Sheet-stretching machine

A drawing machine and plate technology, applied in the field of mechanical engineering, can solve the problems of uneven distribution of tensile stress and tensile strain, high manufacturing cost, and low material utilization rate, so as to improve material utilization rate, reduce manufacturing cost, and improve forming quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

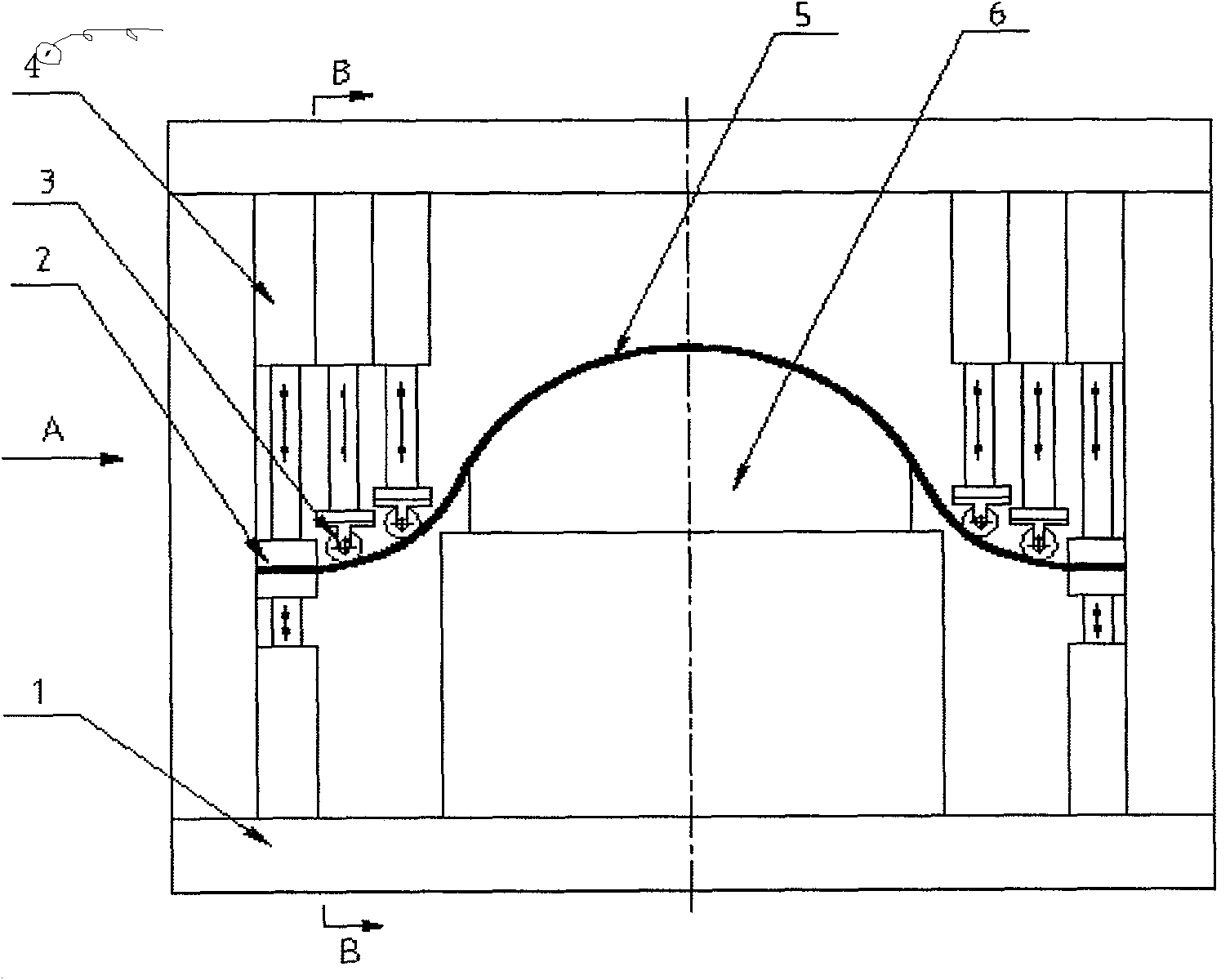

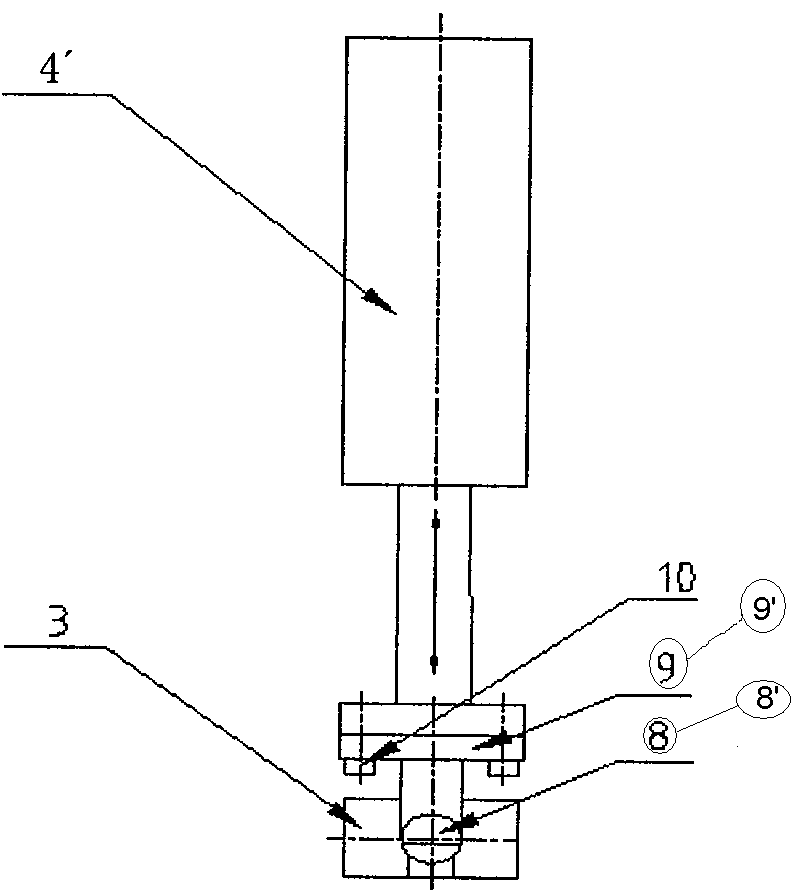

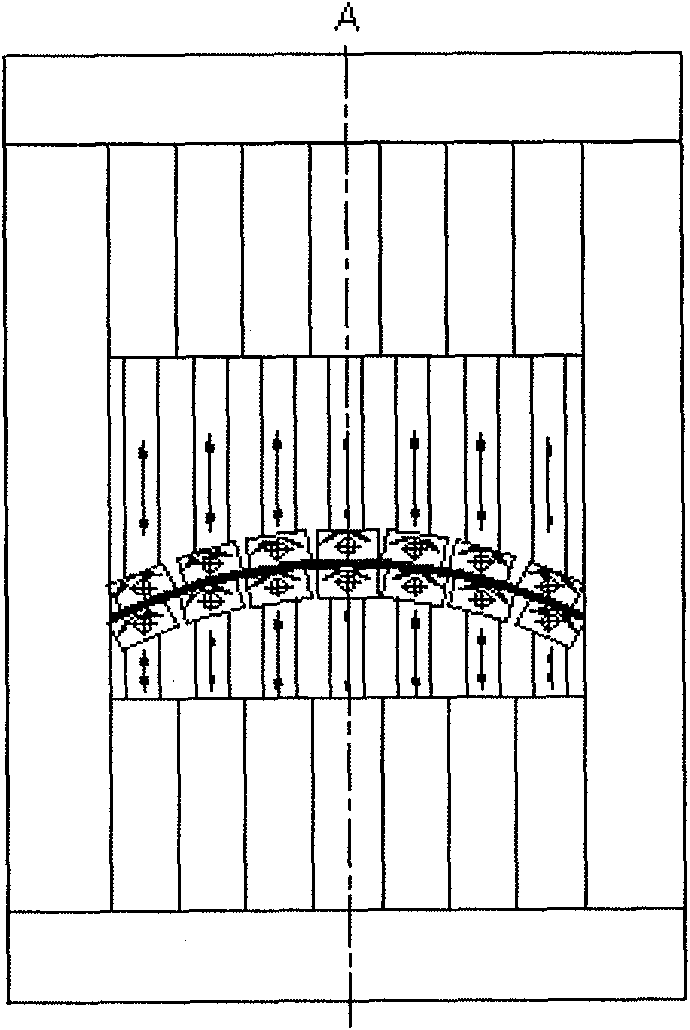

[0064] Fig. 1 is a schematic diagram of a stretching machine. The stretching machine is composed of a frame 1, left and right clamping mechanisms, and a press-down mechanism. The frame 1 supports the left and right clamping mechanisms and the press-down mechanism. In Fig. 1, both the clamping plate 2 and the rollers 3 are powered by the first hydraulic cylinder 4 and the second hydraulic cylinder 4′, and the clamping mechanism clamps the plate through the clamping plate 2 and applies a certain pulling force. The pressing mechanism contacts the sheet material 5 through the roller 3, and exerts a certain pulling force on the sheet material 5 under the cooperation of the drawing die 6, and finally shapes the sheet material 5. figure 2 The difference from Fig. 1 is that the frame 1 is equipped with an adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com