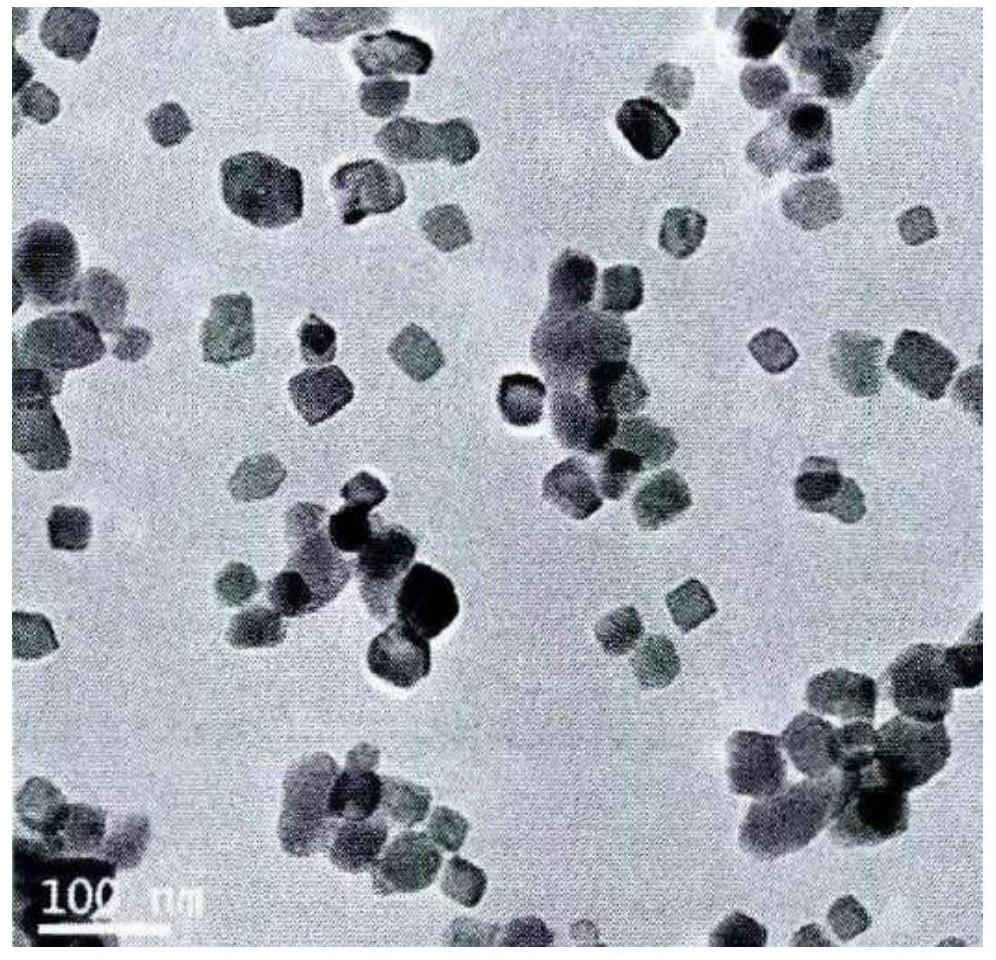

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of preparation method of hyperdispersion functional calcium carbonate

[0032] The present embodiment is a kind of preparation method of ultra-dispersed functional calcium carbonate, and concrete preparation process comprises the following steps of carrying out successively:

[0033] 1) Take 1kg of calcium oxide and add it to 7kg of water at a temperature of 85°C for digestion to obtain a slurry;

[0034] Turn on the excitation current, adjust the magnetic separation intensity of the magnetic separator to 150mT, and start injecting the slurry for magnetic separation;

[0035] After the slurry is magnetically separated, collect the effluent and inject it into the magnetic separator again for repeated magnetic separation, and collect the effluent that repeats the magnetic separation more than 2 times (this embodiment undergoes 2 magnetic separations), which is the calcium hydroxide slurry.

[0036] After the magnetic separator effectively absorbs most...

Embodiment 2~6

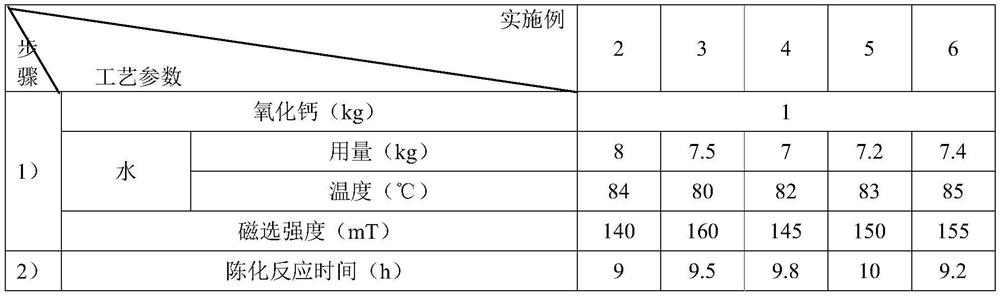

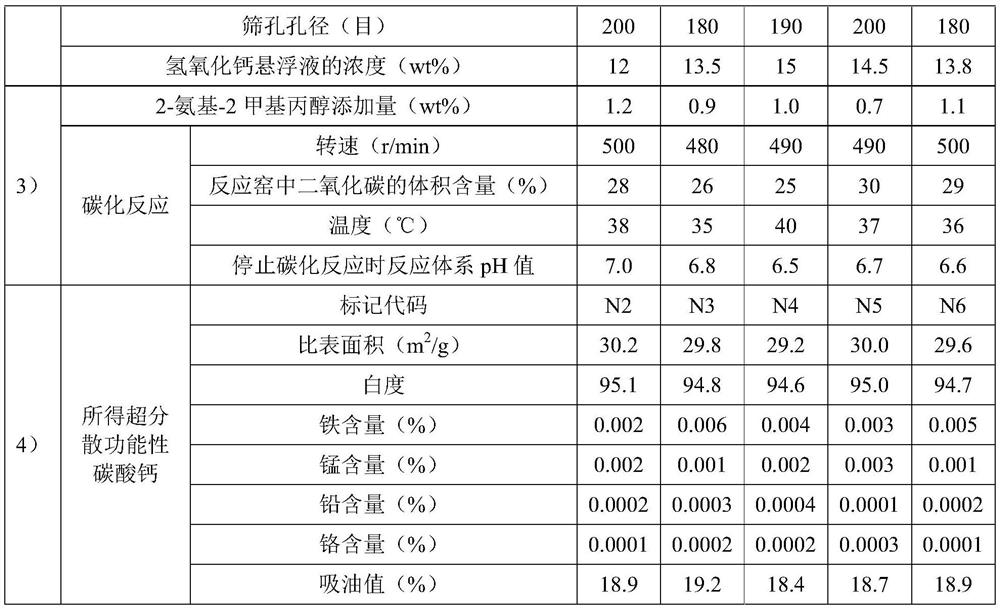

[0042] The preparation method of embodiment 2~6 hyperdispersion functional calcium carbonate

[0043] Embodiments 2 to 6 are respectively a preparation method of hyperdispersed functional calcium carbonate, and their steps are basically the same as in Example 1, the difference is only in the amount of raw materials and process parameters, see Table 1 for details:

[0044] List of each technological parameter in table 1 embodiment 2~6

[0045]

[0046]

[0047] The content of the other parts of Examples 2-6 is the same as that of Example 1.

experiment example 1

[0048] Experimental Example 1 Performance Measurement of Ultra-dispersed Functional Calcium Carbonate

[0049] Comparative example 1~4 is the comparative test of the hyperdispersion functional calcium carbonate preparation process in embodiment 1, and difference is only in:

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com