A light-weight, high-strength, high-toughness single green composite fiber and its preparation method

A composite fiber, high-toughness technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of few reports of single green composite fibers, complex process, non-degradable, etc., to achieve easy availability of renewable raw materials. , the preparation method is simple, the operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

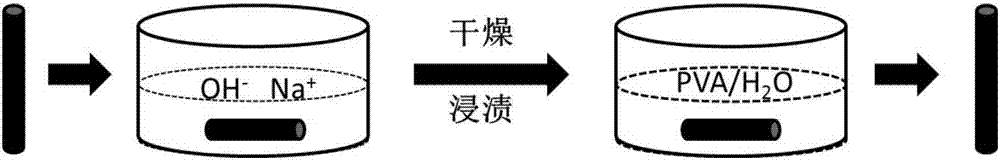

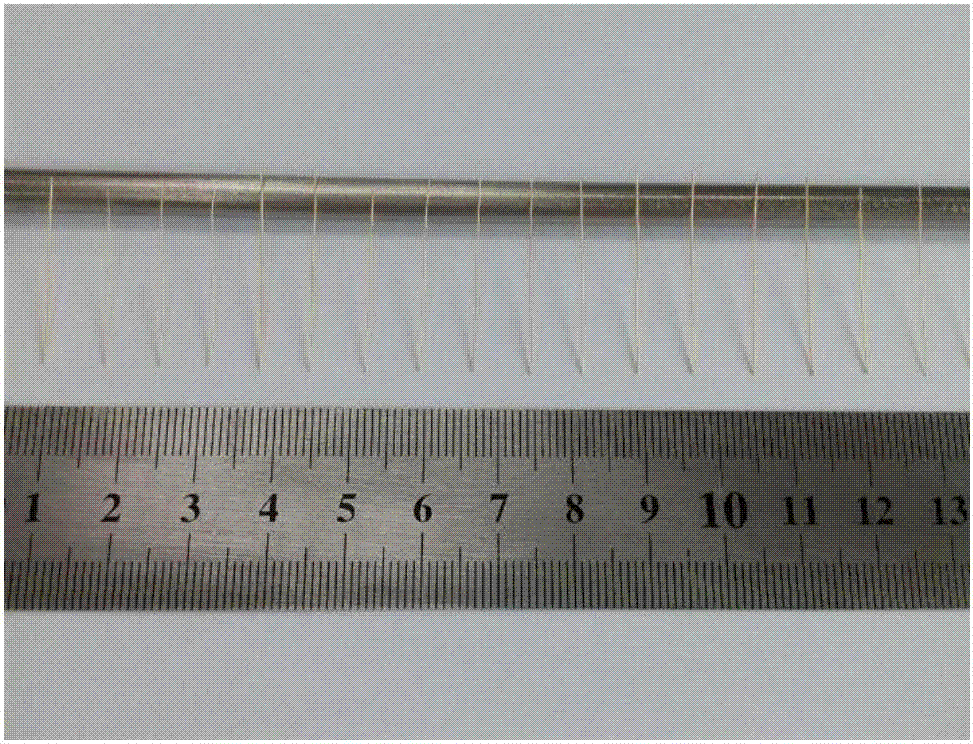

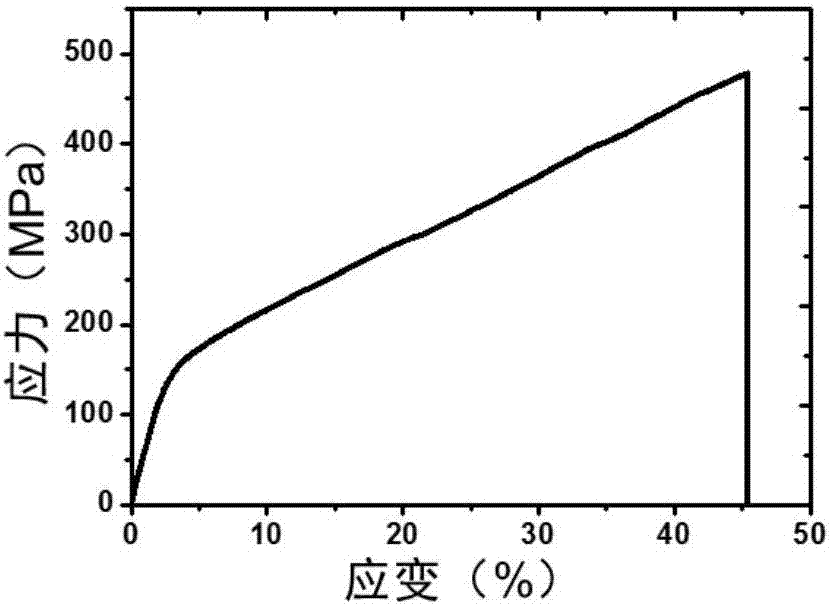

[0030] The coir fiber is cleaned and cut to obtain a group of coir fibers with an average diameter of 0.23 mm and a length of 3 cm. combine figure 1 , the coconut shell fiber is placed in NaOH with a mass concentration of 5wt%, soaked for 20h, taken out, washed with ethanol and deionized water, and dried at room temperature to obtain fiber A1 with a porous structure. Then put the fiber into PVA with a mass concentration of 1 wt%, soak for 10 hours, take it out, and dry it at room temperature. Finally, cross-linking treatment with glutaraldehyde can obtain a group of light-weight, high-strength and high-toughness single green composite fibers, such as figure 2 , the prepared composite fibers have uniform morphology. Its mechanical curve is as image 3 As shown, the tensile strength of the fiber is 478MPa, the modulus is 2GPa, and the toughness is 30MJ m -3 .

Embodiment 2

[0032] Clean and cut the loofah fibers to obtain a group of loofah fibers with an average diameter of 0.5-1 mm and a length of 1 cm. Then the loofah fibers are placed in a NaOH solution with a mass concentration of 1wt%, soaked for 80h, taken out, cleaned with ethanol and deionized water, and dried at room temperature to obtain fibers with exposed nanofibril structures and nanoflower cluster structures A1. Next, fiber A1 was put into CS with a mass concentration of 10wt%, immersed for 50 hours, taken out, and dried at room temperature. Finally, genipin is used for cross-linking treatment to obtain a single green composite fiber with light weight, high strength and high toughness. It was found that the tensile strength of the fiber was 60MPa, the modulus was 5.1GPa, and the toughness was 10MJ m -3 .

Embodiment 3

[0034] The lotus leaf stem fibers are cleaned and cut to obtain a group of lotus leaf stem fibers with an average diameter of 0.05 mm and a length of 2 cm to 3 cm. Then the lotus leaf stem fiber is placed in the H that mass concentration is 10wt%. 2 o 2 , soaked for 2 hours, taken out, washed with ethanol and deionized water, and dried at room temperature to obtain fiber A1 with a bare nanofibril structure. Then put H 2 o 2 The treated fibers were placed in PLA with a mass concentration of 15 wt%, soaked for 20 hours, taken out, and dried at room temperature. Finally, it is cross-linked by heating to obtain a single green composite fiber with light weight, high strength and high toughness. The test results show that the tensile strength of the fiber is 560MPa, the modulus is 7.2GPa, and the toughness is 50MJ m -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com