Modified alkali lignin chelated zinc fertilizer and preparation method thereof

A technology of alkali lignin and chelated zinc, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of weak chelating ability and few varieties, and achieve improved chelating ability, strong chelating ability, and renewable raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

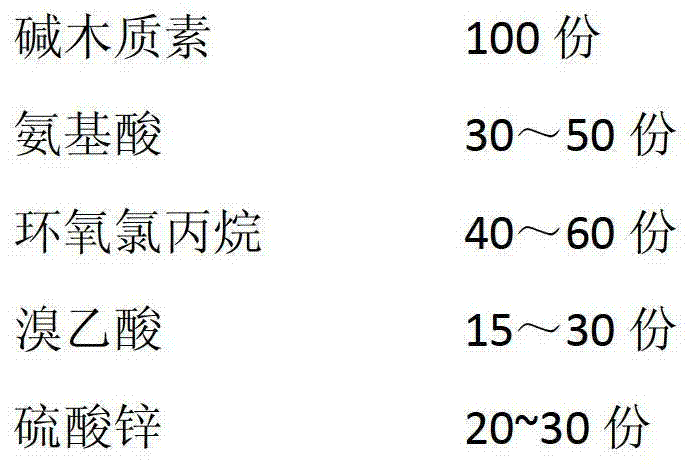

Method used

Image

Examples

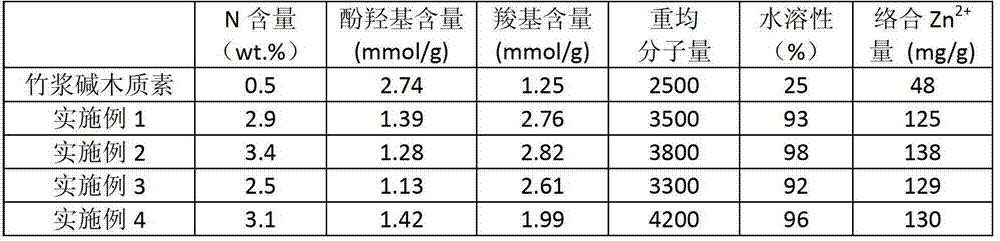

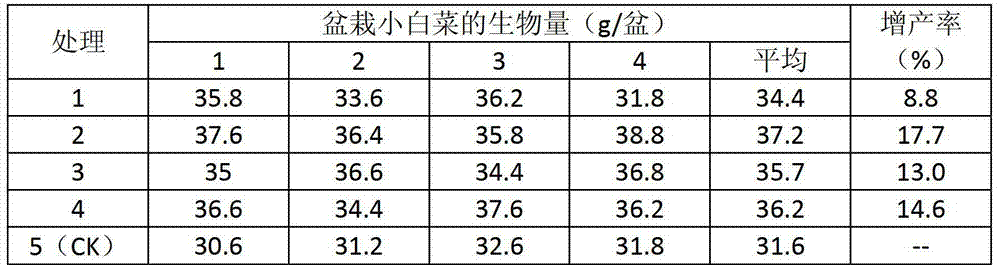

Embodiment 1

[0028] Take 100g of wheatgrass alkali lignin powder and add it to water, adjust the pH value to 10 with NaOH solution with a mass percentage concentration of 50%, stir evenly and dissolve it into an aqueous solution with a mass percentage concentration of 40%; add 40g of sarcosine, drop epoxy chlorine Propane 50g (dropped within 30min), then heated up to 80°C and reacted for 2h; then adjusted the pH value of the system to 11 with NaOH solution with a concentration of 50% by mass percentage, added dropwise 30g of bromoacetic acid, and reacted at 80°C for 1.5 h; then adjust the pH value of the system to 6 with dilute hydrochloric acid with a concentration of 20% by mass, add 25g of zinc sulfate, and perform a chelation reaction at 55°C for 2 hours, and obtain a modified alkali lignin chelated zinc fertilizer after the reaction.

Embodiment 2

[0030] Take 100g of wheatgrass alkali lignin powder and add it to water, adjust the pH value to 9 with NaOH with a concentration of 50% by mass under stirring, and dissolve it evenly to form an aqueous solution with a concentration of 30% by mass; add 45g of glycine, and dropwise add epichlorohydrin 40g (dropped within 30 minutes), then heated up to 90°C and reacted for 3h; then adjusted the pH value of the system to 12 with NaOH solution with a mass percentage concentration of 50%, added dropwise 20g of bromoacetic acid, and reacted at 75°C for 2h; Then adjust the pH value of the system to 5 with dilute hydrochloric acid with a concentration of 30% by mass, add 30 g of zinc sulfate, and perform a chelation reaction at 60° C. for 0.5 h. After the reaction, a modified alkali lignin chelated zinc fertilizer is obtained.

Embodiment 3

[0032] Take 100g of bamboo pulp alkali lignin powder and add it to water, adjust the pH value to 11 with NaOH with a concentration of 50% by mass under stirring, and dissolve it evenly to form an aqueous solution with a concentration of 35% by mass; add 15g of tyrosine and aspartic acid acid 20g, add 55g of epichlorohydrin dropwise (control the dripping within 30min), then raise the temperature to 75°C and react for 2.5h; then adjust the pH value of the system to 10 with NaOH solution with a concentration of 50% by mass percentage, add bromine dropwise 15g of acetic acid, reacted at 90°C for 1h; then adjusted the pH value of the system to 7 with dilute hydrochloric acid with a mass percentage concentration of 25%, added 20g of zinc sulfate, and carried out chelation reaction at 70°C for 1h, and obtained modified Alkali lignin chelated zinc fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com