Mould for forming axial tensile-strength test piece of cement-based material and test method

A cement-based material, tensile strength technology, applied in the direction of using stable tension/pressure test material strength, electromagnetic measurement device, electric/magnetic solid deformation measurement, etc. Affect the test results and other problems, to achieve the effect of reducing the embedding depth, simple and convenient operation, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings:

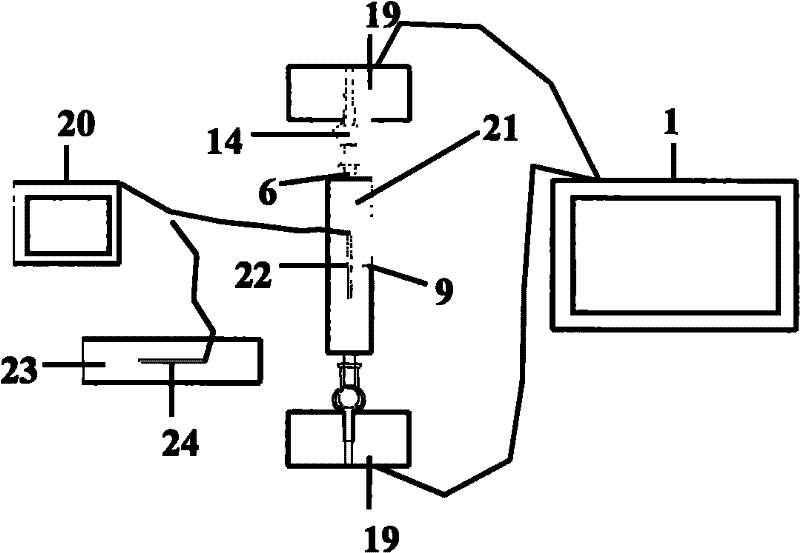

[0036] The structure of the present invention is as figure 1 , figure 2 As shown, it includes the test machine for applying the load, the test die for forming the test piece, the force transmission device for the test piece and the data acquisition device.

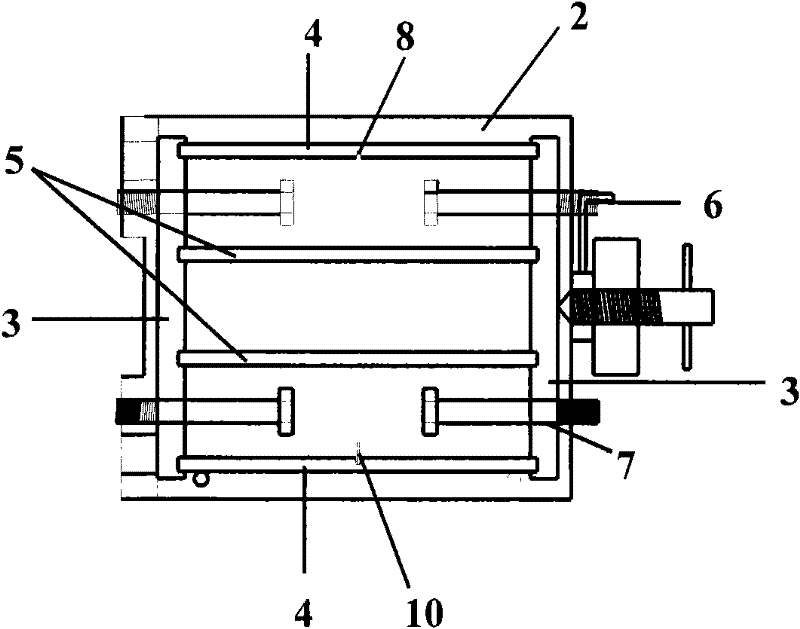

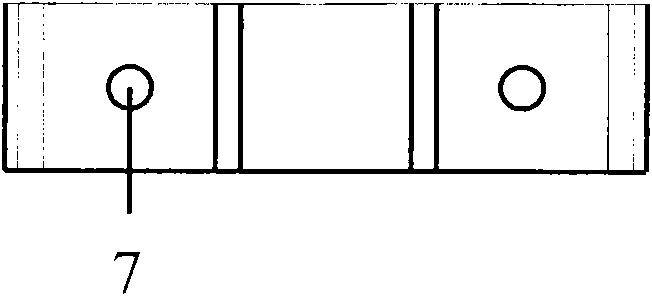

[0037] The structure of the forming part of the first test piece is as follows figure 2As shown, the mold for forming the first test piece to be tested is an improved standard cement mortar triple test mold, the size of which is 40mm × 40mm × 160mm, and the improved standard cement mortar triple test mold consists of a base plate 2, Two end plates 3, two side plates 4 and two middle plates 5, two end plates 3 and two side plates 4 are installed on the bottom plate, and the bottom plate, end plates and side plates form a cavity. Two middle plates are installed in parallel on the bottom plate and located in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com