Non-jet normal-pressure thermal plasma generator

A technology of plasma generator and atmospheric pressure heating, which is applied in the field of plasma, can solve the problems of material utilization, processing efficiency and processing effect, unstable operation, and low power limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

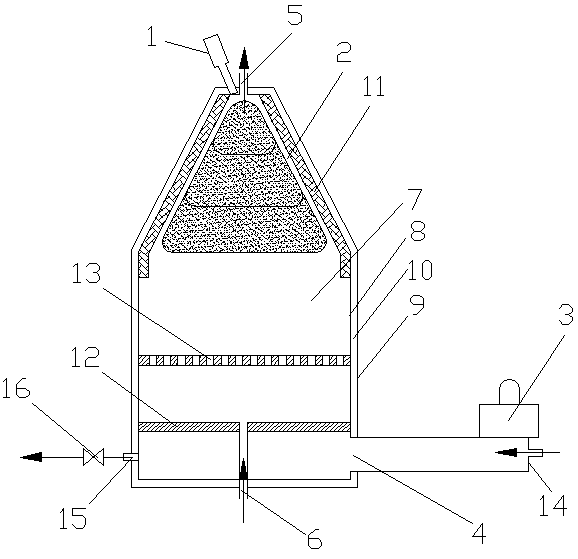

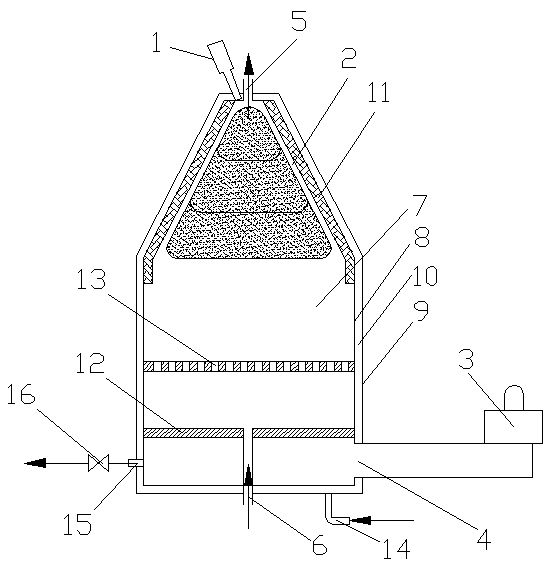

[0041] A non-jet flow atmospheric pressure thermal plasma generator, including an igniter 1 and a microwave source 3, and also includes a reaction chamber, on which a gas channel I5 and a gas channel II6 are opened, and the reaction chamber includes a cylindrical cavity 7 and the tapered chamber 2 located above the cylindrical chamber 7, the tapered chamber 2 communicates with the cylindrical chamber 7, the cylindrical chamber 7 has a microwave feeding port 4, and the microwave source 3 is connected to the microwave feeding port 4 , the igniter 1 is connected to the conical cavity 2 .

[0042] This embodiment is the most basic implementation mode. There are gas channel I and gas channel II on the reaction chamber. The reaction chamber includes a cylindrical chamber and a conical chamber located above the cylindrical chamber. The conical chamber communicates with the cylindrical chamber. , There is a microwave feed port on the cylindrical cavity, the microwave source is connect...

Embodiment 2

[0044] A non-jet flow atmospheric pressure thermal plasma generator, including an igniter 1 and a microwave source 3, and also includes a reaction chamber, on which a gas channel I5 and a gas channel II6 are opened, and the reaction chamber includes a cylindrical cavity 7 and the tapered chamber 2 located above the cylindrical chamber 7, the tapered chamber 2 communicates with the cylindrical chamber 7, the cylindrical chamber 7 has a microwave feeding port 4, and the microwave source 3 is connected to the microwave feeding port 4 , the igniter 1 is connected to the conical cavity 2 .

[0045] The reaction chamber is a double-layer metal structure, including an inner chamber 8 and an outer chamber 9, and an interlayer 10 for introducing a fluid medium is formed between the inner chamber 8 and the outer chamber 9.

[0046] The inner wall of the inner cavity body 8 of the tapered cavity 2 is lined with a thermal insulation layer 11, and the thickness of the thermal insulation la...

Embodiment 3

[0051] A non-jet flow atmospheric pressure thermal plasma generator, including an igniter 1 and a microwave source 3, and also includes a reaction chamber, on which a gas channel I5 and a gas channel II6 are opened, and the reaction chamber includes a cylindrical cavity 7 and the tapered chamber 2 located above the cylindrical chamber 7, the tapered chamber 2 communicates with the cylindrical chamber 7, the cylindrical chamber 7 has a microwave feeding port 4, and the microwave source 3 is connected to the microwave feeding port 4 , the igniter 1 is connected to the conical cavity 2 .

[0052] The reaction chamber is a double-layer metal structure, including an inner chamber 8 and an outer chamber 9, and an interlayer 10 for introducing a fluid medium is formed between the inner chamber 8 and the outer chamber 9.

[0053] The inner wall of the inner cavity body 8 of the tapered cavity 2 is lined with a thermal insulation layer 11, and the thickness of the thermal insulation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com