Patents

Literature

35results about How to "Increased means of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

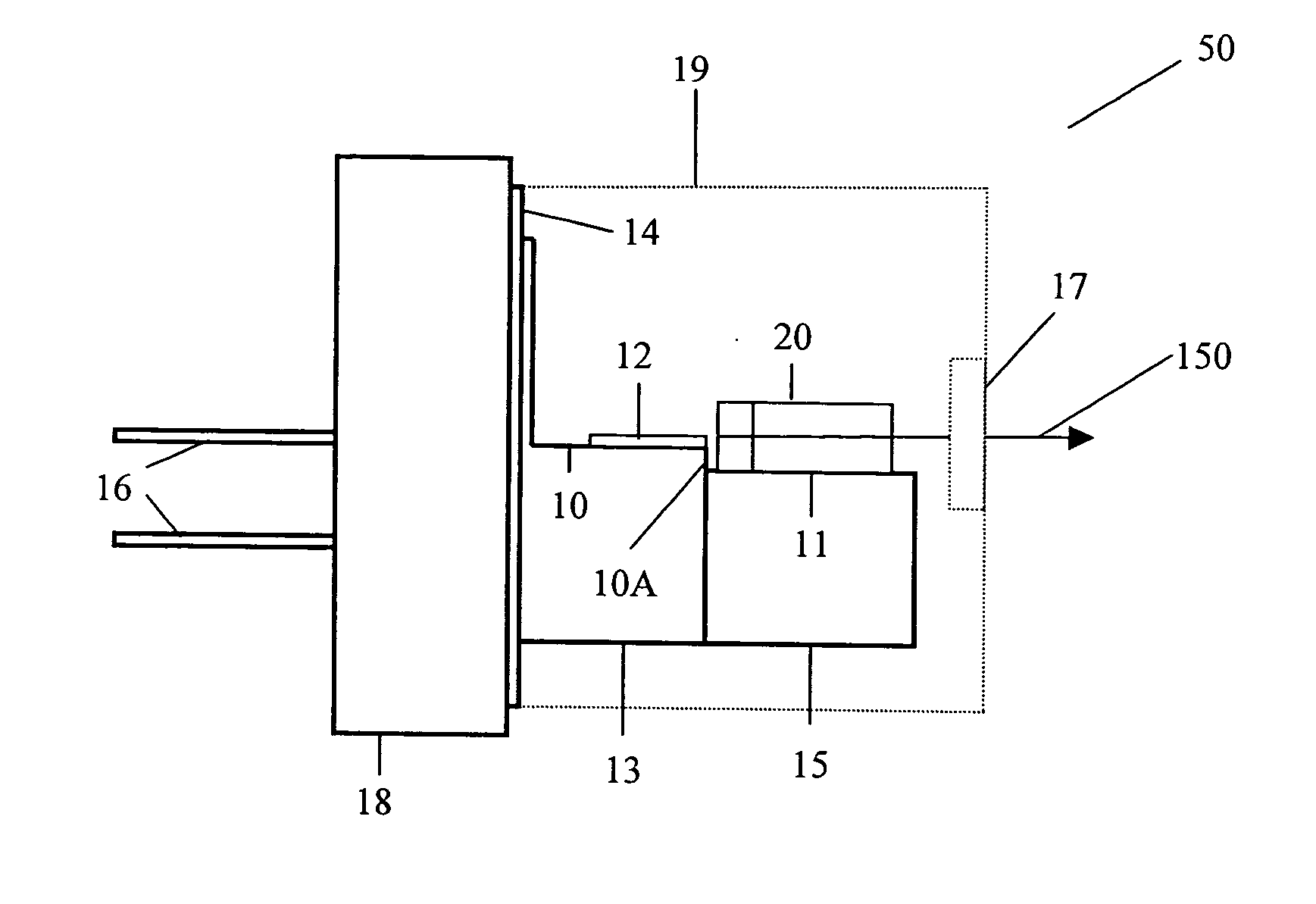

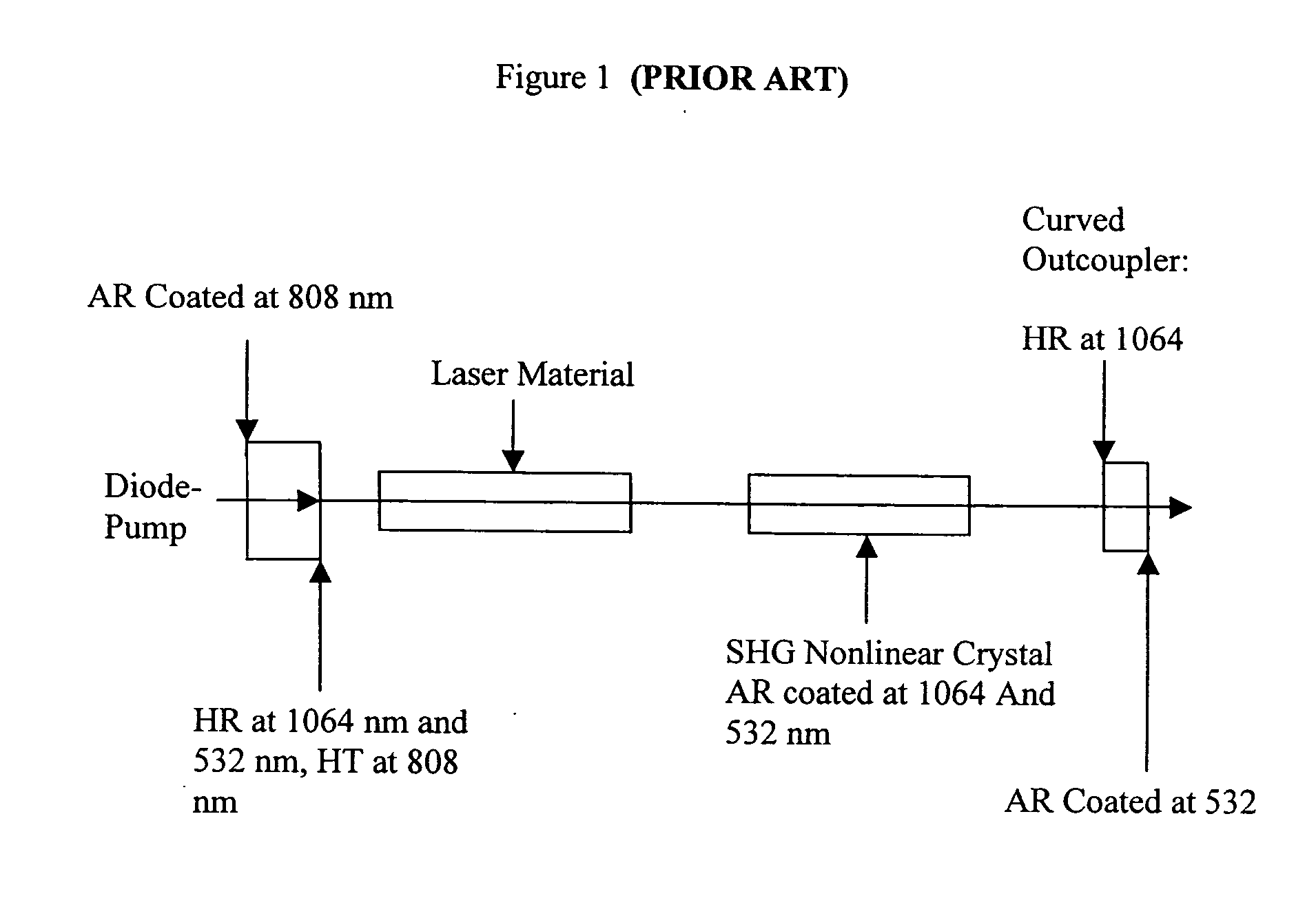

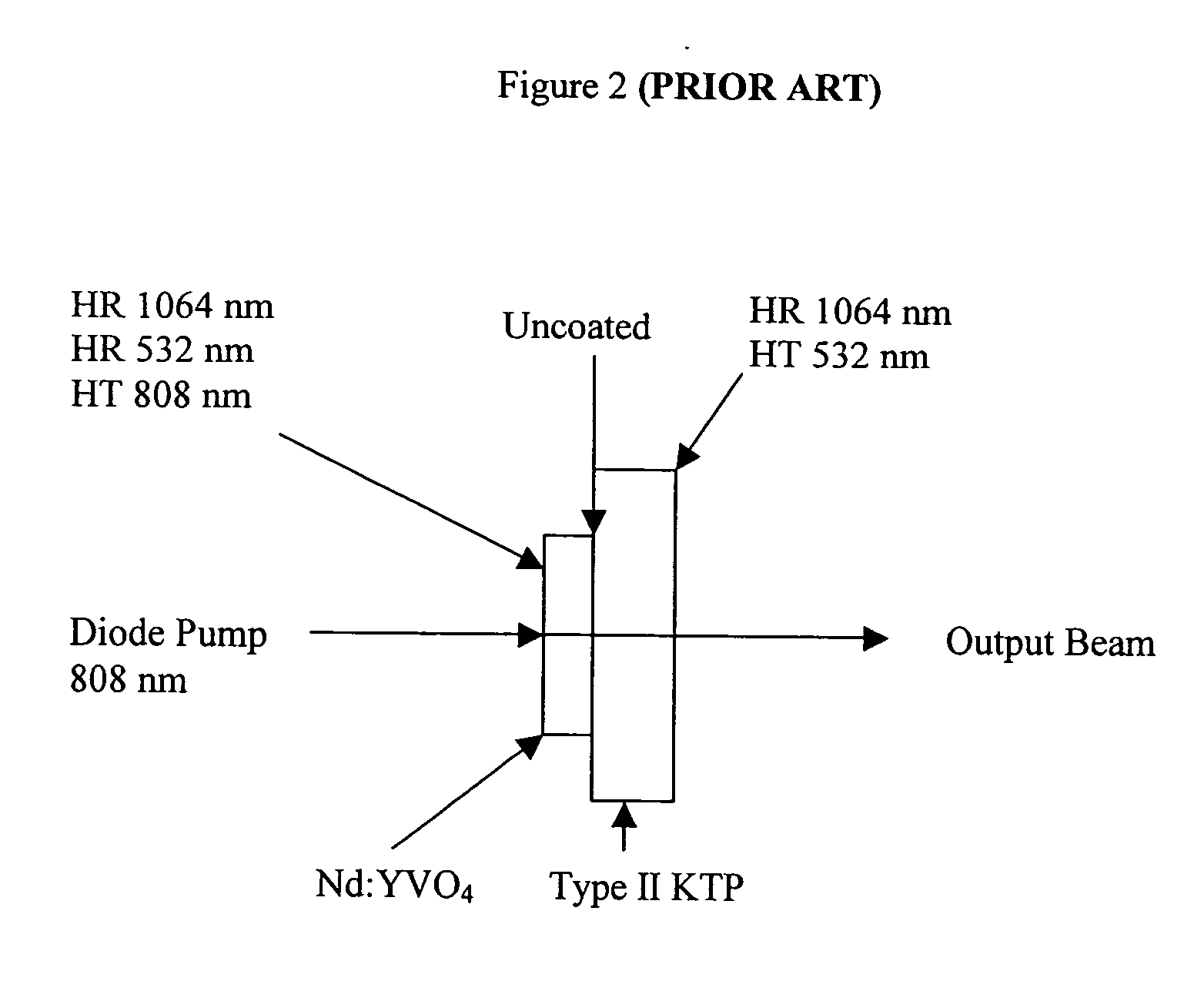

High density methods for producing diode-pumped micro lasers

InactiveUS20050063441A1Low-cost high-densityHigh beam qualityMicrobiological testing/measurementActive medium materialLow noiseMicrochip laser

A miniaturized laser package is provided comprising a standard semiconductor laser package modified to accept a solid state microchip assembly pumped by the diode laser. Standard packages described in the invention include TO and HHL packages all of which are characterized by small dimensions, well sealed housing, robust mounting features, known characterized materials and economical production and assembly techniques characteristic of the semiconductor processing industry. In particular, the microchip lasers are produced using high density techniques that lend themselves to mass production, resulting in very low unit costs. At the same time, the compact laser devices provide a solution to the problem of providing laser radiation at high beam quality and good reliability features with a variety of wavelengths and operational characteristics and low noise features not available from diode lasers yet relying primarily on standardized designs, materials and techniques common to diode laser manufacturing. The devices constructed according to methods taught by the invention can therefore be readily integrated into numerous applications where power, reliability and performance are at a premium but low cost is essential, eventually replacing diode lasers in many existing systems but also enabling many new commercial, biomedical, scientific and military systems.

Owner:SNAKE CREEK LASERS

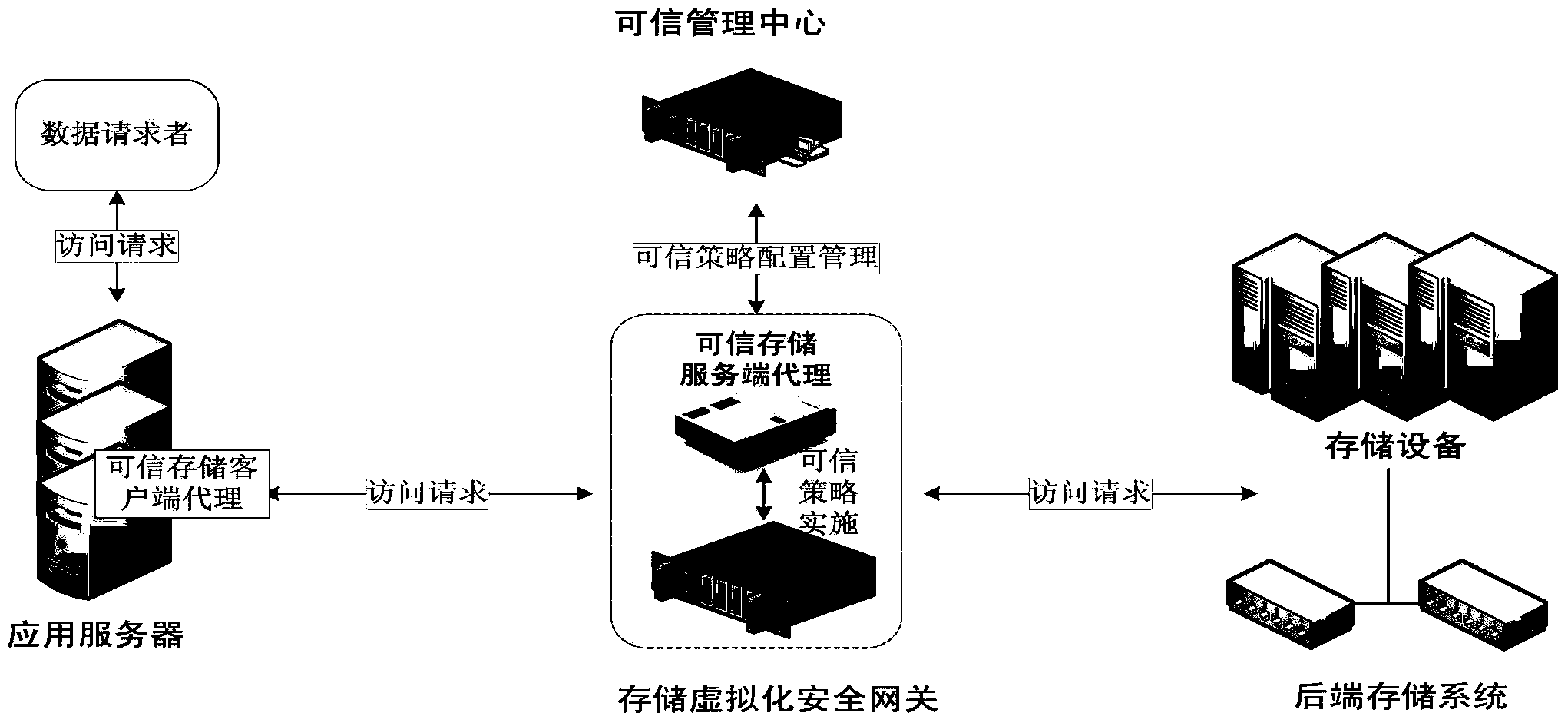

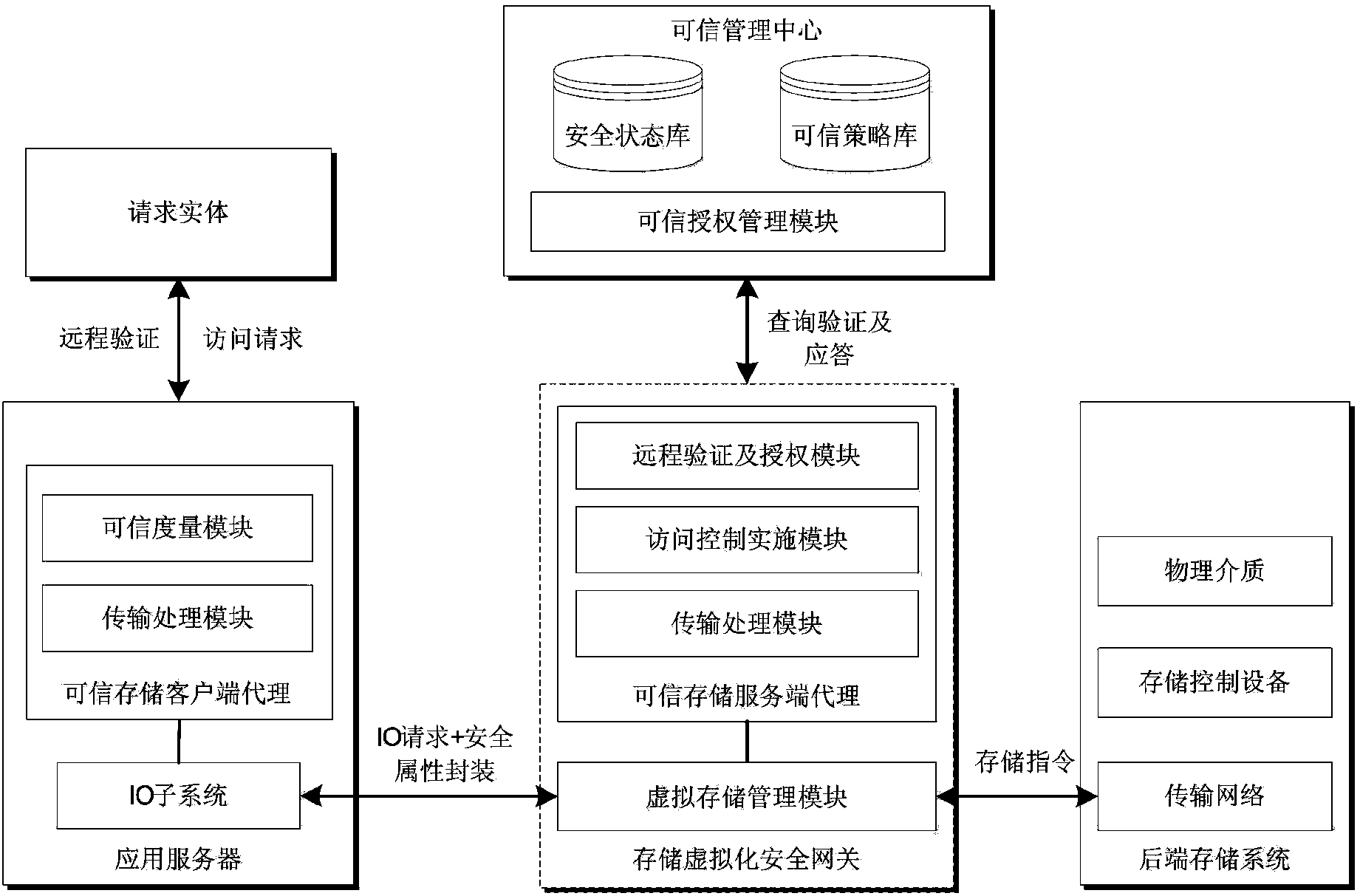

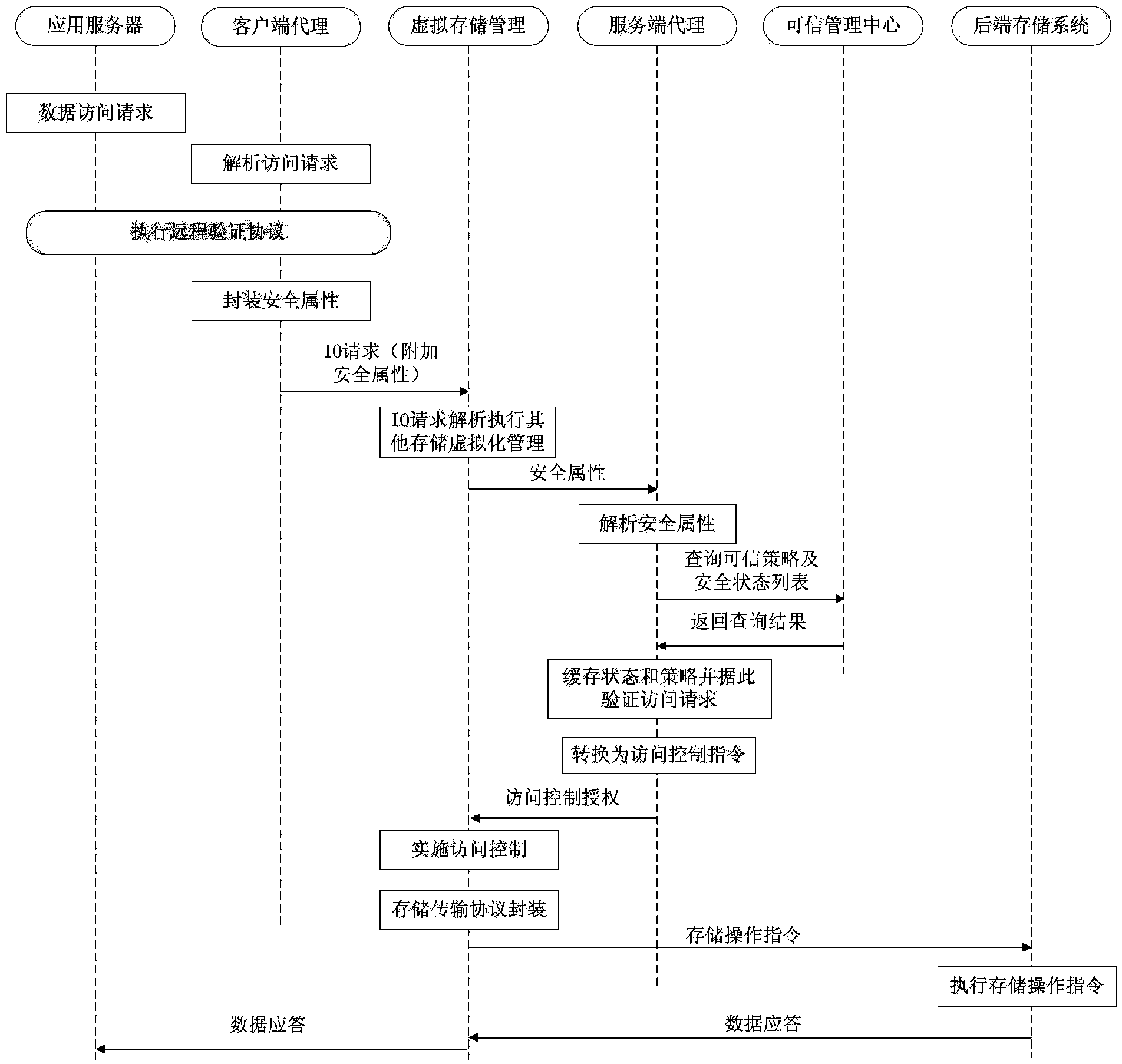

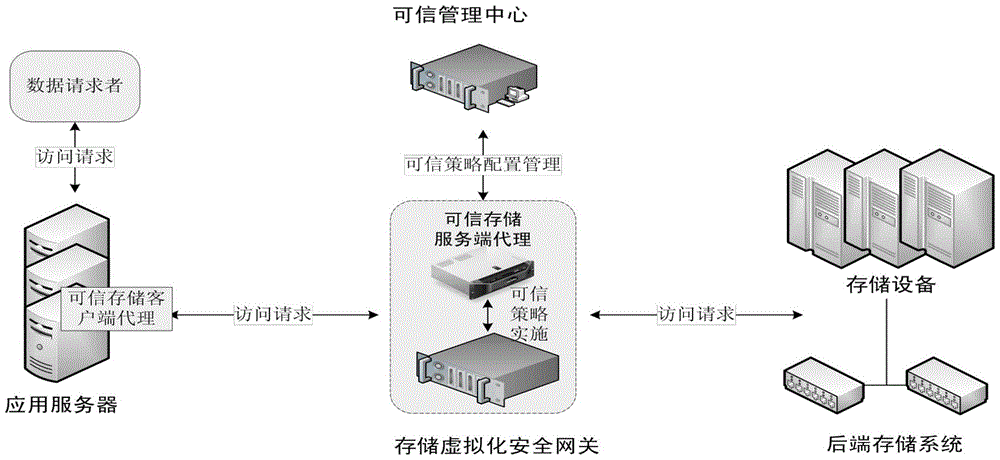

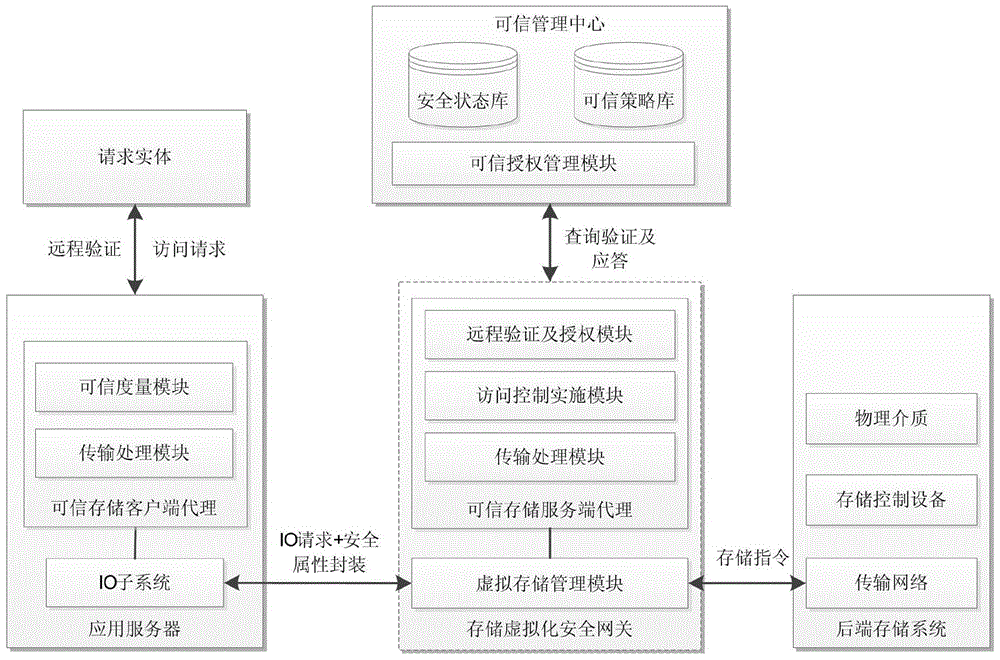

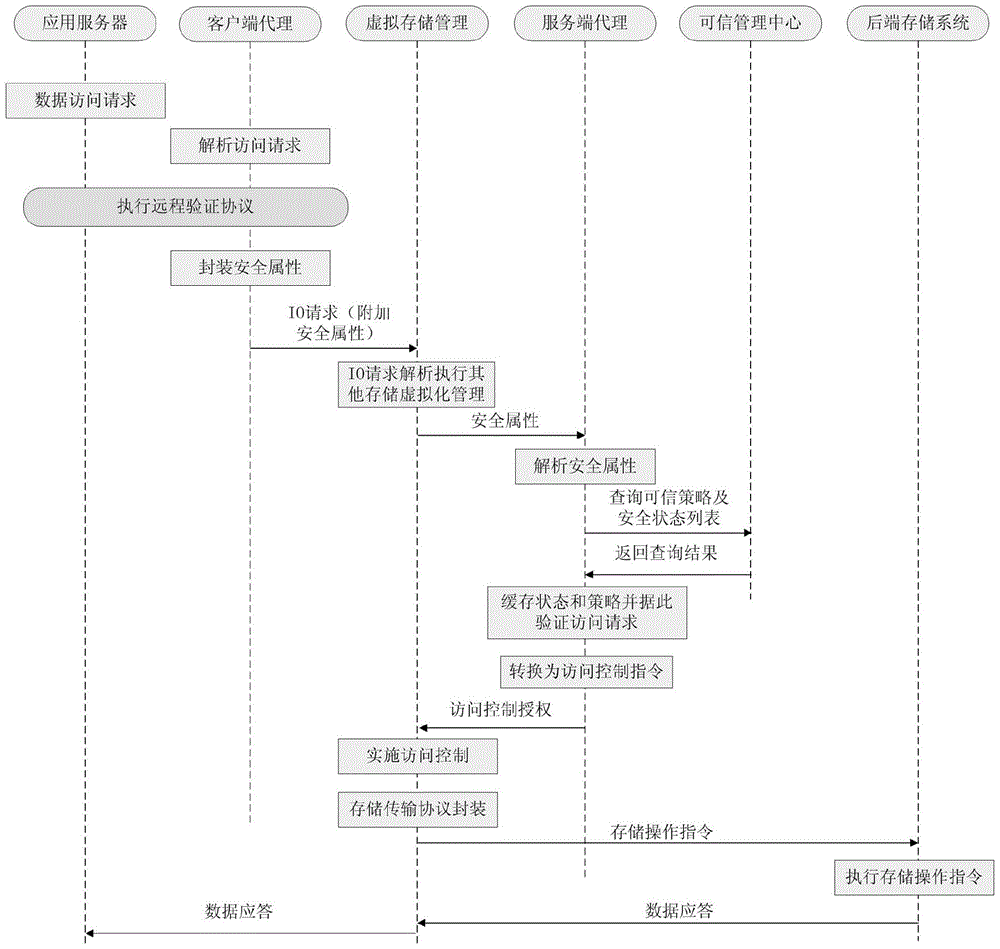

System and method for trusted storage of data

InactiveCN103927489AHigh strengthIllegal access reductionDigital data protectionPlatform integrity maintainanceControl flowApplication server

The invention discloses a system and method for trusted storage of data. The system mainly comprises four logical entities, namely, a trusted management center, an application server, a storage virtualization security gateway and a rear-end storage system. The trusted management center serves as a configuration and management entity for a trusted strategy. The application server serves as an entity sending a data access request. The storage virtualization security gateway serves as an entity receiving the data request of an application layer and achieving mapping of a virtual port, converting of a virtual storage device address and a physical storage device address and encapsulating of an IO request through the virtualization technology. The rear-end storage system provides a physical medium for data storage and operation. On the basis of the storage virtualization technology, a data access control flow in the trusted technology is provided for the storage virtualization security gateway or an agent layer so that strict security check and control can be carried out on an access request for a storage system, and illegal access or vicious data access operation can be prevented.

Owner:娄绍钢 +1

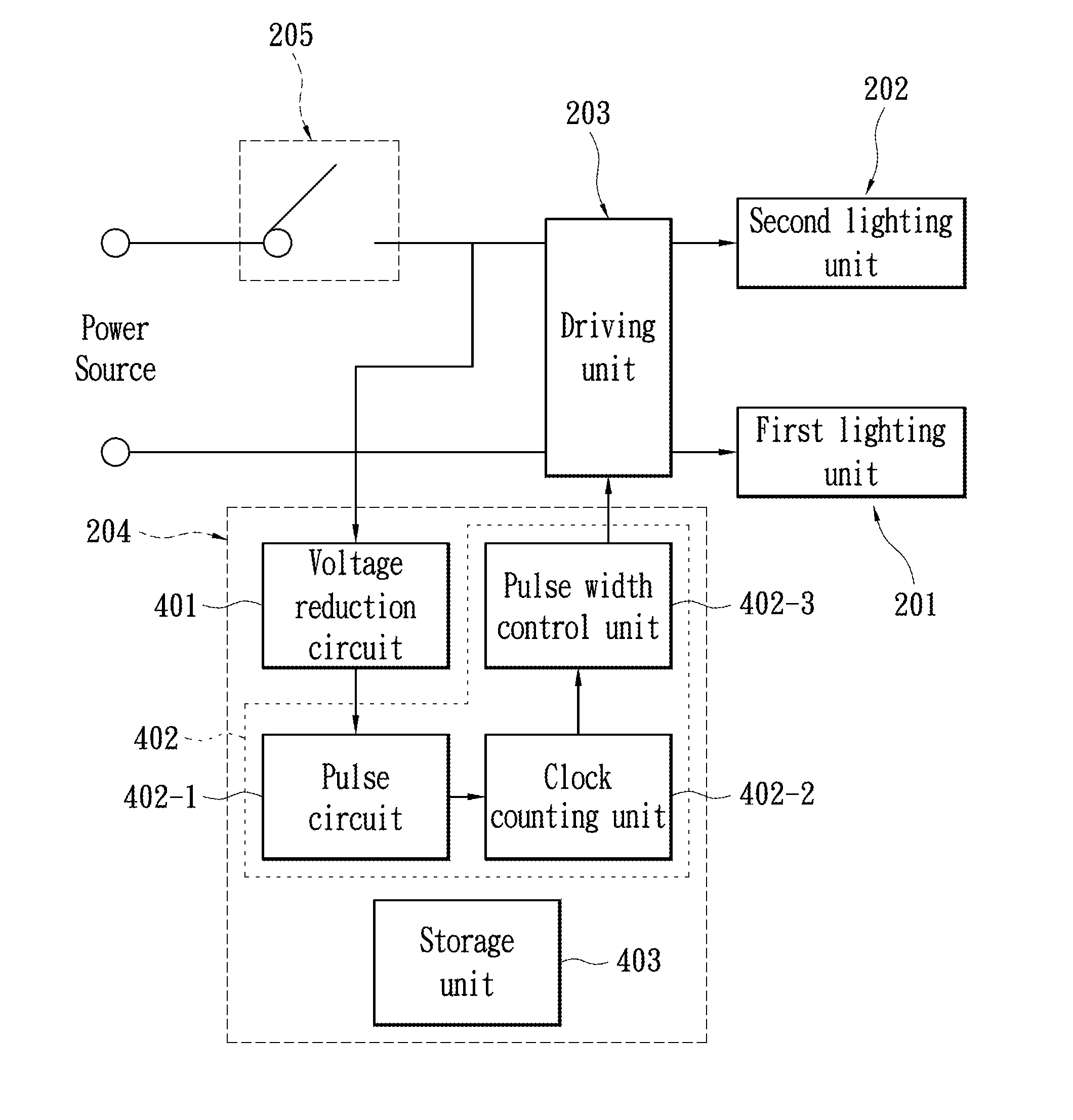

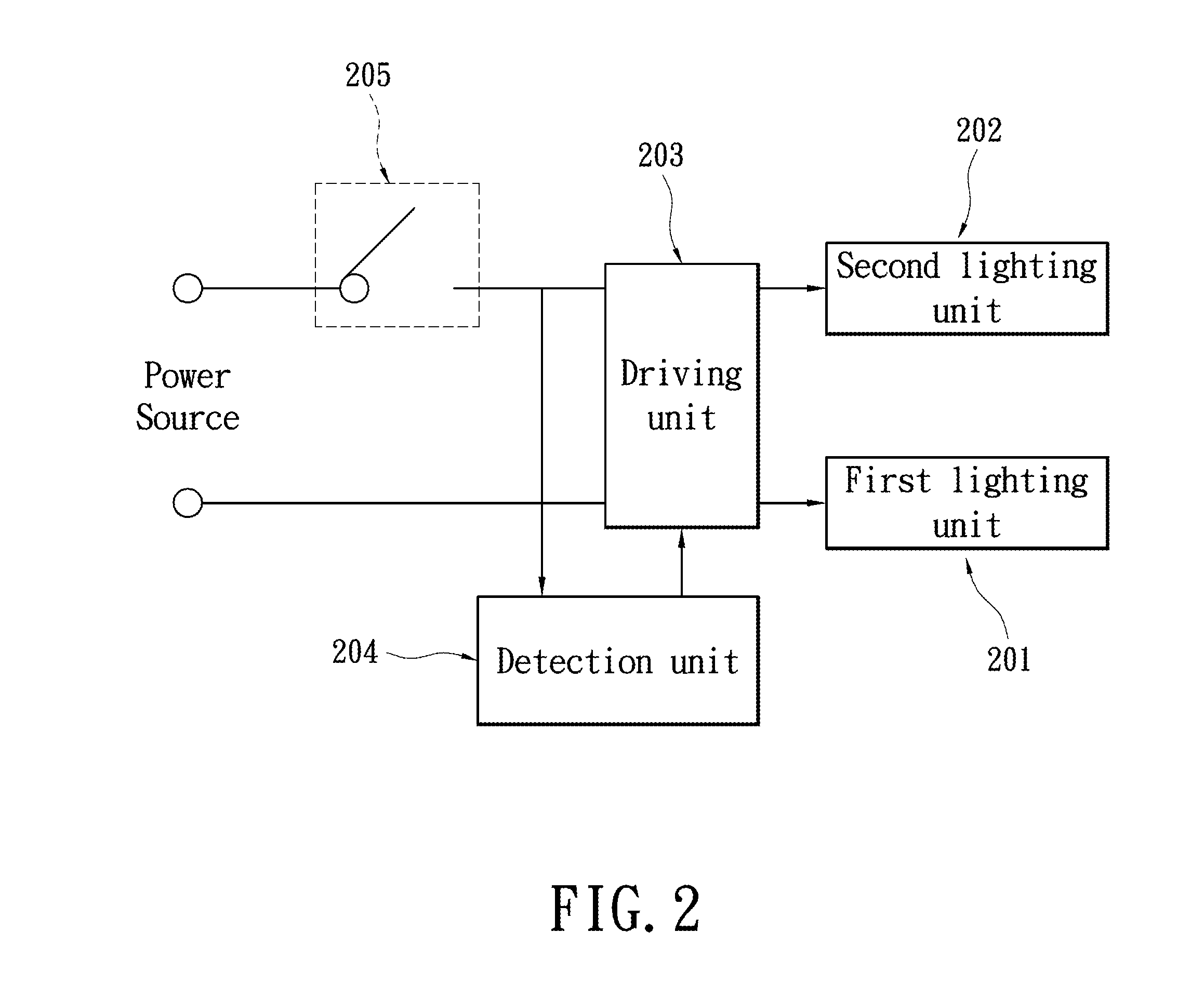

LED lighting apparatus and dimming method thereof

InactiveUS20130200814A1Increase heightIncreased means of controlElectrical apparatusElectroluminescent light sourcesEffect lightEngineering

An LED lighting apparatus and a dimming method thereof are disclosed. The LED lighting apparatus is coupled to a power source through a power switch. The method includes providing a first lighting unit and a second lighting unit; detecting whether or not the power switch has been turned on; and gradually adjusting a light mixing ratio between the first lighting unit and the second lighting unit according to a turn-on duration of the power switch and storing a color temperature value, accordingly.

Owner:LEXTAR ELECTRONICS CORP

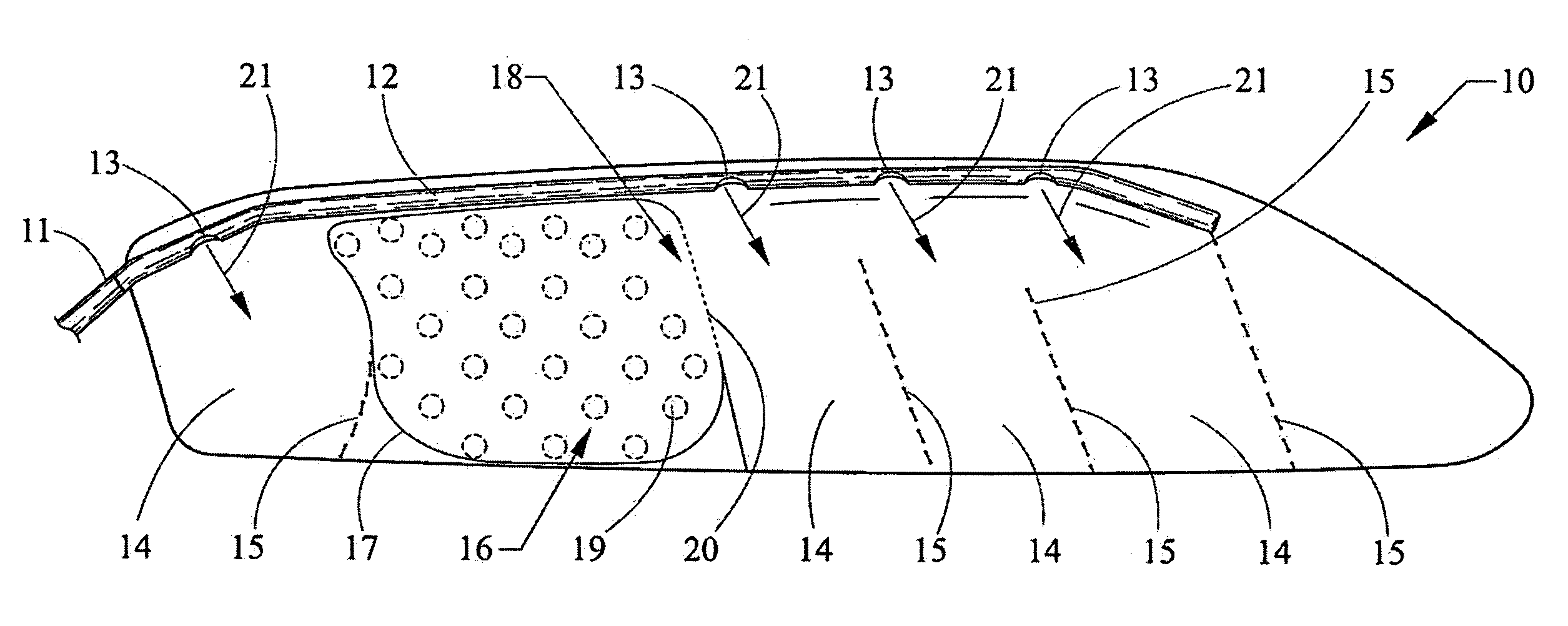

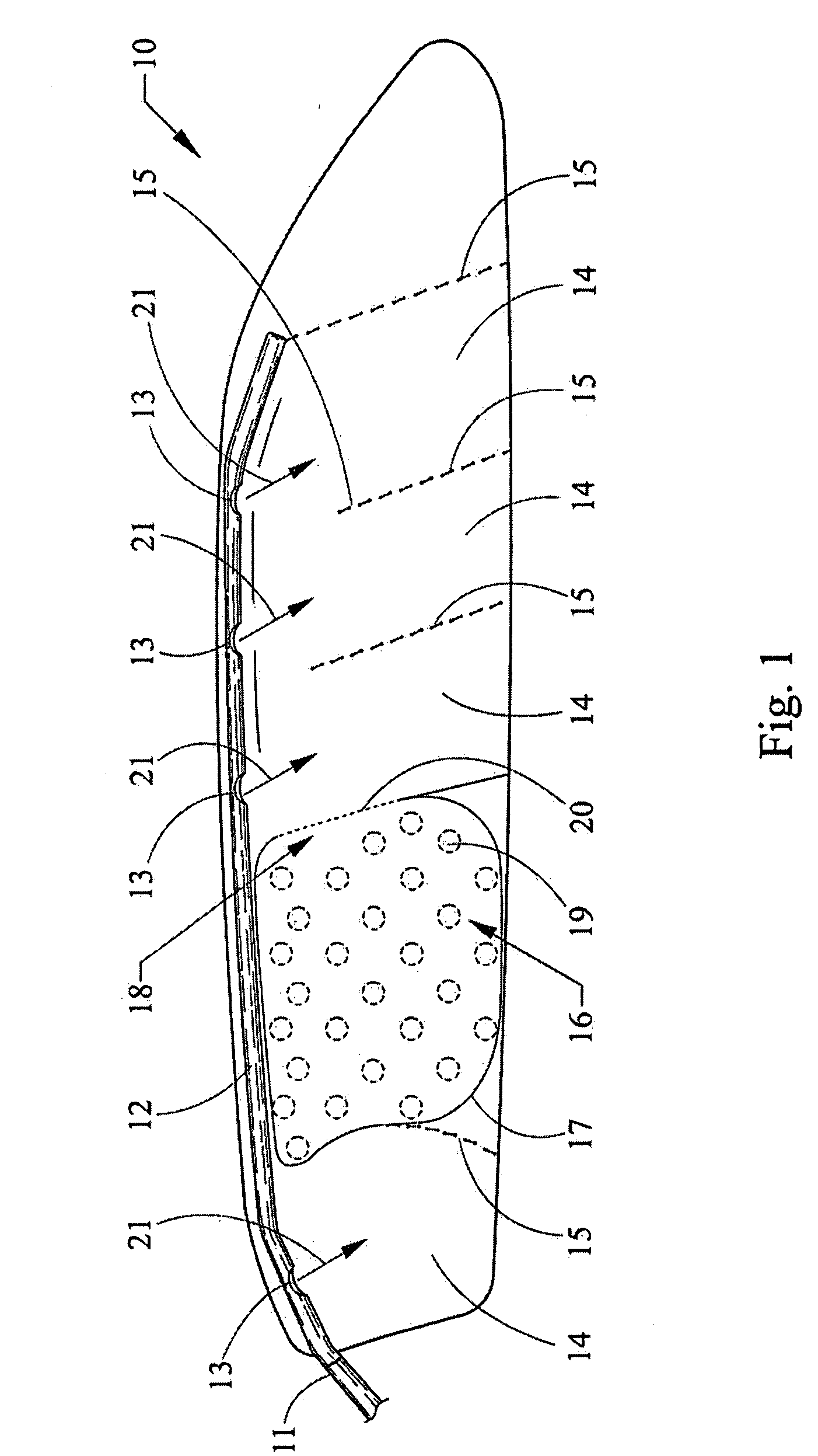

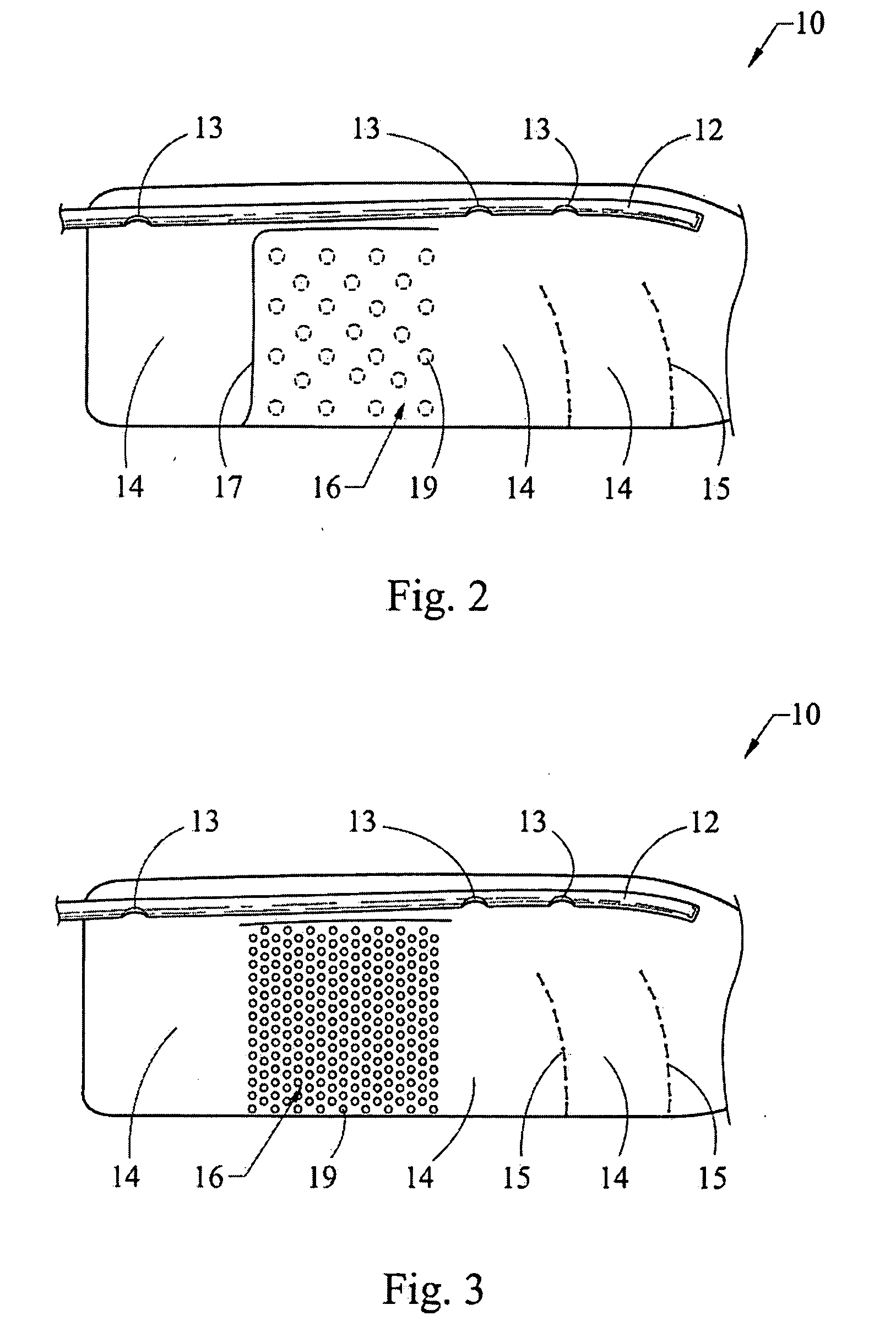

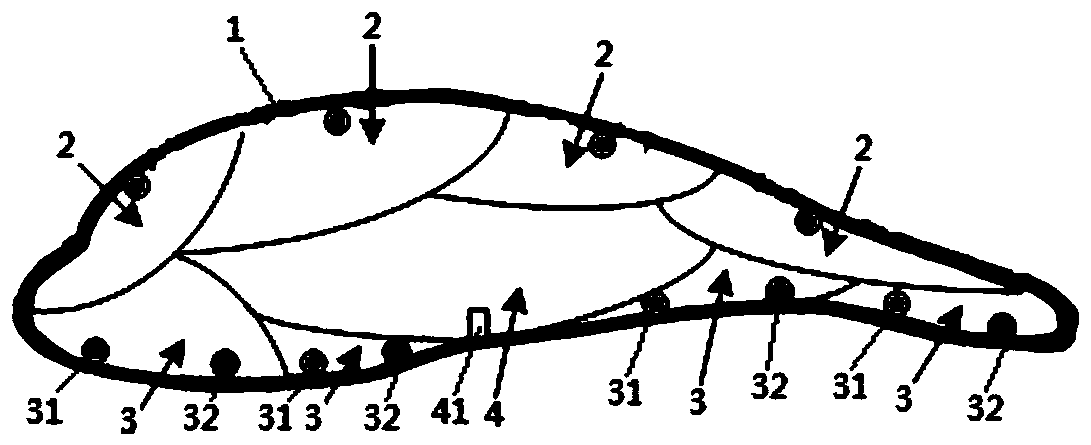

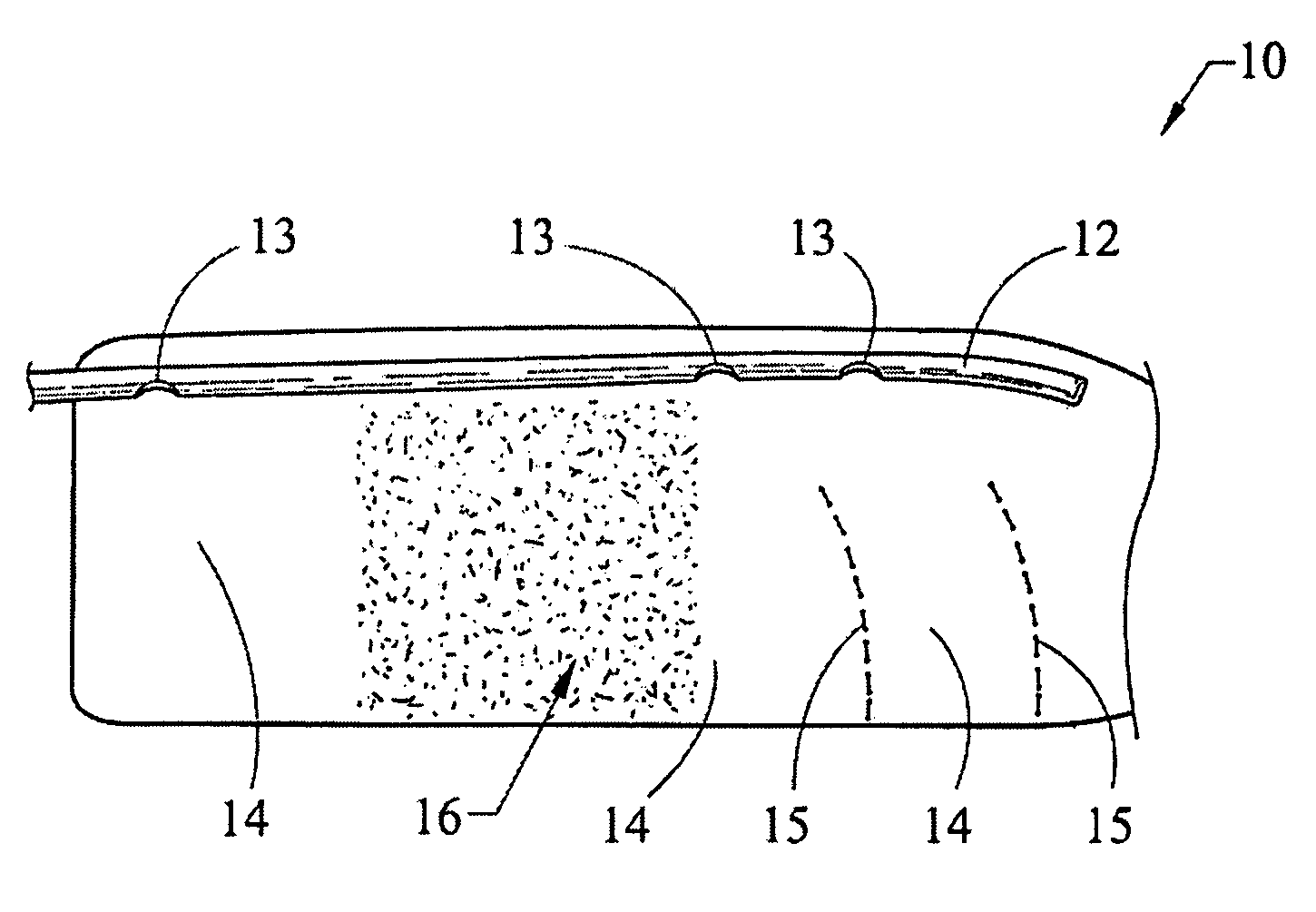

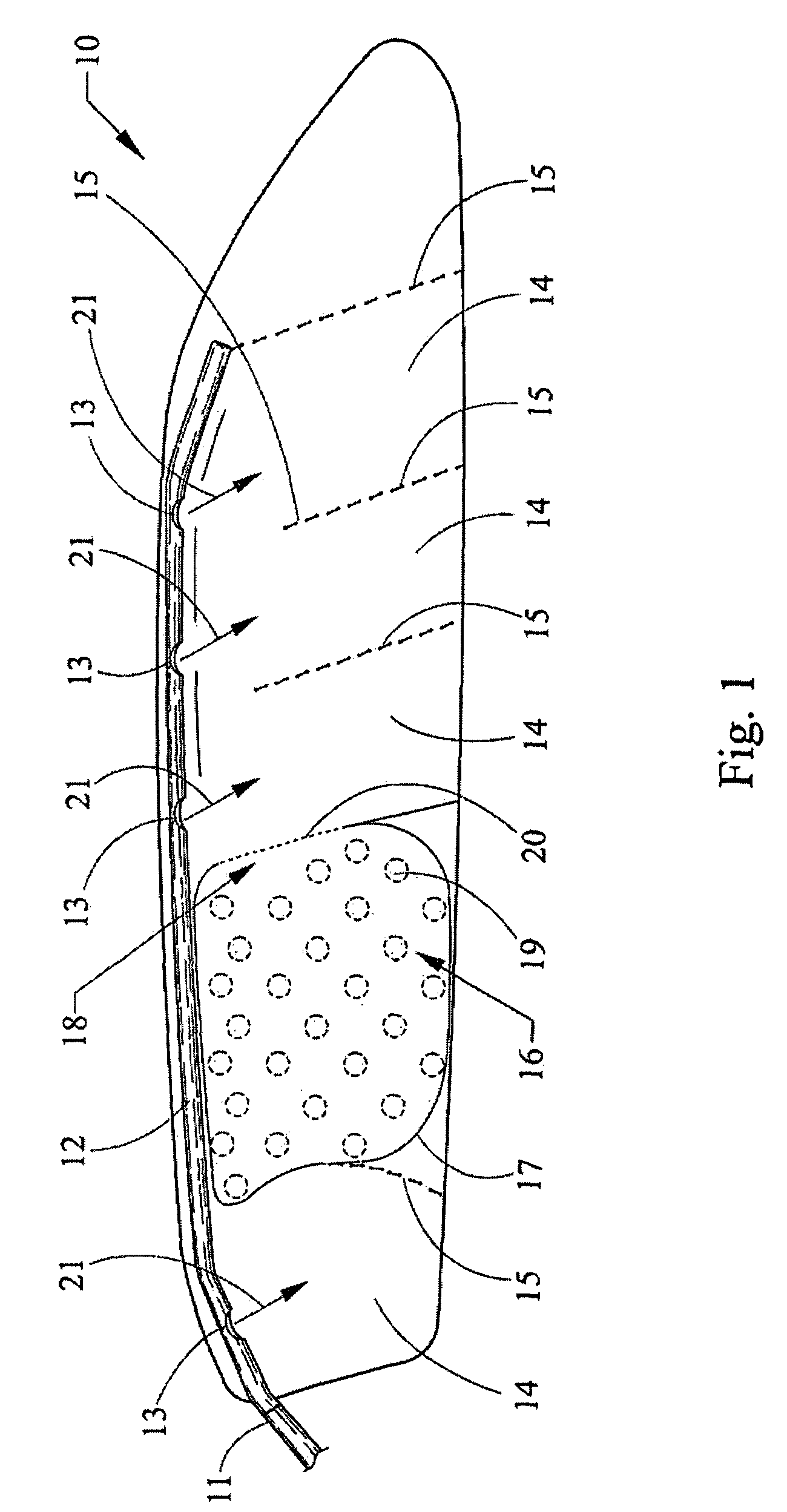

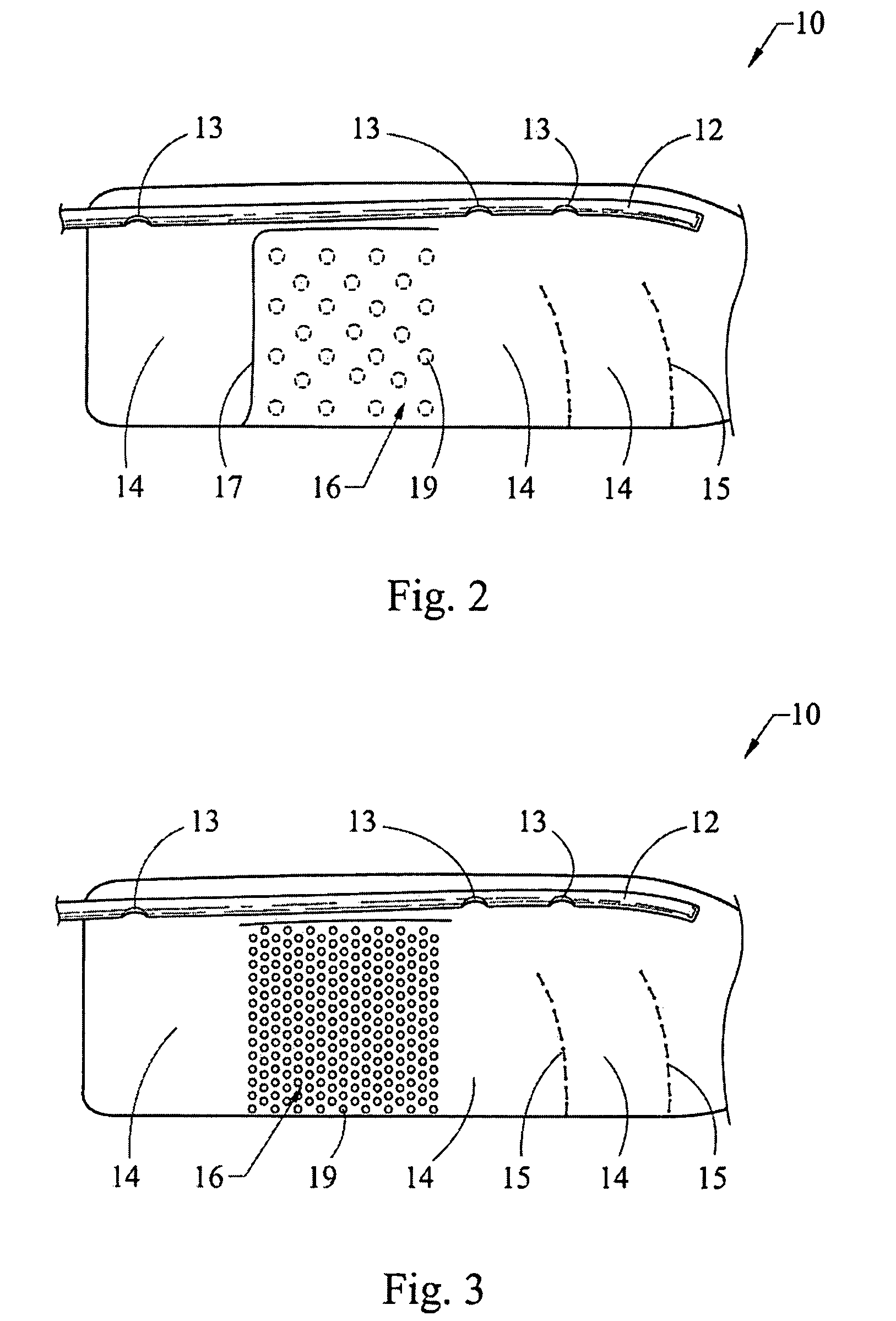

Side Air Bag With a Controlled Opening of a Pressure Equalization Chamber

InactiveUS20080012274A1Limited elasticityLow elastic modulusPedestrian/occupant safety arrangementEngineeringSide impact

A side-impact air bag system for motor vehicles with an air bag (10) extending across at least a part of the longitudinal extent of the vehicle. The air bag (10) is formed by two layers of fabric which are joined to each other and is located in the region of the roof frame of the vehicle in its folded state, before it is unfolded in the form of a curtain. An inflation device (11) releases an inflating gas, and the air bag (10) contains at least one primary chamber (14) which can be inflated by directly feeding gas into it, as well as at least one additional pressure equalization chamber (16), which is separated from the immediately inflatable primary chamber (14). The pressure equalization chamber (16) is equipped across its surface with additionally placed connections (19) of the fabric layers of the air bag (10) in such a manner that the gas stream entering the pressure equalization chamber (16) after inflation of the directly inflatable primary chamber (14) as a function of the pressure acting upon it, inflates portions of the pressure equalization chamber (16) by separation of the additional connections (19).

Owner:AUTOLIV DEV AB

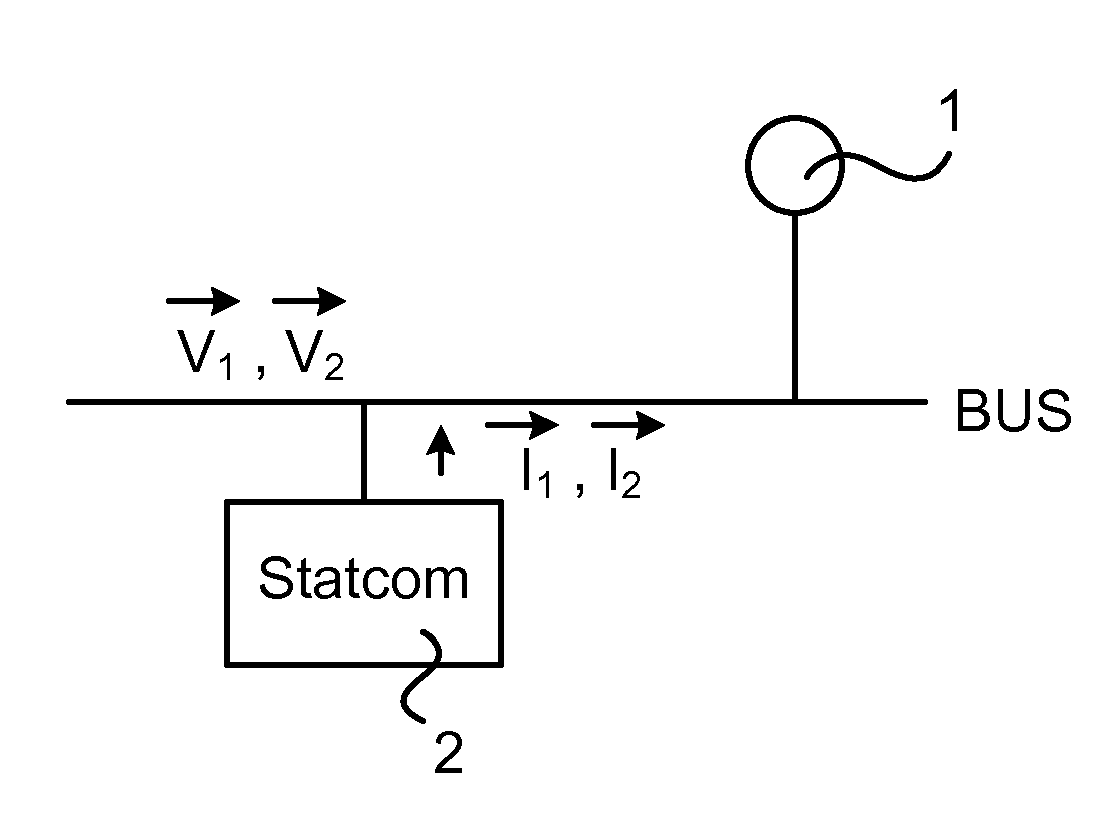

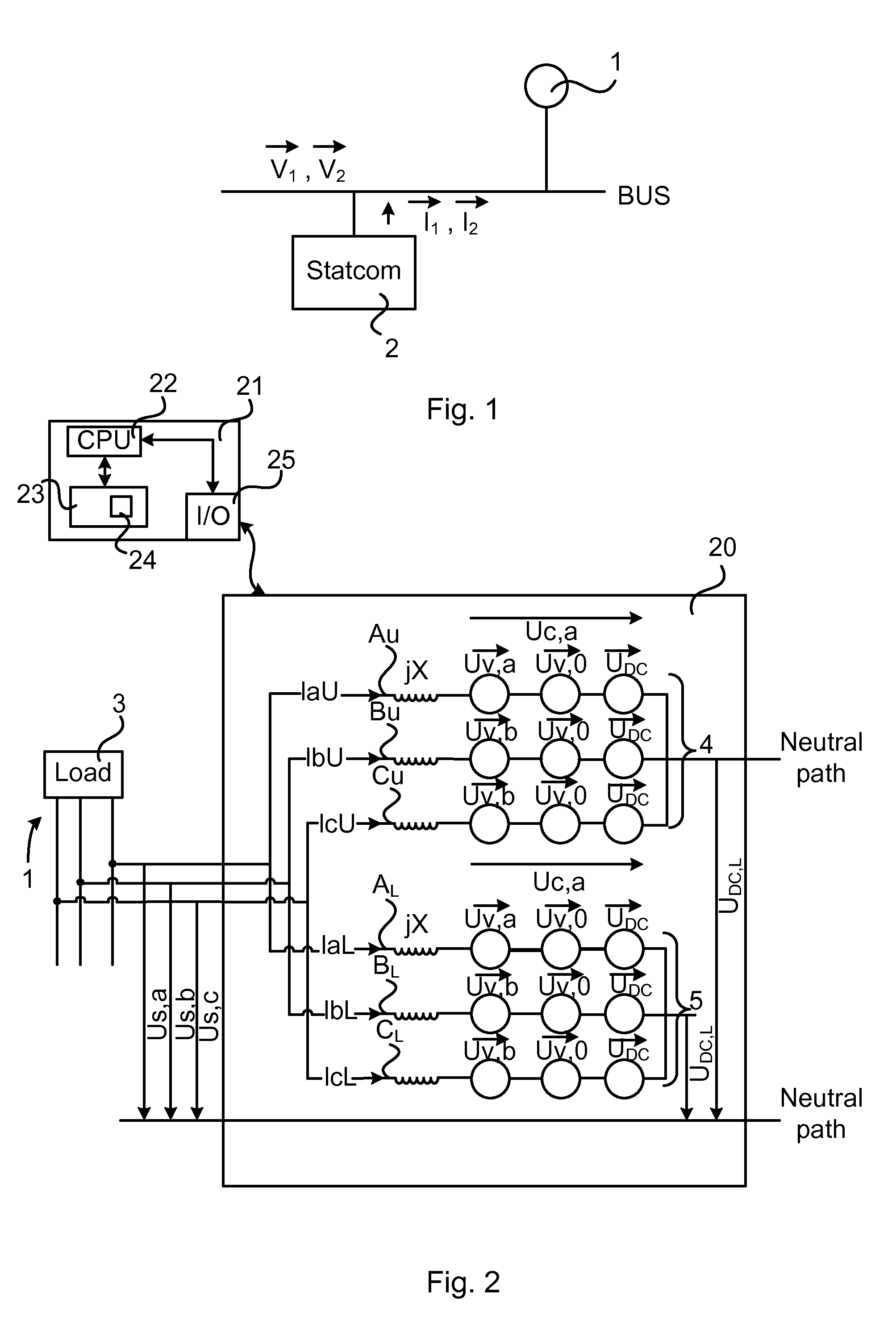

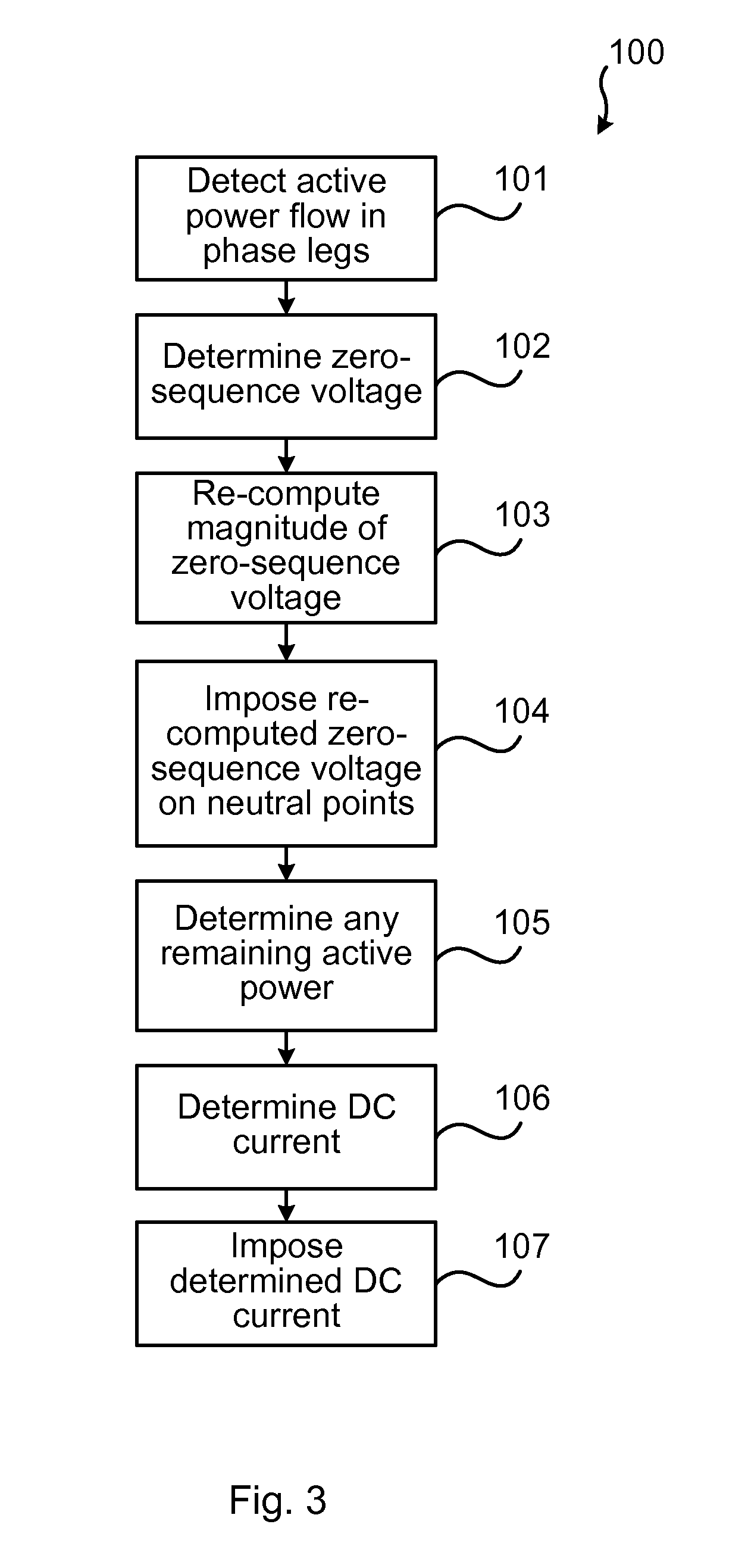

Methods and devices for controlling active power flow in a three-phase modular multilevel converter

InactiveUS20160139578A1Reducing active power flowEliminating active power flowMechanical power/torque controlActive power filteringActive power filterEngineering

The invention relates to methods and devices for controlling unbalanced active power flow in a three-phase modular multilevel converter 20. The converter 20 comprises a first and second converter 4, 5 both comprising three phase legs arranged in a wye-connection. The first and second converters 4, 5 are interconnected in a double-wye connection, and their neutral paths are independently floating. The method 200 comprises: detecting an active power flow in the phase legs; determining a zero-sequence voltage, the determination providing magnitude and phase of the zero-sequence voltage; re-computing the magnitude of the zero-sequence voltage while keeping the phase of the zero-sequence voltage fixed, the magnitude being re-computed with the requirement that the resulting voltage over the phase legs is smaller than or equal to a maximum allowed leg voltage, the re-computed magnitude and the phase giving a re-computed zero-sequence voltage; imposing the re-computed zero-sequence voltage on the neutral point of the first and second converters, thereby reducing the active power flow determining remaining active power based on the re-computed magnitude of the zero-sequence voltage; determining a DC current giving a product with a DC voltage of the first and second converters 4, 5 that will counteract remaining active power; and imposing the DC current on the phase legs.

Owner:ABB (SCHWEIZ) AG

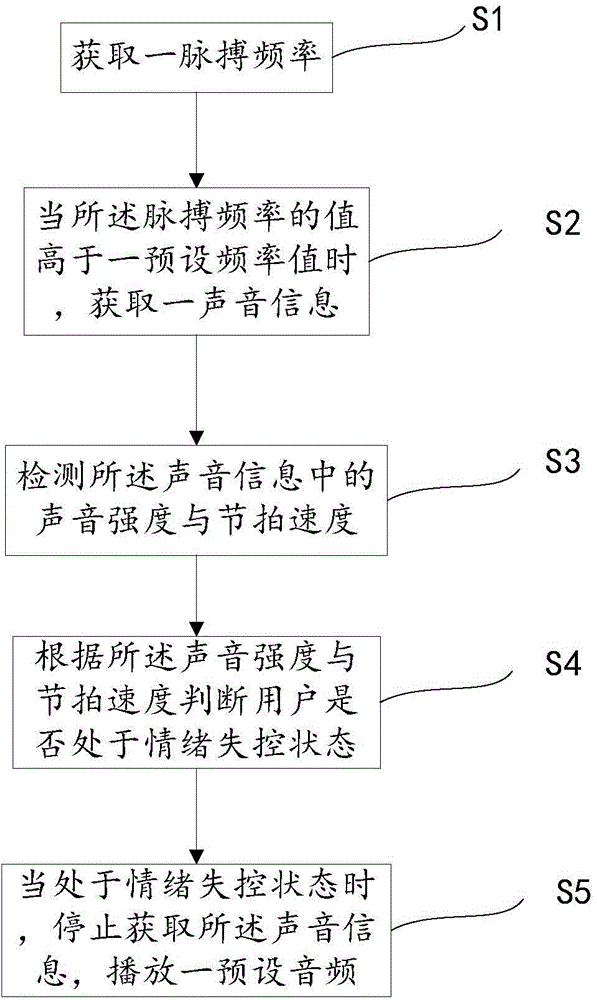

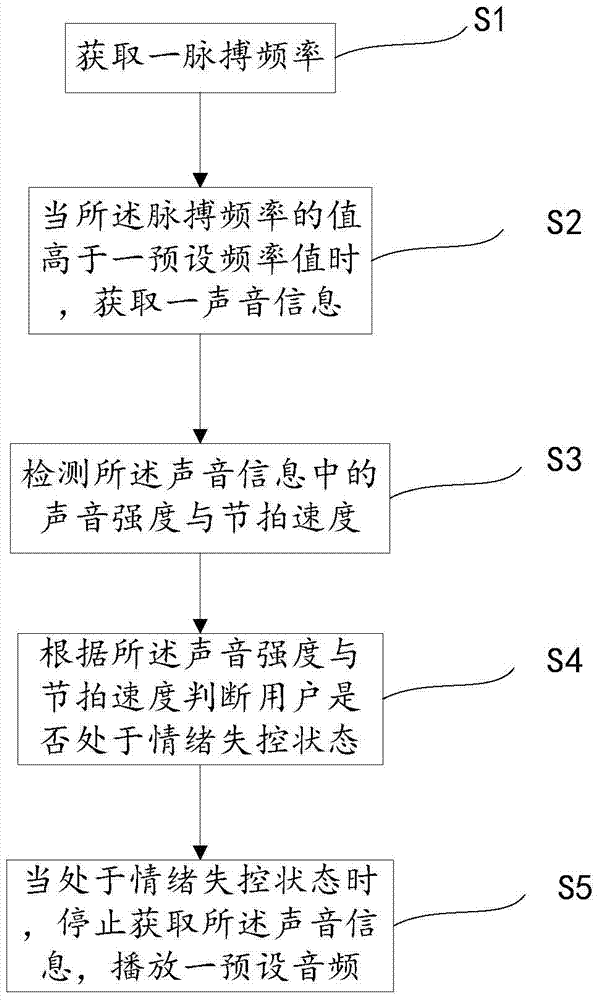

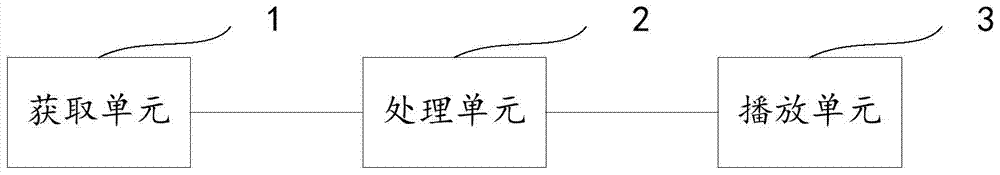

Method and device for controlling emotion

The invention provides a method and device for controlling emotion. The method comprises the steps that 1, pulse frequency is acquired; 2, when a value of the pulse frequency is larger than a preset frequency value, acoustic information is acquired; 3, the acoustic intensity and beat speed in the acoustic information are detected; 4, whether a user is in an emotion-uncontrolled state or not is judged according to the acoustic intensity and beat speed; 5, when the user is in the emotion-uncontrolled state, acoustic information acquisition is stopped, and a preset audio is played. In this way, the problems that the emotion-uncontrolled state is automatically detected and emotion control is automatically performed according to the state are solved.

Owner:PHICOMM (SHANGHAI) CO LTD

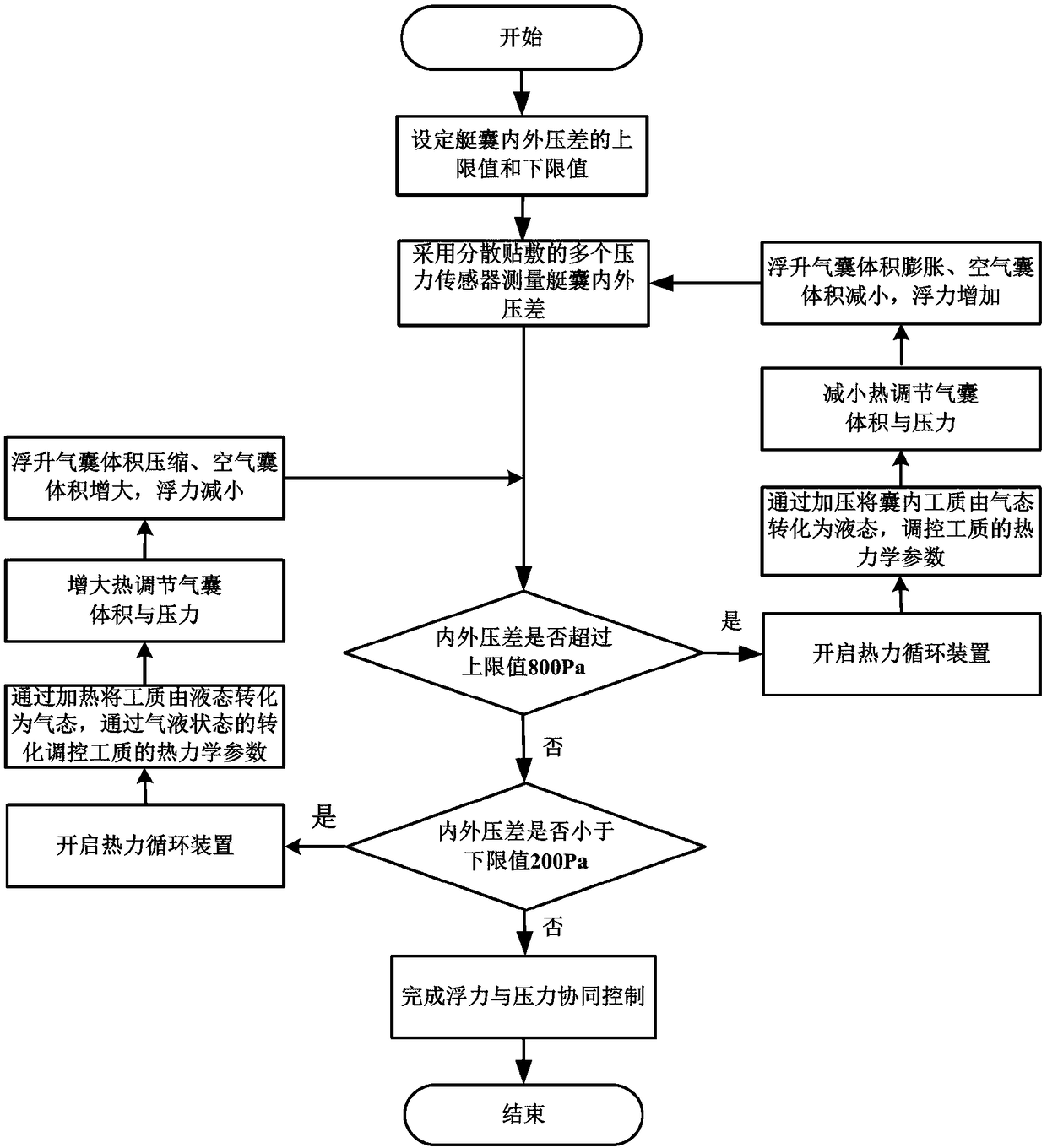

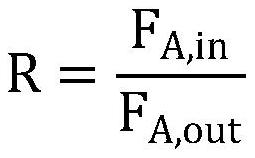

Stratospheric airship buoyancy and pressure cooperative control method

InactiveCN108725734AIncreased means of controlImprove control efficiencyRigid airshipsGas-bag arrangementsLower limitStratosphere

The invention provides a stratospheric airship buoyancy and pressure cooperative control method and belongs to the technical field of aircraft flight control. The method includes setting an upper limit value Pu and a lower limit value P1 of the pressure difference between the inside and the outside of a stratospheric airship body, measuring the air pressure P and P' inside and outside the stratospheric airship body respectively, calculating the pressure difference between the inside and the outside of the stratospheric airship body that Pe=P-P', comparing the pressure difference Pe and the upper limit Pu and the lower limit value Pl of the stratospheric airship body and adjusting the buoyancy and the pressure cooperatively by adopting a buoyancy lift airbag, an air bag and an adjusting airbag according to the relation. The thermodynamic parameters of a working medium are adjusted by a thermodynamic cycle device, so that the volume and the pressure of the adjusting airbag are changed, and the pressure and the buoyancy of the stratospheric airship are adjusted accordingly.

Owner:NAT UNIV OF DEFENSE TECH

Side air bag with a controlled opening of a pressure equalization chamber

InactiveUS7556288B2Low elastic modulusIncreased means of controlPedestrian/occupant safety arrangementEngineeringPressure balance

A side-impact air bag system for motor vehicles with an air bag (10) extending across at least a part of the longitudinal extent of the vehicle. The air bag (10) is formed by two layers of fabric which are joined to each other and is located in the region of the roof frame of the vehicle in its folded state, before it is unfolded in the form of a curtain. An inflation device (11) releases an inflating gas, and the air bag (10) contains at least one primary chamber (14) which can be inflated by directly feeding gas into it, as well as at least one additional pressure equalization chamber (16), which is separated from the immediately inflatable primary chamber (14). The pressure equalization chamber (16) is equipped across its surface with additionally placed connections (19) of the fabric layers of the air bag (10) in such a manner that the gas stream entering the pressure equalization chamber (16) after inflation of the directly inflatable primary chamber (14) as a function of the pressure acting upon it, inflates portions of the pressure equalization chamber (16) by separation of the additional connections (19).

Owner:AUTOLIV DEV AB

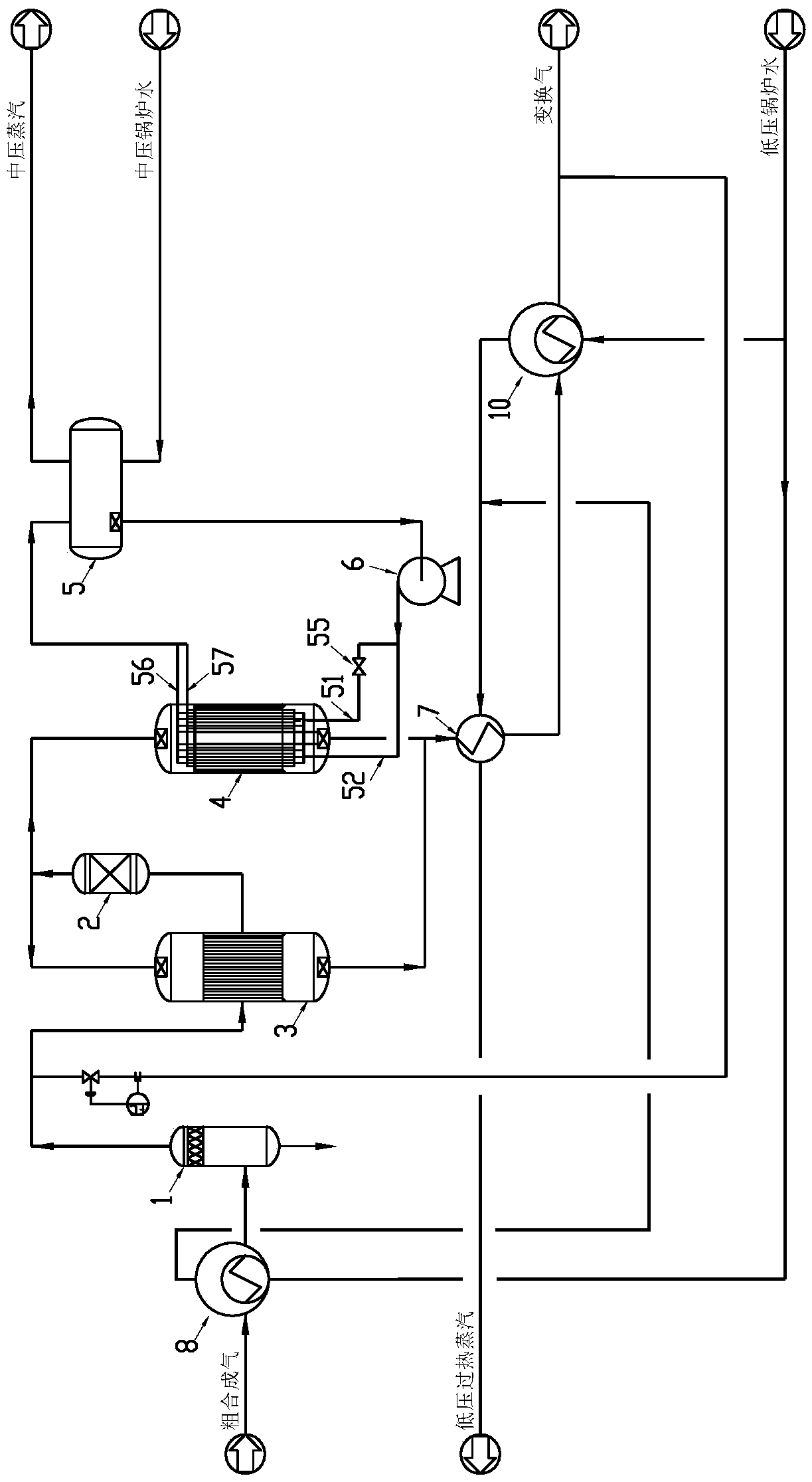

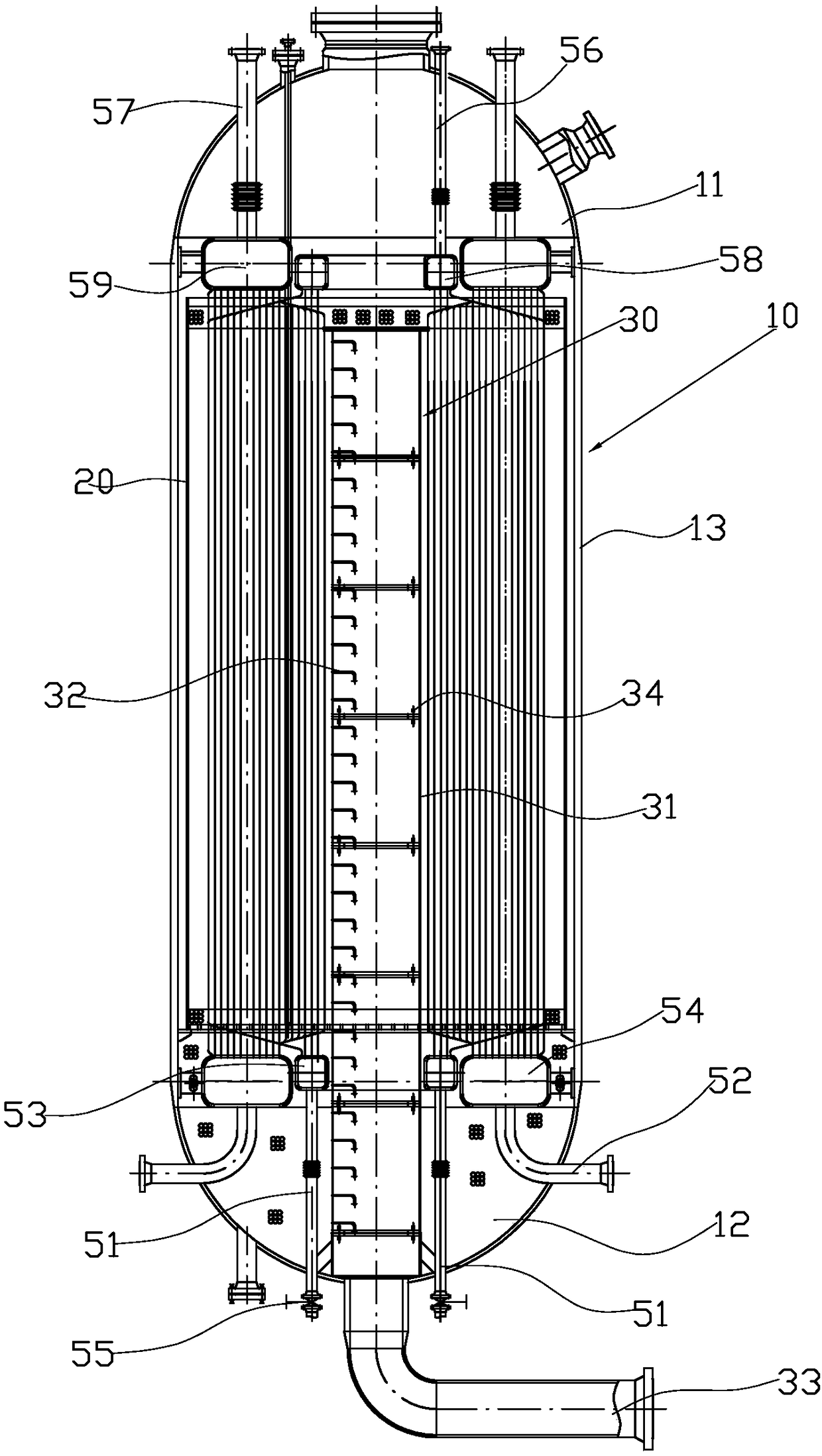

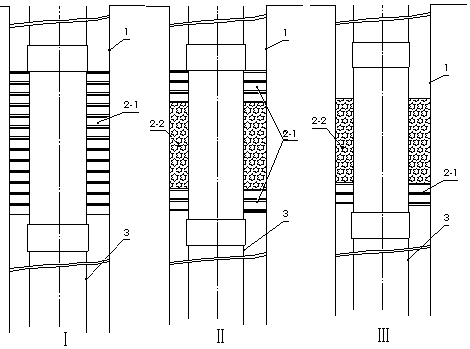

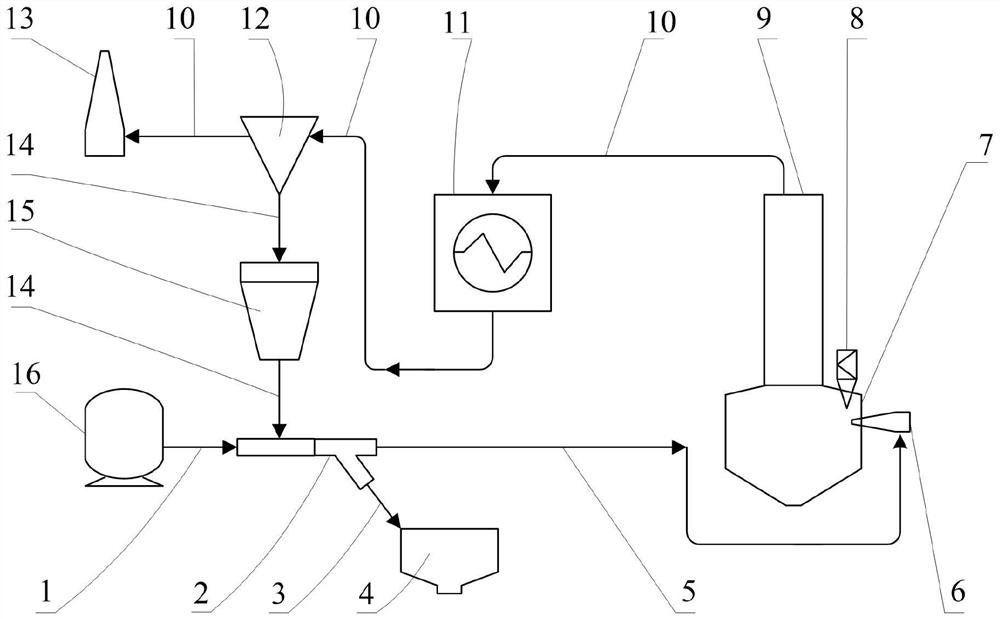

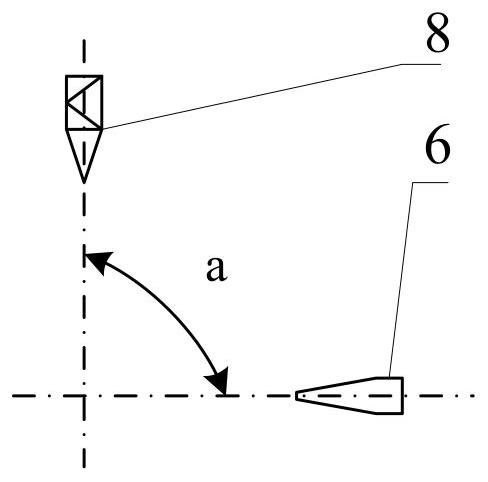

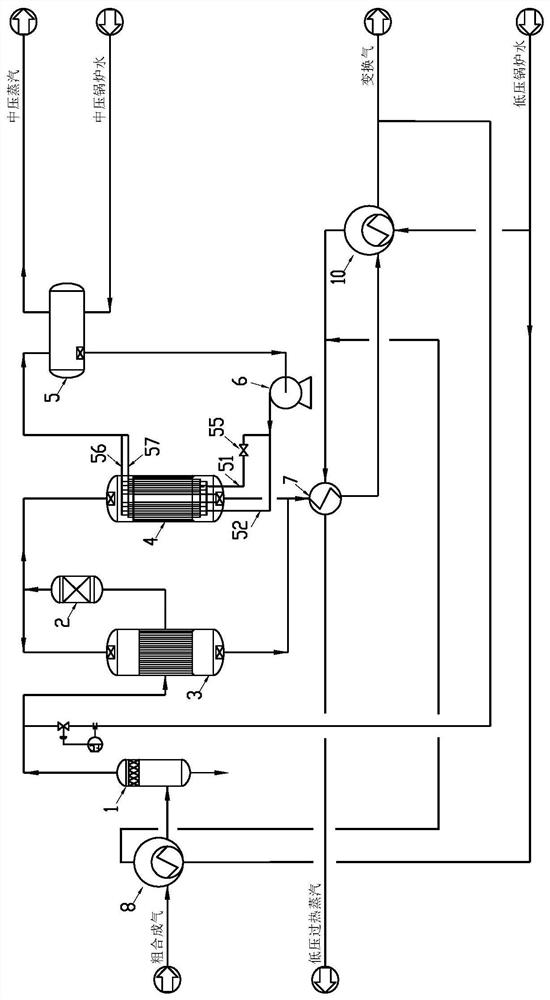

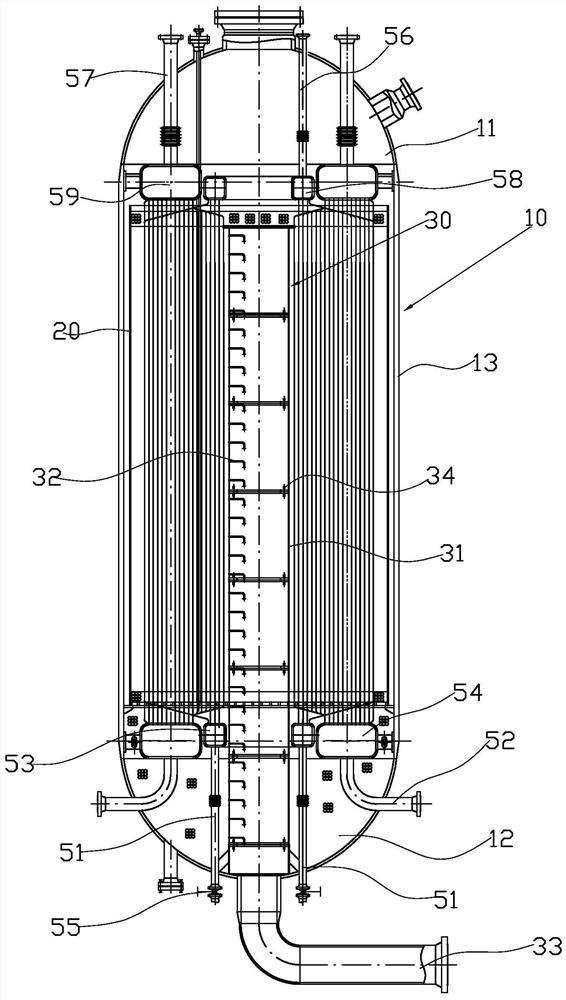

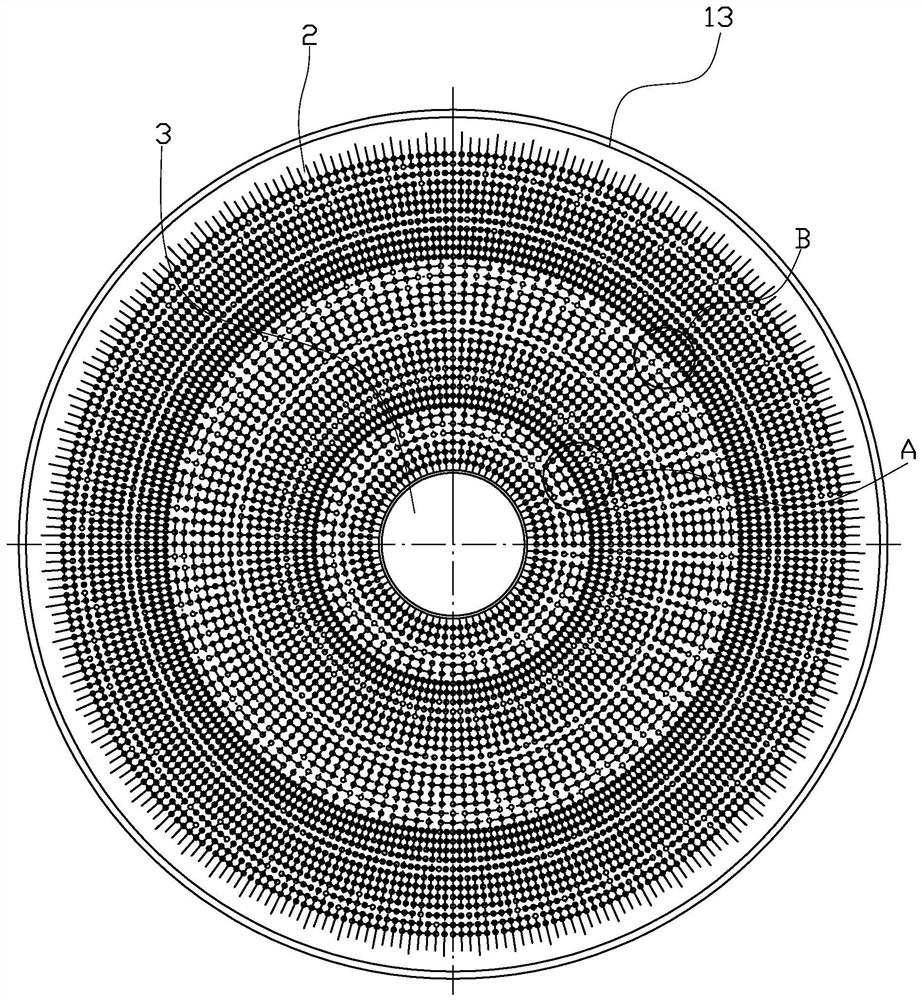

CO shift process matched with synthesis of methanol

The invention relates to a CO shift process matched with synthesis of methanol. The CO shift process is characterized by comprising the following steps: raw gas firstly enters a low-pressure steam generator for cooling and is subjected to liquid separation to adjust water-gas ratio; the raw gas subjected to liquid separation is divided into two paths, wherein one path accounts for 45 to 55 percentto serve as non-transforming gas, and the rest is used as a second path, is subjected to temperature improvement and detoxification in sequence, is divided again and then enters a gas-cooled converter and an isothermal transformation furnace which are arranged in parallel for isothermal transformation respectively; heat is recovered, subsequently the transformed gas is mixed with the first path of non-transforming gas to serve as synthesis gas; the mole ratio of H2 to CO in the synthesis gas is controlled at 2.1 to 2.3. According to the CO shift process disclosed by the invention, byproductsof medium pressure saturated steam and low pressure overheat stream are generated; the gas-cooled converter uses the transforming gas as a refrigerant; by multiple times of dividing conversions, the CO shift process has the advantages of short flow, small size of the converter, no over-temperature risk, adjustable heat exchange area of the used isothermal transformation furnace, small pressure fluctuation of the byproduct medium pressure steam and more stable system operation.

Owner:SINOPEC NINGBO ENG +2

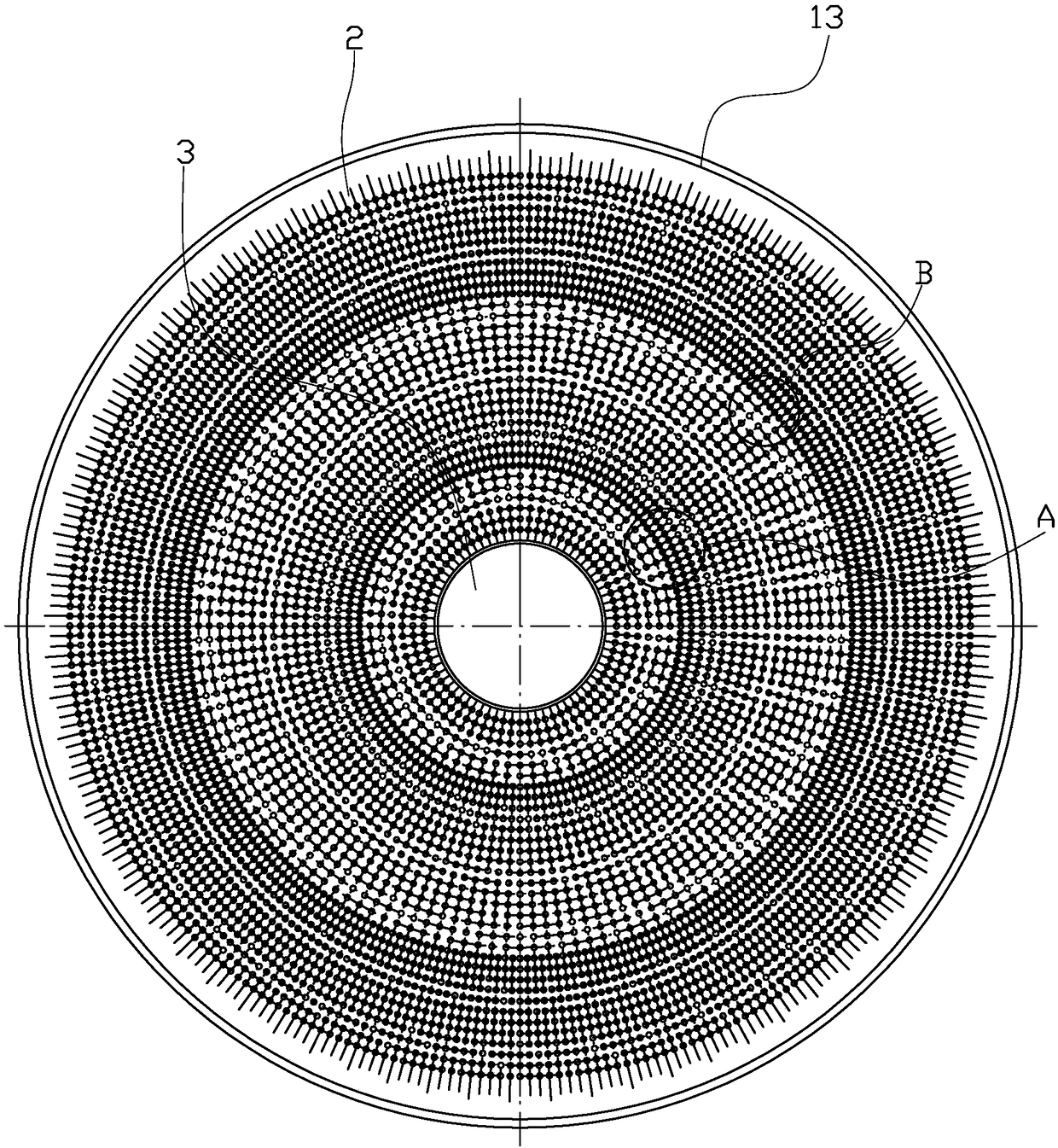

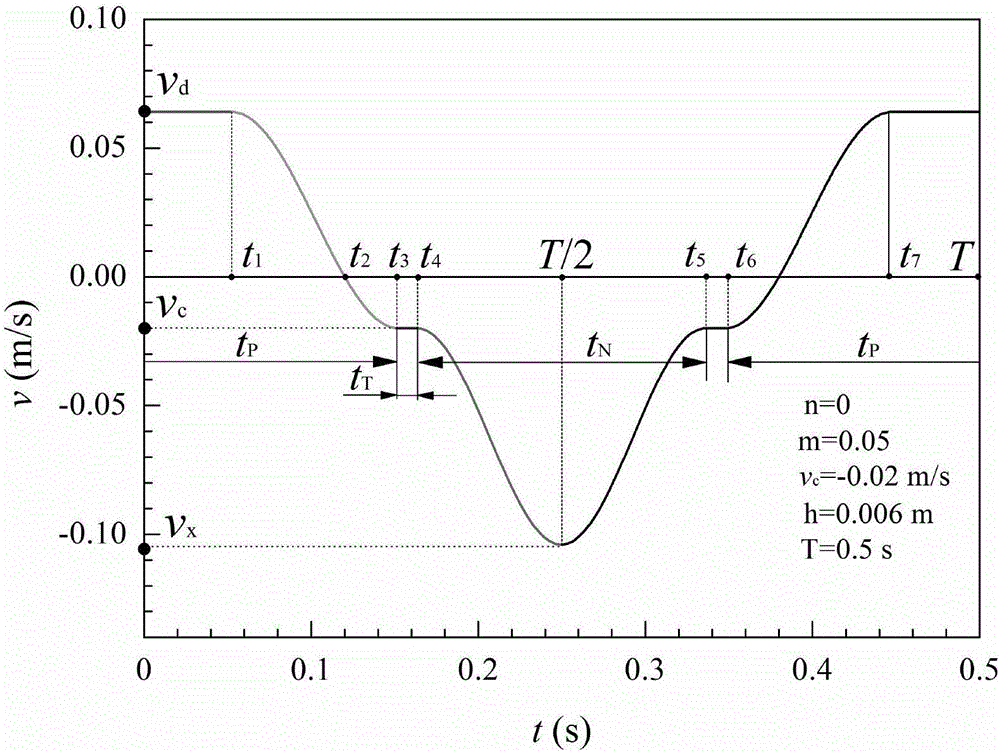

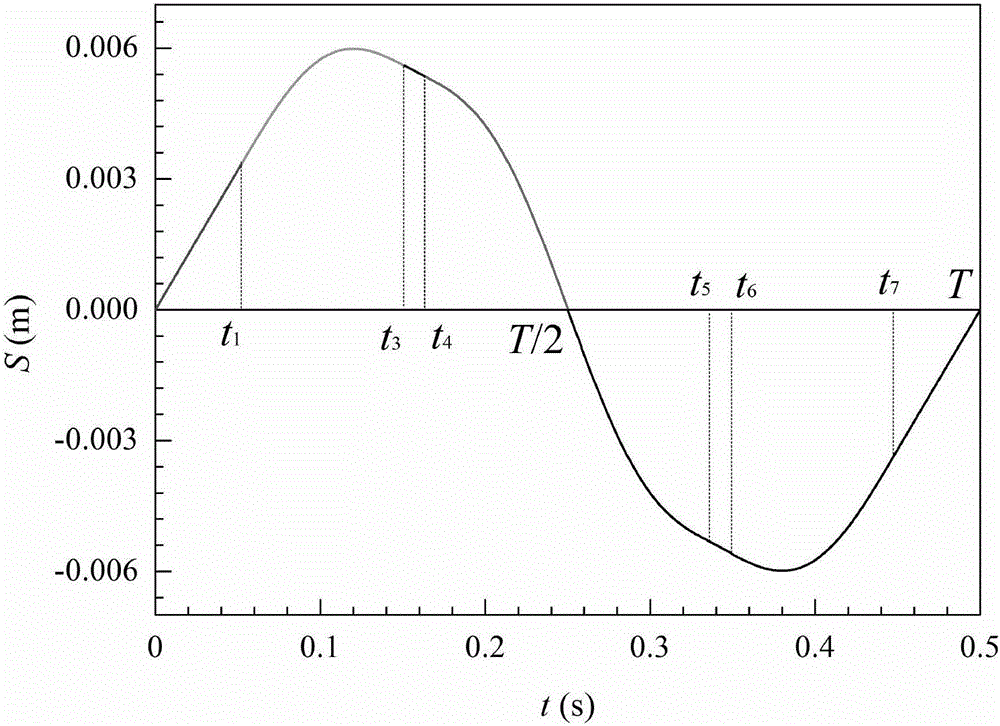

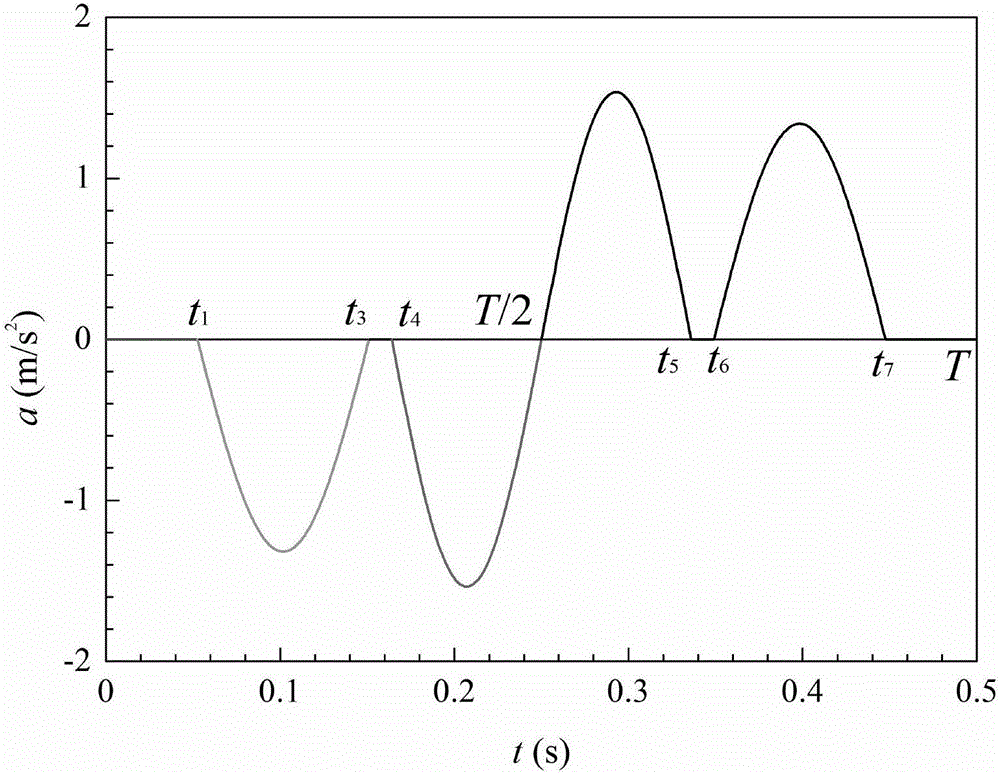

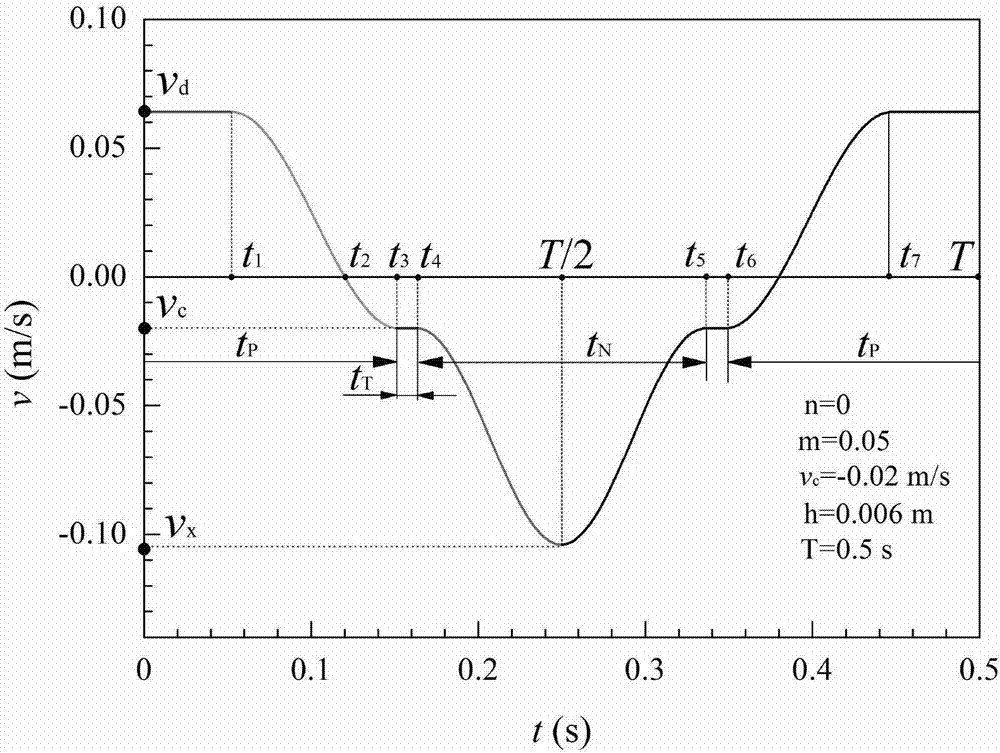

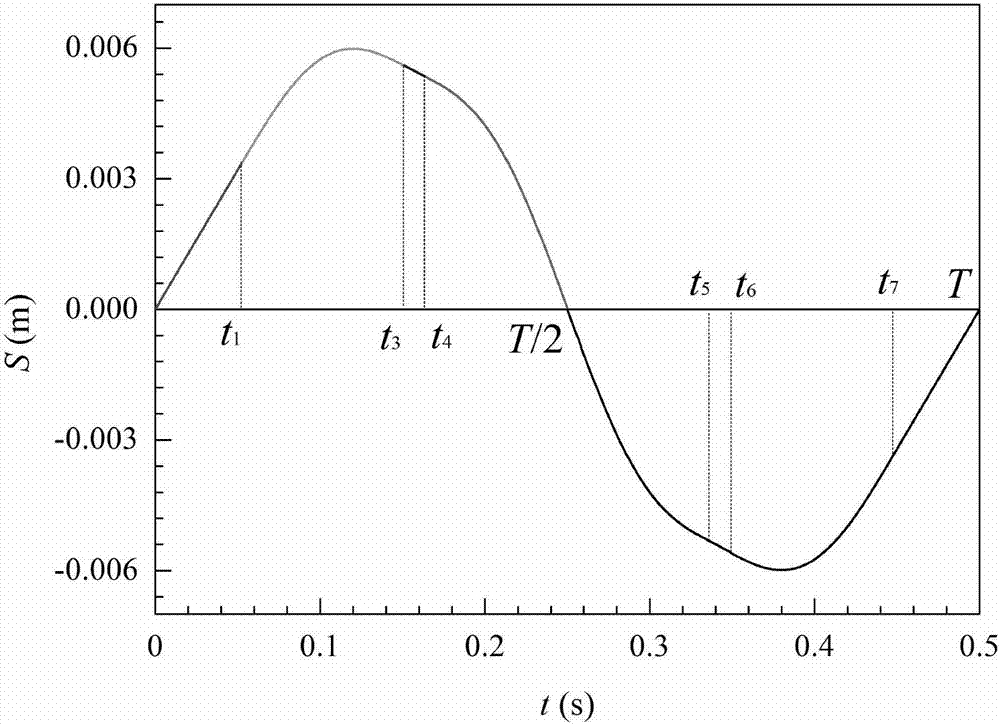

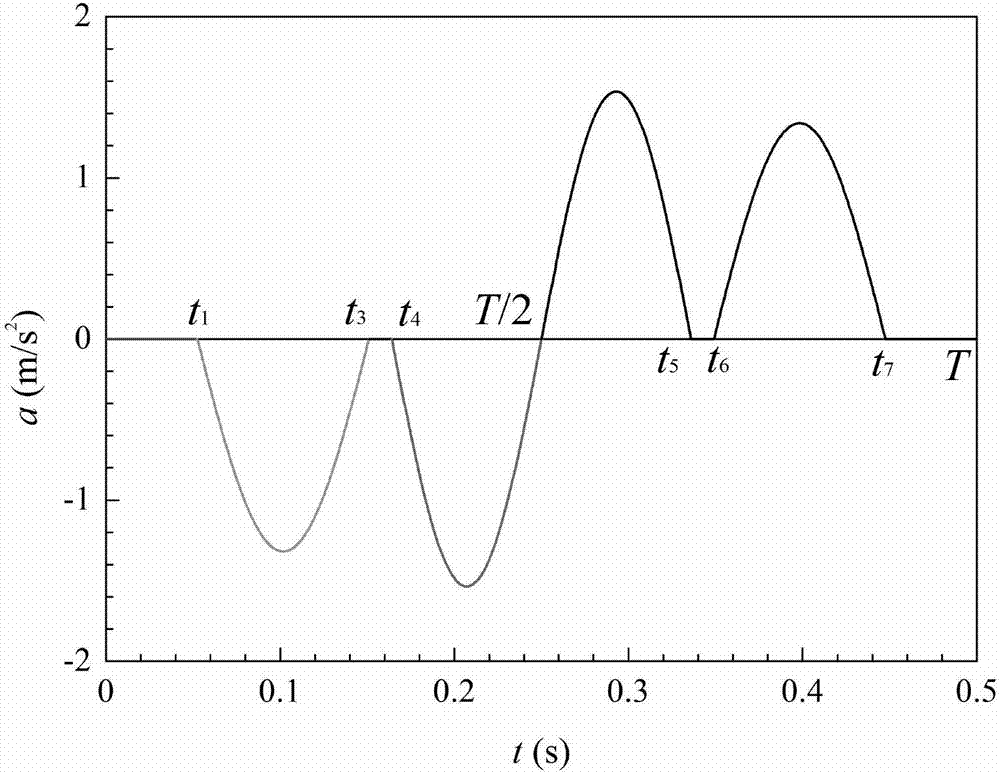

Non-sinusoidal vibration method of continuous casting mold

The invention provides a non-sinusoidal vibration method of a continuous casting mold. The non-sinusoidal vibration method includes steps of controlling a driving device of the continuous casting mold so that the continuous casting mold vibrates non-sinusoidally in line with eight-stage speed determined as the following eight-stage speed function in each vibration cycle; introducing a new vibration control variable, namely the constant-speed duration factor m, increasing the control means for the waveforms to facilitate the vibration control according to the actual conditions. The casting speed and vibration waveform can be combined for different billet speed, and different vibration schemes can be designed; the consumption of casting powder can be increased, continuous casting lubrication is facilitated, and friction, cracks and binding are reduced. Therefore, the vibration speed of the crystallizer is equal to the extension of the casting speed, and the uniform outward heat transfer of the continuous casting and stable growth of the initial base are facilitated.

Owner:NORTHEASTERN UNIV

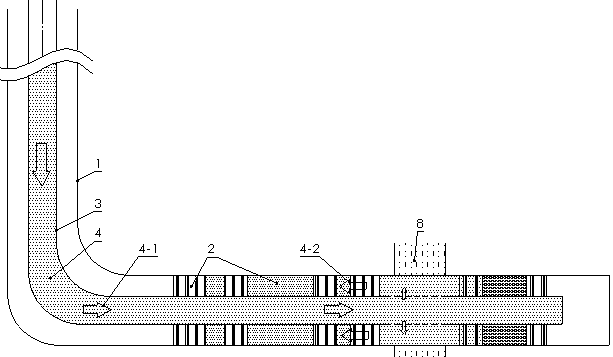

Iron ore tunnel kiln magnetizing roasting layering material distributing reduction method

The invention discloses an iron ore tunnel kiln magnetizing roasting layering material distributing reduction method. Iron ore is divided into different granularity degrees according to the granularity range; the reduction coal is flatly laid in the bottom of a tunnel kiln car according to the proportion that the reduction coal accounts for 4-6% of the total weight of iron ore; the iron ore of various granularity degrees is laid at the upper portion of the reduction coal of the tunnel kiln car, and the granularity range of each layer of iron ore is gradually increased from the bottom layer to the top layer in a layer-by-layer manner; facing materials are flatly laid at the upper portion of iron ore of various granularity degrees of the tunnel kiln car; the tunnel kiln car loaded with materials is pushed into a tunnel kiln for magnetizing roasting; and after magnetizing roasting is finished, the tunnel kiln car loaded with the materials is pushed out of the tunnel kiln. According to the method, over reduction of iron ore can be effectively prevented, the control means of iron ore magnetizing roasting is improved, and the surplus carbon recycling and utilizing cost is low. In addition, the mixing technology of iron ore and a reducing agent before magnetizing roasting of the iron ore tunnel kiln is reduced or eliminated, and the production cost of the roasted ore is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

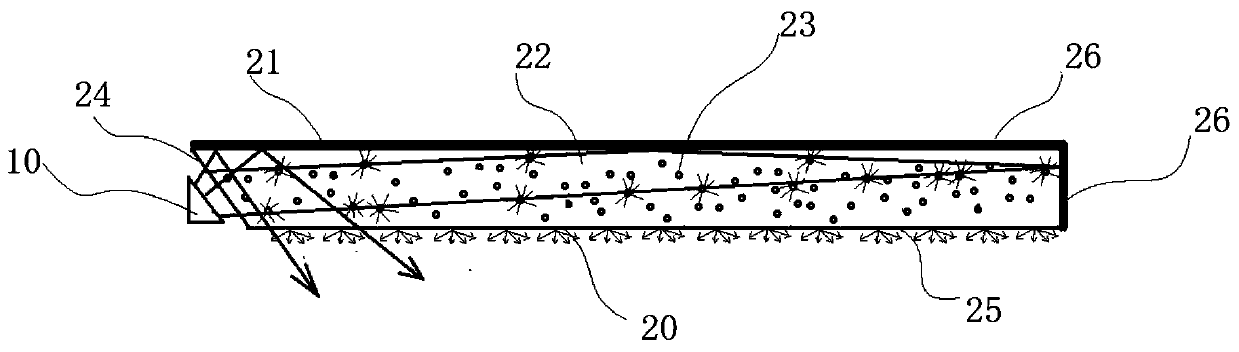

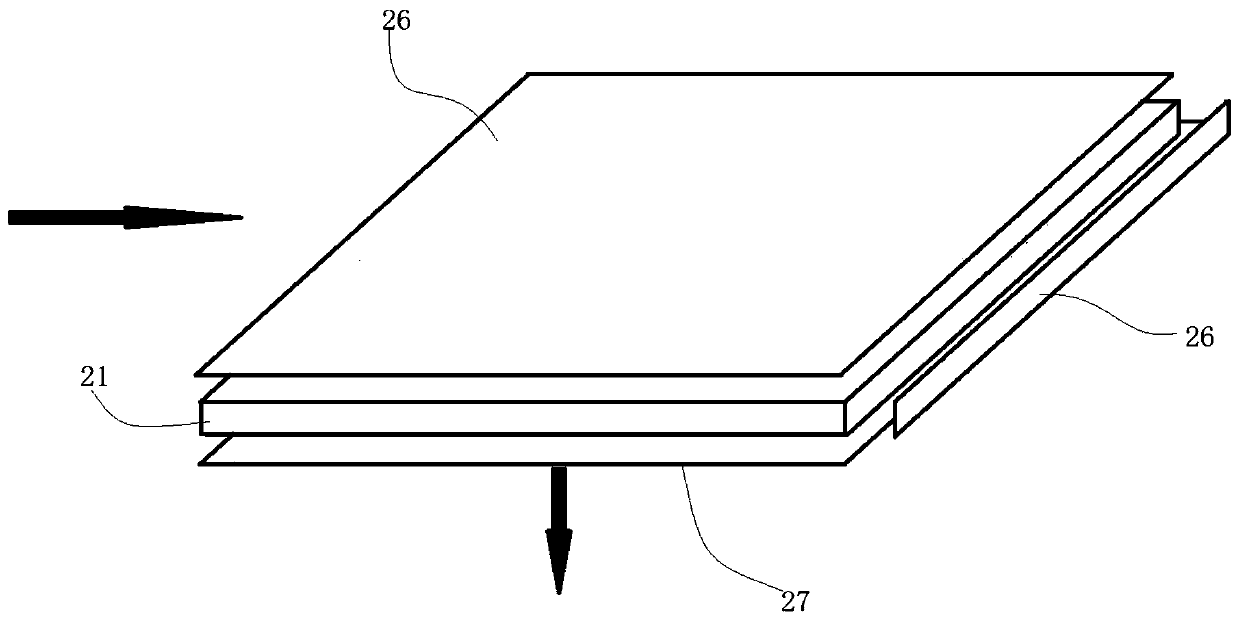

Artificial lighting device capable of generating sky blue skylight

InactiveCN110778927AEvenly distributedNot easy to accumulateSpectral modifiersSemiconductor devices for light sourcesSocial benefitsGrowth plant

The invention discloses an artificial lighting device capable of generating sky blue skylight. The device comprises two parts: an artificial light source and a scatterer. A submicron particle solutionis used as a main body of the scatterer to generate the sky blue skylight, and solve the problems that in the prior art, particles are easy to accumulate, and the particles are cured during placement; and furthermore, the device is easy to manufacture and applicable in industrial production; the emitted blue light can meet requirements in the numerous fields of domestic lighting, indoor decoration, plant growth and the like; and the artificial lighting device has good economic benefits and also can generate good social benefits.

Owner:CHINA JILIANG UNIV

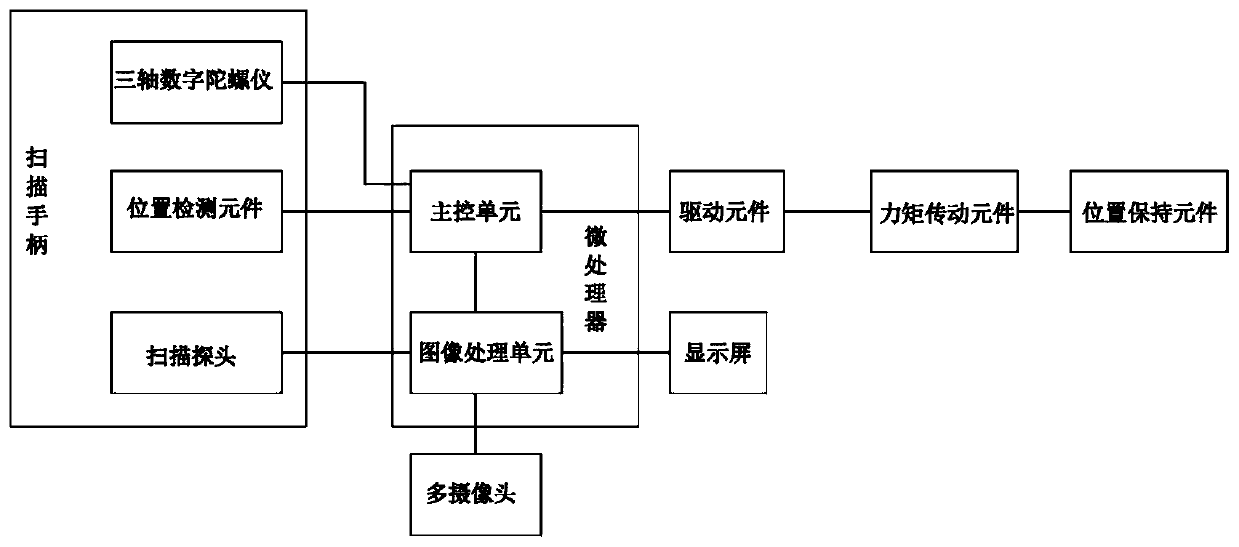

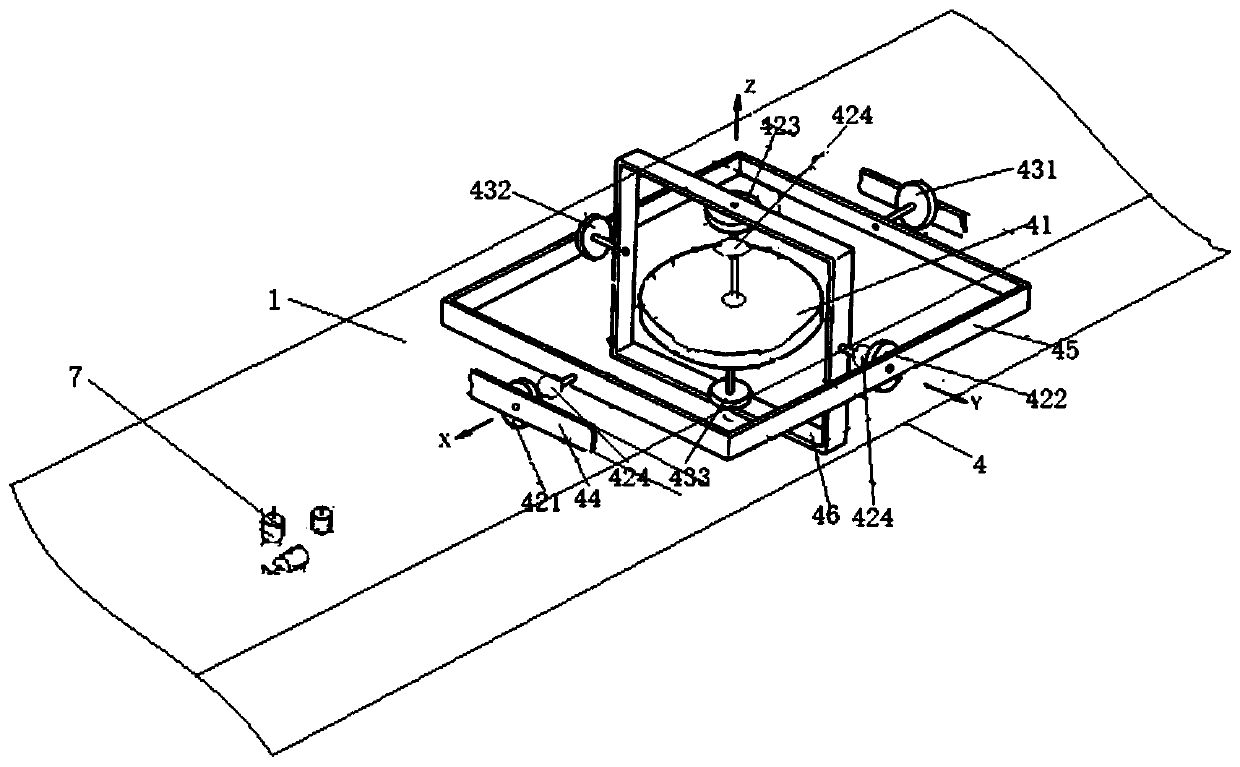

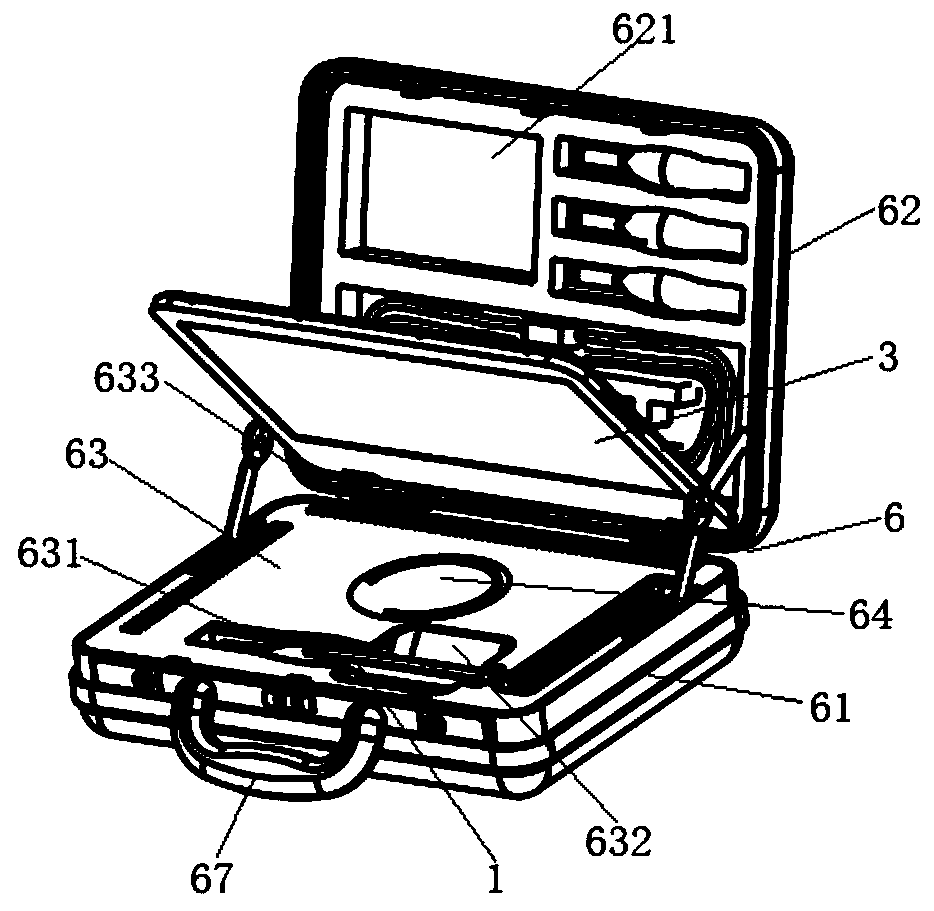

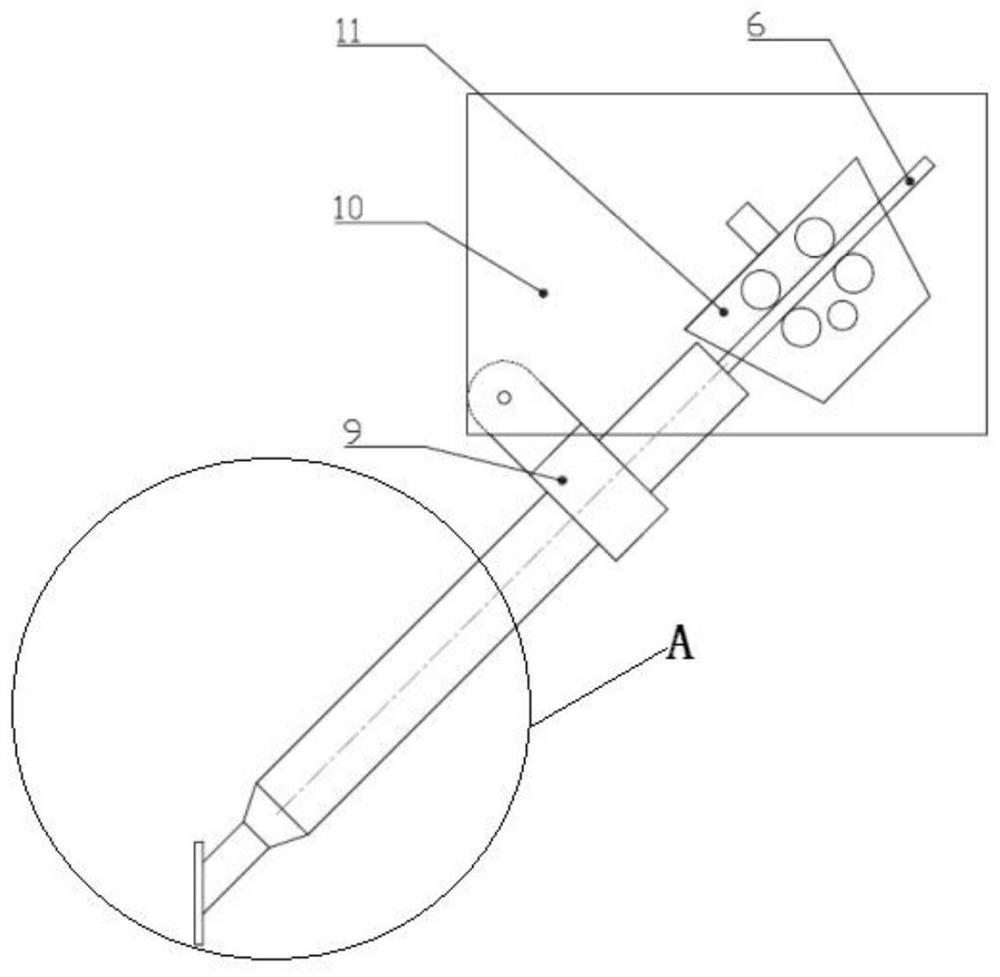

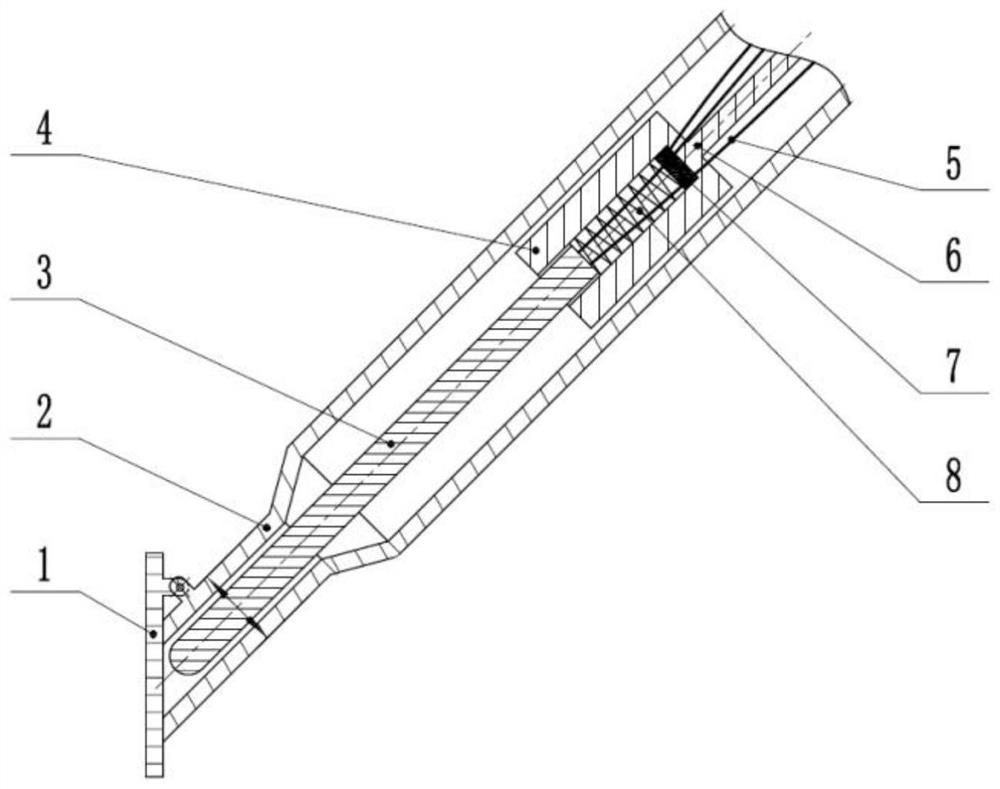

Oral cavity scanning device and use method thereof

ActiveCN110827975AImprove accuracyImprove clarityMedical equipmentDental prostheticsImaging processingGyroscope

An oral cavity scanning device and a using method thereof belong to the technical field of oral cavity scanners. The oral cavity scanning device comprises a scanning handle, a microprocessor and a display screen; a main control unit and an image processing unit are arranged in the microprocessor, and a three-axis digital gyroscope, an inertia driving platform and a scanning probe are arranged in the scanning handle. The inertia driving platform comprises a position maintaining element, a torque transmission element, a position detecting element and a driving element; the scanning probe is connected with the display screen through the image processing unit, and the image processing unit is connected with the main control unit. The three-axis digital gyroscope and the position detecting element are connected with the driving element through the main control unit, and the driving element is connected with the position maintaining element through the torque transmission element. The scanning angle and speed of the scanning handle are controllable, the scanning accuracy and definition are higher, and integration and multifunction are achieved. The accuracy and efficiency of gum model scanning are improved, and the labor intensity is reduced.

Owner:延边修恩生物科技有限公司

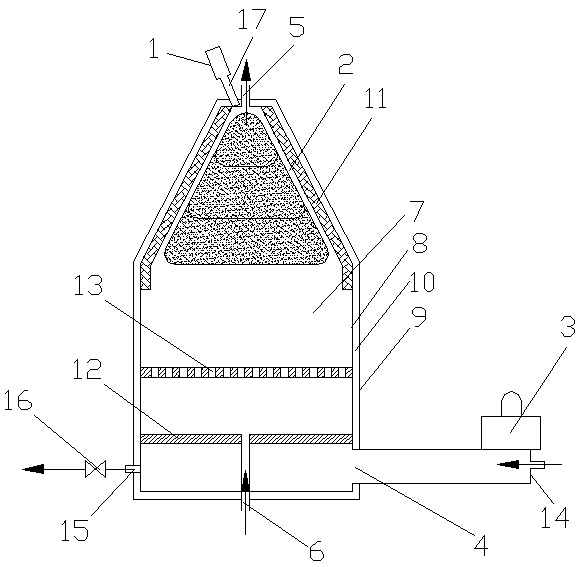

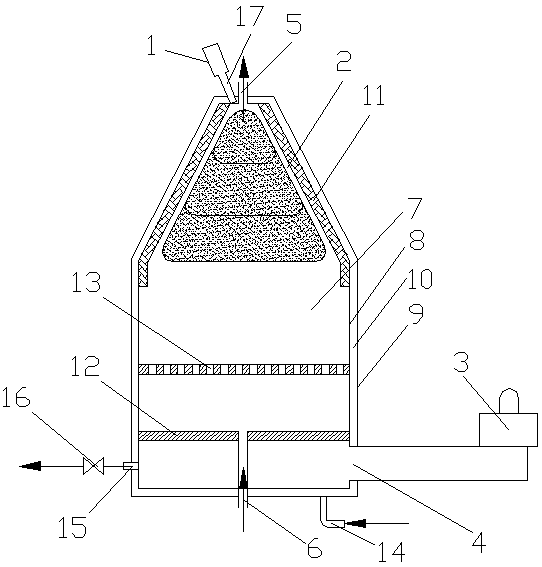

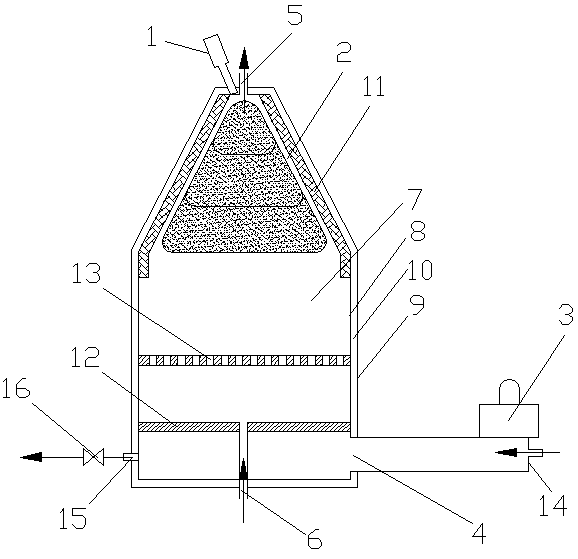

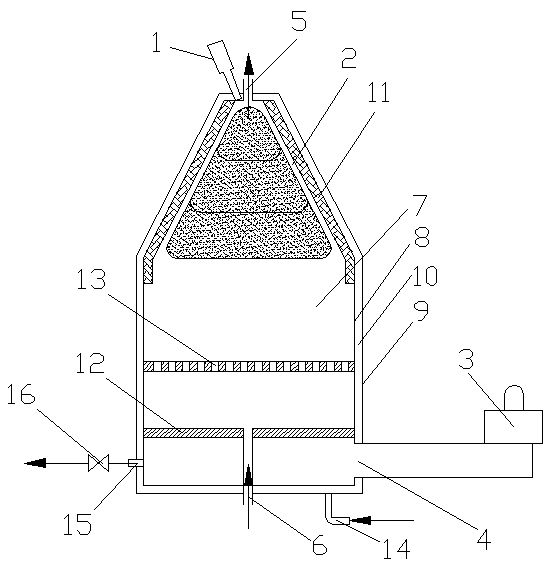

Non-jet normal-pressure large-volume microwave plasma generation method

ActiveCN111491437AIncrease in sizeGuaranteed temperature conditionsPlasma techniqueEngineeringMicrowave power

The invention discloses a non-jet normal-pressure large-volume microwave plasma generation method, and belongs to the technical field of microwave plasmas. The method is characterized by comprising the following steps: a, starting an igniter, and spraying generated small plasmas or chemical flames into a conical cavity; b, starting a microwave source, and inputting microwaves into a reaction cavity through a microwave feed port; and c, turning off the igniter, increasing the microwave power of the microwave source, and amplifying the small plasmas in the conical cavity to obtain non-jet normal-pressure high-power and large-volume microwave plasmas. According to the invention, to-be-treated gas can be fully and uniformly heated, so that the reaction efficiency is improved; uniform distribution in a set space range is realized, destructive breakdown discharge can be effectively prevented, and heat dissipation balance is easy to control; reasonable temperature, stable structure and long-term operation stability of the whole generator are ensured under the condition of reducing heat dissipation as much as possible; and the whole operation process is simple, reliable and easy to control.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

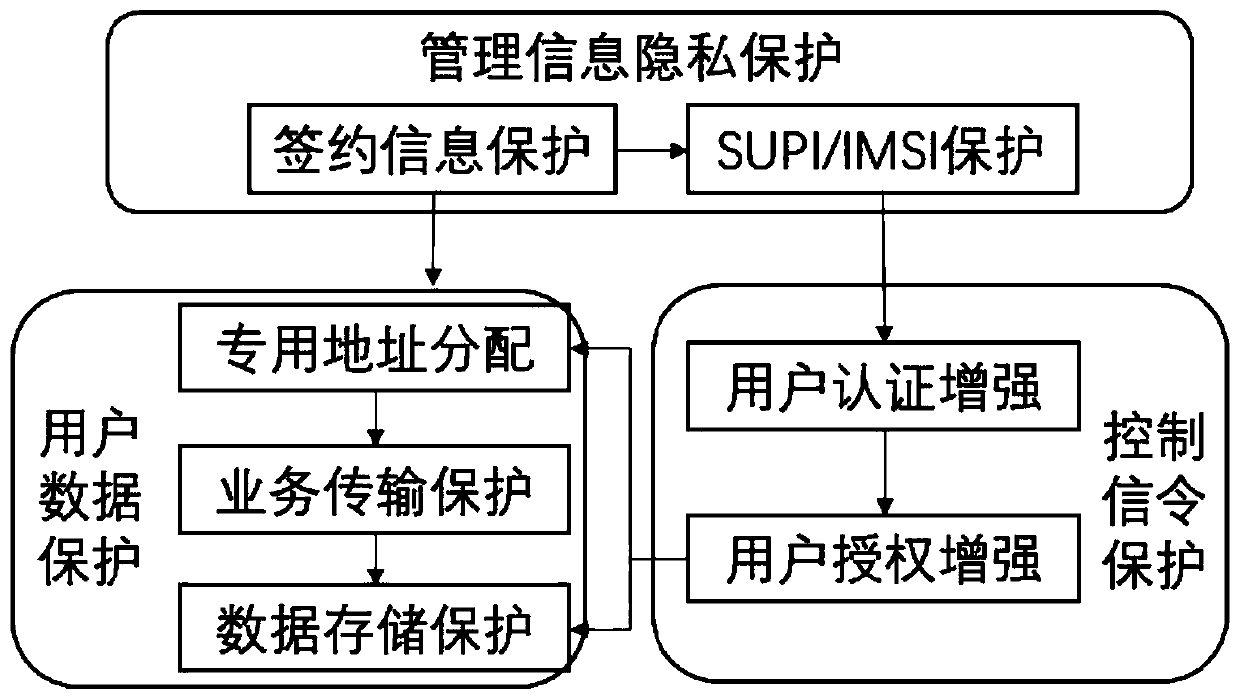

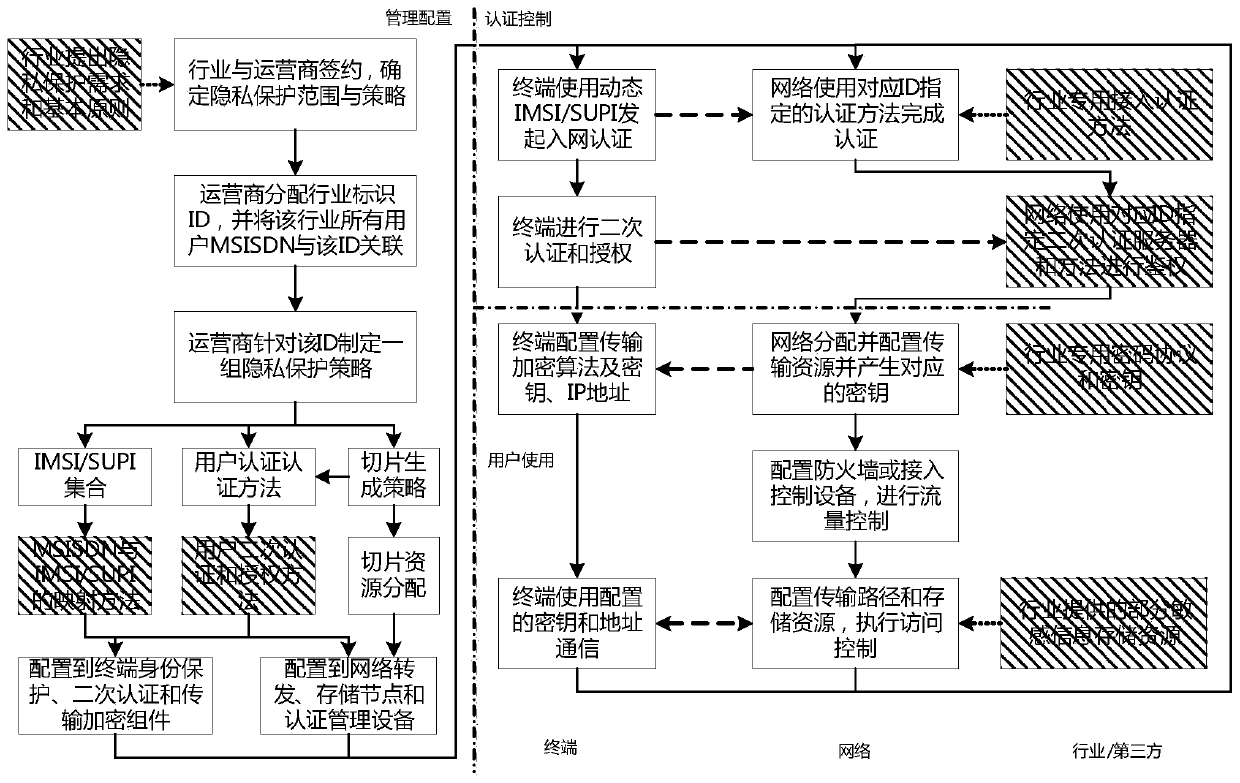

Industry-user-oriented mobile communication network privacy protection method and system

ActiveCN111385794AAddress the need for privacy protectionAvoid the barrel effectSecurity arrangementData transmissionPrivacy protection

The invention relates to the technical field of wireless communication, and discloses an industry-user-oriented mobile communication network privacy protection method and an industry-user-oriented mobile communication network privacy protection system. According to the industry-user-oriented mobile communication network privacy protection method, information of users is classified, thus, omnibearing privacy protection enhancement is carried out on industry applications from three aspects of management, control and users; the management layer protects a user network identity and resource configuration, a control layer protects related processes of user network access authentication; and the user layer protects a user data communication address, a data transmission channel and data network storage; privacy protection of management information, control information and user data information of industry users is realized; and a privacy protection framework and a systematic process for industry application are provided to prevent harm and risks, unified privacy protection is carried out, wooden barrel effect or fragile points are avoided, and privacy and sensitive data cannot be leaked or utilized when a mobile communication network is used in the vertical industry.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP +2

Non-sinusoidal Vibration Method of Continuous Casting Mold

The invention provides a method for non-sinusoidal vibration of a continuous casting crystallizer. The specific process is as follows: controlling the driving device of the continuous casting crystallizer so that the continuous casting crystallizer follows an eight-segment speed waveform determined by the following eight-segment speed function in each vibration cycle. Carry out non-sinusoidal vibration: and introduce a new vibration control variable, namely the isokinetic duration factor m, to increase the waveform control method to facilitate vibration control according to actual production conditions; combine the casting speed and vibration waveform to target different castings Speed, different vibration schemes can be designed; it can increase the consumption of mold slag, which is beneficial to the lubrication of the continuous casting billet, reduces friction, and reduces cracking and adhesion phenomena; it can extend the time for the vibration speed of the crystallizer to be equal to the casting speed, It is conducive to the uniform heat transfer of the continuous casting billet to the outside and the stable growth of the initial solidification billet shell.

Owner:NORTHEASTERN UNIV LIAONING

Non-jet normal-pressure thermal plasma generator

PendingCN111491435AGuaranteed temperature conditionsAggregation is not limitedPlasma techniqueMicrowavePlasma generator

The invention discloses a non-jet normal-pressure thermal plasma generator, and belongs to the technical field of microwave plasmas. The non-jet normal-pressure thermal plasma generator comprises an igniter and a microwave source, and is characterized by further comprising a reaction cavity; a gas channel I and a gas channel II are formed in the reaction cavity; the reaction cavity comprises a cylindrical cavity and a conical cavity located above the cylindrical cavity, wherein the conical cavity is communicated with the cylindrical cavity; a microwave feed port is formed in the cylindrical cavity; the microwave source is connected with the microwave feed port; and the igniter is connected to the conical cavity. According to the invention, large and uniform thermal plasmas can be formed, so that the gas to be treated is fully and uniformly heated, and the reaction efficiency is improved; uniform distribution in a set space range is realized, destructive breakdown discharge can be effectively prevented, and heat dissipation balance is easy to control; and reasonable temperature, stable structure and long-term operation stability of the whole generator are ensured under the conditionof reducing heat dissipation as much as possible.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

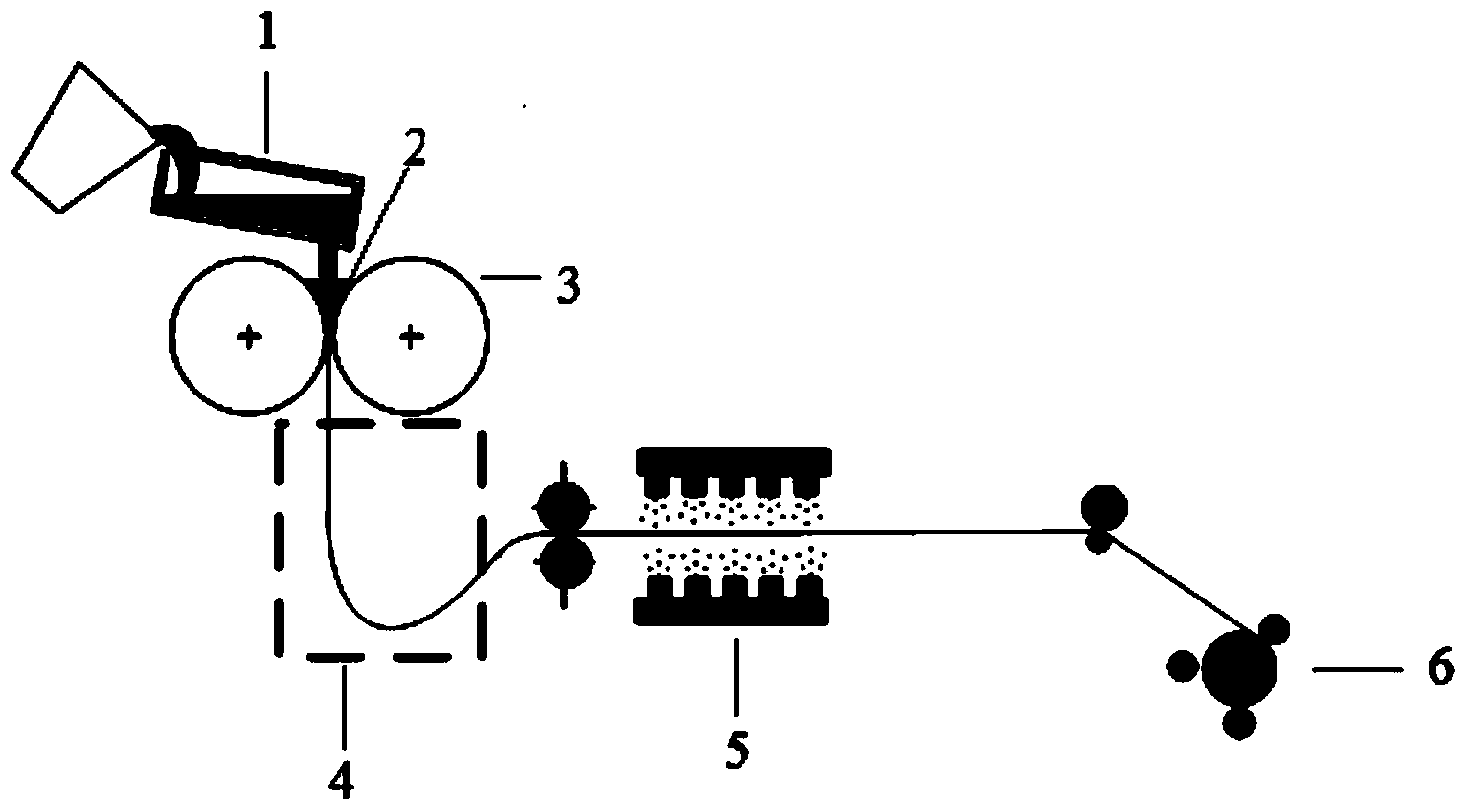

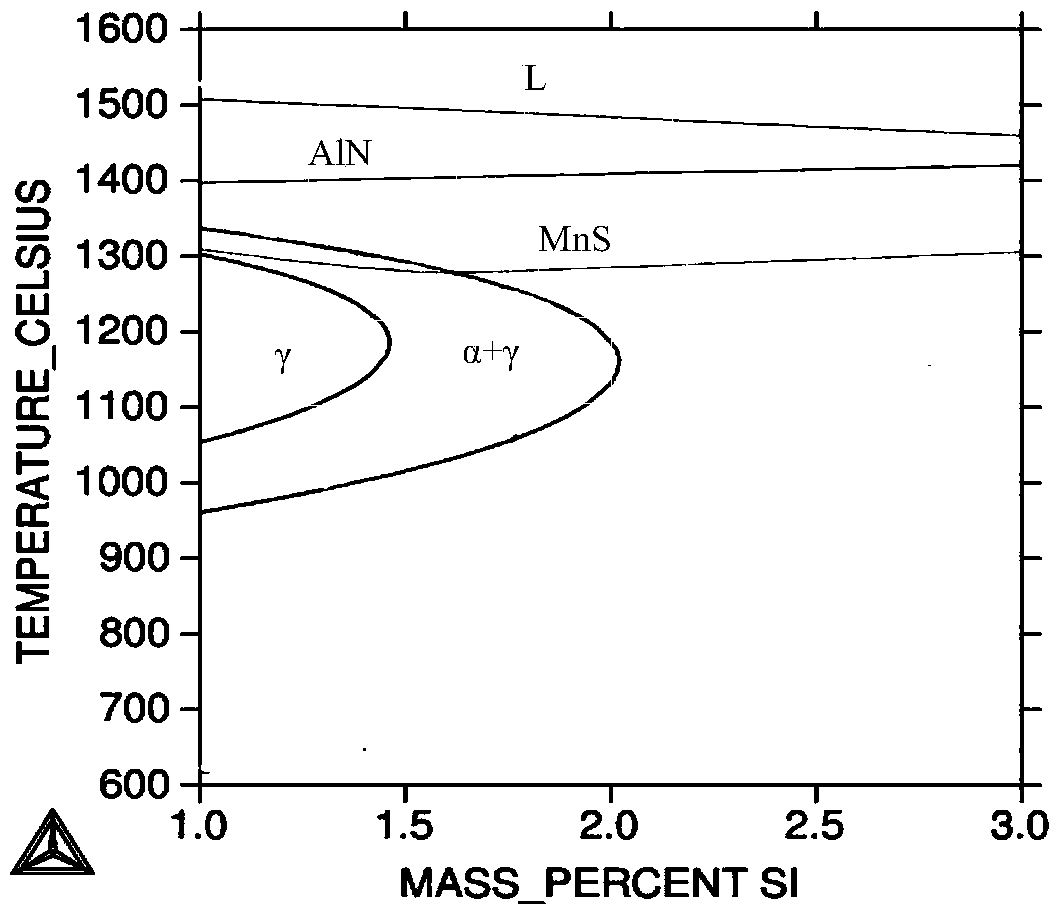

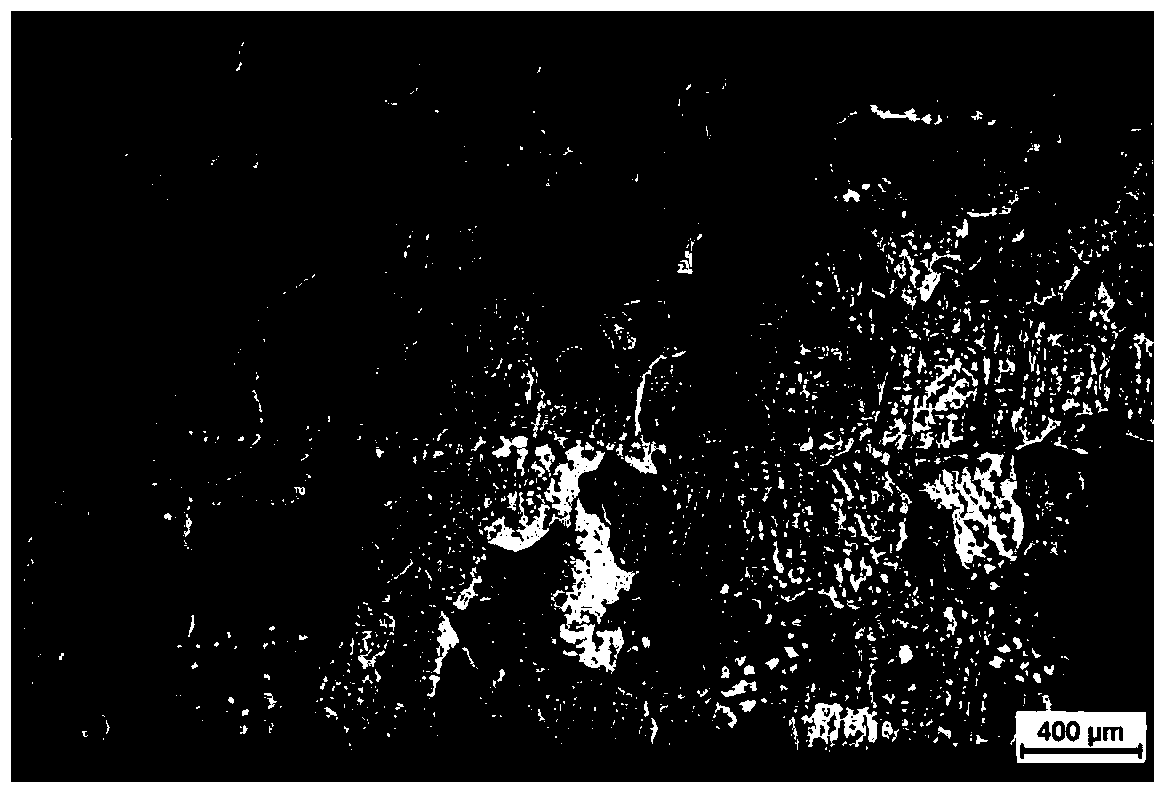

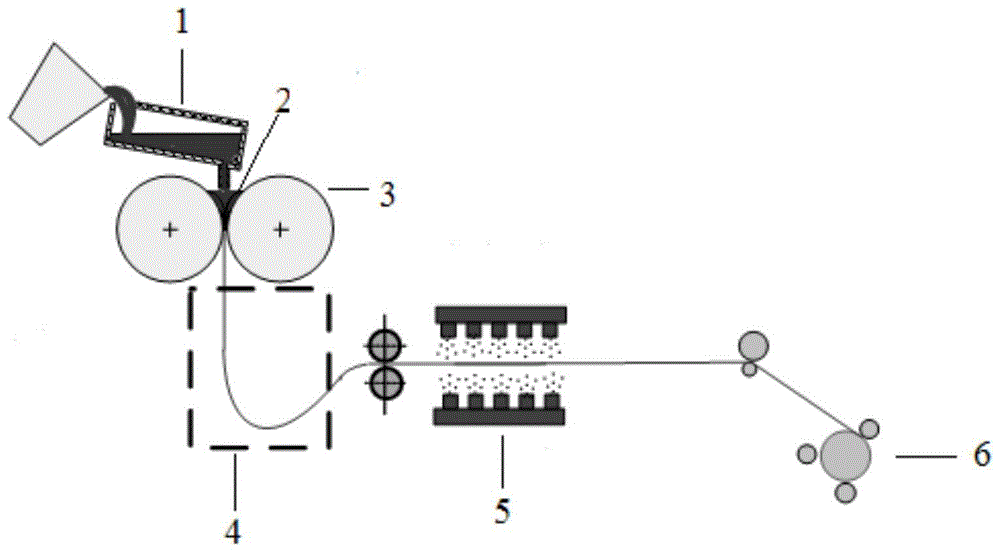

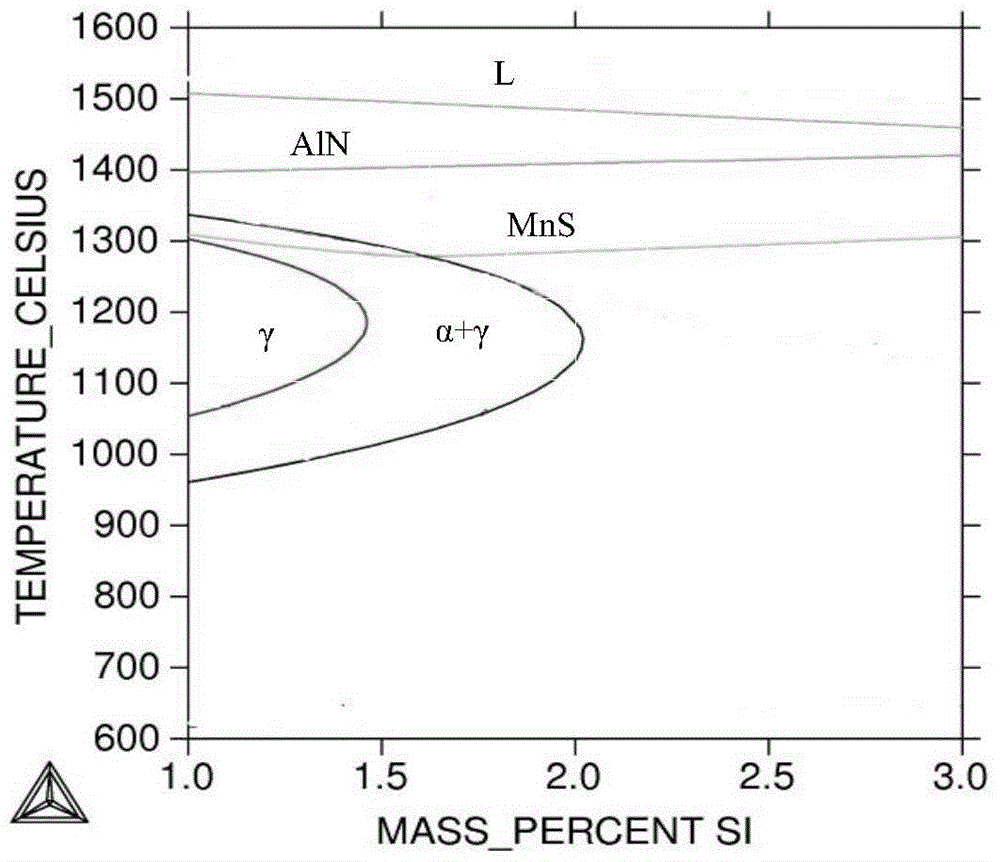

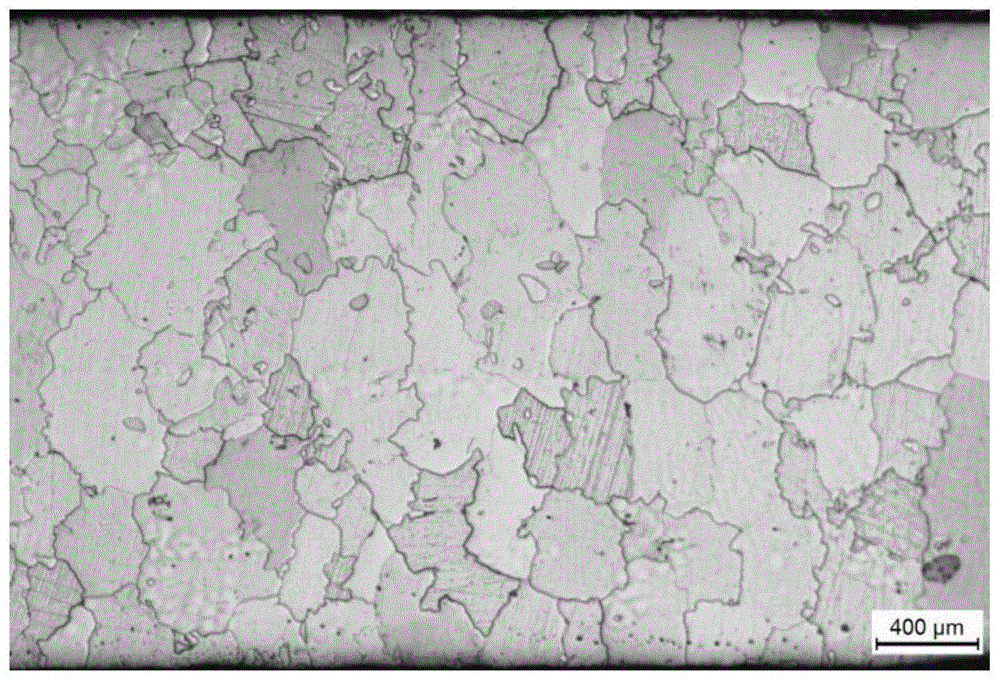

Method for controlling precipitates and impurities in twin-roll thin-strip casting process of non-oriented silicon steel

The invention belongs to the technical field of metallurgy, aims at the problem of not having a proper method for controlling precipitates and impurities in the process of producing non-oriented silicon steel in a twin-roll thin-strip casting manner, and provides a method for controlling the precipitates and impurities in the twin-roll strip casting process of non-oriented silicon steel. The method comprises the following steps of solidifying and forming molten non-oriented silicon steel by a twin-roll thin-strip casting machine so as to obtain cast strips with a thickness of 2.0-2.6 mm; taking the cast strips out of rolls, feeding the cast strips in a secondary cooling zone after casting, and slowly cooling the cast strips in a slow cooling chamber; feeding the cast strips into a tertiary cooling zone for fast cooling; cooling and coiling the cast strips which are subjected to the fast cooling by the tertiary cooling zone, and then obtaining non-oriented silicon steel cast strips. By utilization of the method, AlN precipitates in the cast strips reach a level of 0.5-2.0 microns, and the precipitation of MnS is obviously inhibited, so that the influence of the AlN and MnS precipitates on recrystallized grain growth and magnetic domain-wall movement is essentially eliminated, and a basis is laid for developing high-quality non-oriented silicon steel.

Owner:NORTHEASTERN UNIV

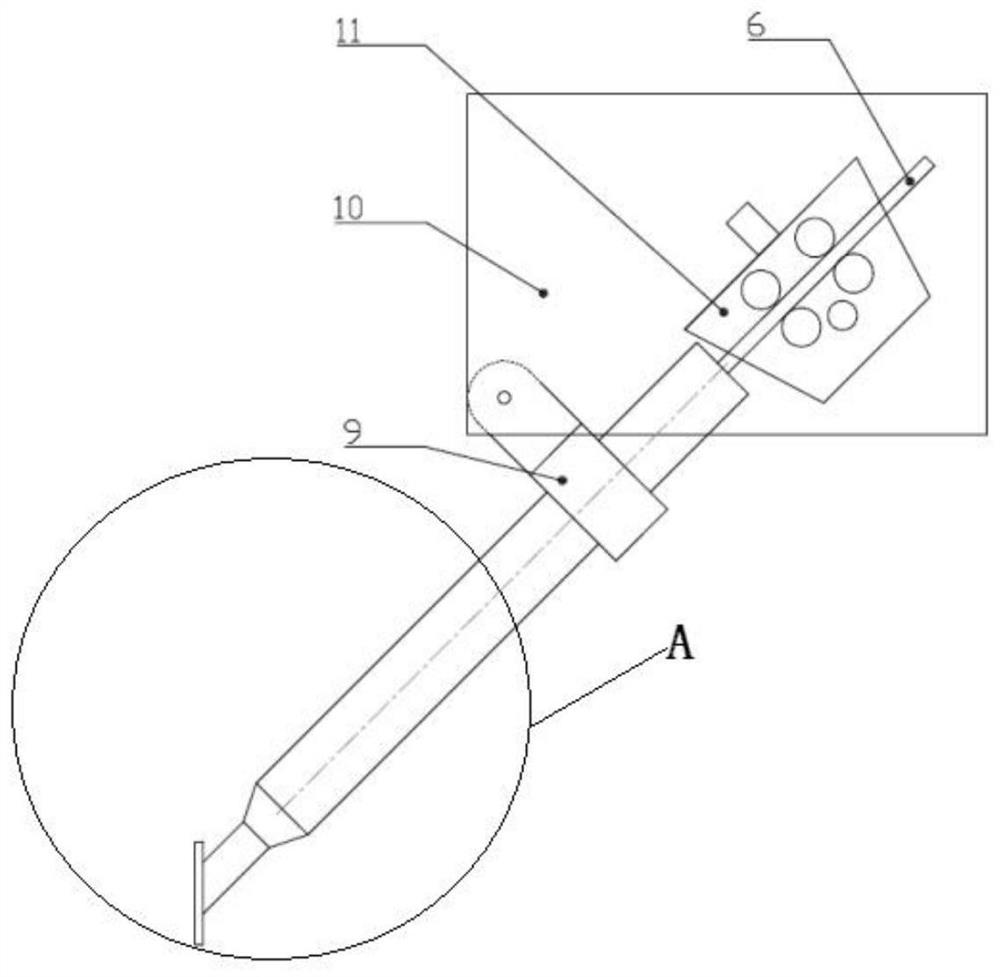

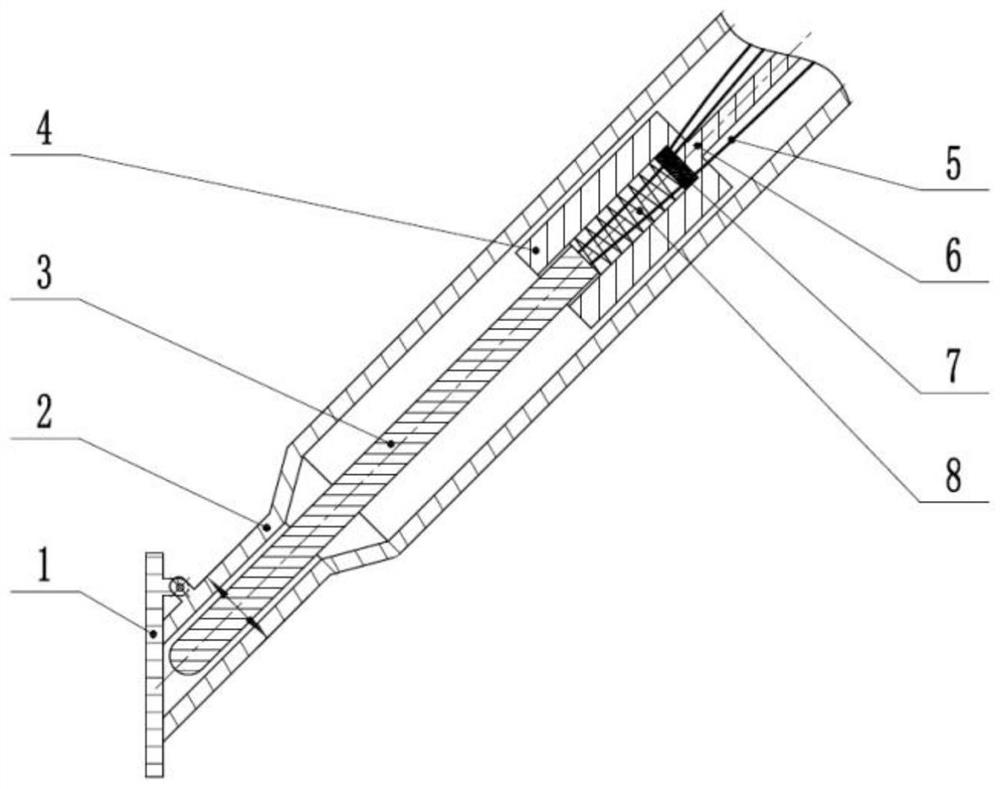

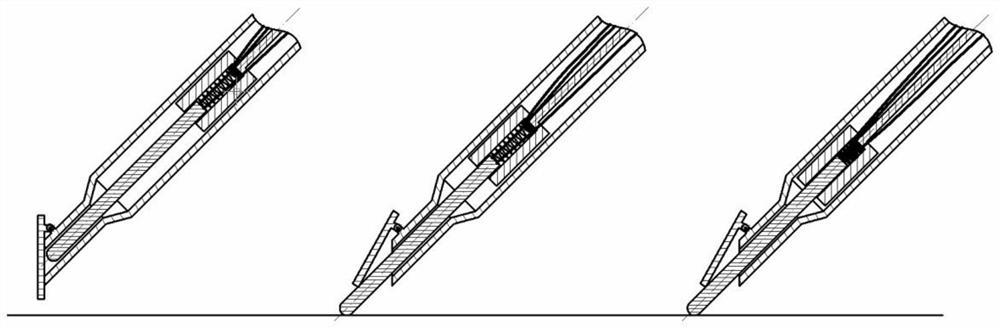

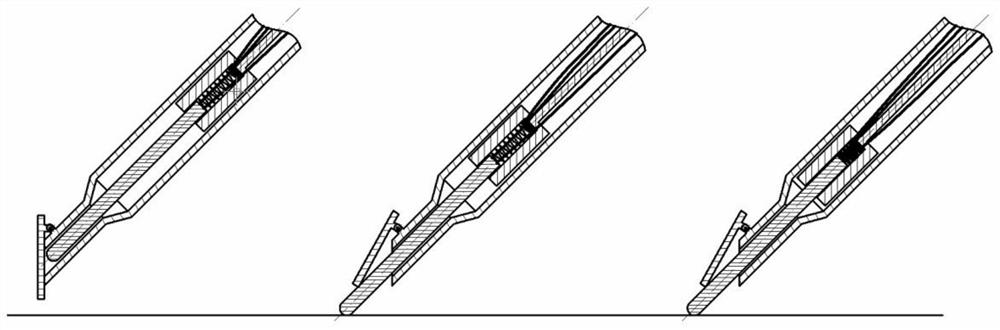

Surface temperature measuring device for electron beam fuse wire additive manufacturing part and measuring method of surface temperature measuring device

ActiveCN112059182AEasy to detectAvoid pollutionAdditive manufacturing apparatusIncreasing energy efficiencyThermocoupleElectron bunches

The invention discloses a surface temperature measuring device for an electron beam fuse wire additive manufacturing part and a measuring method of the surface temperature measuring device. The surface temperature of the formed part can be detected more simply and conveniently, so that the measuring operation is prevented from being influenced by splashing, stacking height and the movement of a workbench during a surface temperature measuring process. The measuring method is contact type temperature measurement, and the temperature of the forming surface can be measured; a metal steam protection baffle can prevent metal steam from polluting a temperature measuring couple and prevent metal steam from polluting a baffle hinge, so that the device can be effective for a long time; a spring anda pressure-sensitive element are fed into the temperature measuring couple, so that hard collision between a thermocouple and a formed base body is effectively prevented, the service life is prolonged, and control means are increased; and the device can control a forming temperature field to tend to be consistent together with a machining program, so that the forming process is more stable, and the forming appearance quality and the internal structure and performance are greatly improved.

Owner:浙江智熔增材制造技术有限公司

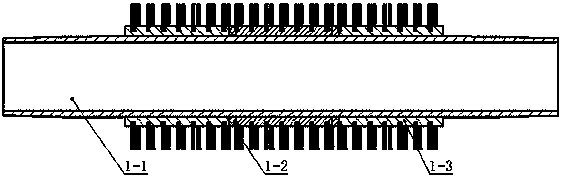

Annulus flow control nipple of oil and gas well and application method thereof

The invention discloses an annulus flow control nipple of an oil and gas well and an application method thereof, and belongs to the field of downhole process pipe string tools of oil and gas wells. Aannulus flow control nipple tool is formed by arranging a brush bristle layer outside a conventional nipple; during using, depending on an annulus flow control unit (set) formed by a brush bristle ring of the annulus flow control nipple in a pipe string annulus, a semi-permeable blocking ring section is formed in the downhole, the functions of packing, blocking and filtering are provided for different production purposes, the new solution for controlling the annulus fluid state is provided for flow control sand prevention, fracturing construction and enhanced perforation construction of a production well, and the purposes of solving corresponding production and construction are achieved. According to the annulus flow control nipple tool of the oil and gas well and the application method thereof, operation is easy, convenient and fast, construction is easy, the cost is lowered advantageously, and power consumption is reduced advantageously.

Owner:刘向京

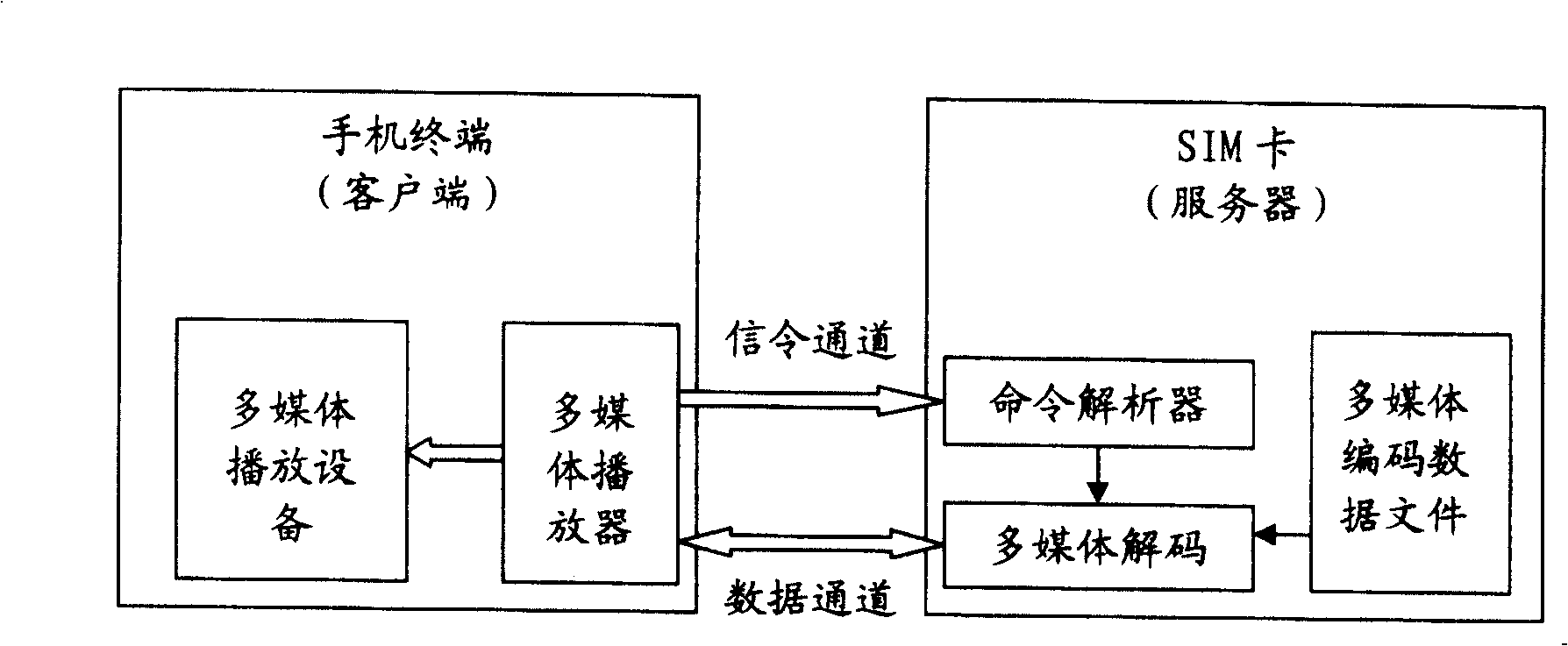

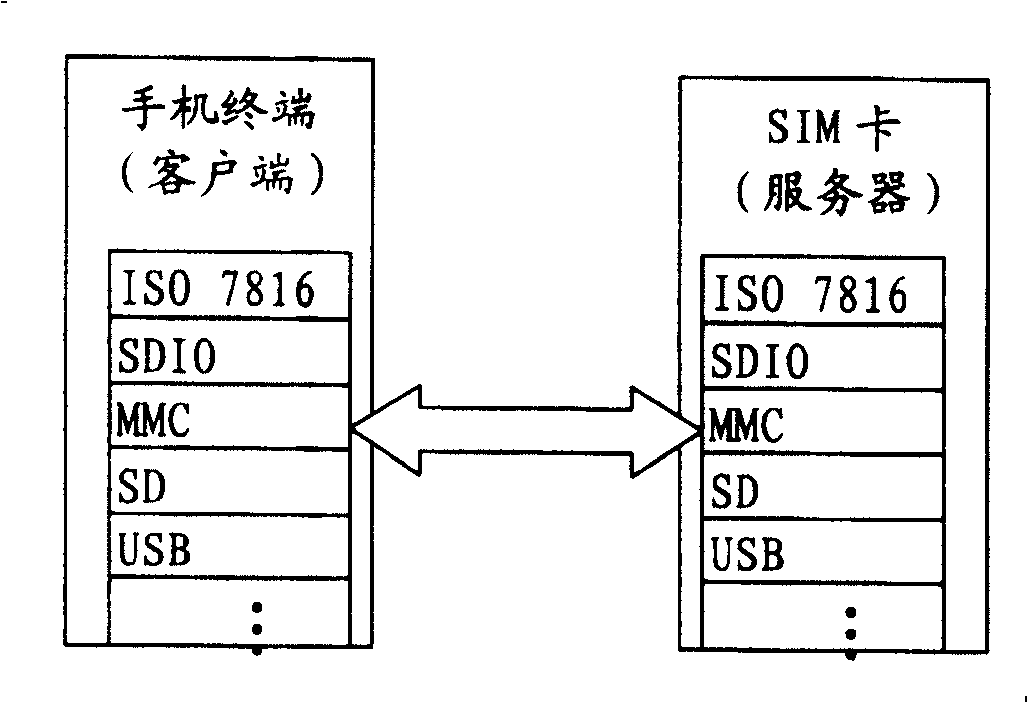

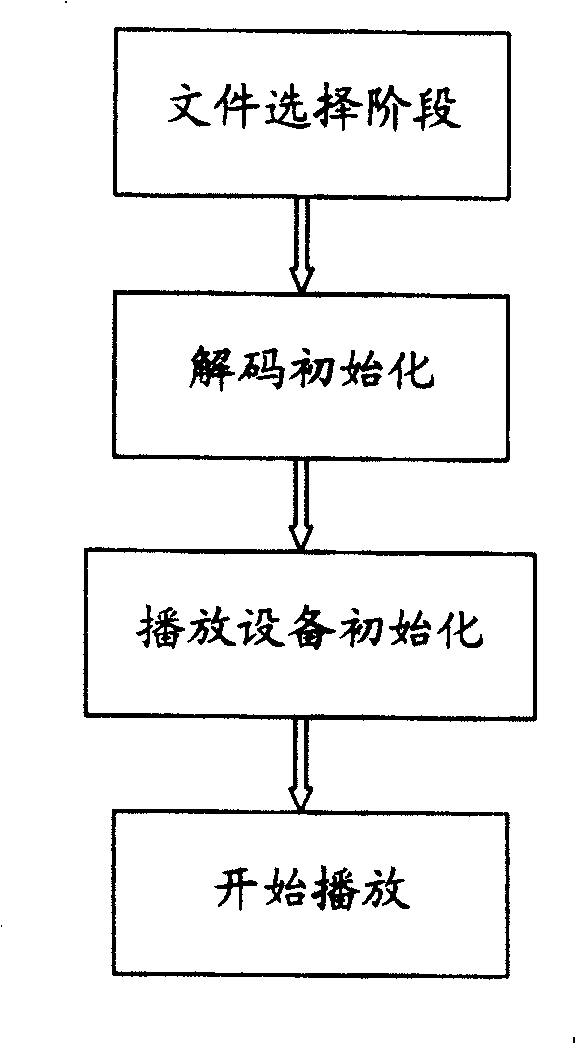

Method and system for realizing multimedia playing on cell phone terminal via SIM card

ActiveCN100425097CIncreased means of controlImprove controlSubstation equipmentRadio/inductive link selection arrangementsControl signalSmart card

A method for realizing multimedia play at mobile phone terminal through SIM card utilizes mobile phone terminal to realize display and play and utilizes SIM card to realize decoding function. The system with signaling channel for transmitting multimedia play control signal and data channel for transmitting large capacity of data at high speed between mobile phone terminal and SIM card is also disclosed.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

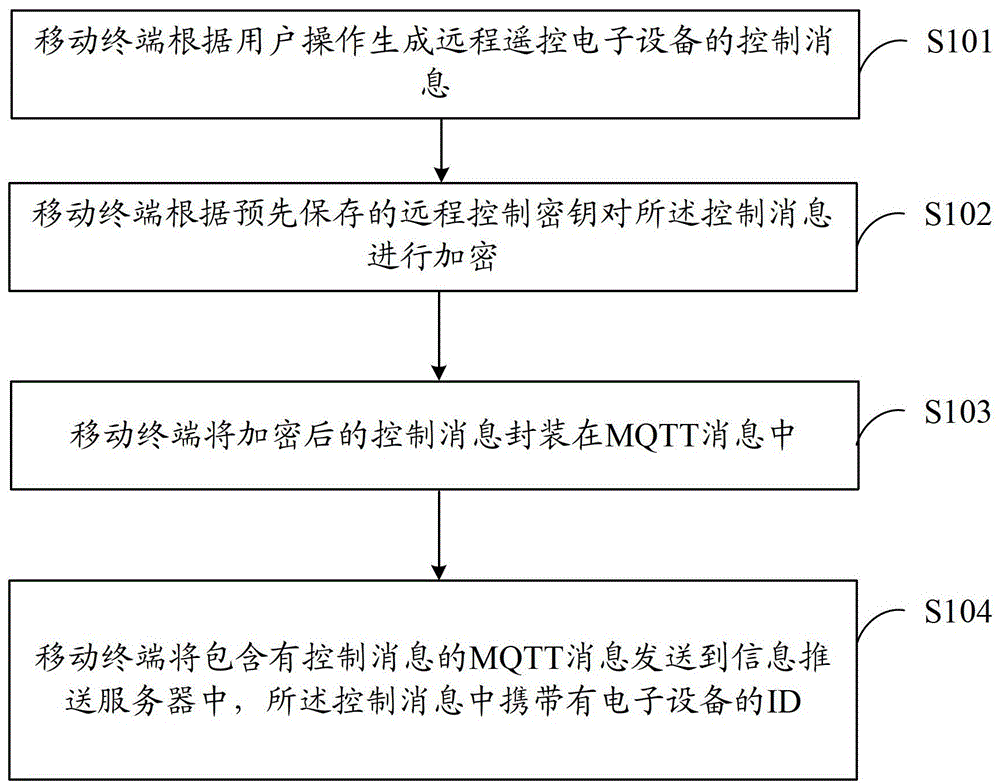

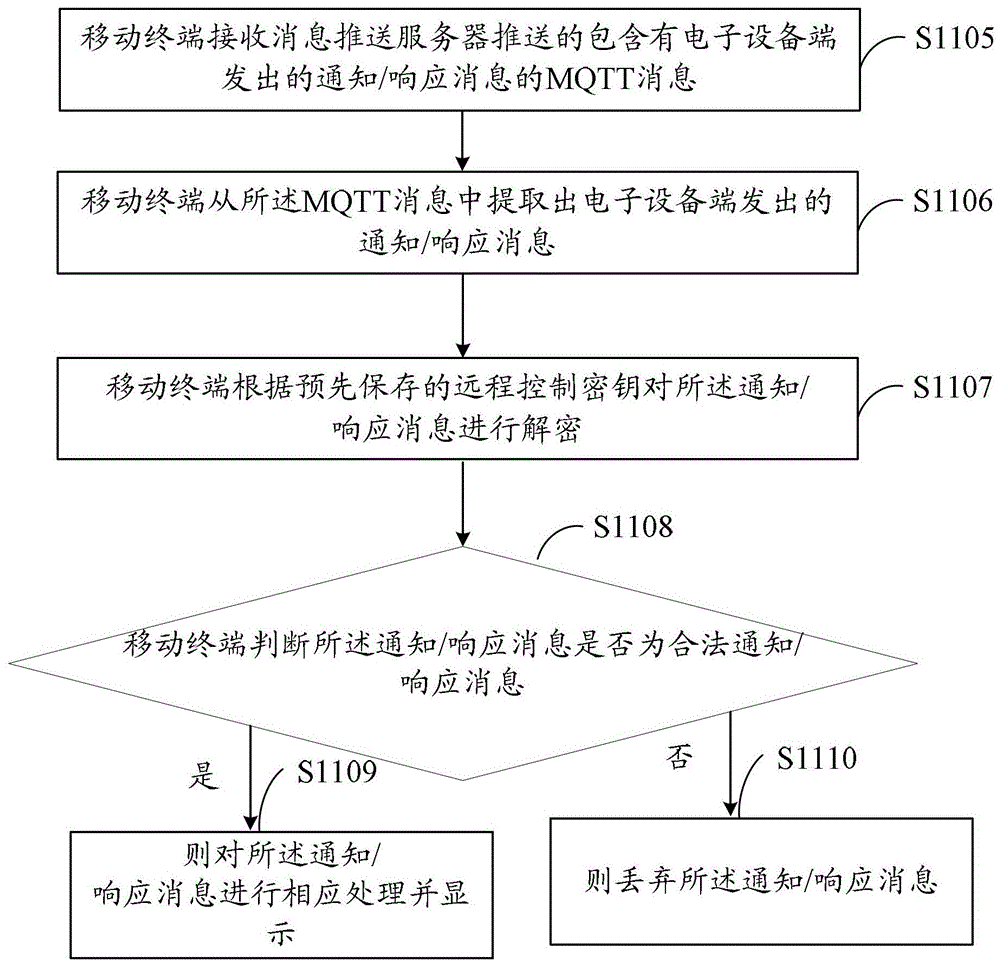

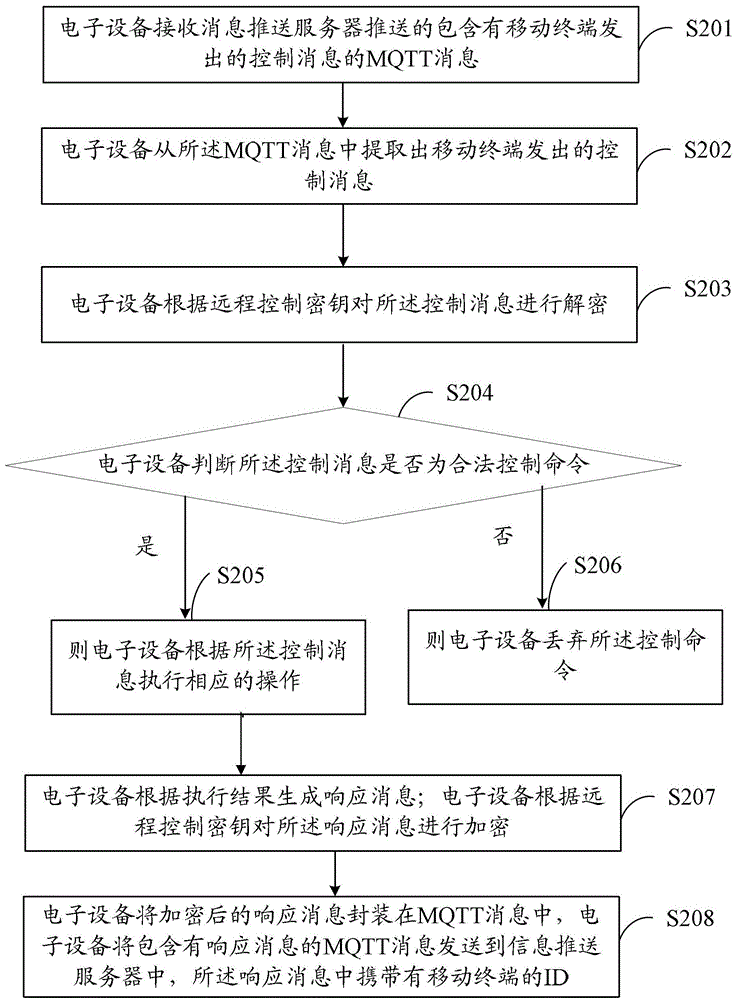

Method and system for remote control of electronic equipment, mobile terminal, and electronic equipment

ActiveCN103079176BReduce overheadReduce power consumptionMessaging/mailboxes/announcementsSecurity arrangementRemote controlComputer terminal

Owner:TCL CORPORATION

A method for iron ore tunnel kiln magnetization roasting layered distribution reduction method

The invention discloses an iron ore tunnel kiln magnetizing roasting layering material distributing reduction method. Iron ore is divided into different granularity degrees according to the granularity range; the reduction coal is flatly laid in the bottom of a tunnel kiln car according to the proportion that the reduction coal accounts for 4-6% of the total weight of iron ore; the iron ore of various granularity degrees is laid at the upper portion of the reduction coal of the tunnel kiln car, and the granularity range of each layer of iron ore is gradually increased from the bottom layer to the top layer in a layer-by-layer manner; facing materials are flatly laid at the upper portion of iron ore of various granularity degrees of the tunnel kiln car; the tunnel kiln car loaded with materials is pushed into a tunnel kiln for magnetizing roasting; and after magnetizing roasting is finished, the tunnel kiln car loaded with the materials is pushed out of the tunnel kiln. According to the method, over reduction of iron ore can be effectively prevented, the control means of iron ore magnetizing roasting is improved, and the surplus carbon recycling and utilizing cost is low. In addition, the mixing technology of iron ore and a reducing agent before magnetizing roasting of the iron ore tunnel kiln is reduced or eliminated, and the production cost of the roasted ore is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

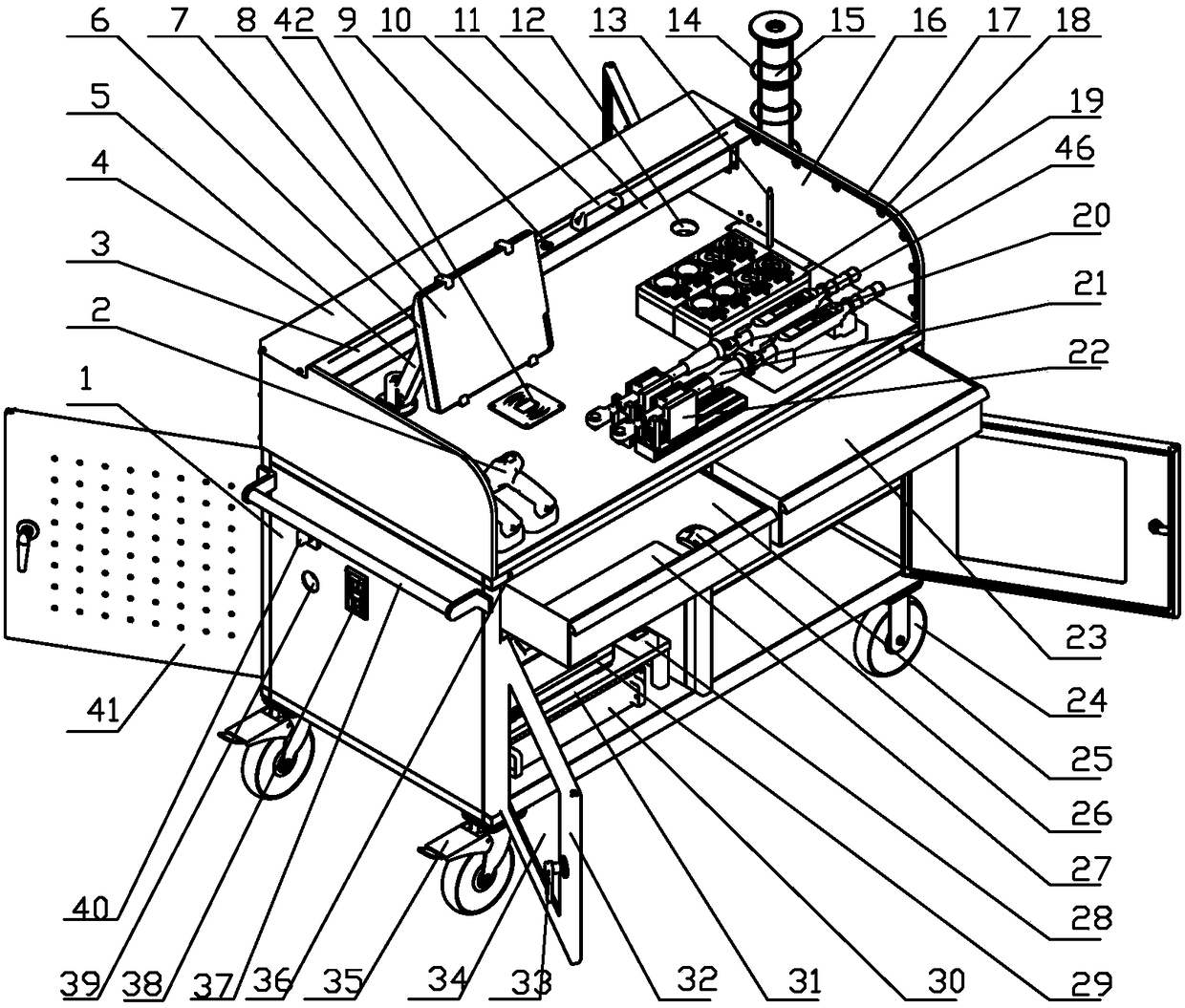

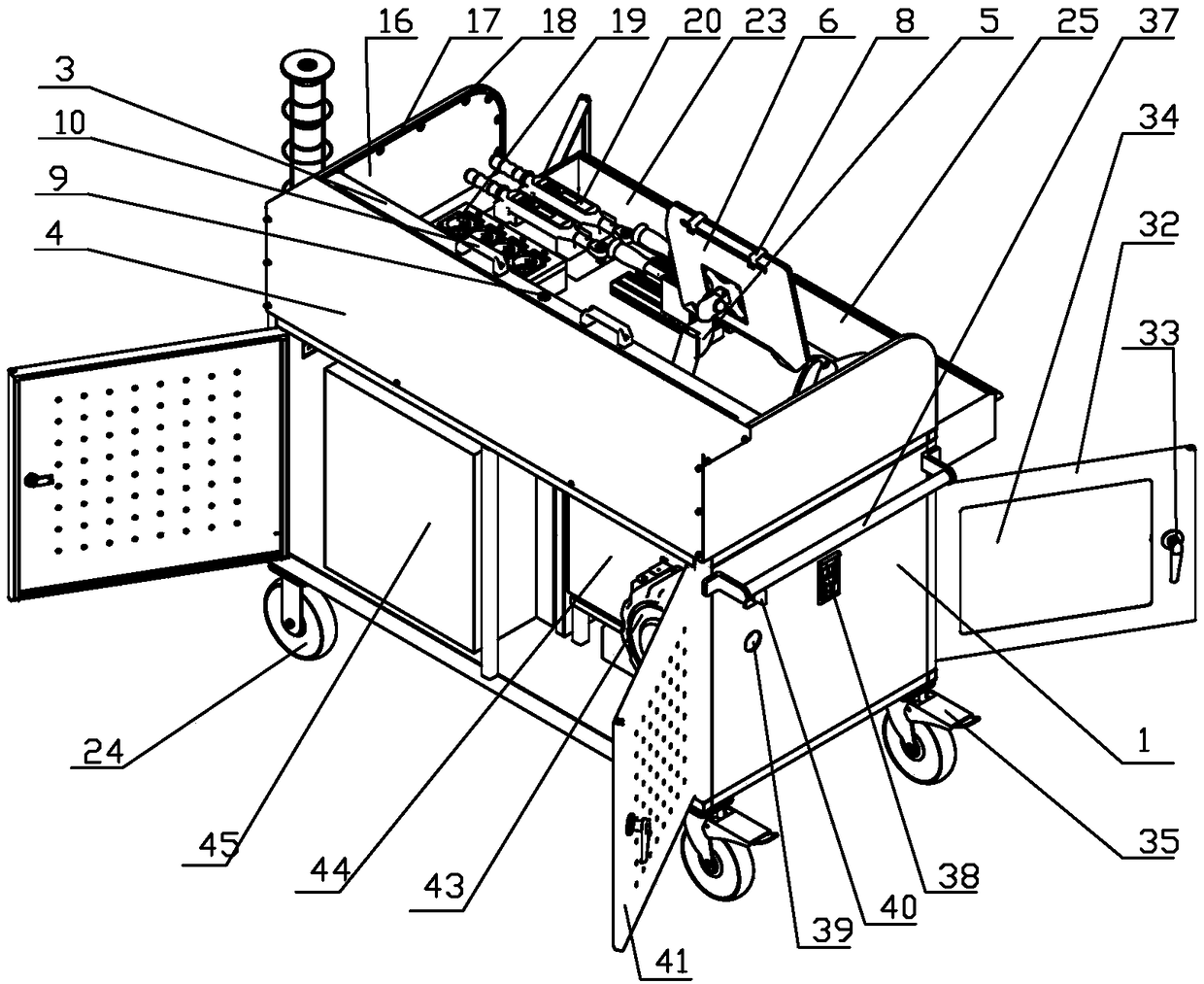

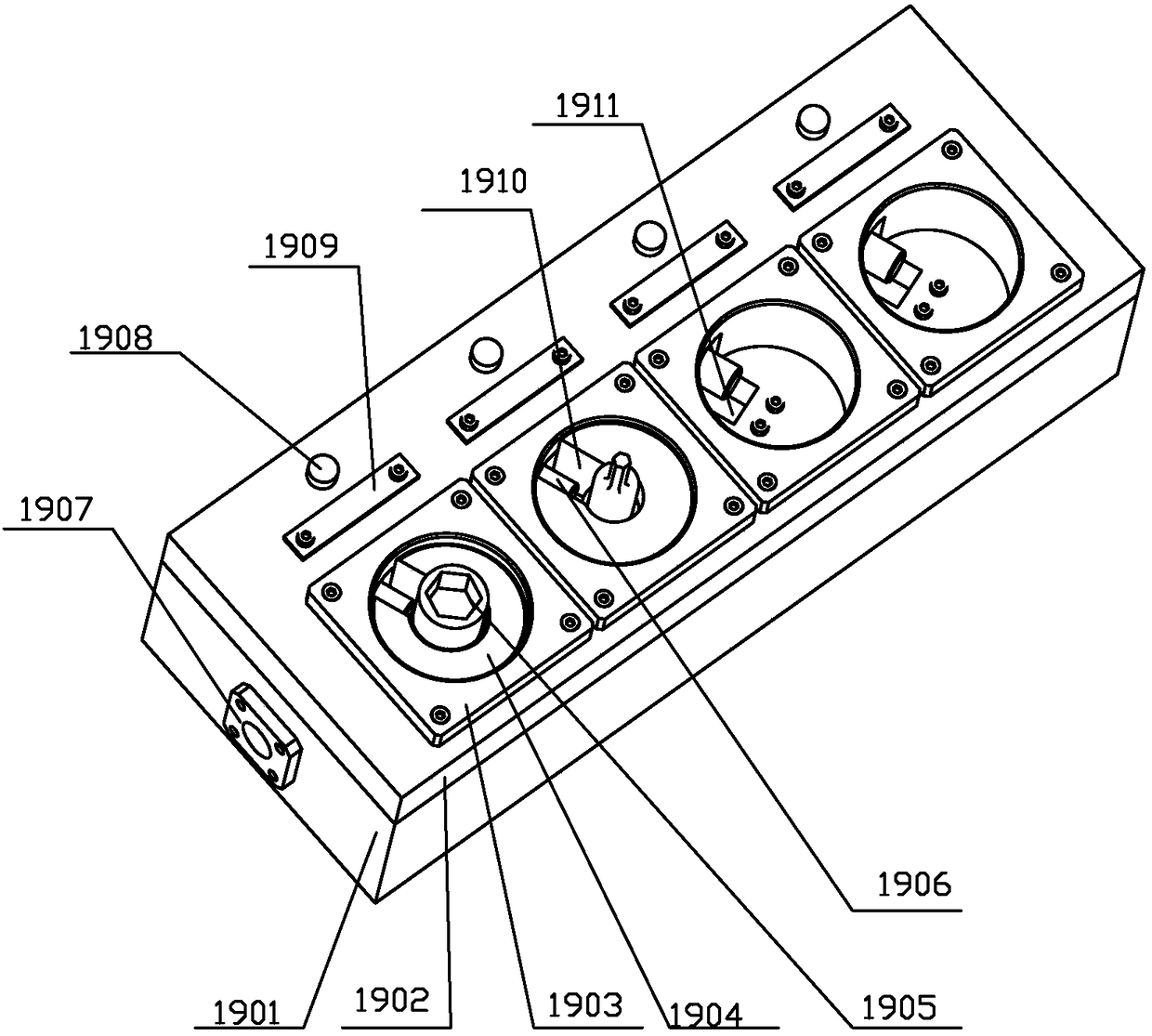

Intelligent assembly and maintenance work vehicle for high-speed EMU

ActiveCN106041865BRealize retrospective queryReduce labor intensitySpannersWrenchesCard readerUninterruptible power supply

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

Boiler control device and method

PendingCN114110648AIncreased means of controlSolve pollutionCombustion technology mitigationNon-combustible gases/liquids supplyTemperature controlCombustion chamber

The invention discloses a boiler control device and method, and relates to the field of boiler control. Fuel characteristics of the boiler and heat exchange characteristics of the hearth are coupled, the temperature of the combustion chamber of the boiler is controlled by adjusting the amount of fly ash fed into the hearth, and the combustion condition of fuel and the generation condition of nitric oxide are further controlled; the problems that the temperature of a combustion chamber deviates from a design value, fuel combustion is insufficient, boiler overtemperature coking is caused, and the generation amount of thermal nitrogen oxides is too high due to design errors, deviation of in-furnace fuel characteristics from the design value, boiler load changes and the like of a traditional boiler are solved. According to the invention, a boiler combustion chamber temperature control means is added, so that the combustion condition of the boiler can be improved, the emission of nitrogen oxides of the boiler can be controlled, the boiler efficiency can be improved, the coking risk of the boiler can be reduced, and the emission of pollutants can be reduced.

Owner:成都海泰科欣远节能科技有限公司 +1

A method and device for controlling emotions

ActiveCN104939810BReduce processHigh precisionSpeech analysisCatheterVocal intensityComputer science

The invention provides a method and device for controlling emotion. The method comprises the steps that 1, pulse frequency is acquired; 2, when a value of the pulse frequency is larger than a preset frequency value, acoustic information is acquired; 3, the acoustic intensity and beat speed in the acoustic information are detected; 4, whether a user is in an emotion-uncontrolled state or not is judged according to the acoustic intensity and beat speed; 5, when the user is in the emotion-uncontrolled state, acoustic information acquisition is stopped, and a preset audio is played. In this way, the problems that the emotion-uncontrolled state is automatically detected and emotion control is automatically performed according to the state are solved.

Owner:PHICOMM (SHANGHAI) CO LTD

Surface temperature measuring device and method for electronic beam fuse additive manufacturing parts

ActiveCN112059182BEasy to detectAvoid pollutionAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringThermocouple device

The surface temperature measuring device and its measuring method for electron beam fuse additive manufacturing parts described in the present invention can detect the surface temperature of formed parts more simply and conveniently, so as to avoid splashing and stacking height when measuring the surface temperature. , the influence of workbench movement; The measurement method of the present invention is contact temperature measurement, can measure the temperature of forming surface; Metal vapor protection baffle can prevent the pollution of metal vapor to thermocouple, prevent metal vapor from contaminating the baffle at the same time The pollution of the hinge makes the device effective for a long time; the thermocouple is fed with springs and pressure-sensitive components, which can effectively prevent the hard collision between the thermocouple and the forming substrate, prolong the service life and increase the control means; the device can be used together with the processing program to control the forming The temperature field tends to be consistent, making the forming process more stable, and greatly improving the appearance quality, internal structure and performance of the forming.

Owner:浙江智熔增材制造技术有限公司

A co-shift process for methanol synthesis

The invention relates to a CO conversion process for methanol synthesis, which is characterized in that it includes the following steps: the crude gas first enters a low-pressure steam generator to cool down and separates the liquid to adjust the water-gas ratio, and the crude gas after the liquid separation is divided into two streams, About 45% to 55% of one strand is used as non-shifted gas, and the rest is used as the second strand after being heated up, detoxified, and divided again, and then enters the parallel air-cooled shift furnace and isothermal shift furnace for isothermal shift and heat recovery. After that, it is mixed with the first non-shifted gas and used as synthesis gas to control the H in the synthesis gas 2 The molar ratio with CO is controlled at 2.1-2.3. The invention produces medium-pressure saturated steam and low-pressure superheated steam by-products, and the air-cooled shift furnace uses shift gas as a refrigerant; multiple split-share shifts are adopted, the process is short, the size of the shift furnace is small, and there is no risk of overheating. The isothermal shift furnace used The heat exchange area can be adjusted, the pressure fluctuation of the by-product medium pressure steam is small, and the system operation is more stable.

Owner:SINOPEC NINGBO ENG +2

Control method of precipitates and inclusions in twin-roll strip continuous casting of non-oriented silicon steel

The invention belongs to the field of metallurgical technology. Aiming at the problem that there is no suitable control method for precipitates and inclusions in the process of producing non-oriented silicon steel by twin-roller thin strip continuous casting, a twin-roller thin strip continuous casting process of non-oriented silicon steel is proposed. Methods for controlling precipitates and inclusions. The method is to solidify and shape the non-oriented silicon steel molten steel through a double-roller thin strip continuous casting machine, with a cast strip thickness of 2.0 to 2.6mm; after the cast strip comes out of the roll and enters the post-casting secondary cooling section, it is slowly cooled through the slow cooling chamber; Entering the third cooling section, it is quickly cooled immediately; the cast strip that has been quickly cooled in the third cooling section is cooled and then coiled to obtain a non-oriented silicon steel cast strip. Through this method, the AlN precipitates in the cast strip can reach the level of 0.5-2.0 μm, while the MnS precipitation is significantly suppressed, basically eliminating the influence of both on the growth of recrystallized grains and the movement of magnetic domain walls, laying the foundation for the development of high-quality stainless steel. Grain-oriented silicon steel lays the foundation.

Owner:NORTHEASTERN UNIV LIAONING

A system and method for trusted data storage

InactiveCN103927489BHigh strengthIllegal access reductionDigital data protectionPlatform integrity maintainanceControl flowApplication server

The invention discloses a system and method for trusted storage of data. The system mainly comprises four logical entities, namely, a trusted management center, an application server, a storage virtualization security gateway and a rear-end storage system. The trusted management center serves as a configuration and management entity for a trusted strategy. The application server serves as an entity sending a data access request. The storage virtualization security gateway serves as an entity receiving the data request of an application layer and achieving mapping of a virtual port, converting of a virtual storage device address and a physical storage device address and encapsulating of an IO request through the virtualization technology. The rear-end storage system provides a physical medium for data storage and operation. On the basis of the storage virtualization technology, a data access control flow in the trusted technology is provided for the storage virtualization security gateway or an agent layer so that strict security check and control can be carried out on an access request for a storage system, and illegal access or vicious data access operation can be prevented.

Owner:娄绍钢 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com