Surface temperature measuring device for electron beam fuse wire additive manufacturing part and measuring method of surface temperature measuring device

A technology of additive manufacturing and surface temperature, which is applied in the field of additive manufacturing, can solve problems such as the inability to detect the surface temperature to be measured and the increase of measurement data errors, so as to improve the appearance quality of forming, internal structure and performance, prevent hard collision, increase The effect of controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

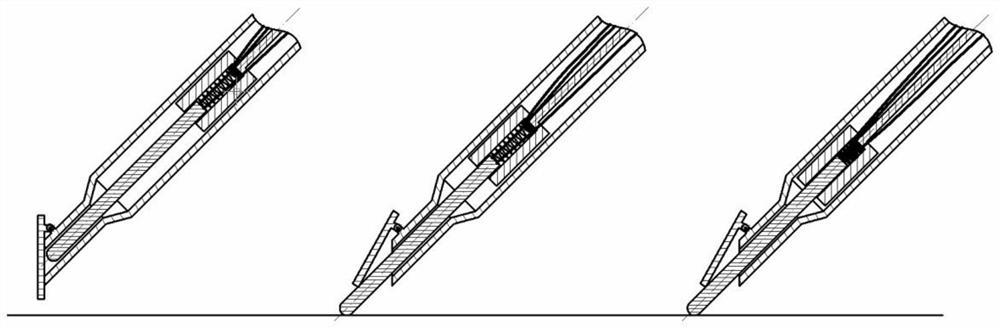

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

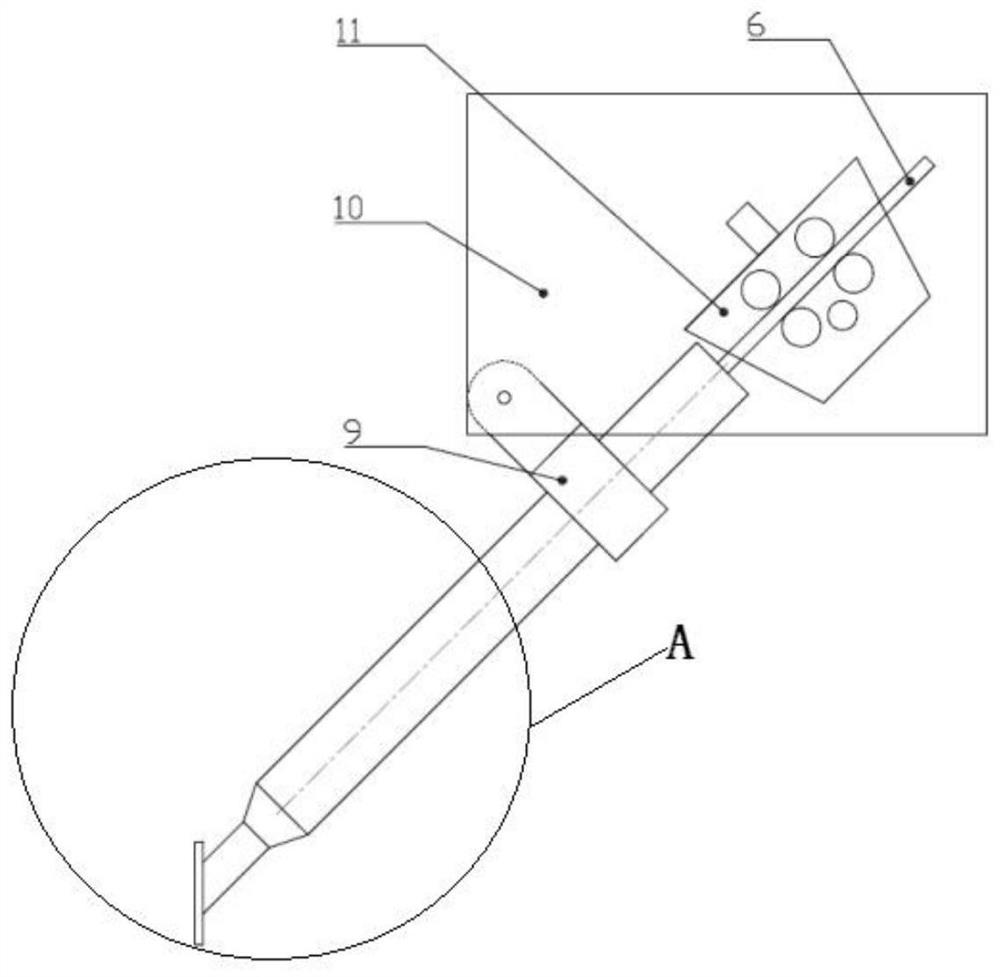

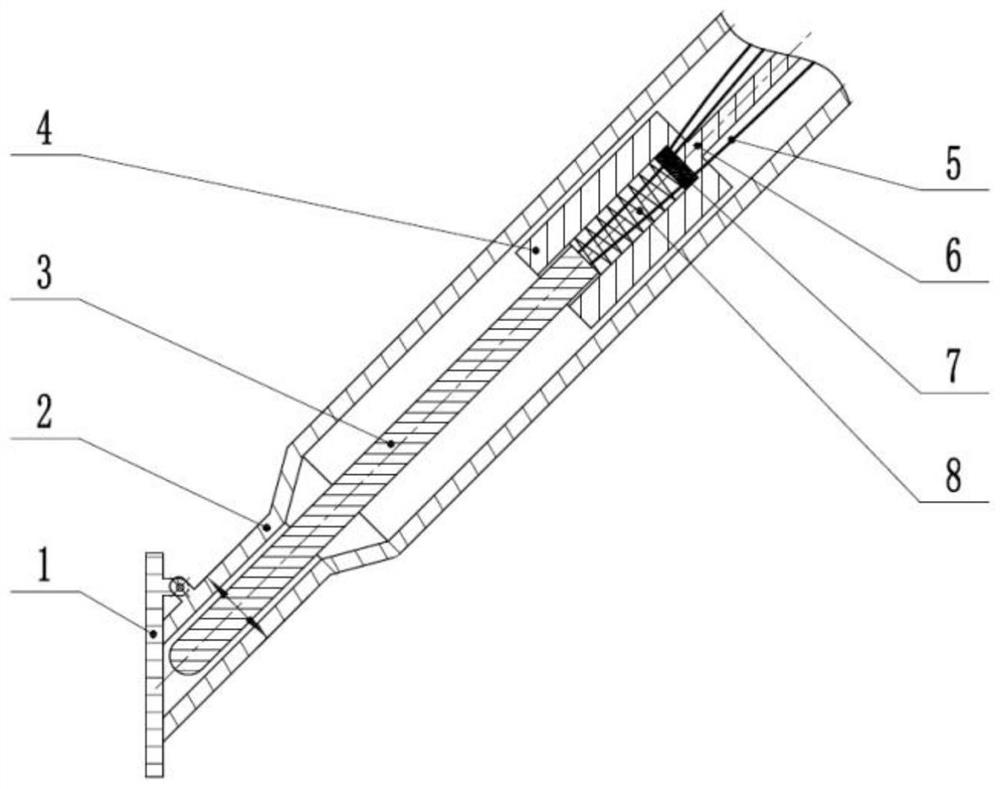

[0014] Such as Figure 1 to Figure 2 As shown, a surface temperature measuring device for electron beam fuse additive manufacturing parts, including metal vapor protection baffle 1, thermocouple guide tube 2, thermocouple 3, spring guide tube 4, wire 5, pressure sensitive sensor bracket 6 , Pressure sensitive sensor 7, spring 8, circular clamp 9, mounting plate 10, wire feeder 11 and controller. The wire feeder 11 is the prior art, and the wire feeder 11 can drive the pressure-sensitive sensor bracket 6 to move forward or backward.

[0015] The metal vapor protection baffle 1 and the circular clamp 9 are respectively arranged at both ends of the thermocouple guide tube 2, the upper part of the metal vapor protection baffle 1 is hinged with the thermocouple guide tube 2, and the lower part of the metal vapor protection baffle 1 Covering on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com