Autothermal reforming device for producing hydrogen from natural gas

A technology of autothermal reforming and natural gas, applied in hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems of unsuitability and bulky reactor, and achieve the effects of reducing heat energy loss, safe and reliable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

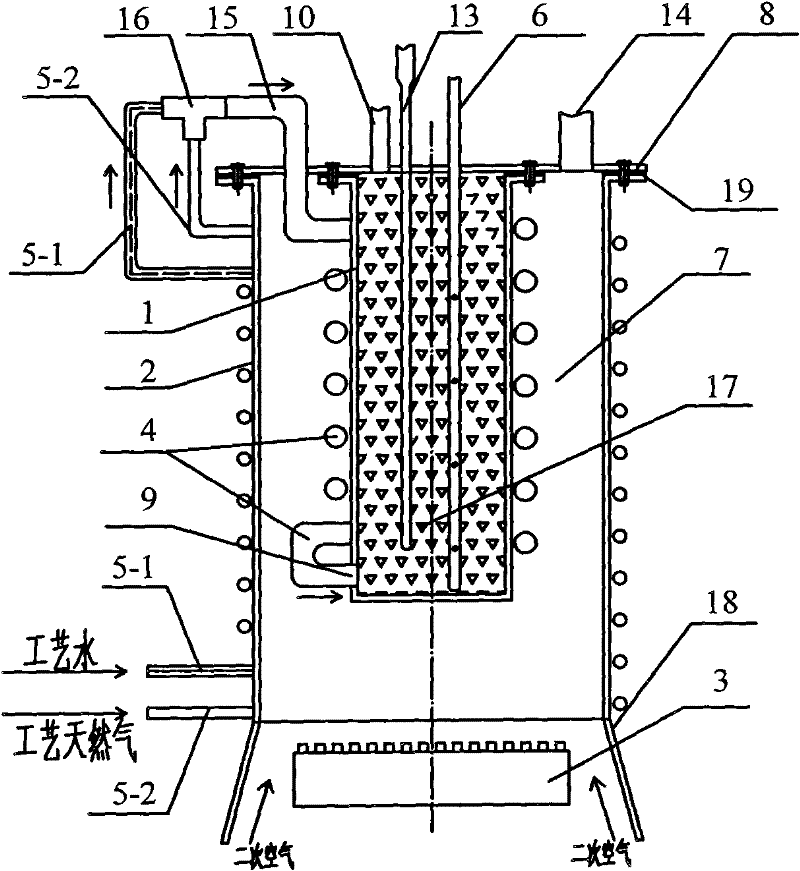

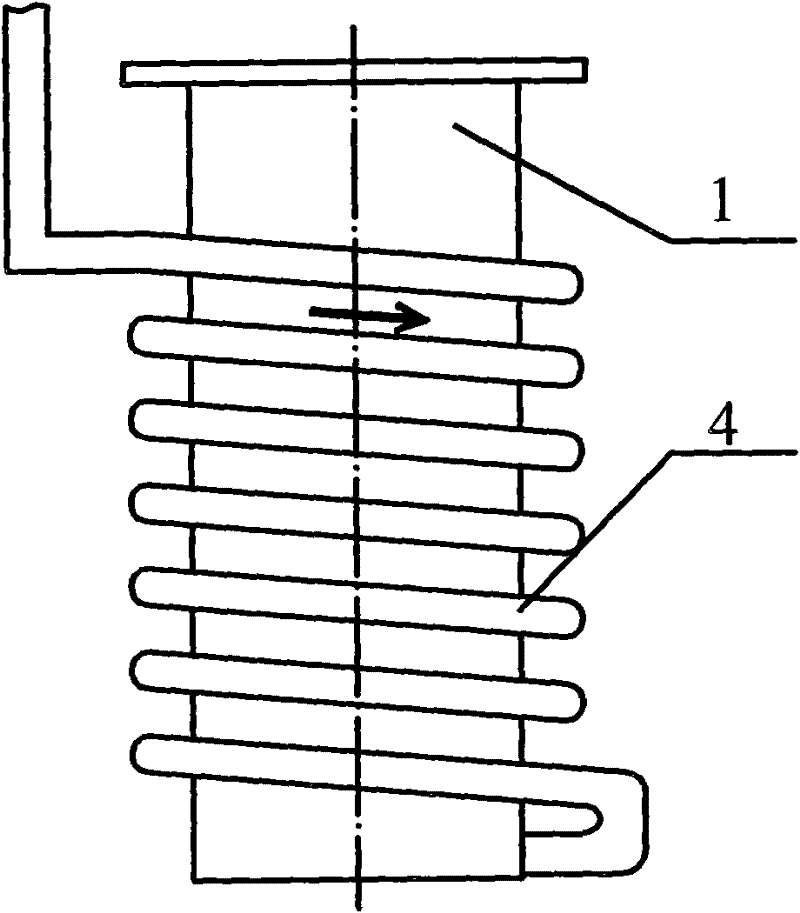

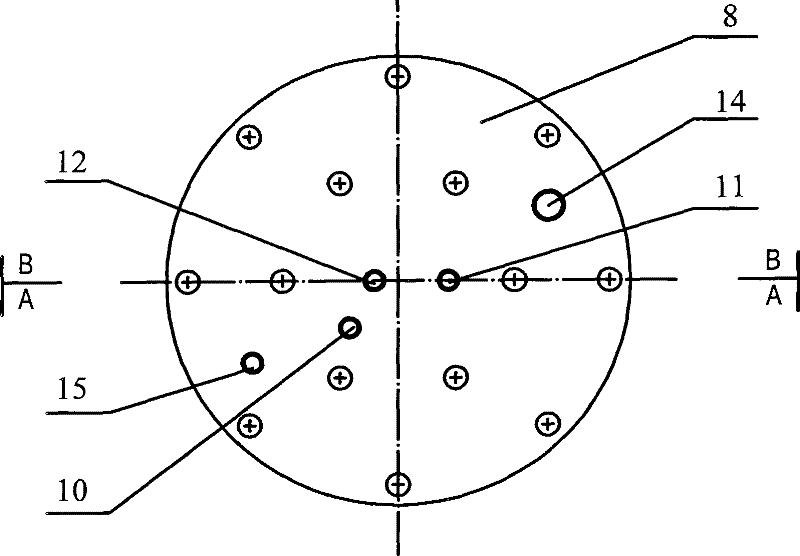

[0036] like figure 1 , 2 , 3, and 5, a device for producing hydrogen by autothermal reforming of natural gas, including an autothermal reforming reactor, an outer wall of a combustion chamber 2, a burner 3, an inner heat exchange coil 4, an outer heat exchange coil, and a combustion Exhaust gas outlet 14, flange 8 and mixing valve 16; the outer wall of the combustion chamber 2 is a hollow circular tube, and the hollow circular tube is equipped with a self-heating reforming reactor; the external heat exchange coil includes a natural gas heat exchange tube 5-1 and a water heat exchange tube The tubes 5-2 are all spirally wound outside the outer wall 2 of the combustion chamber from bottom to top, and are used for preheating natural gas and water; the number of winding turns of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com