A device for providing high-temperature pressing combined effect

A comprehensive, high-temperature technology, applied in the field of strain testing, can solve problems such as the inability to meet the needs of large-area thin-walled test pieces, and achieve the effects of simple and reliable temperature conditions, high safety, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

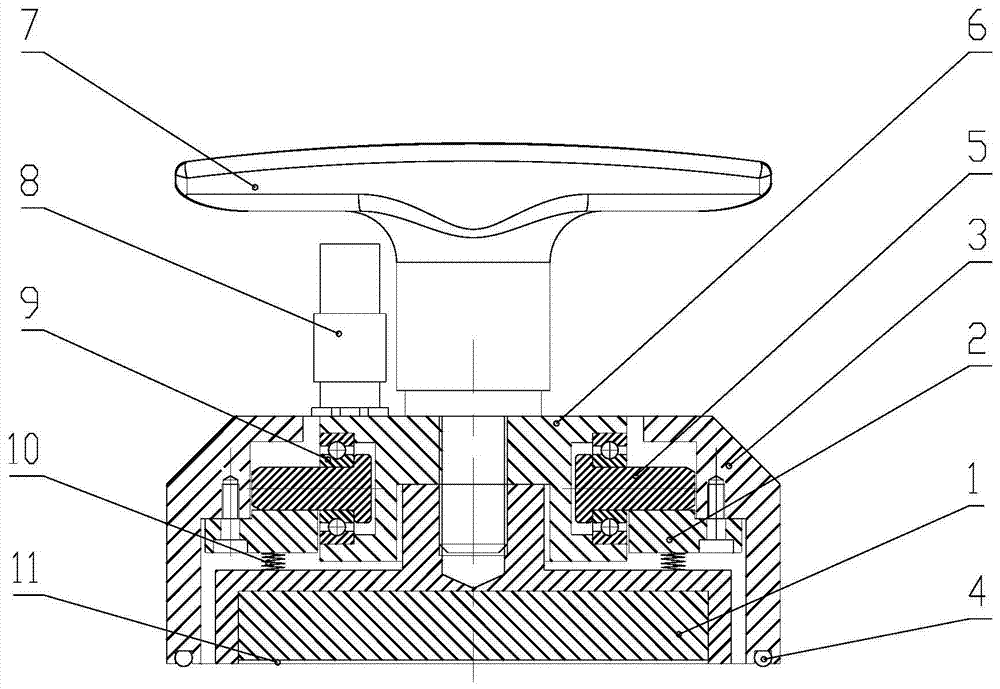

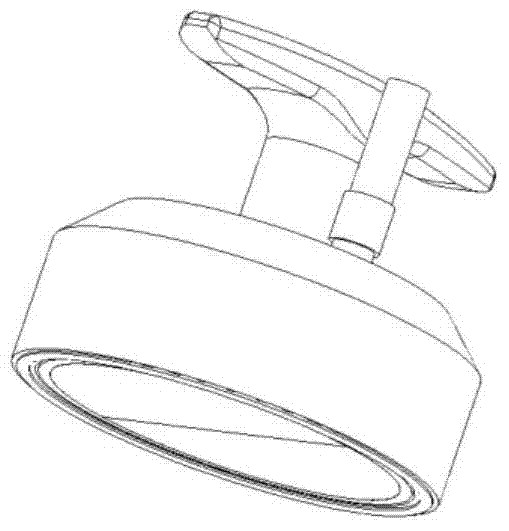

[0032] A device for providing high-temperature press-bonding comprehensive effects of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments:

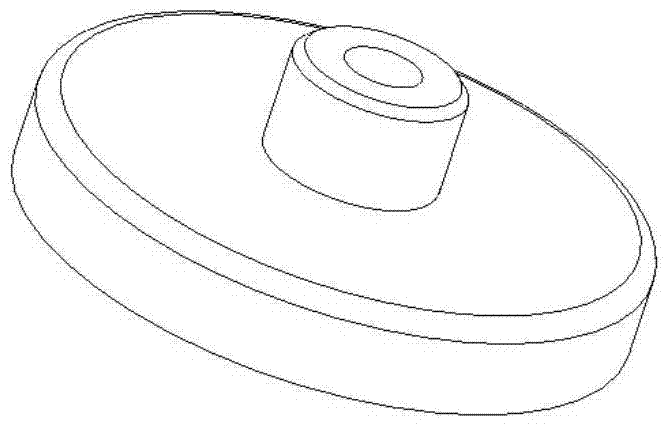

[0033] Such as Figure 1-9 As shown in the figure, a device that provides high-temperature lamination comprehensive function includes a cylindrical magnet 1, a cam slide rail 2, a casing 3, a flexible rubber ring 4, a rolling pin 5, a transition bushing 6, a rotary handle 7, an aviation plug 8, Ball bearing 9, spring 10 and electric heating plate 11. Among them, the casing 3 is an inverted cylinder, with a through hole at its top, a stepped hole on its inner side, four threaded holes at the step, and a circumferential rectangular groove on the bottom end surface. The surface is marked with the words "0", "1", "2", "In" and "Out". The cam slide rail 2 is a round tube with a step. The steps are provided with four through holes along the circumference. The positions of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com