Patents

Literature

92results about How to "Stable pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

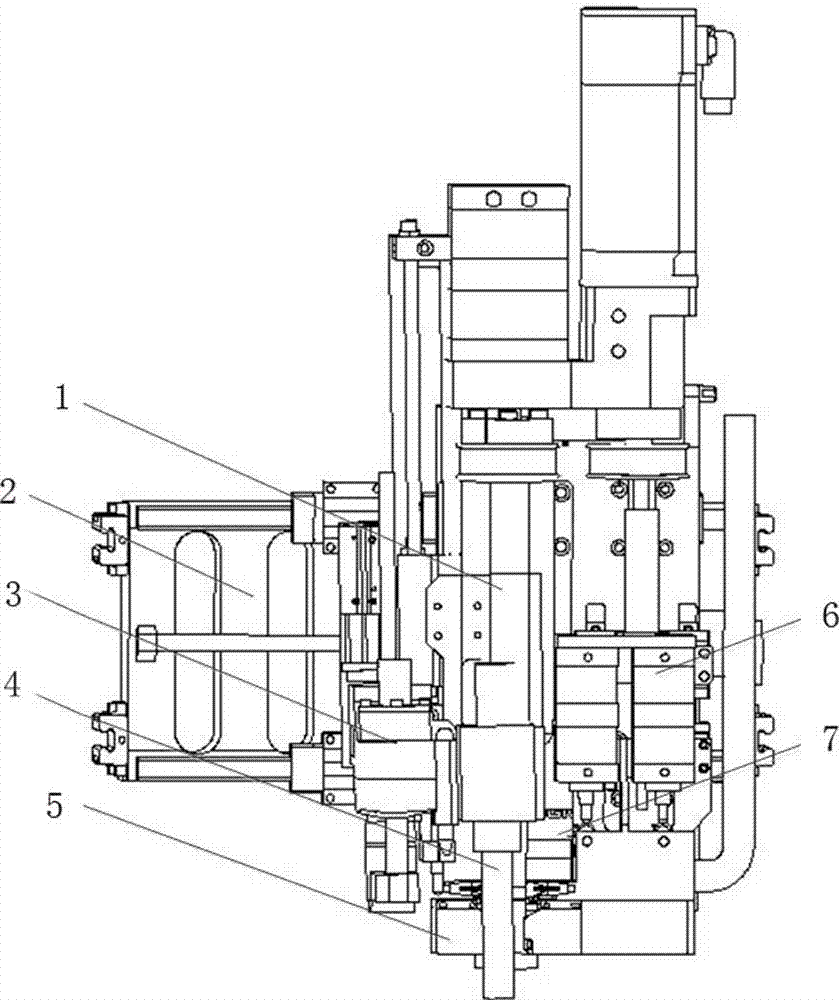

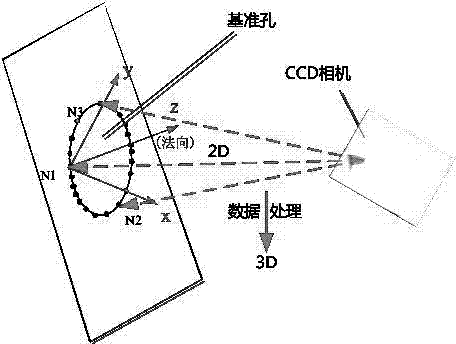

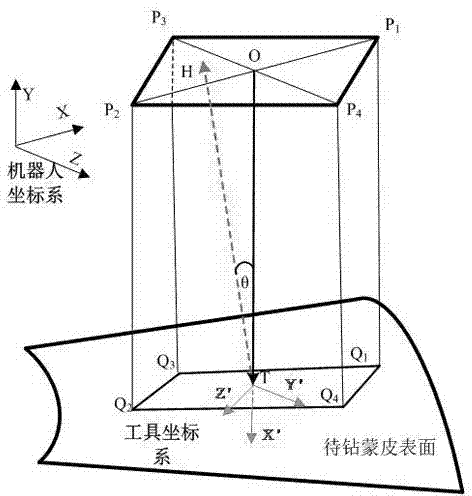

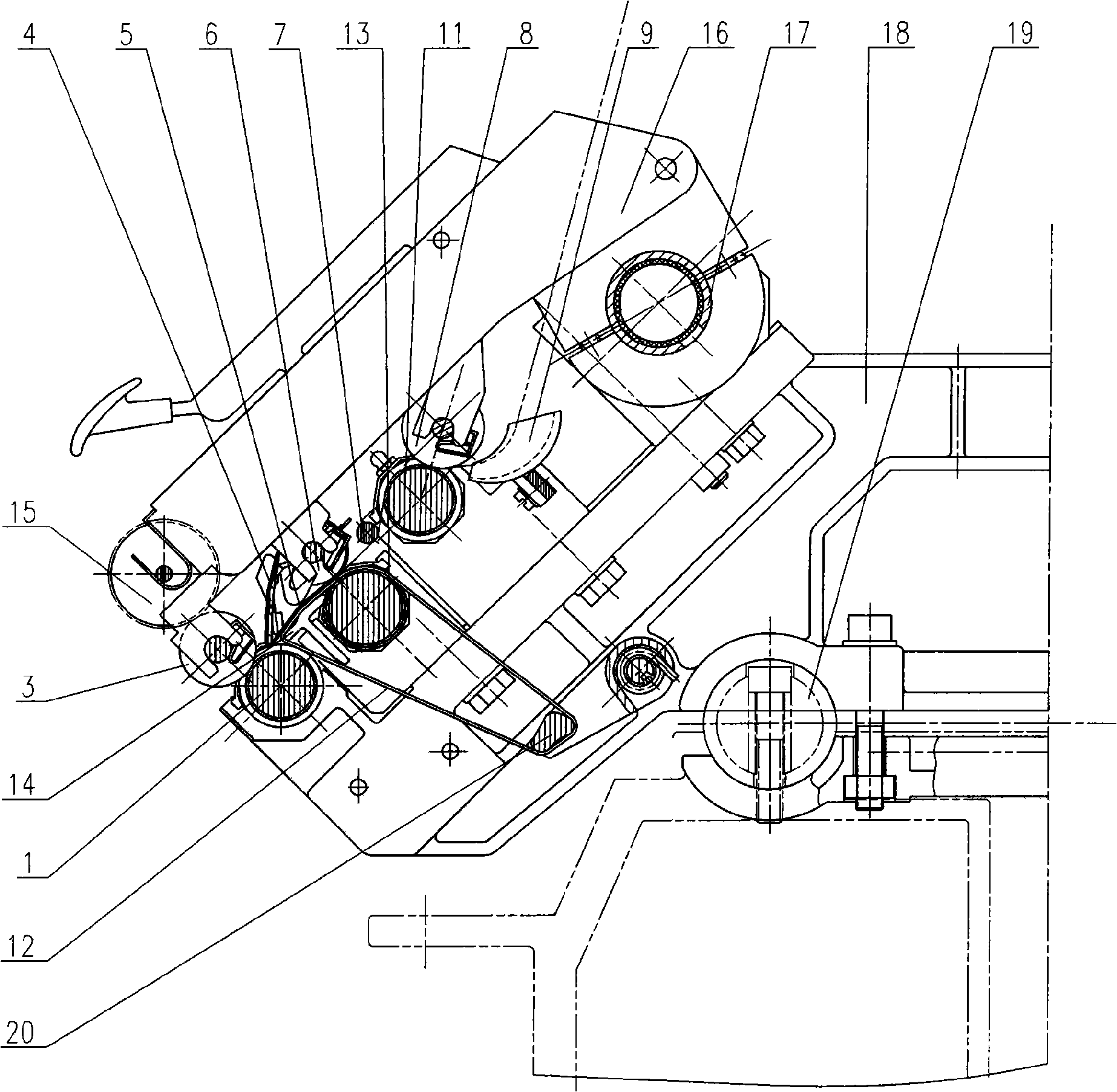

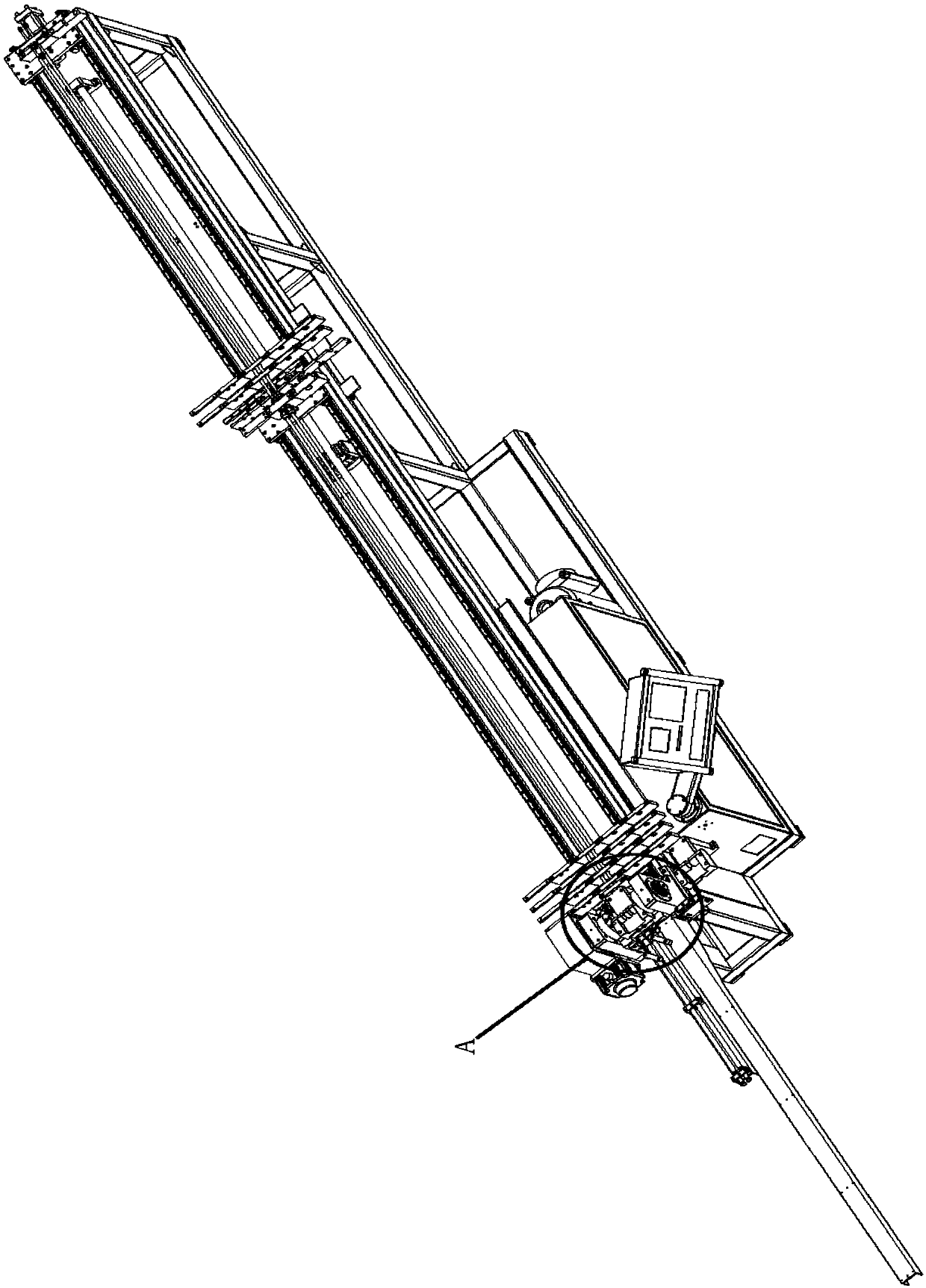

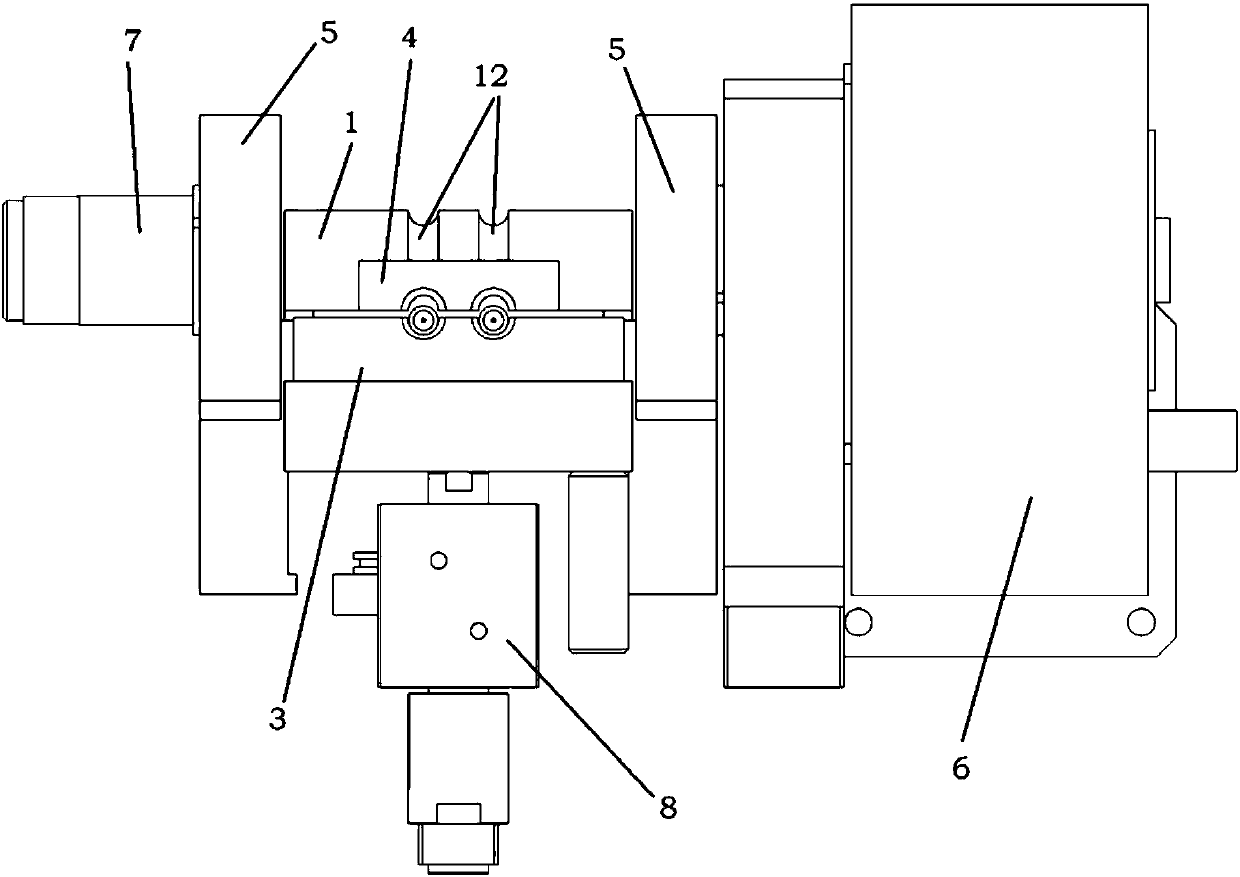

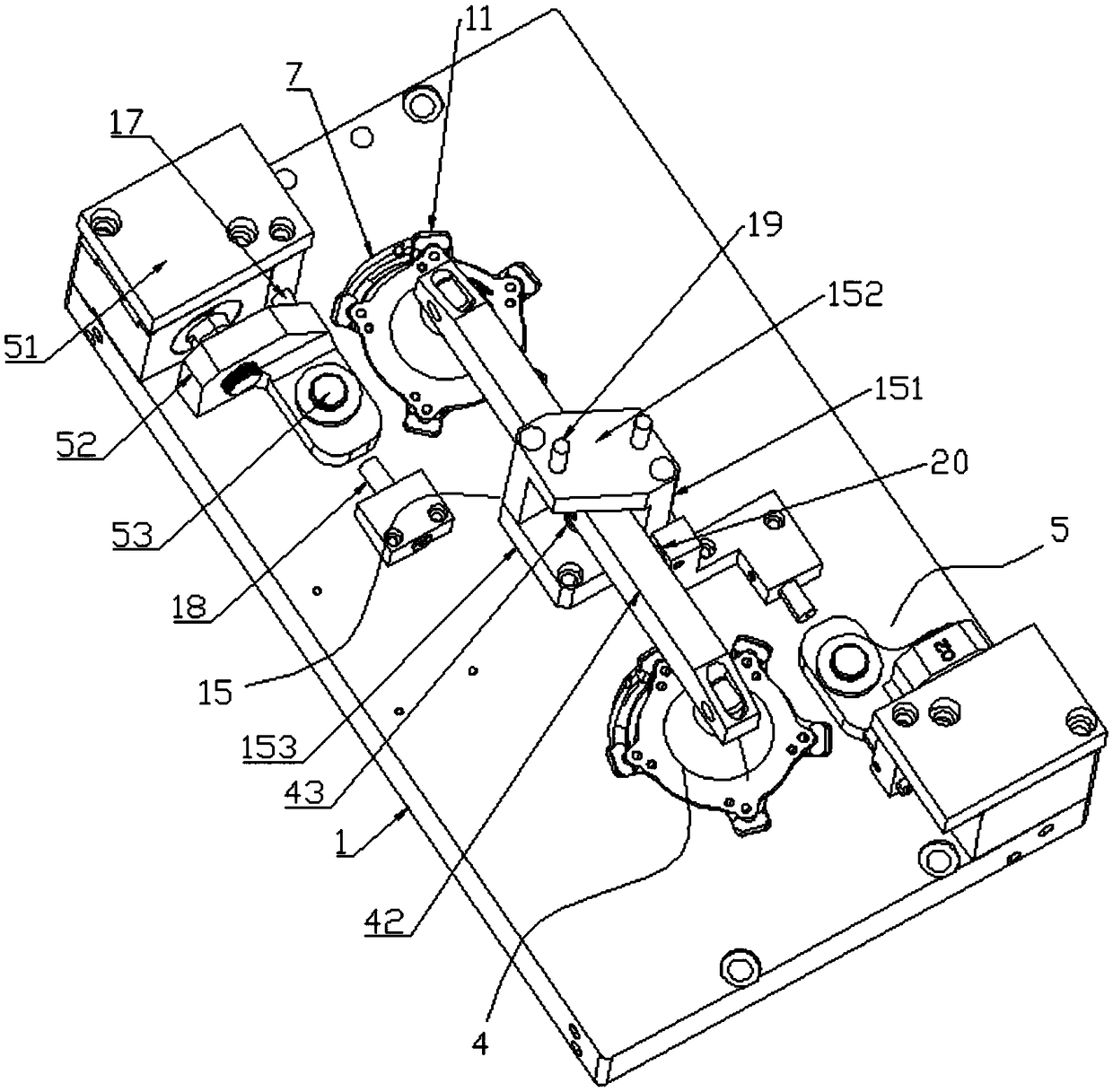

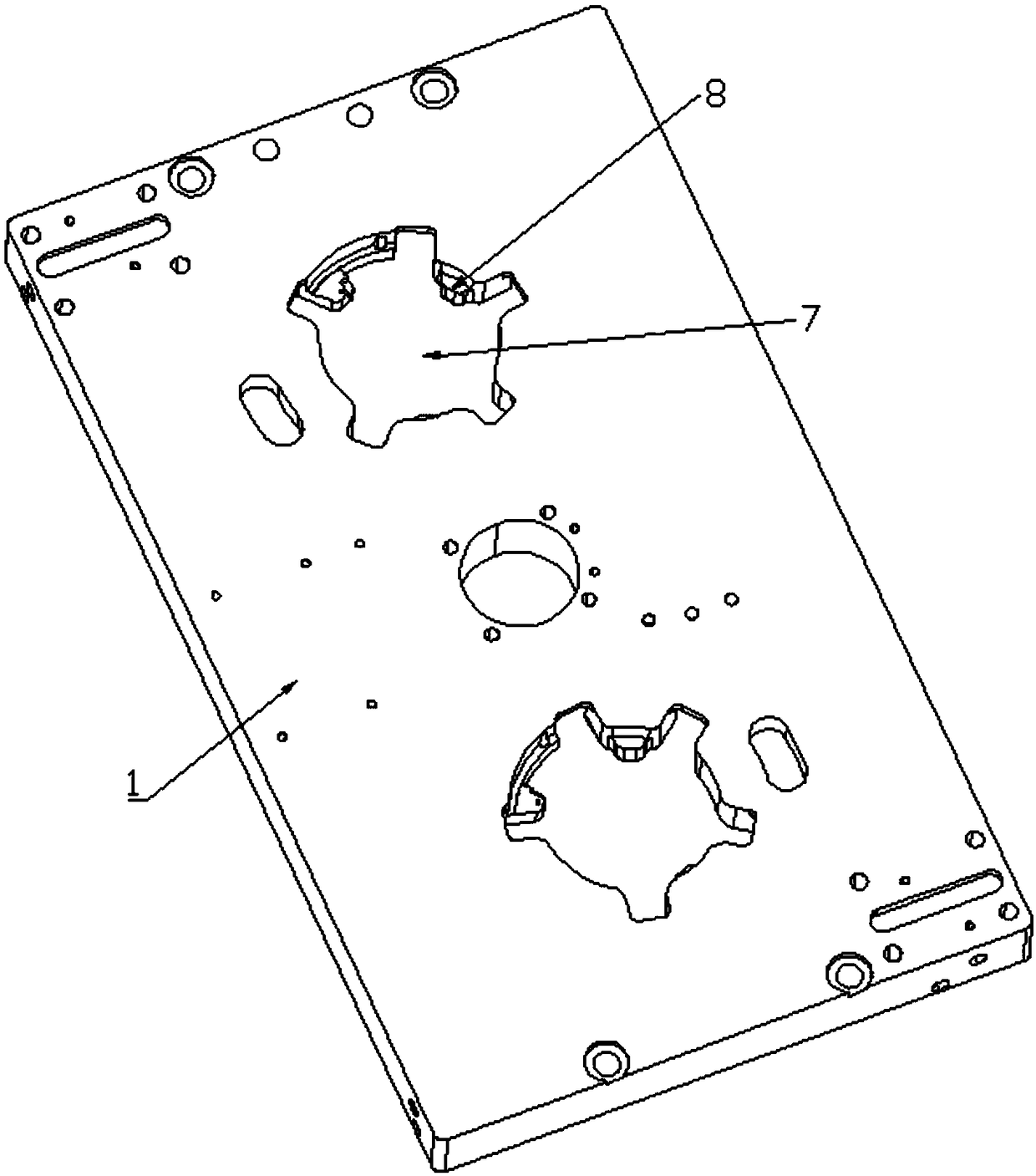

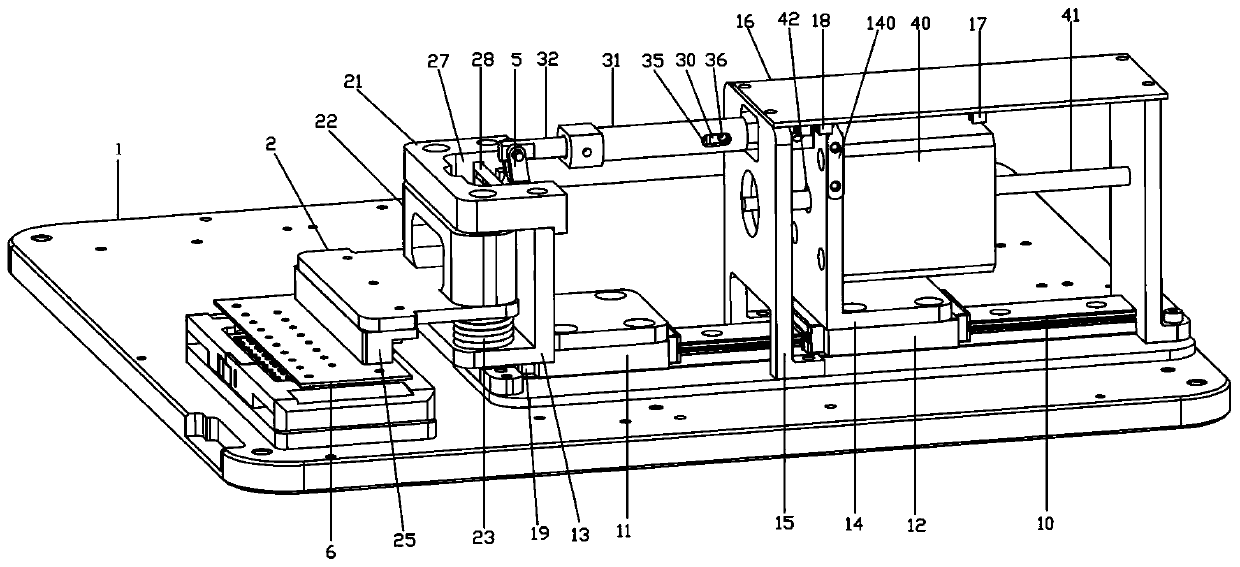

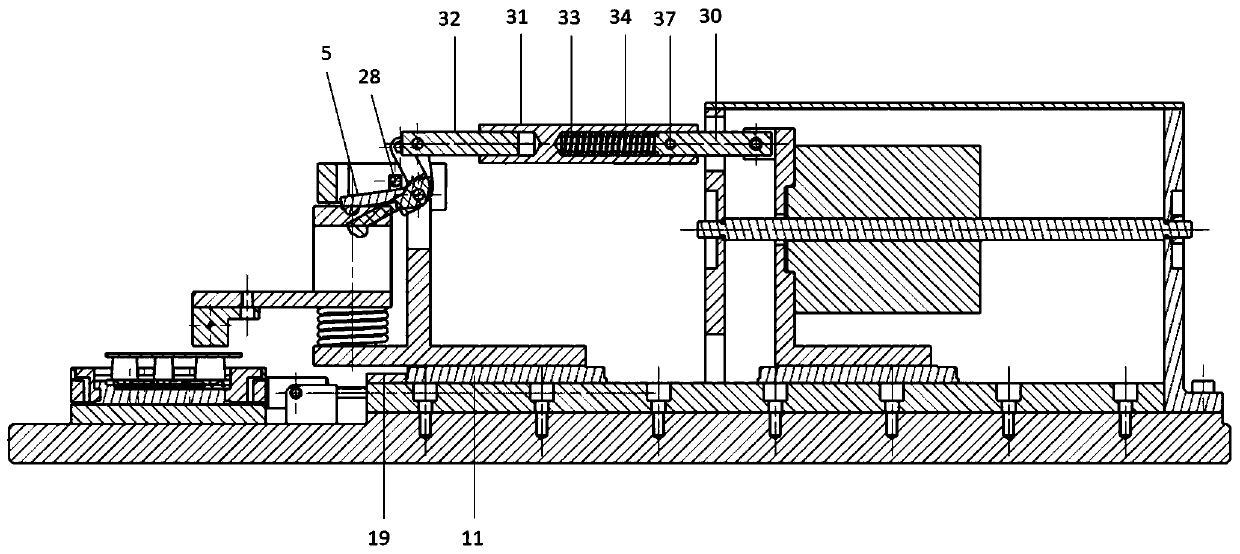

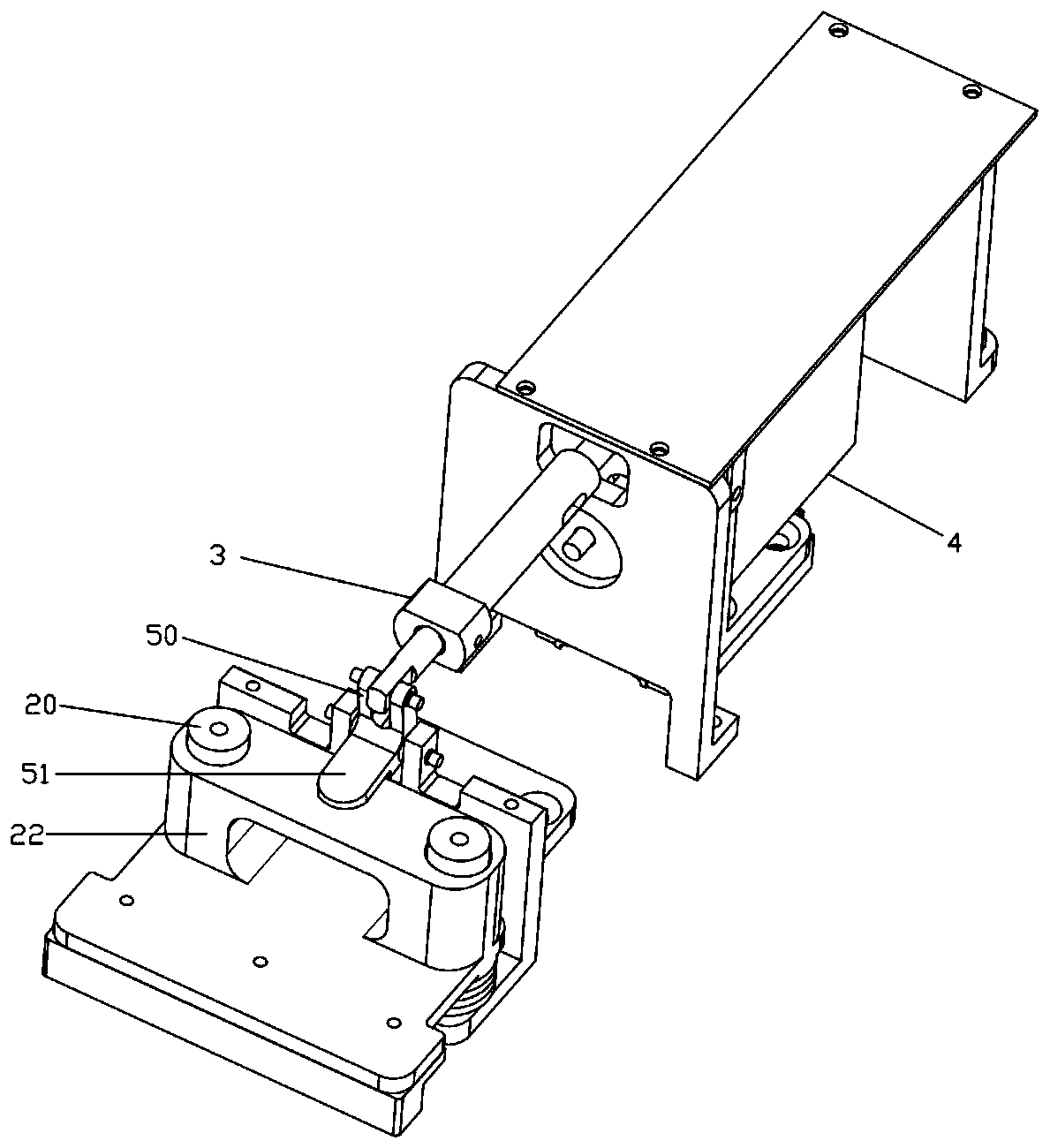

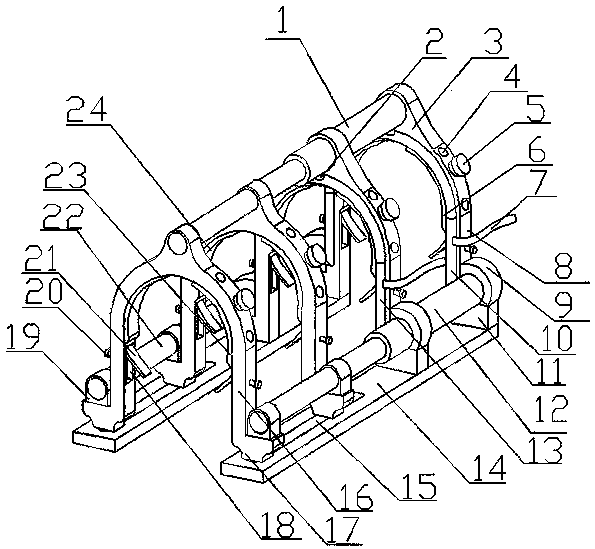

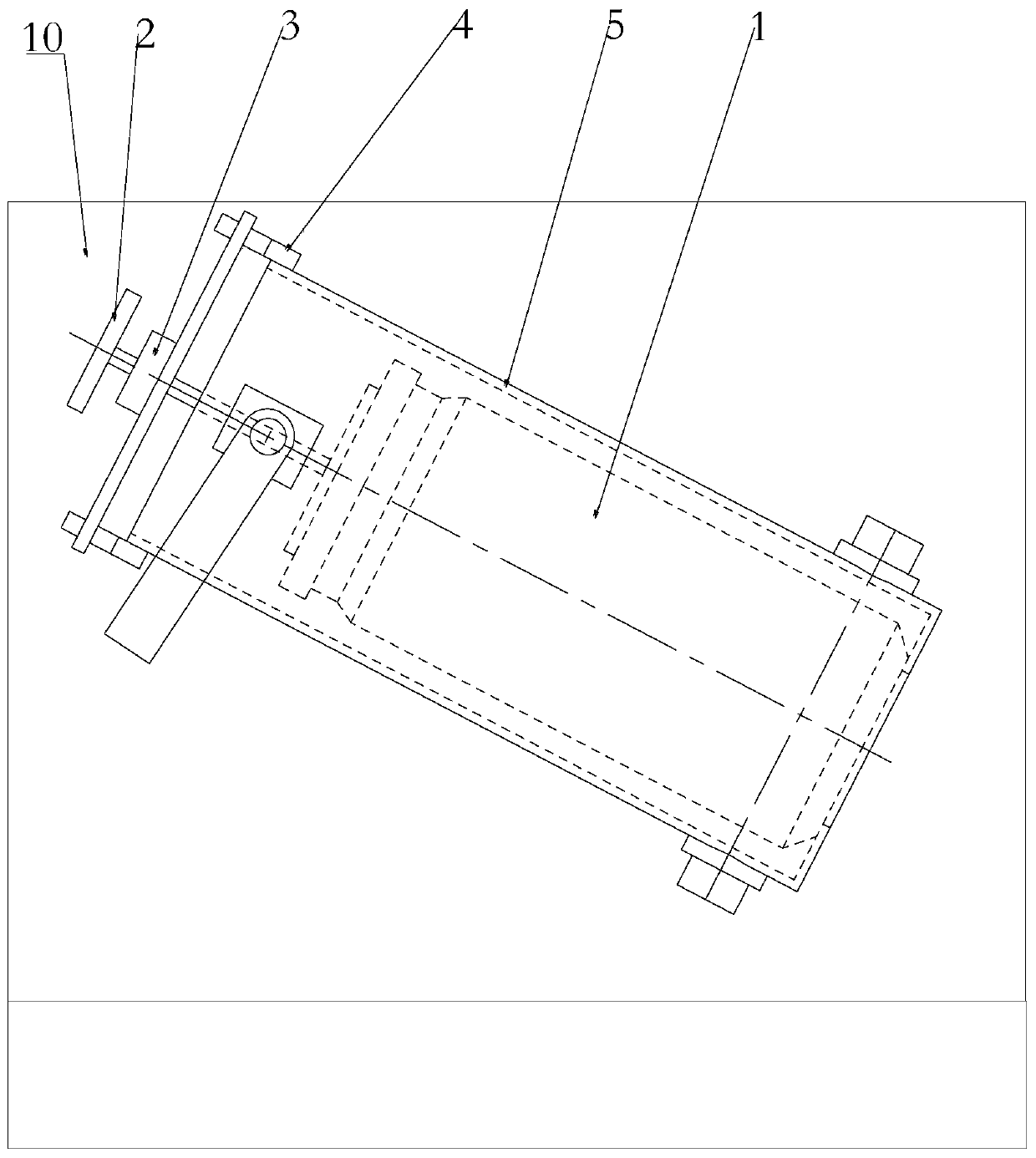

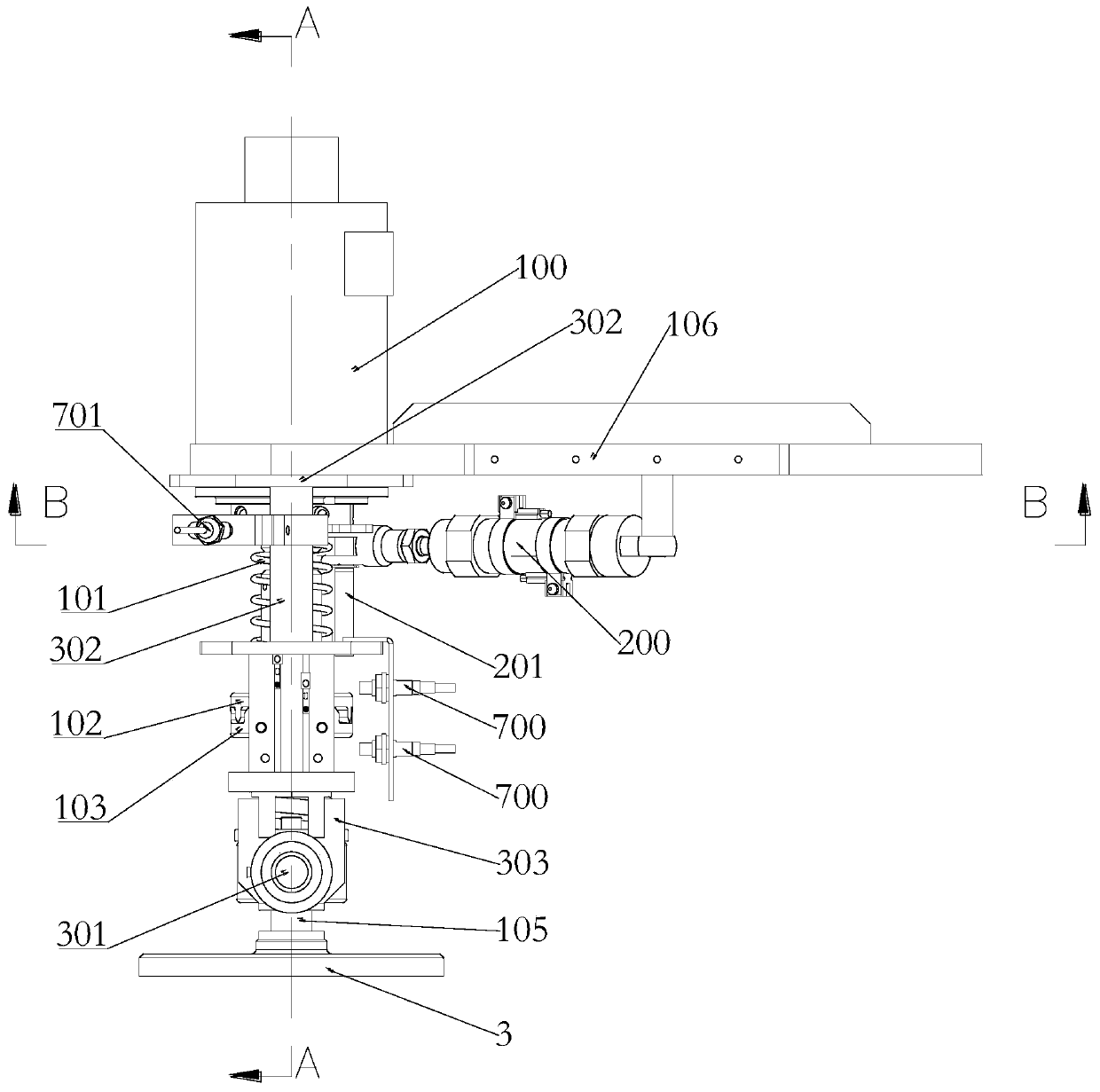

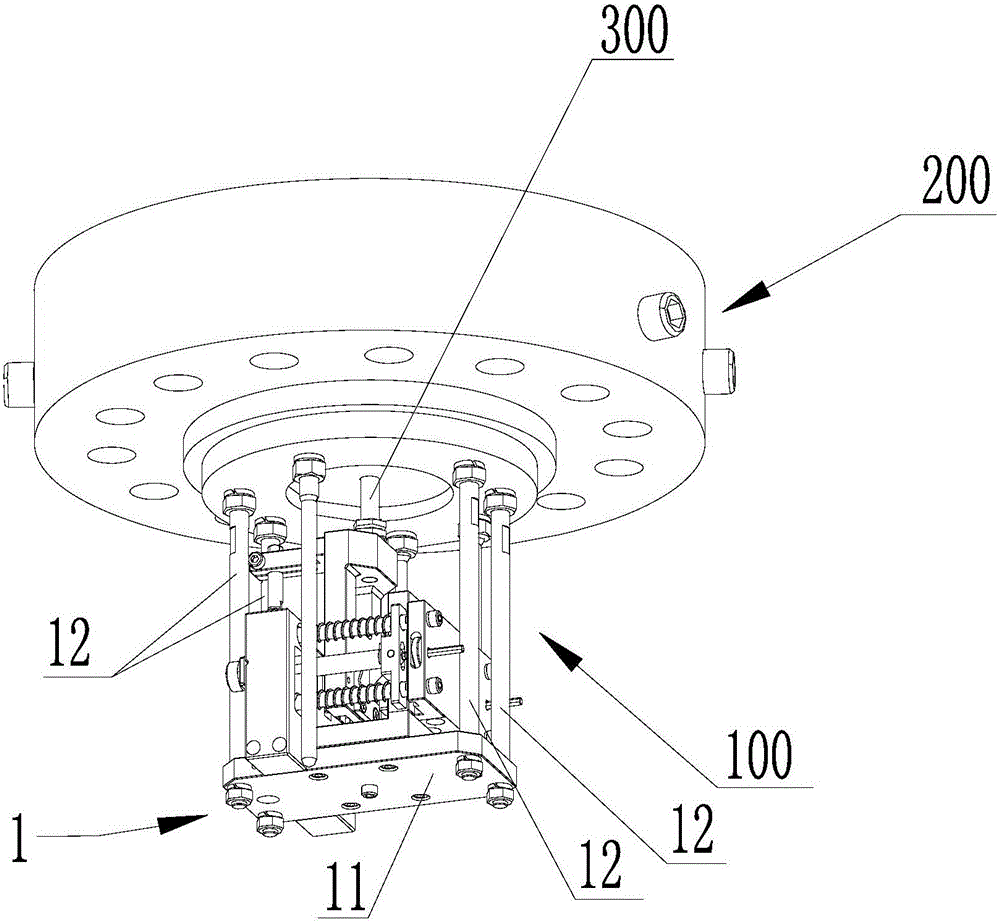

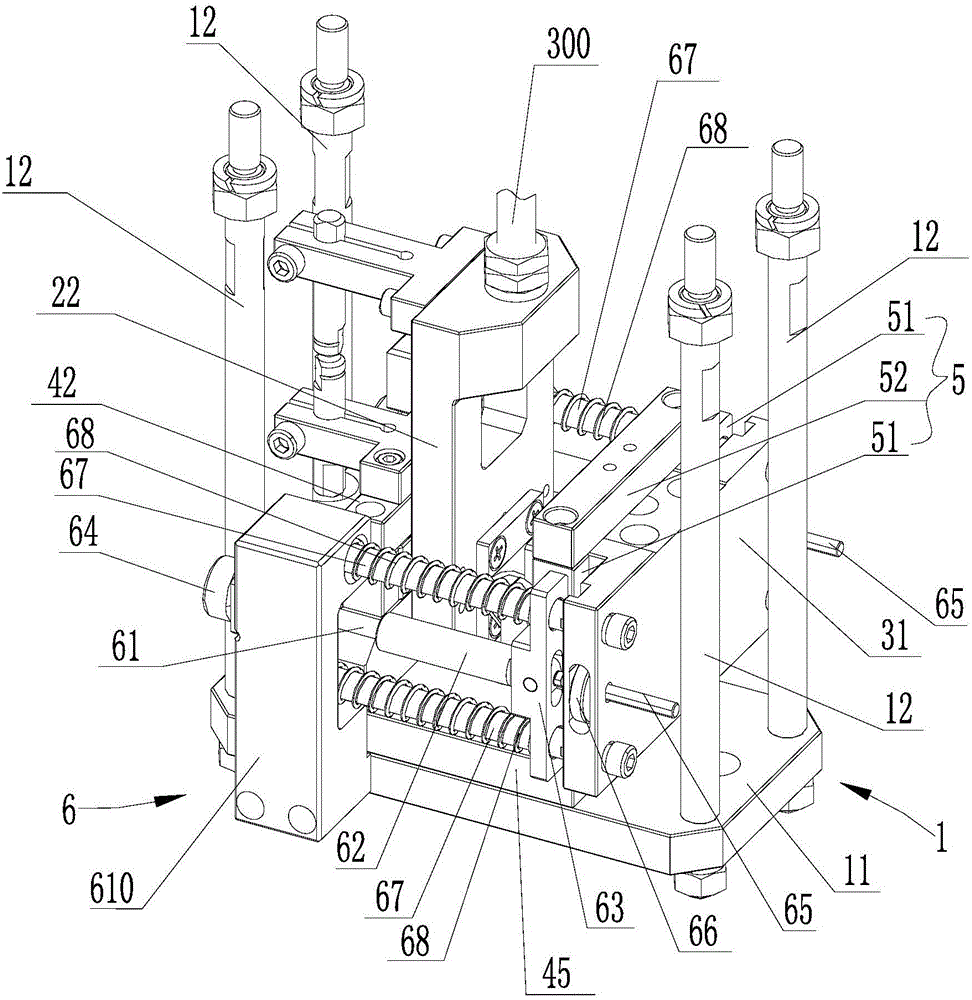

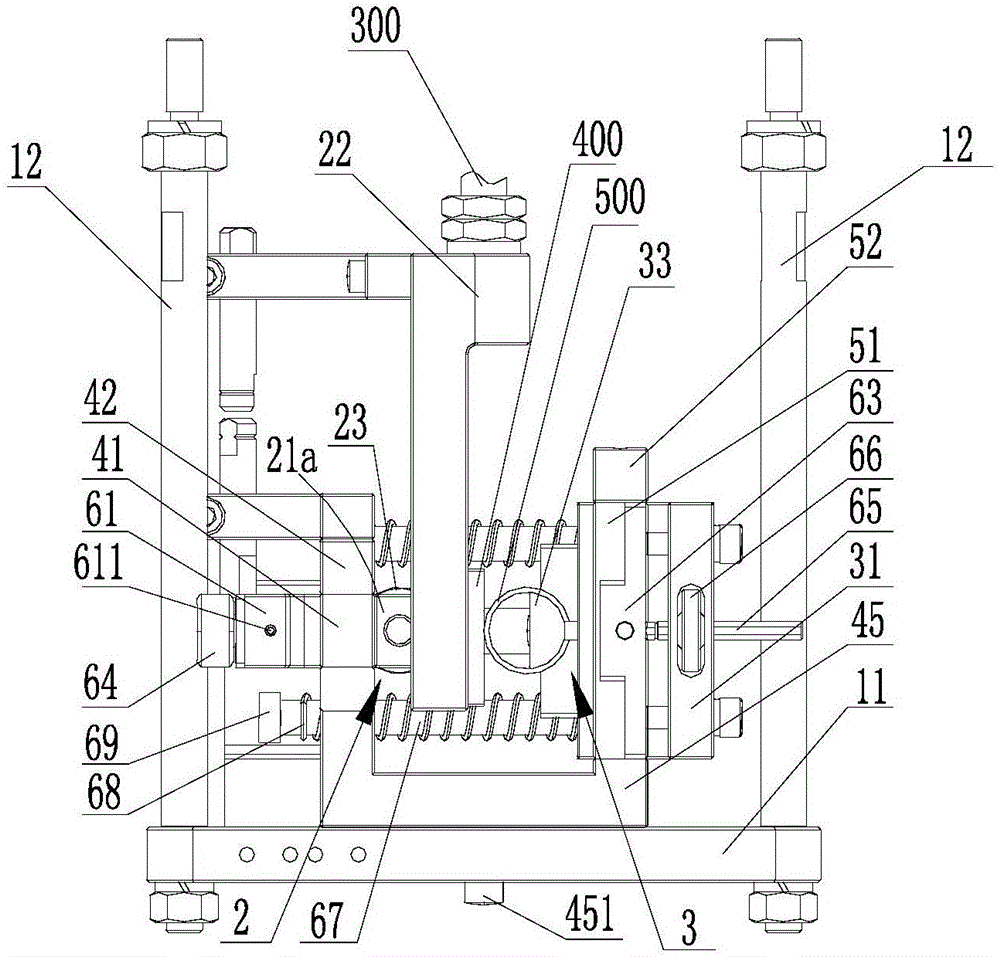

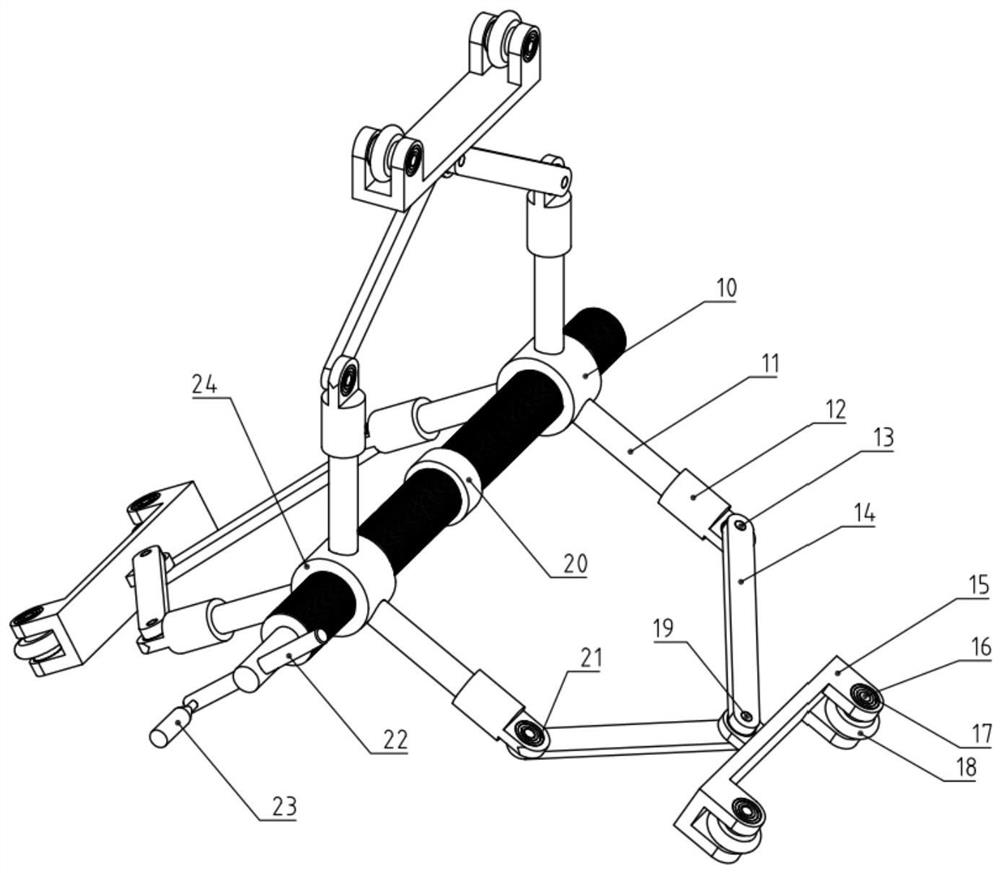

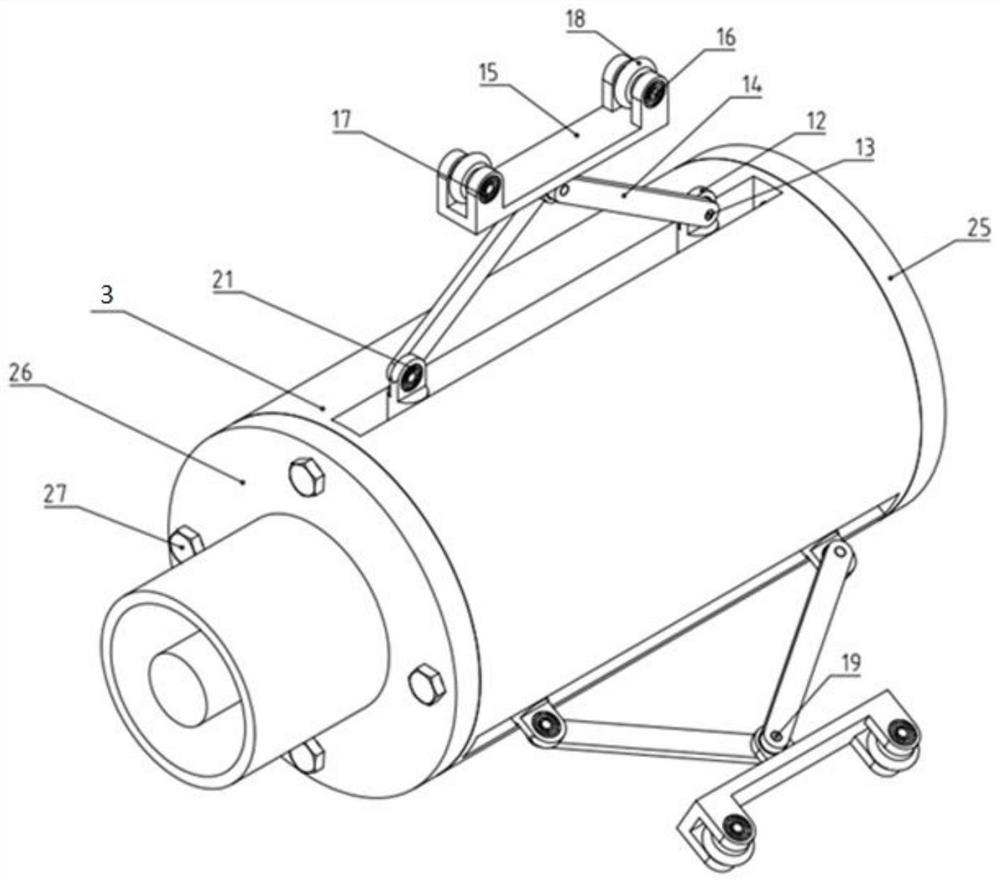

Multifunctional drilling and riveting actuator and working method thereof

ActiveCN104708322AReduce volumeReduce weightOther manufacturing equipments/toolsActuatorData conversion

The invention relates to a multifunctional automatic drilling and riveting actuator based on an autonomous multi-legged mobile platform. According to the multifunctional automatic drilling and riveting actuator, the mobile platform serves as a carrier, product theory information is extracted, a scanning camera and a laser displacement sensor are utilized to establish a drilling and riveting system coordinate system, the relation between the coordinate system and a product coordinate system is established through coordinate conversion, and extracted product theory data are converted to a right-angle three-dimensional coordinate system of the drilling and riveting system; accordingly, the drilling and riveting system can be controlled to conduct drilling and riveting, continuous high-precision and high-efficiency drilling and riveting on products at multiple positions can be achieved.

Owner:江苏航鼎智能装备有限公司

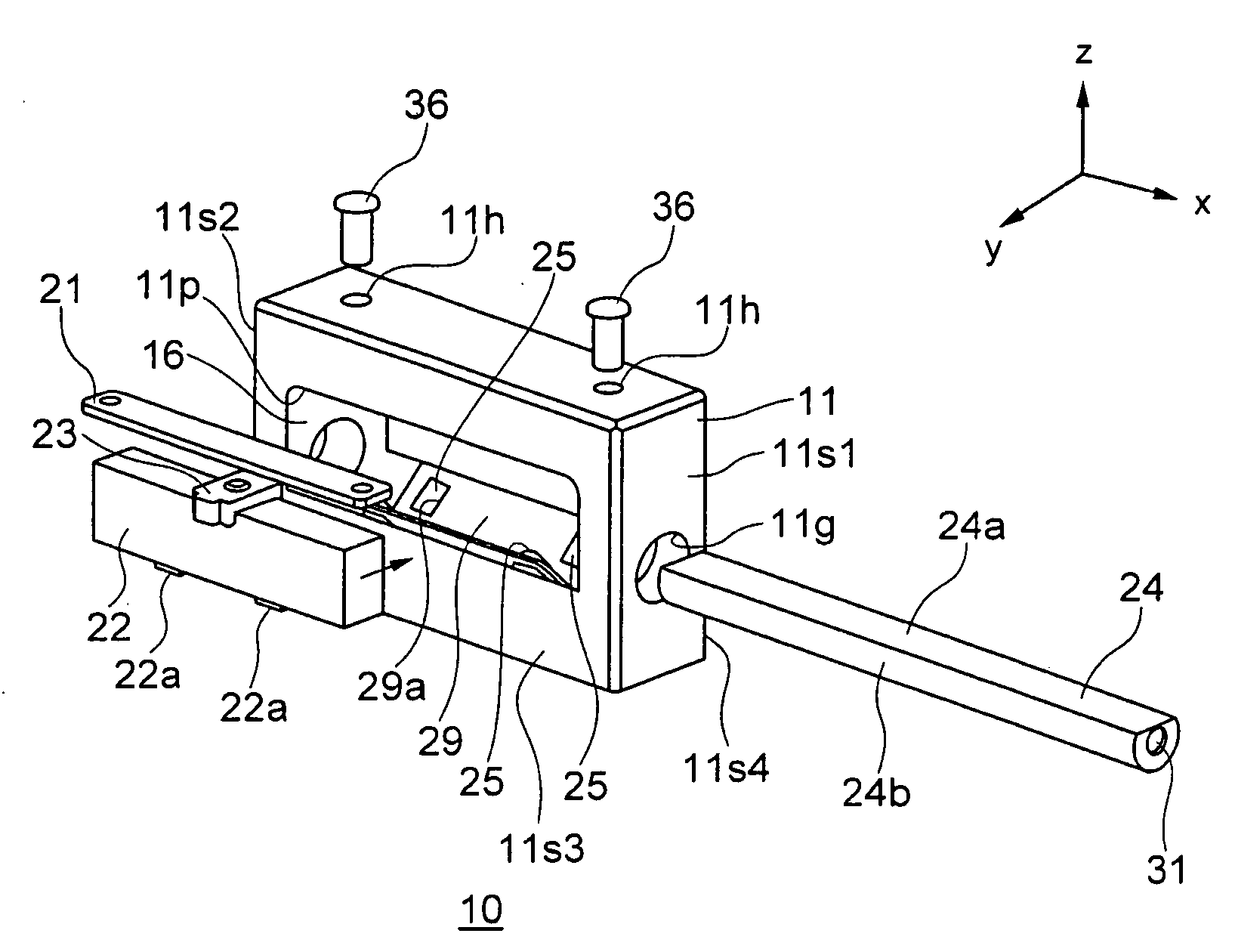

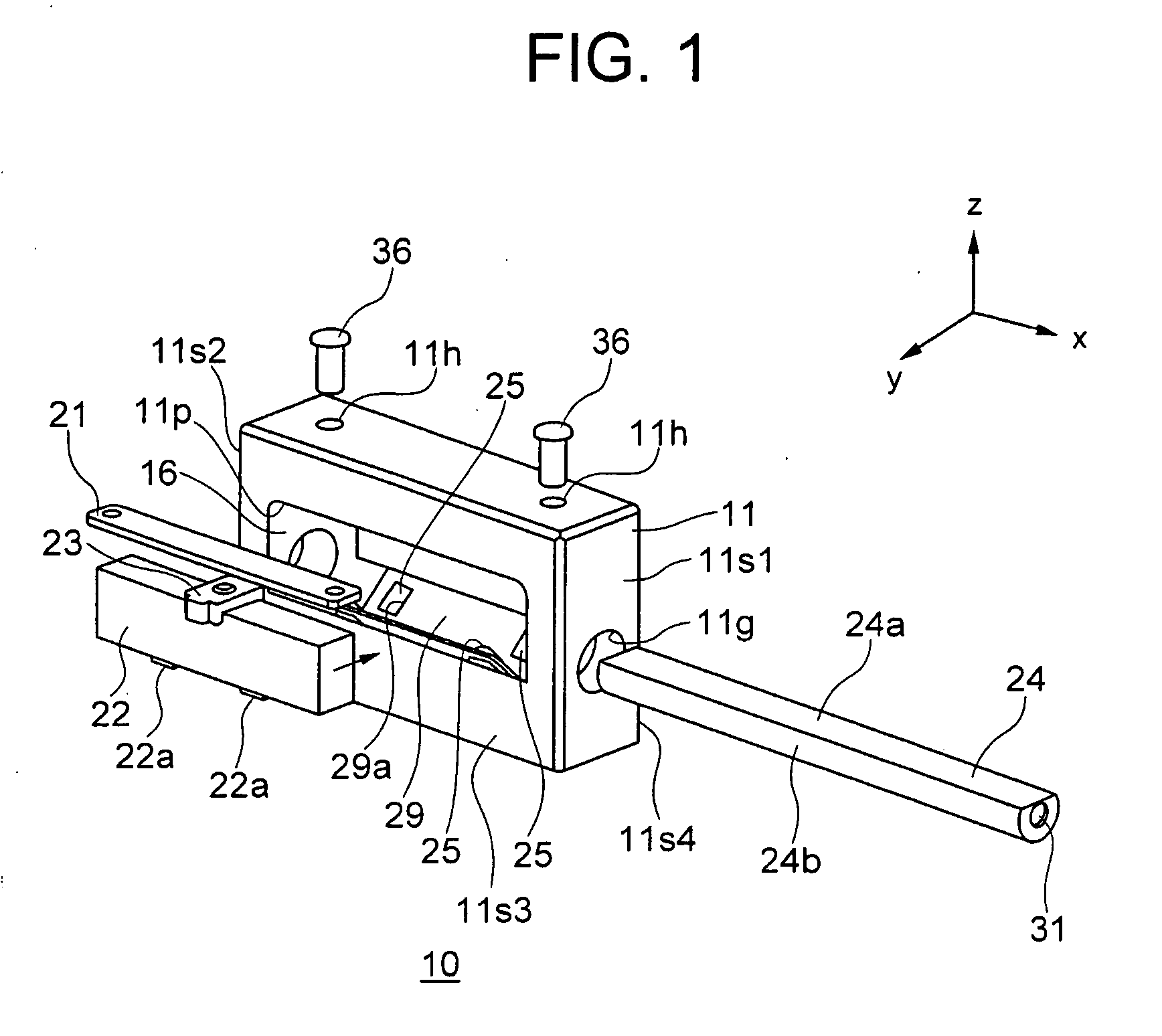

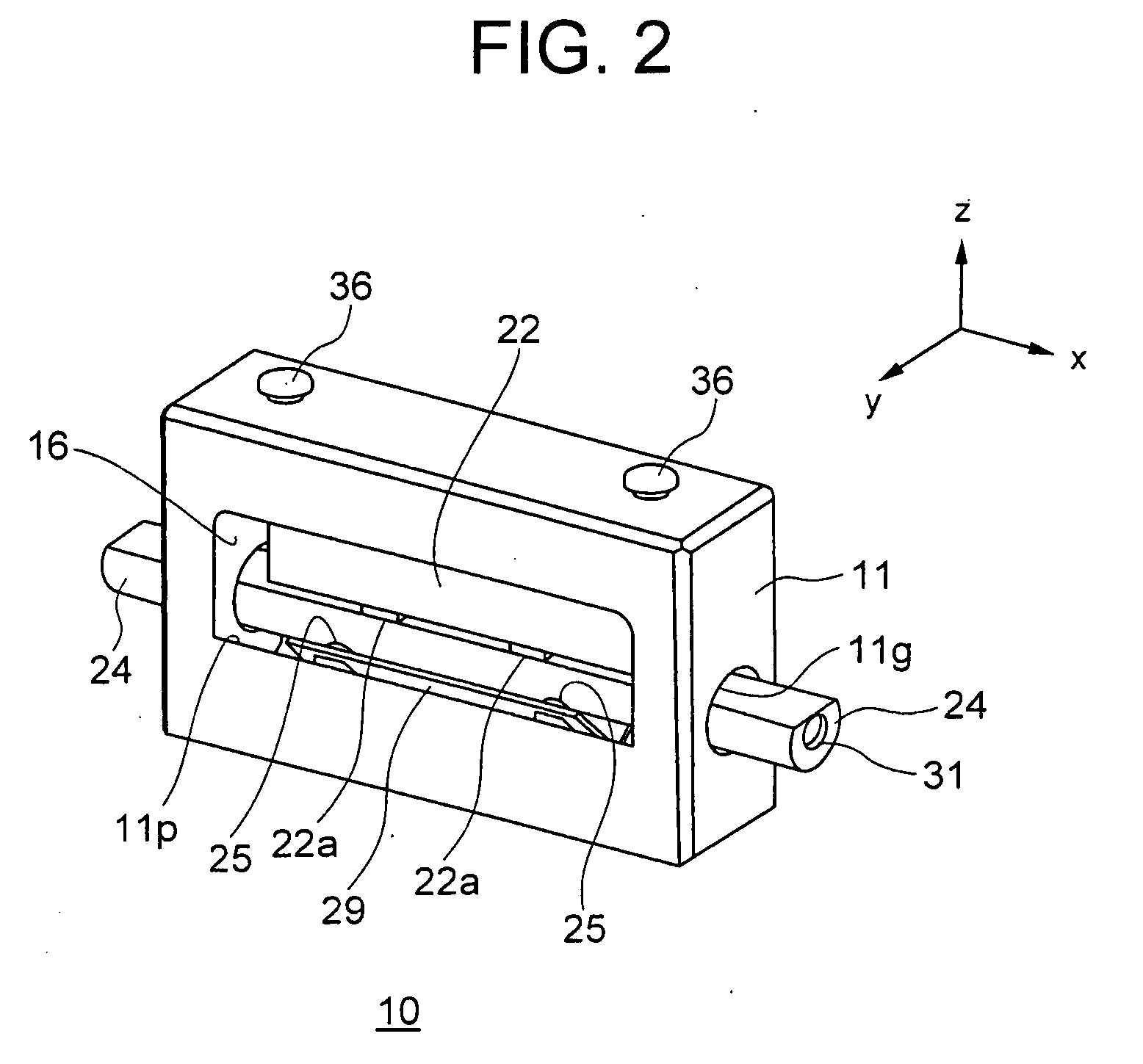

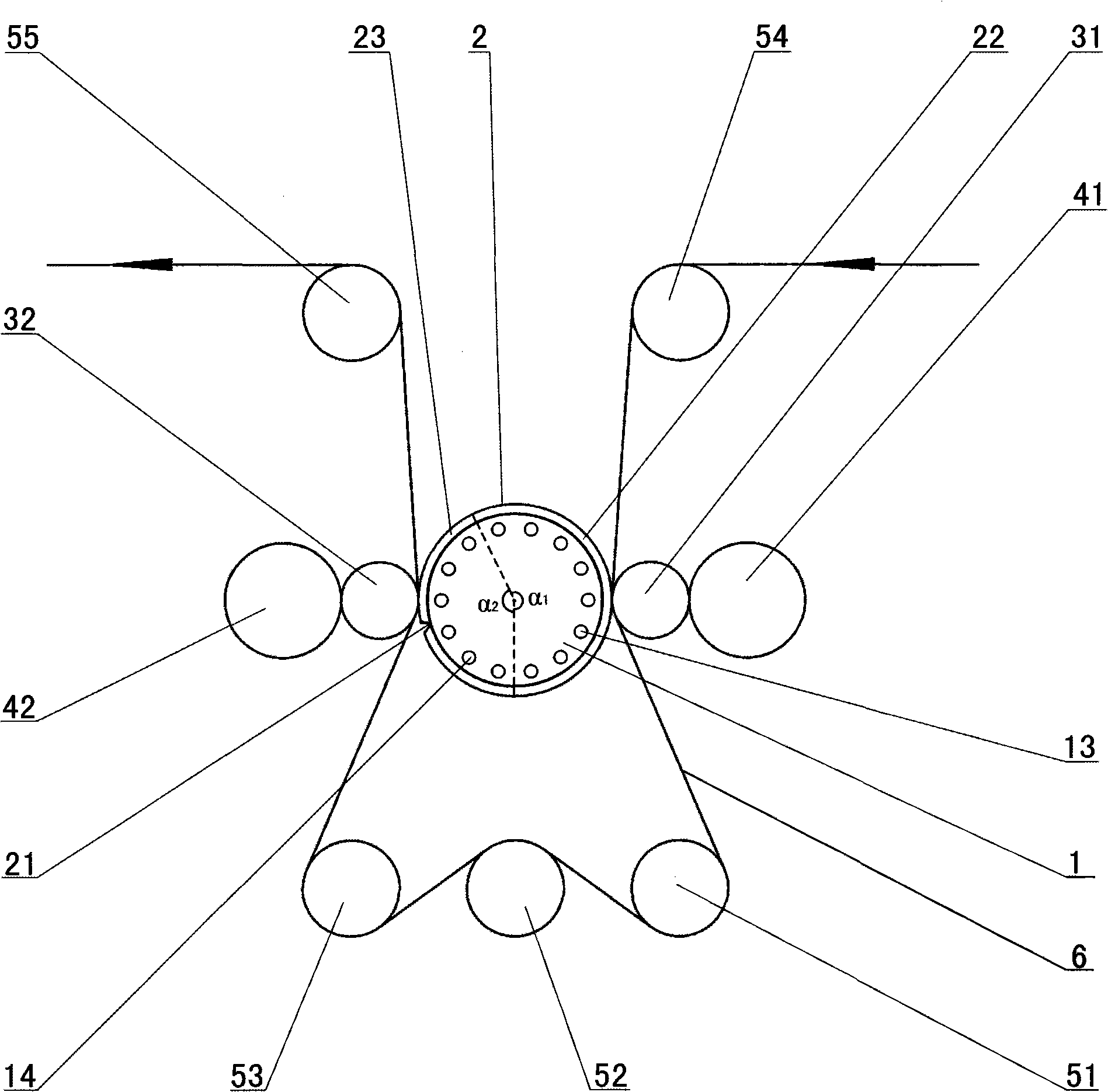

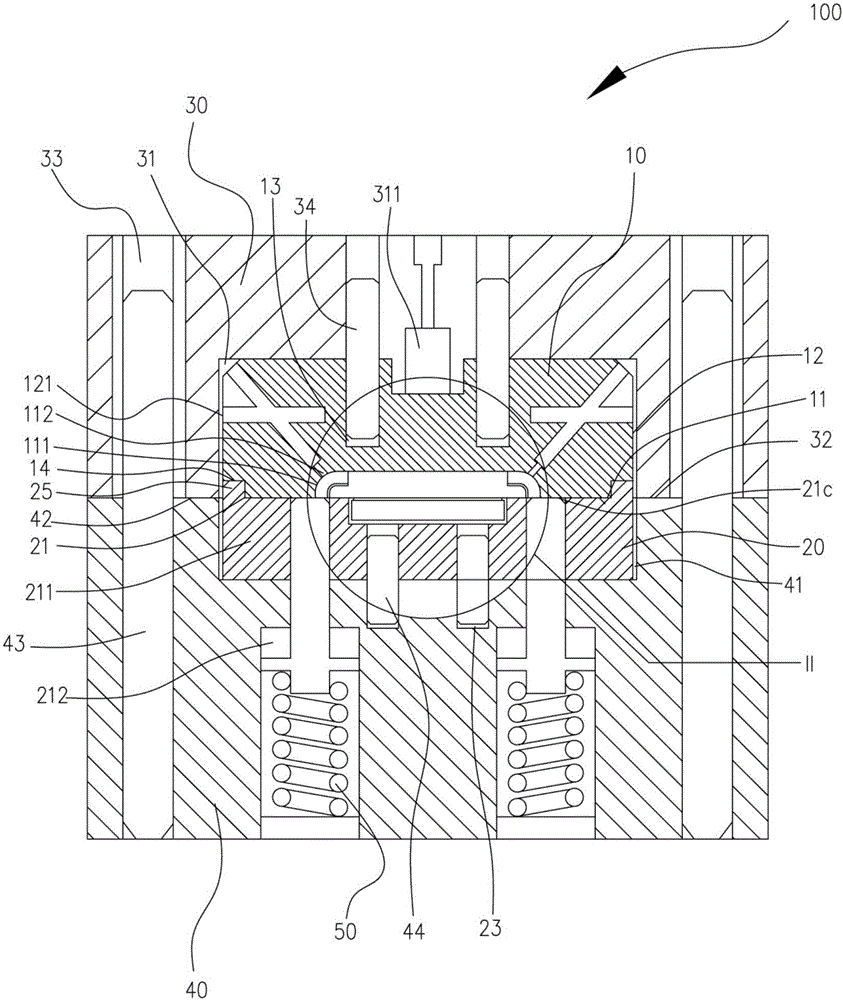

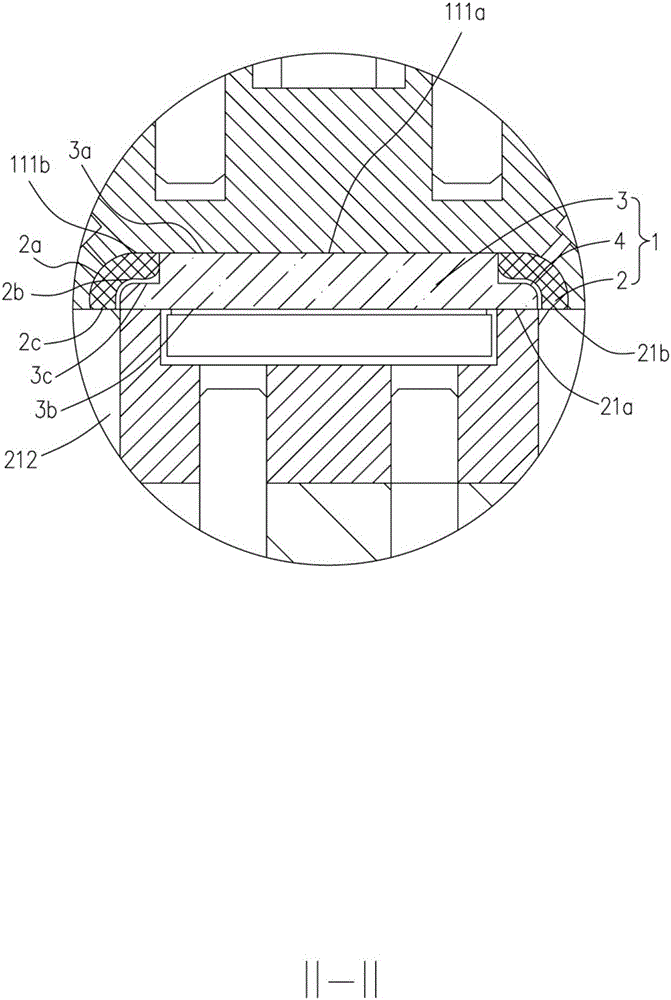

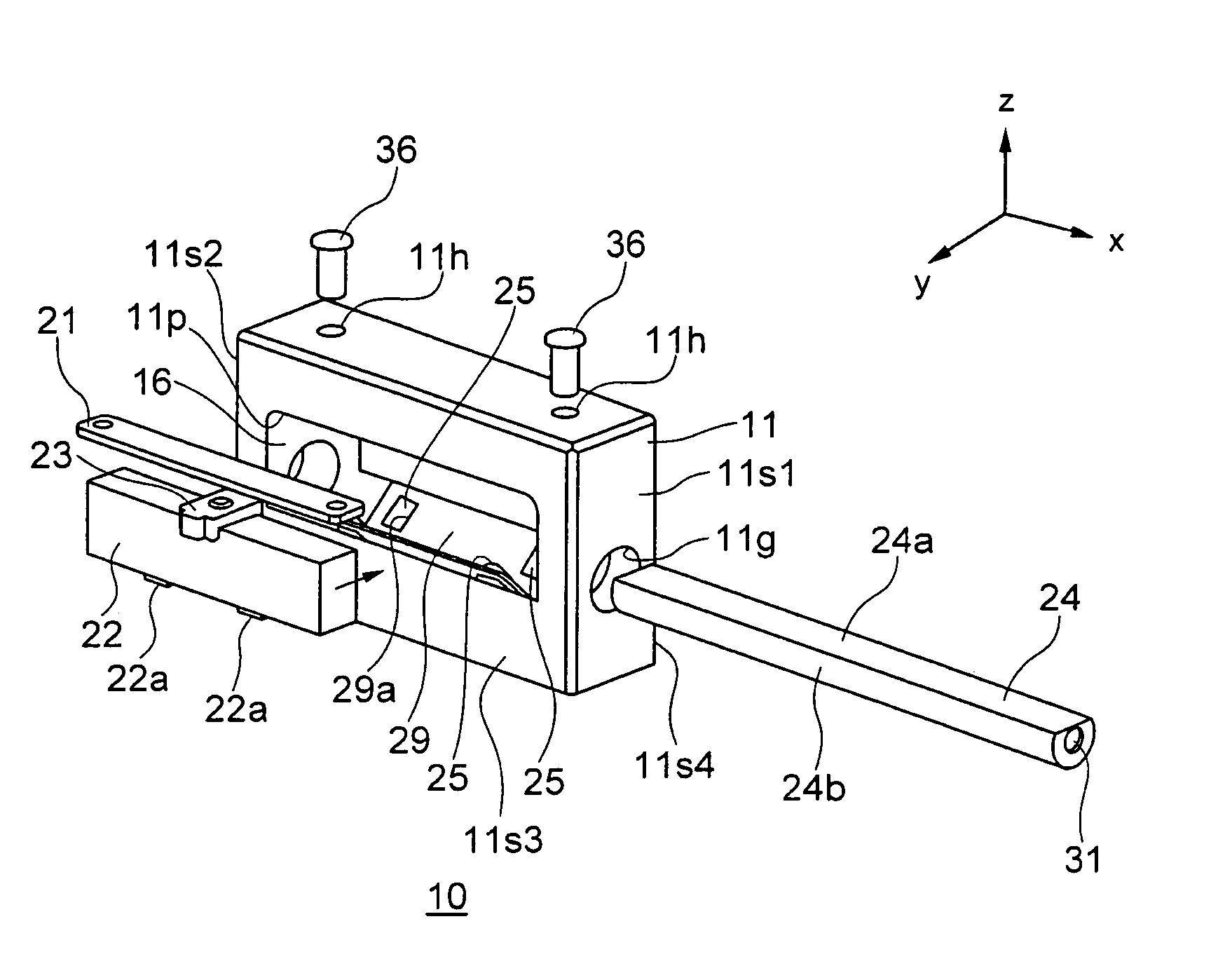

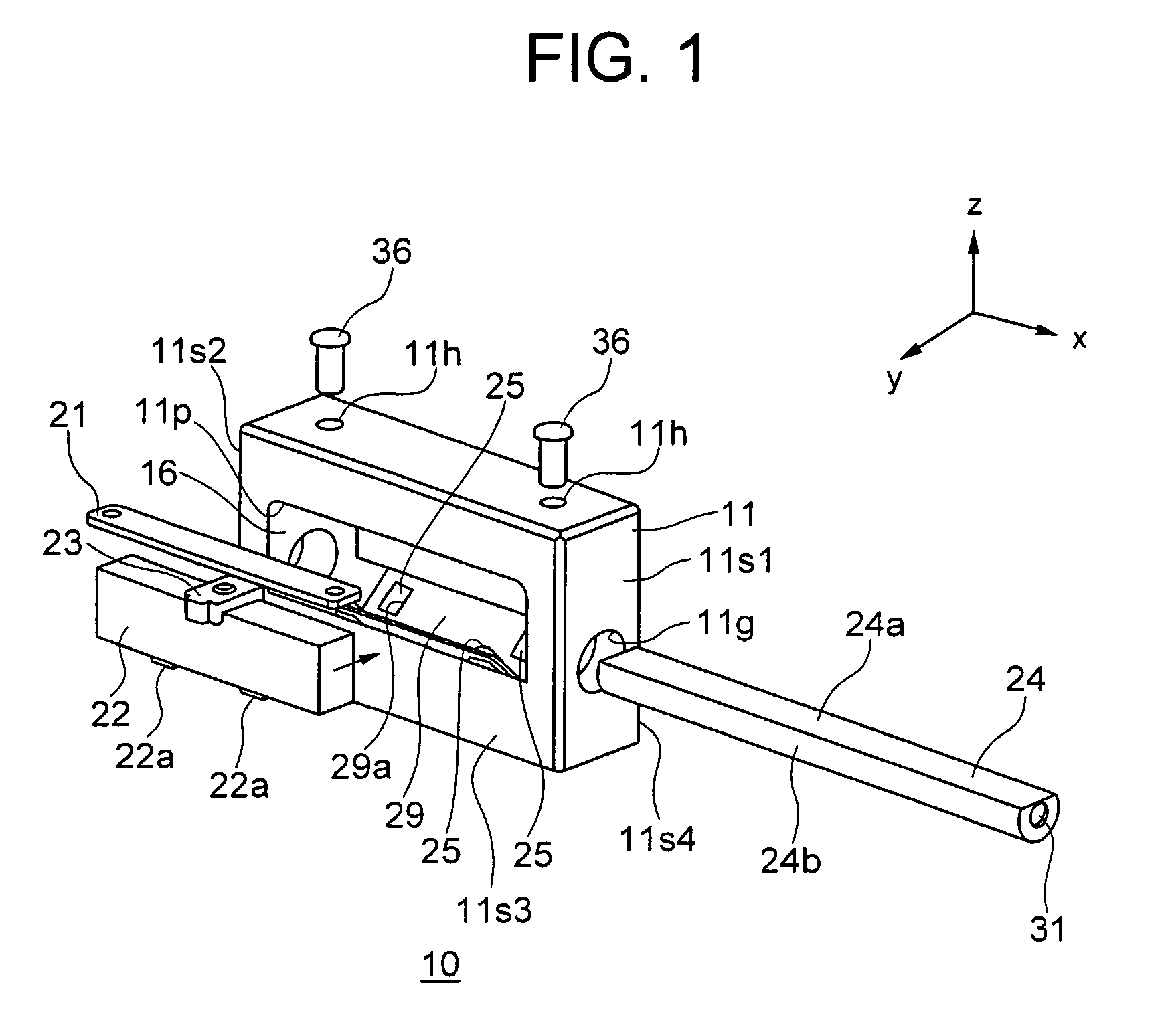

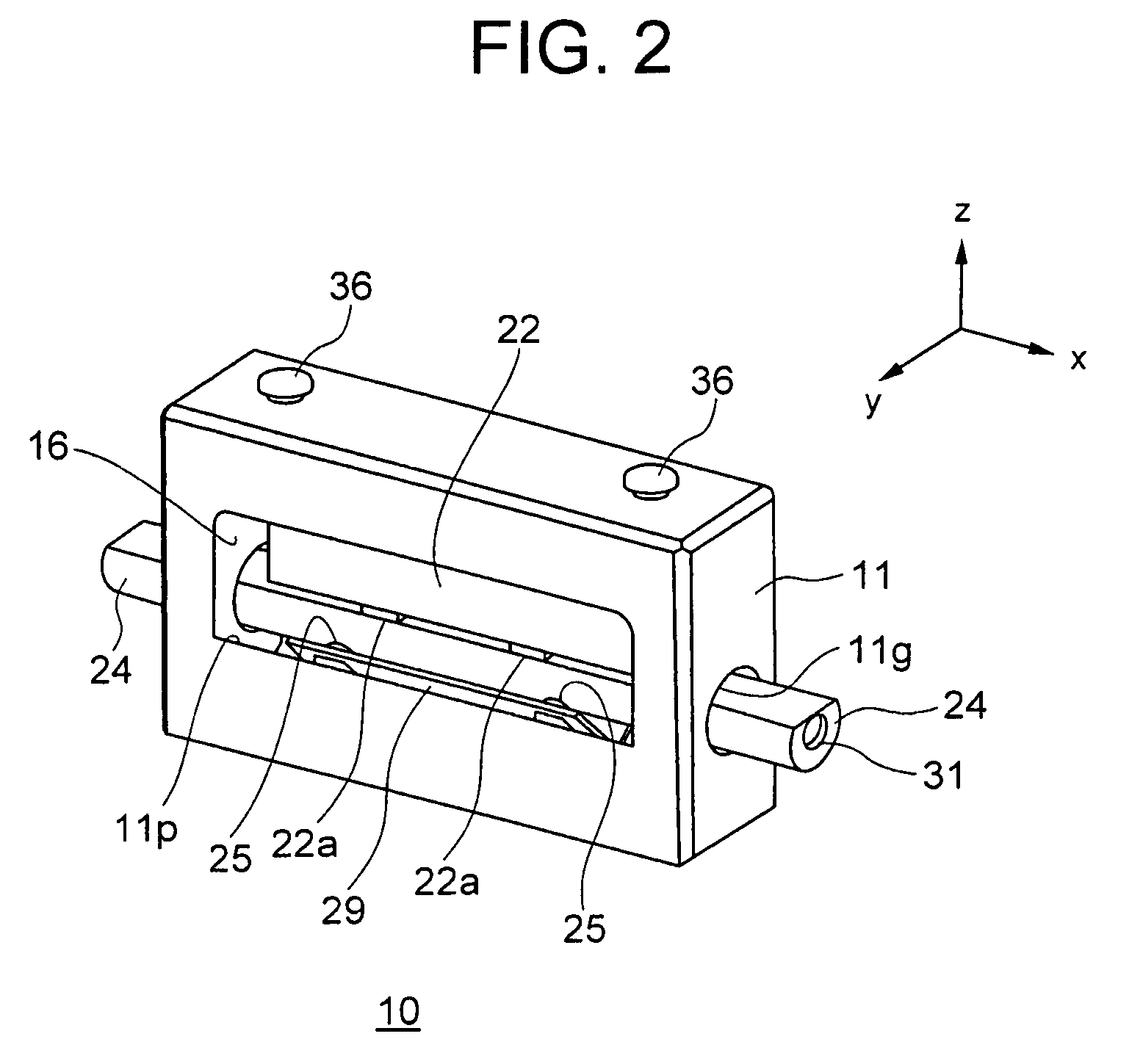

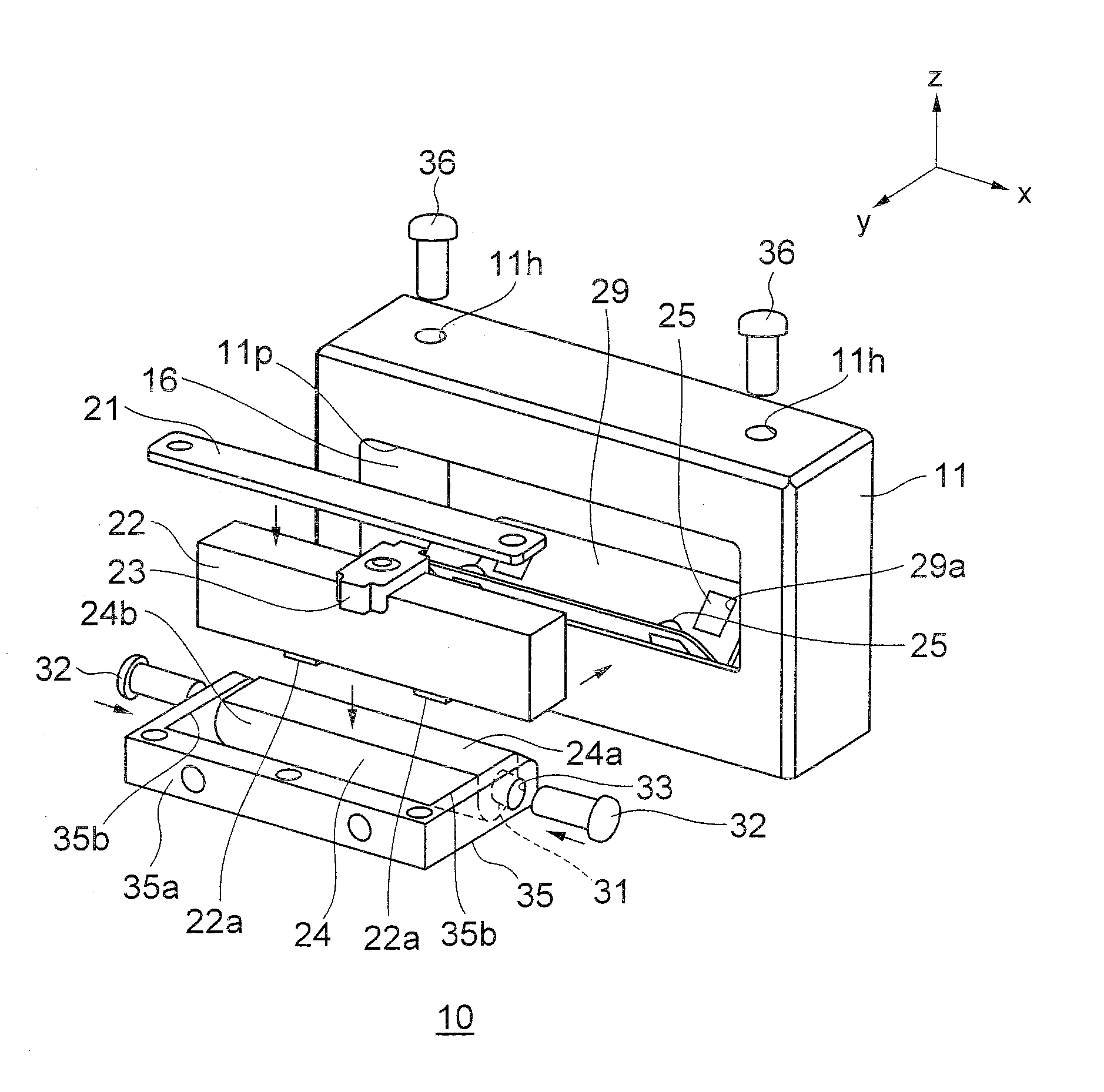

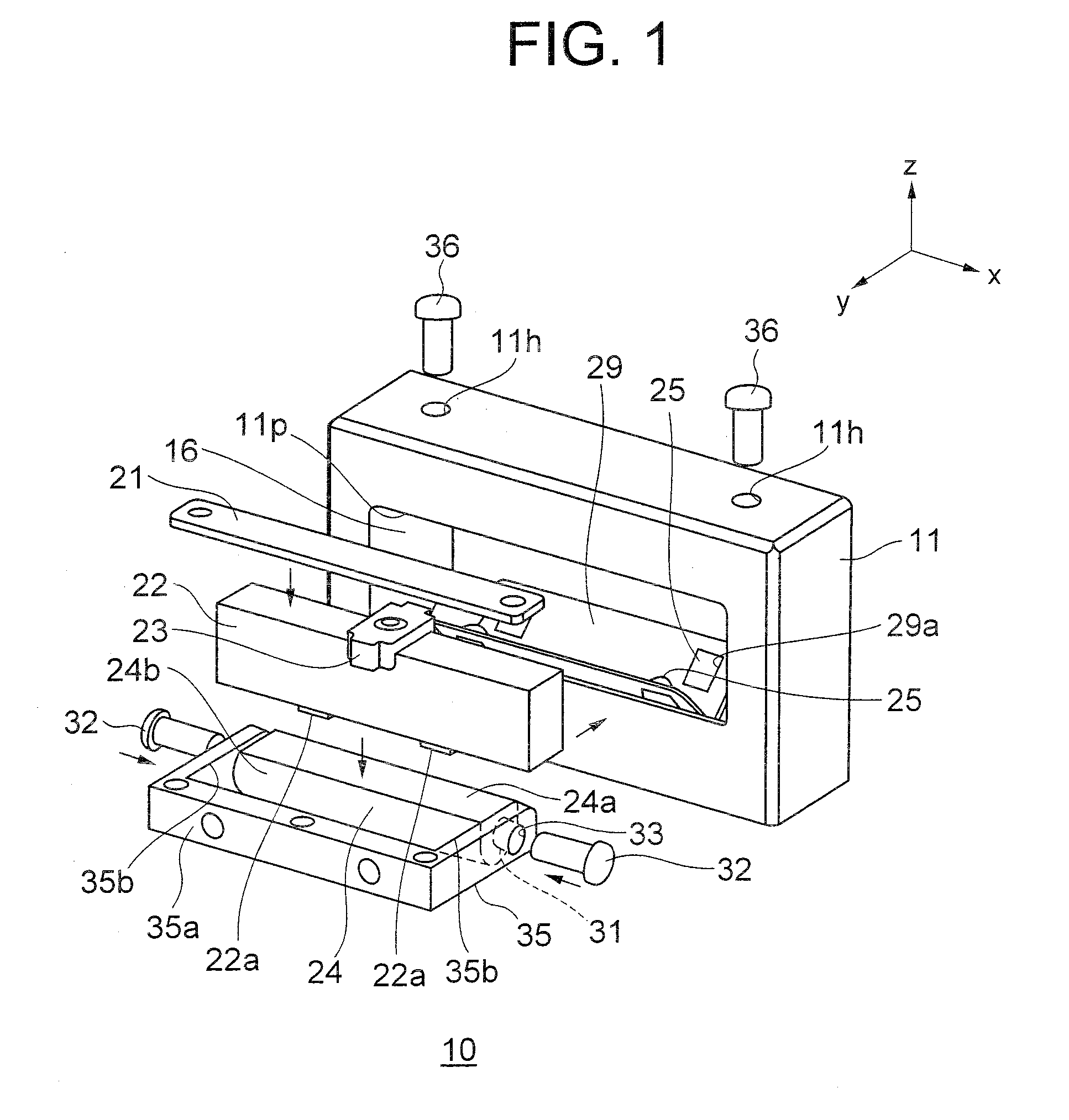

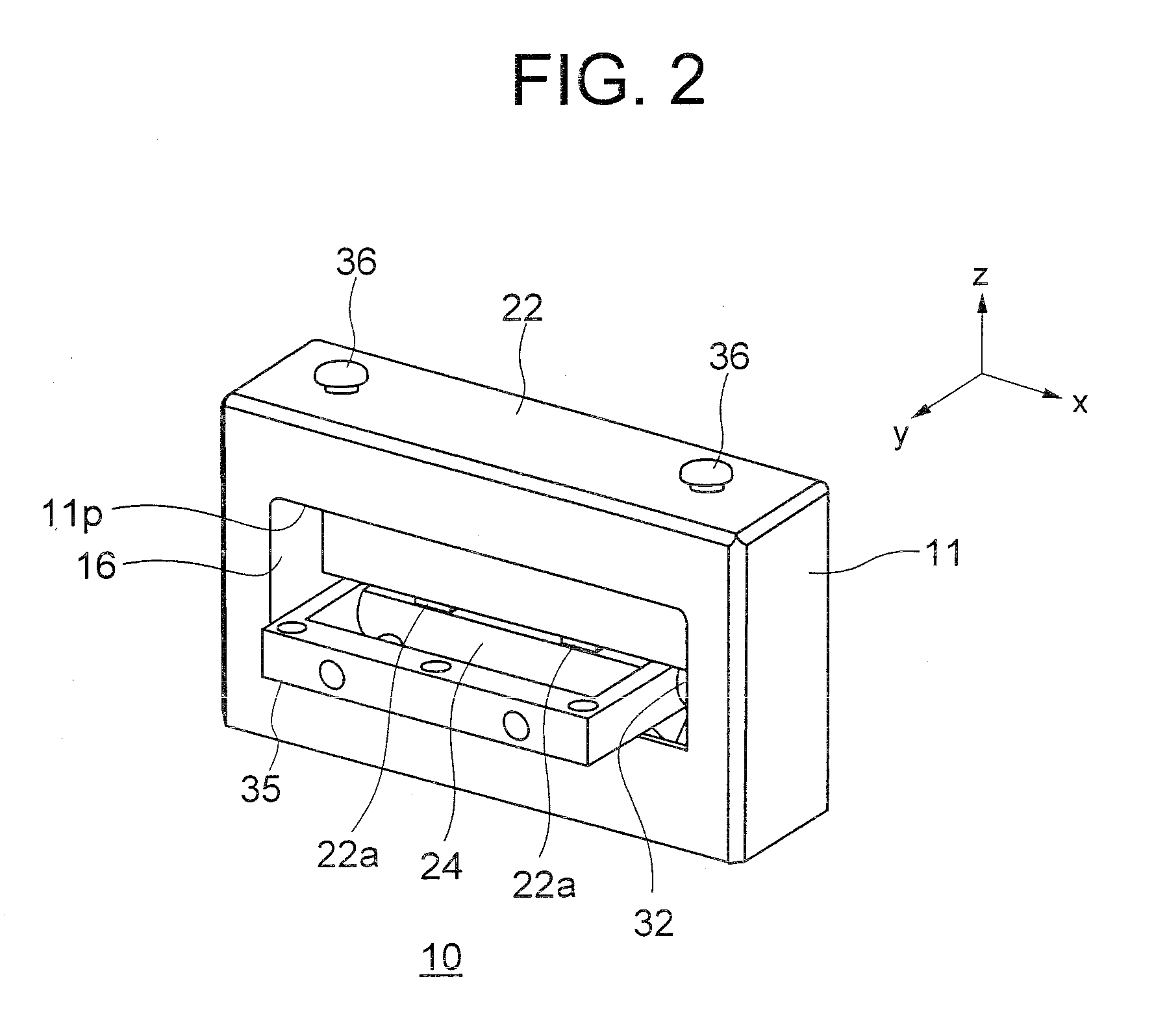

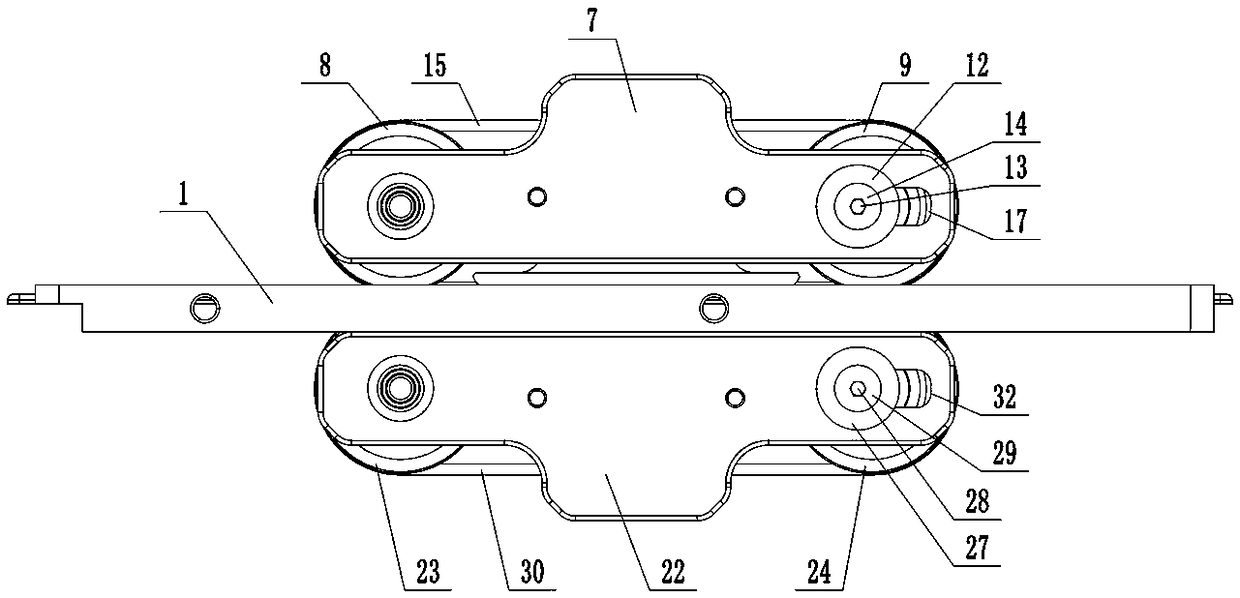

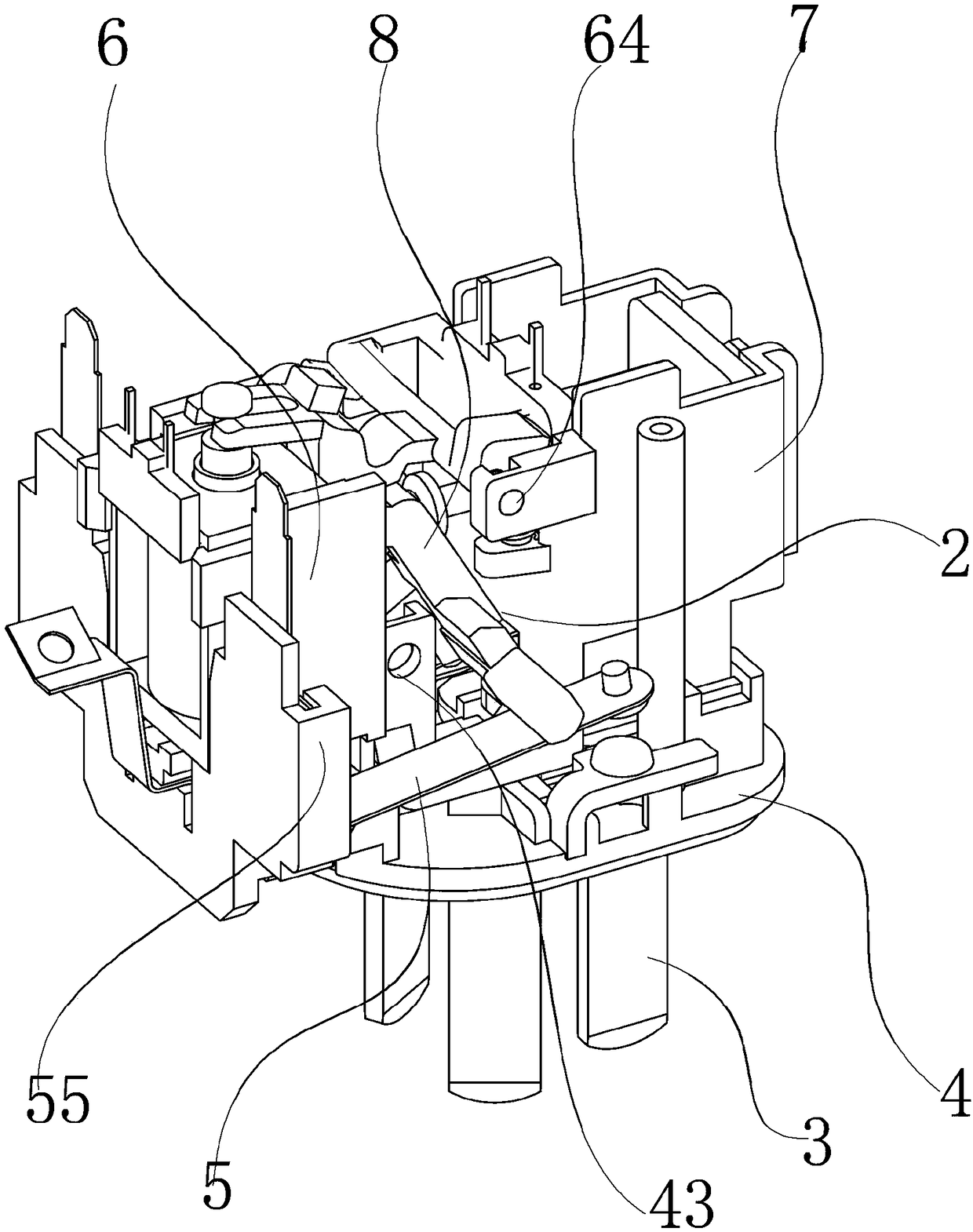

Linear drive ultrasonic motor

ActiveUS20090267454A1Stable pressing forceReduce restrictionsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringUltrasonic motor

A linear drive ultrasonic motor includes at least an ultrasonic vibrator having a piezoelectric element, a driven member which is driven by a frictional force between the driven member and the ultrasonic vibrator, a pressing member which presses the ultrasonic vibrator such that a frictional force is generated between the ultrasonic vibrator and the driven member, a guiding mechanism which movably supports the driven member, and a case member which accommodates the ultrasonic vibrator, the pressing member, and the guiding means. The case member includes a first opening portion for making the driven member pass through, and a second opening portion which opens in a direction different from a direction in which the first opening portion opens and a direction of pressing by the pressing member.

Owner:OLYMPUS CORP

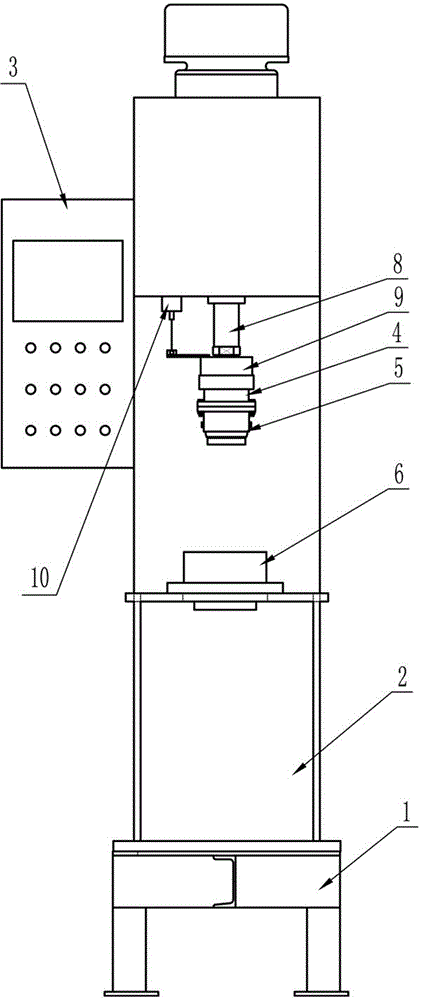

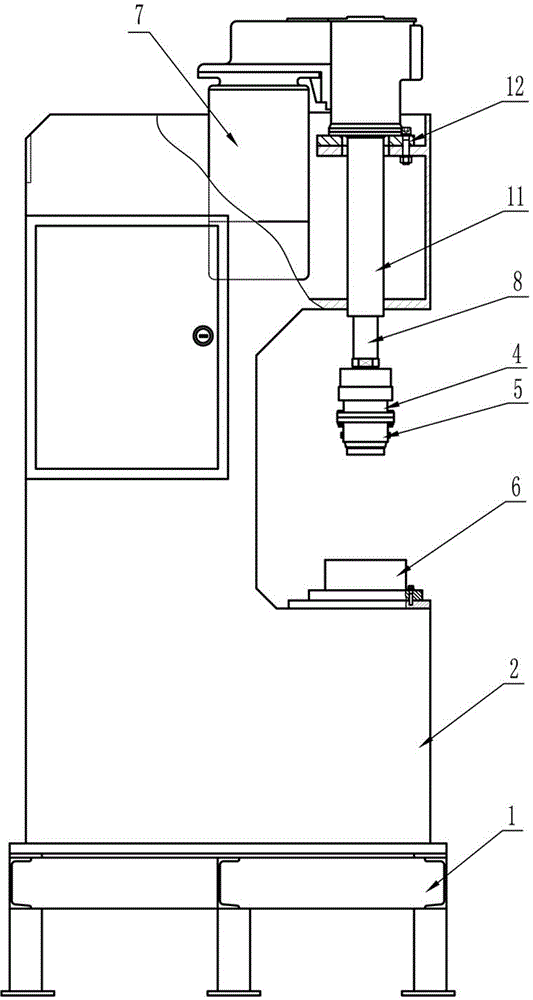

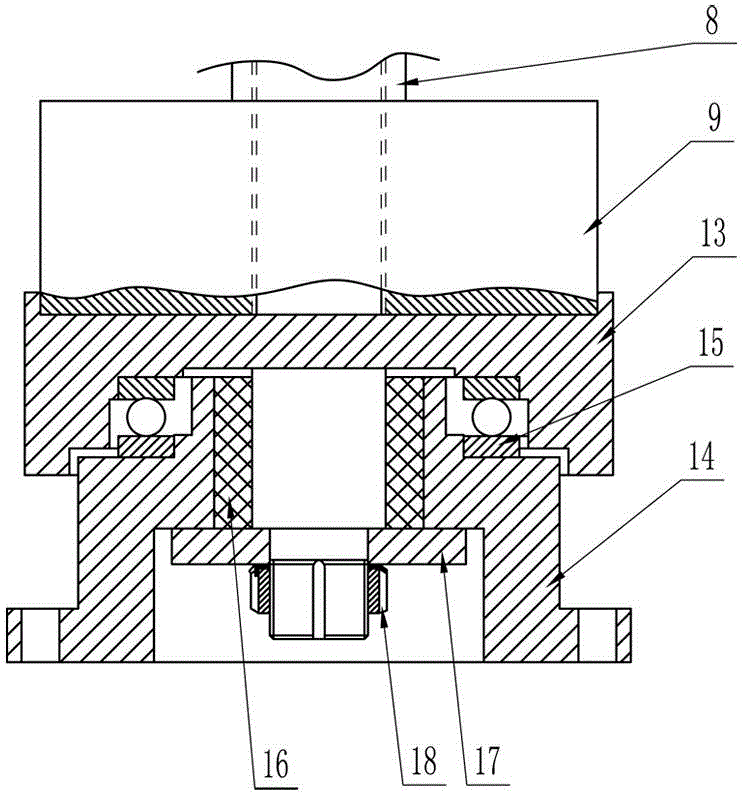

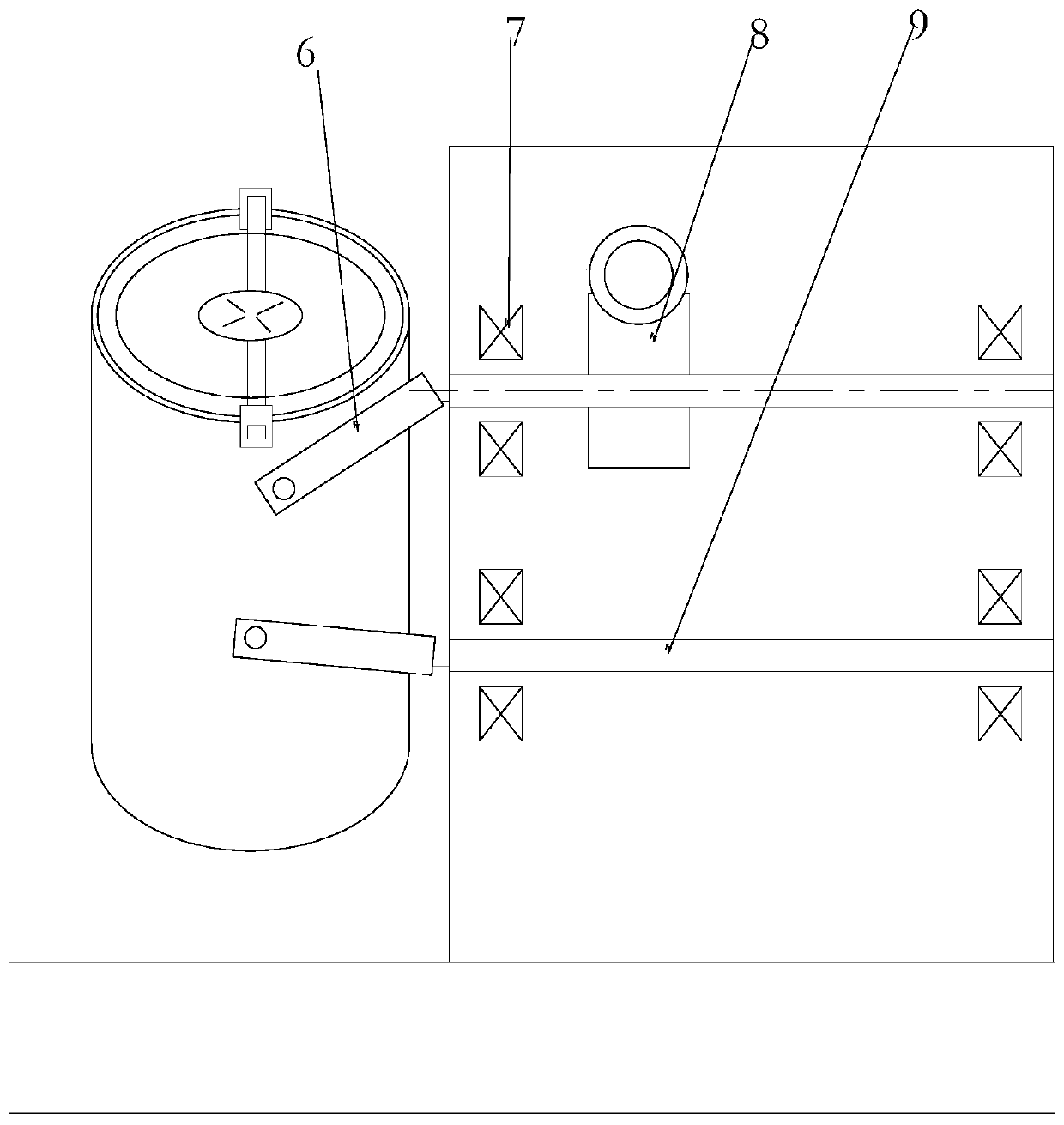

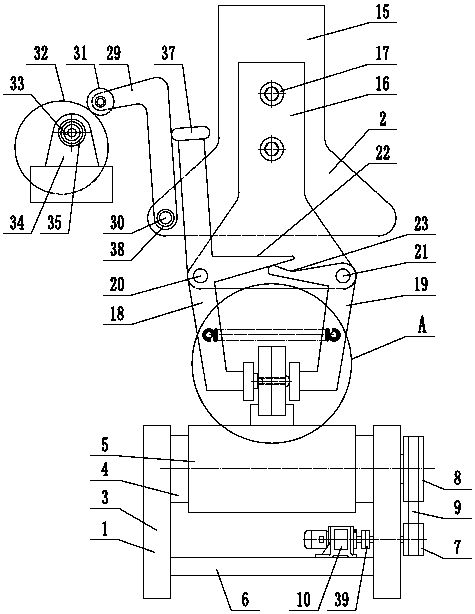

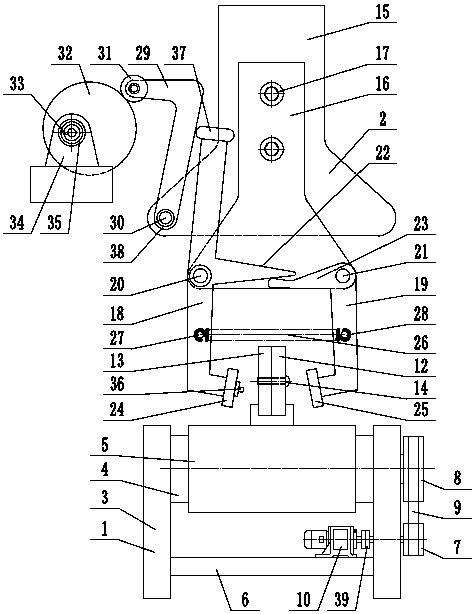

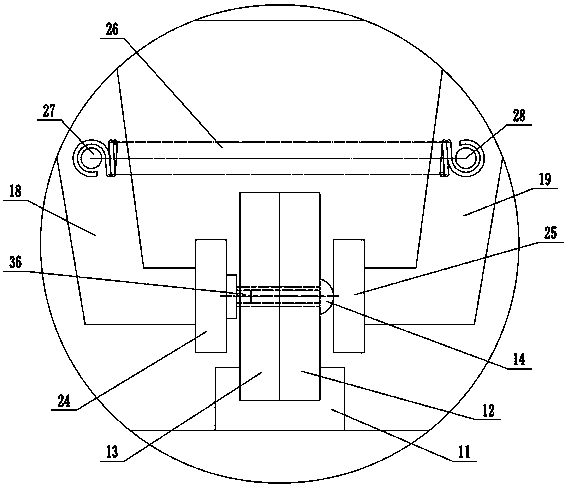

Vertical type bearing pressing machine

InactiveCN106141622ASmall footprintLarge operating spaceMetal working apparatusMotor driveBall bearing

The invention discloses a vertical type bearing pressing machine which comprises a base; a rack is arranged on the base; an operation panel is arranged on the rack; a pushing rod drive device is arranged on the top of the rack; the pushing rod drive device comprises a servo motor and a spiral pair; in use, the servo motor drives a lead screw of the spiral pair to rotate and move; a pushing rod is arranged on a nut support of the spiral pair; a guide sleeve is arranged on the outer part of the pushing rod; a central deviation correcting device is arranged on the pushing rod drive device; a quick-to-change pressure head is arranged on the central deviation correcting device; a clamp is arranged on the bottom of the rack; the central deviation correcting device comprises an upper connecting part and a lower connecting part; a thrust ball bearing is arranged between the two connecting parts; a rubber spring is arranged in an inner cavity of the lower connecting part; a bearing clamping mechanism is arranged on the quick-to-change pressure head; the central deviation correcting device is fixed onto a pressure sensor at the lower end of the pushing rod drive device; and the quick-to-change pressure head is connected onto the central deviation correcting device. The vertical type bearing pressing machine is simple in structure, is convenient to operate, is high in assembly precision, is high in efficiency and is high in practicability.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

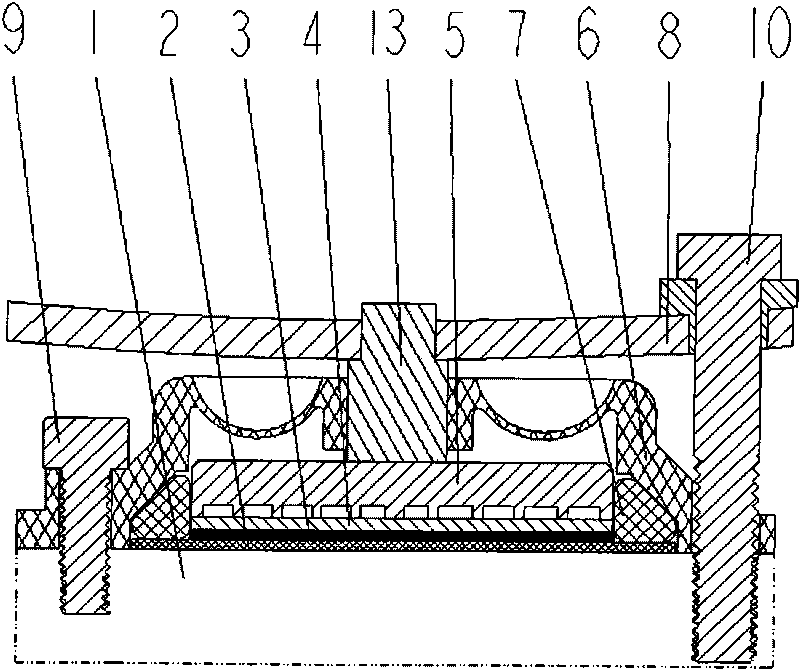

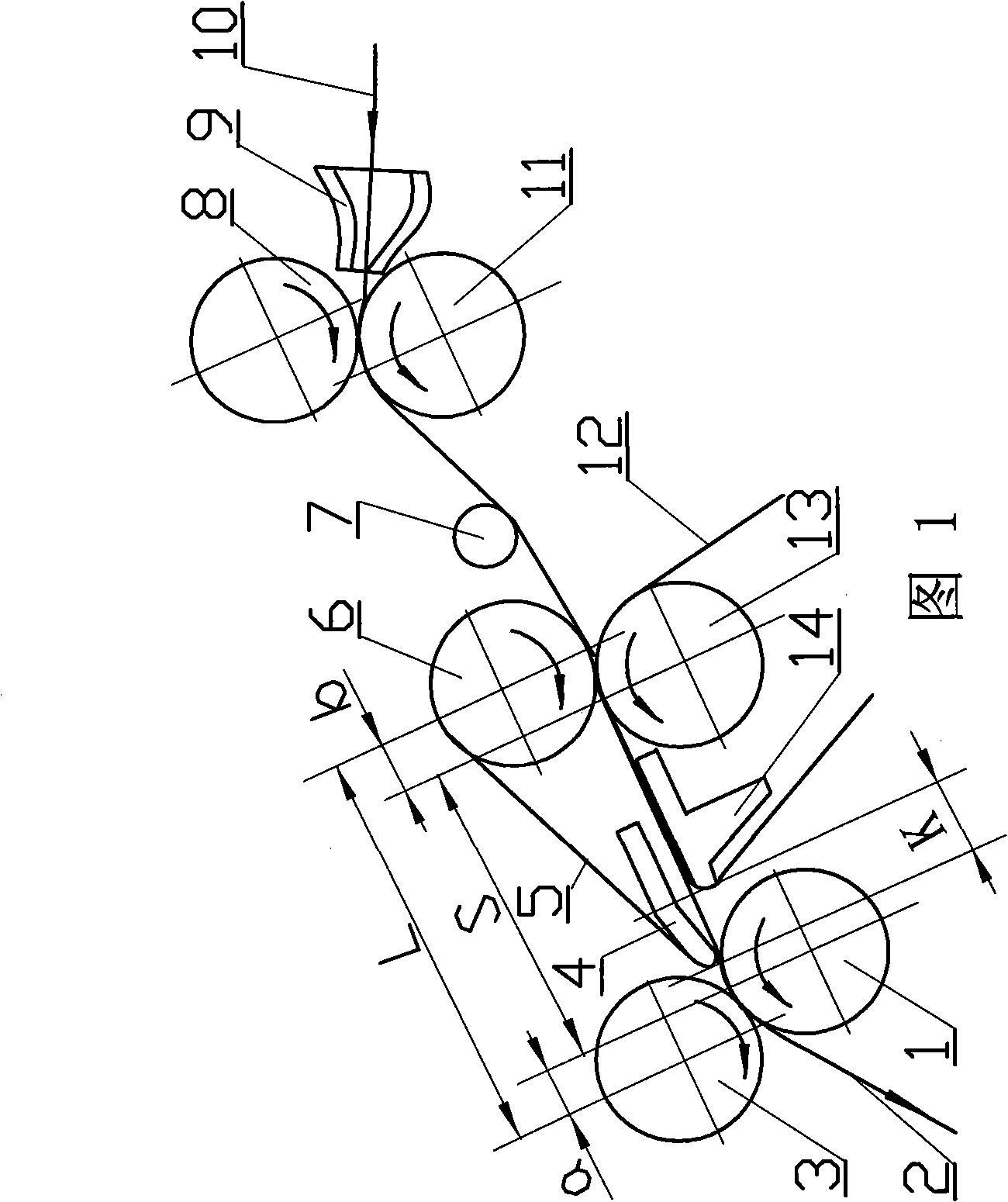

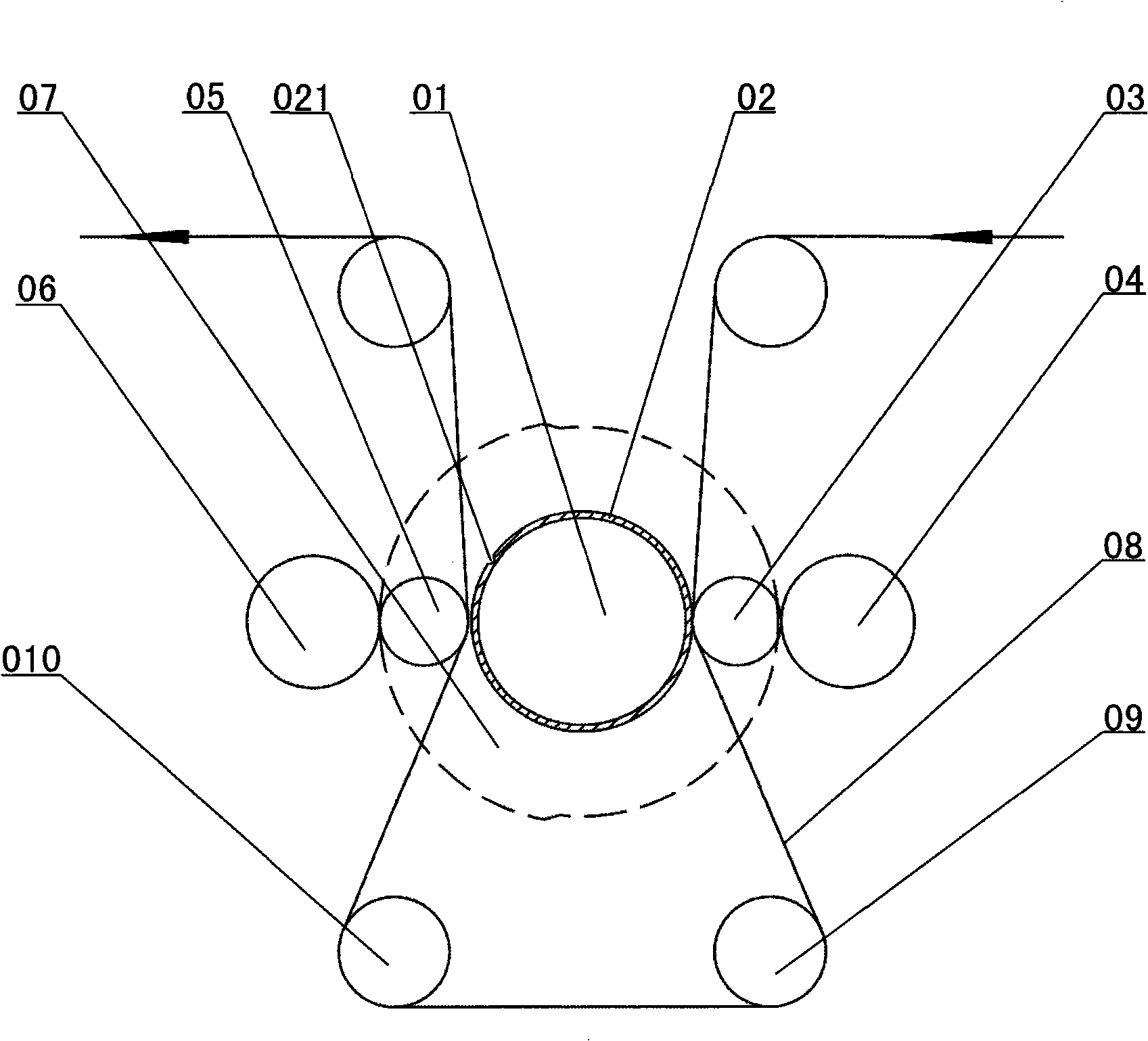

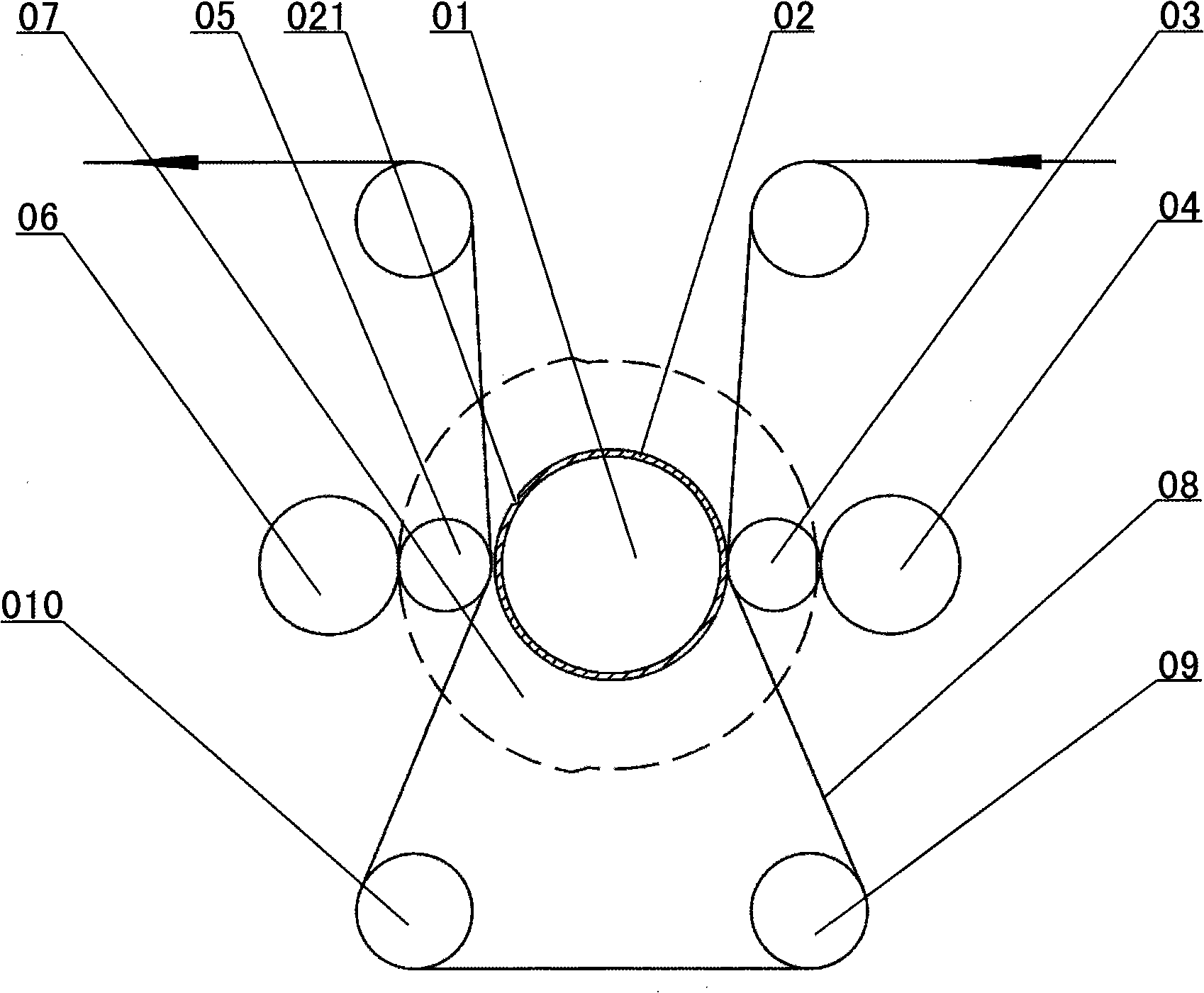

High power drafting device for ring spinning frame

InactiveCN101307515AShorten the lengthExpand the range of the friction fieldDrafting machinesFiberEngineering

The invention discloses a high-power drafting assembly used for a ring spinner, comprising a front drafting roller pair with a front roller and a front belt roller, and a rear drafting roller pair with a rear roller and a rear belt roller, wherein, a middle roller and an upper middle roller are arranged between the front drafting roller pair and the rear drafting roller pair, an upper pin is arranged between the upper middle roller and the front belt roller, while a lower pin is arranged between the middle roller and the front roller, an upper apron is sleeved on the upper middle roller and the upper pin, a lower apron is sleeved on the middle roller and the lower pin, the forward setting distance K between the upper pin front edge and the lower pin front edge is at least 3 millimeters, the ratio of the setting distance L from the upper middle roller to the front belt roller and the setting distance S from the roller to the front roller is between 1.1 and 1.6. The high-power drafting assembly can shorten the freestream flow zone length to the utmost extent, extend the control area of the apron, effectively increase the drafting multiple of the drafting assembly and guarantees the quality of the completed filament.

Owner:DONGTAI TEXTILE MASCH CO LTD

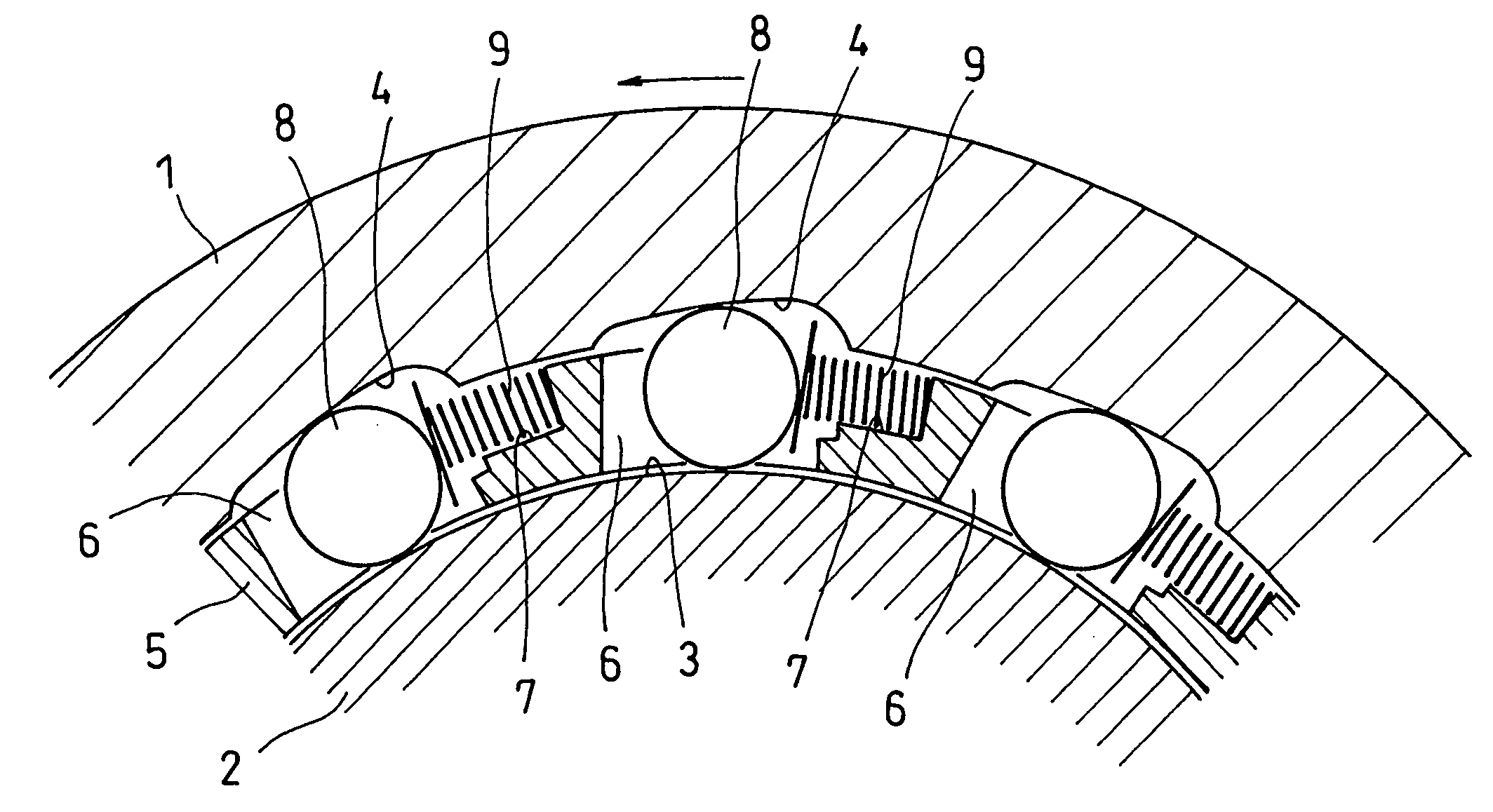

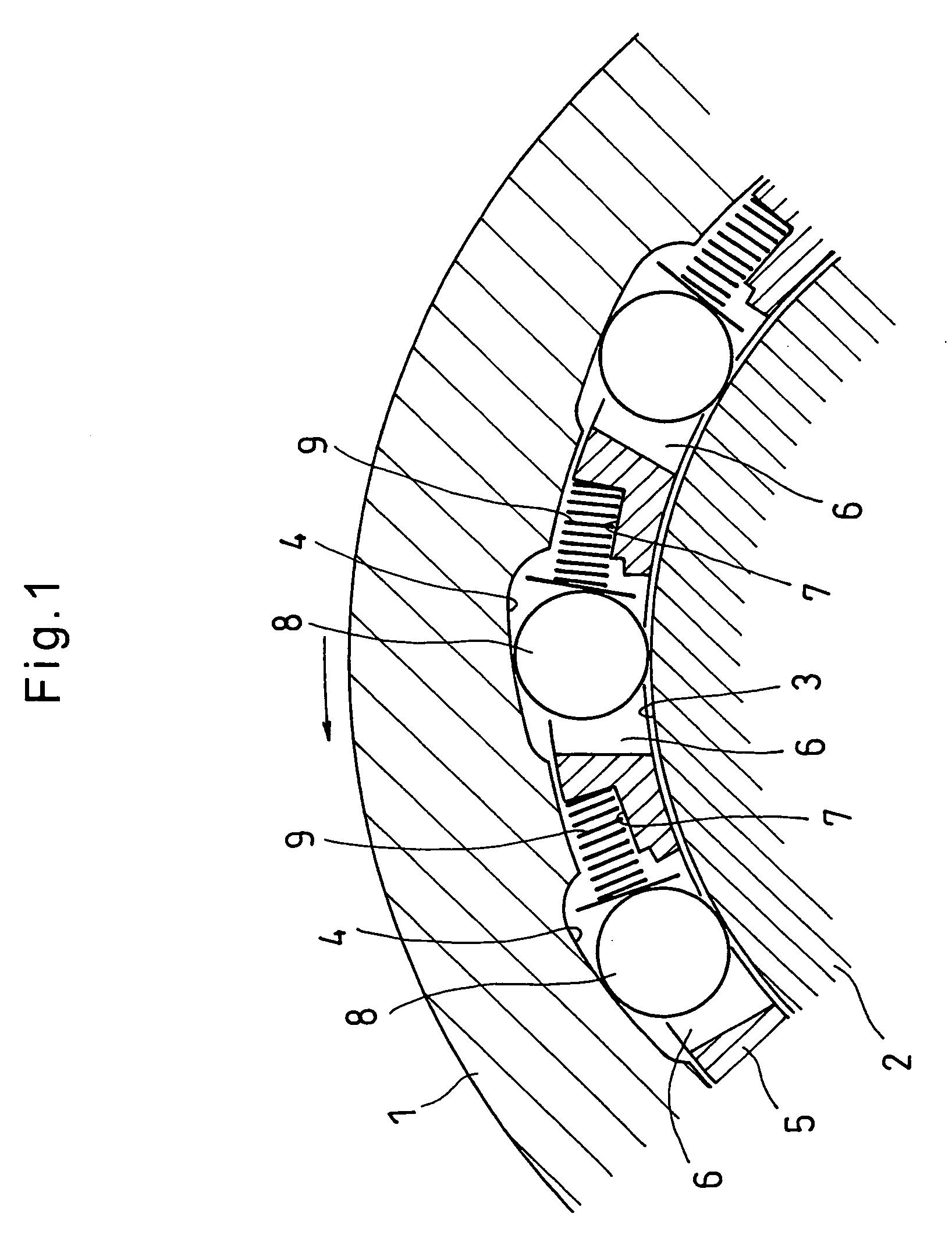

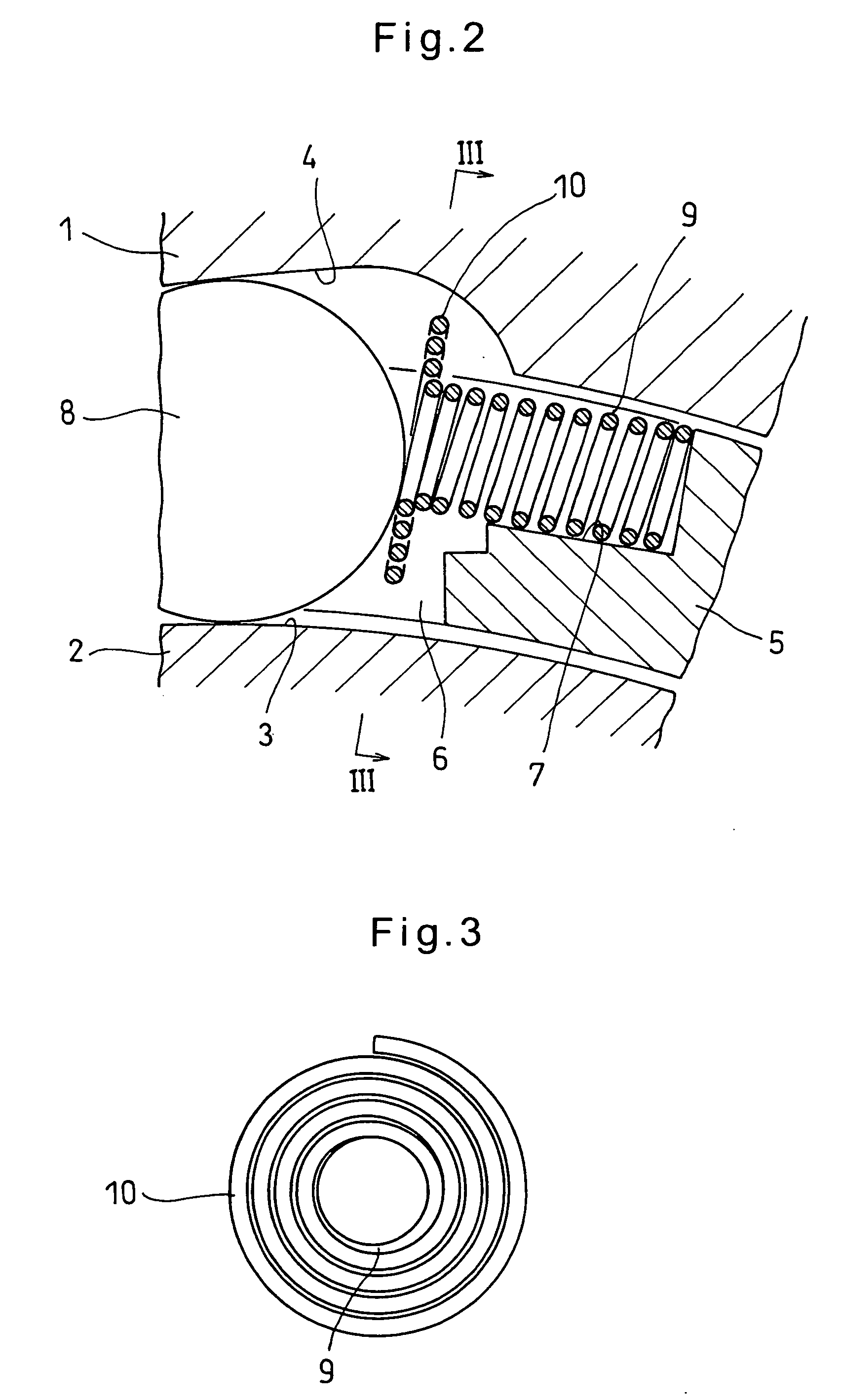

One-way clutch

InactiveUS20080236977A1Minimize inclinationStable pressing forceMechanical actuated clutchesWound springsCoil springEngineering

A one-way roller clutch includes an outer ring, and an inner ring mounted inside the outer ring and having an outer cylindrical surface. The outer ring has on its inner periphery a plurality of cam surfaces each defining a wedge-shaped space in cooperation with the cylindrical surface of the inner ring. Rollers are each mounted between one of the cam surfaces and the cylindrical surface. Each roller is biased by a coil spring toward a narrow portion of the corresponding wedge-shaped space. Each coil spring has at its end facing the roller a radially outwardly extending spiral roller abutment portion. The roller abutment portion prevents the end of the coil spring from slipping along and separating from the roller, thus stabilizing the attitude of the coil spring.

Owner:NTN CORP

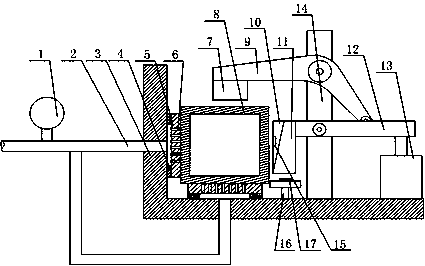

Laser holograph mould pressing method

ActiveCN101274576AEasy and fast installation and commissioning processPressing force is stableDecorative surface effectsRotary pressesEngineeringWorking temperature

The invention relates to a laser holography graph-text stamping method. The method comprises that a stamping working plate is installed on a cylinder, and at least two stamping working positions are arranged along the circumferential direction of the stamping working plate. The method is characterized in that: a certain pressing force is maintained between the stamping working plate and the cylinder at each stamping working position; the stamping working plate is divided into a stamping working area the temperature of which reaches the stamping working temperature and a transitional area the temperature of which is lower than the stamping working temperature, and the joints of the two ends of the stamping working plate are positioned at the transitional area; at each stamping working position, the stamping working area is used for stamping the laser holography graph-text at the stamping materials, and for leading the laser holography graph-text stamped at the stamping materials by each stamping working position to be subsequently connected. The laser holography graph-text stamping method of the invention does not lead to plate joints corresponding to the joints at the stamping materials, and leads continuous laser holography graph-text to be stamped at the stamping materials; the installation process and the testing process of devices used by the method of the invention are easy and fast; a compression roller and the cylinder are not mutually compacted, thus leading to stable operation and good product quality.

Owner:SHANTOU DONGFENG PRINTING CO LTD

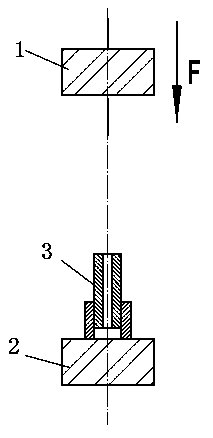

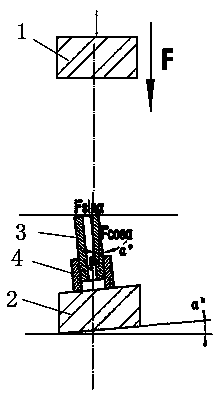

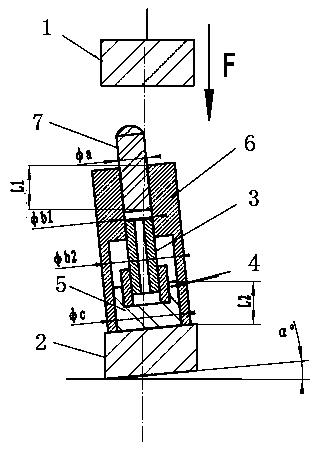

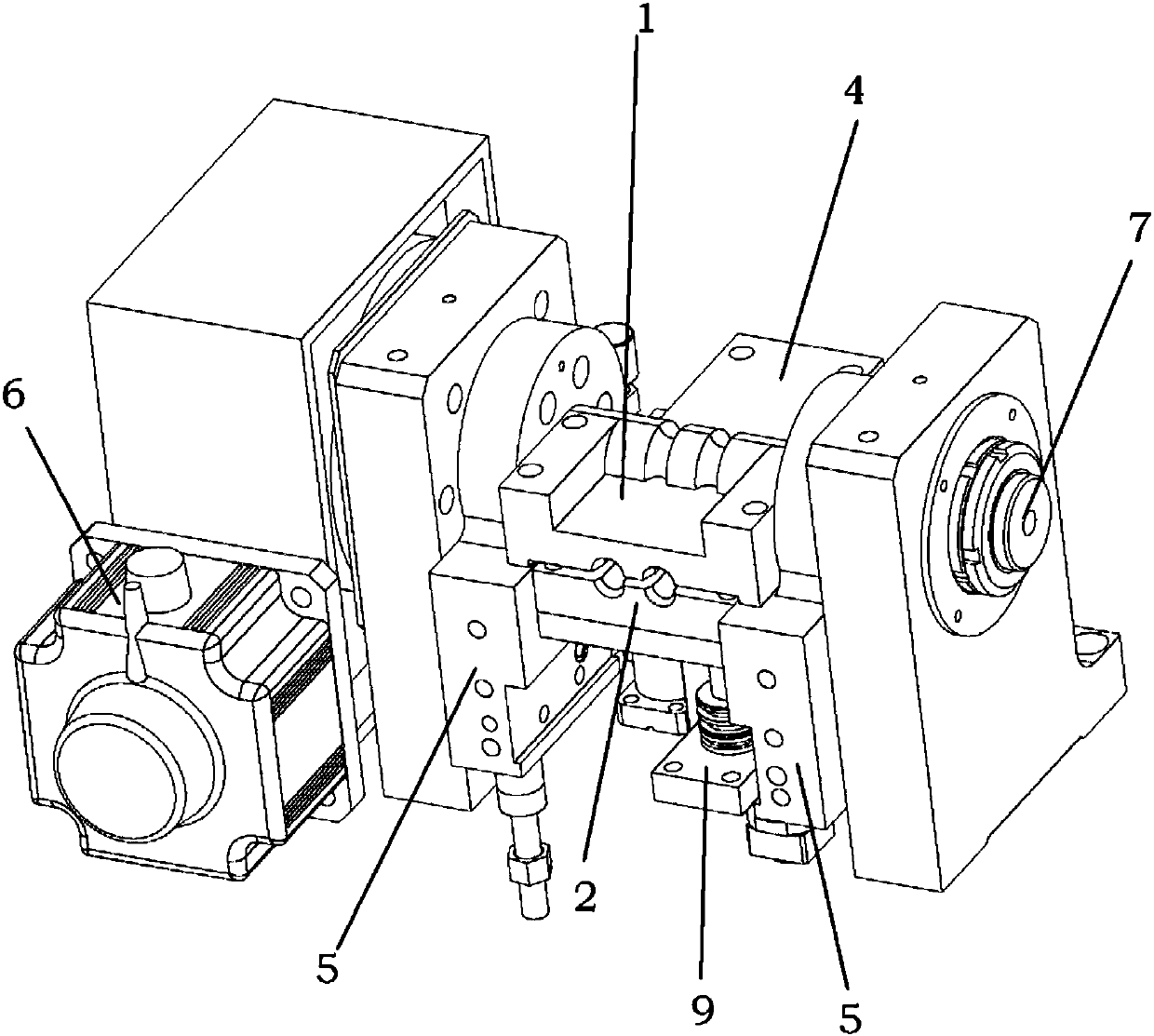

Metal part interference fitting device and fitting method

ActiveCN105499960AReduce the phenomenon of improper assemblyStable pressing forceMetal working apparatusInterference fitEngineering

The invention discloses a metal part interference fitting device and a fitting method. The fitting device comprises an equipment base of equipment to be fitted, a first metal part to be fitted, a second metal part to be fitted, a pressing head for pressing and fitting the first metal part, a pressing base adapted to the second metal part, a guide tool used for guiding the first metal part, and a positioning tool used for positioning the first metal part, wherein the first metal part is pressed and fitted into the second metal part; and the pressing base is arranged on the equipment base. With the adoption of the metal part interference fitting device, problems of pressing inclination, directional expansion and great difference caused by factors of equipment and the like can be greatly reduced, a pressing-in force needed by metal part interference fit is stably realized, the probability of not assembling in place is lowered, the coaxiality of an assembly part after the interference fit is greatly improved, and a stable corresponding relation between a releasing force and the pressing-in force of the assembly piece after the interference fit is greatly improved.

Owner:DONGGUAN XIANGTONG PHOTOELECTRIC TECH

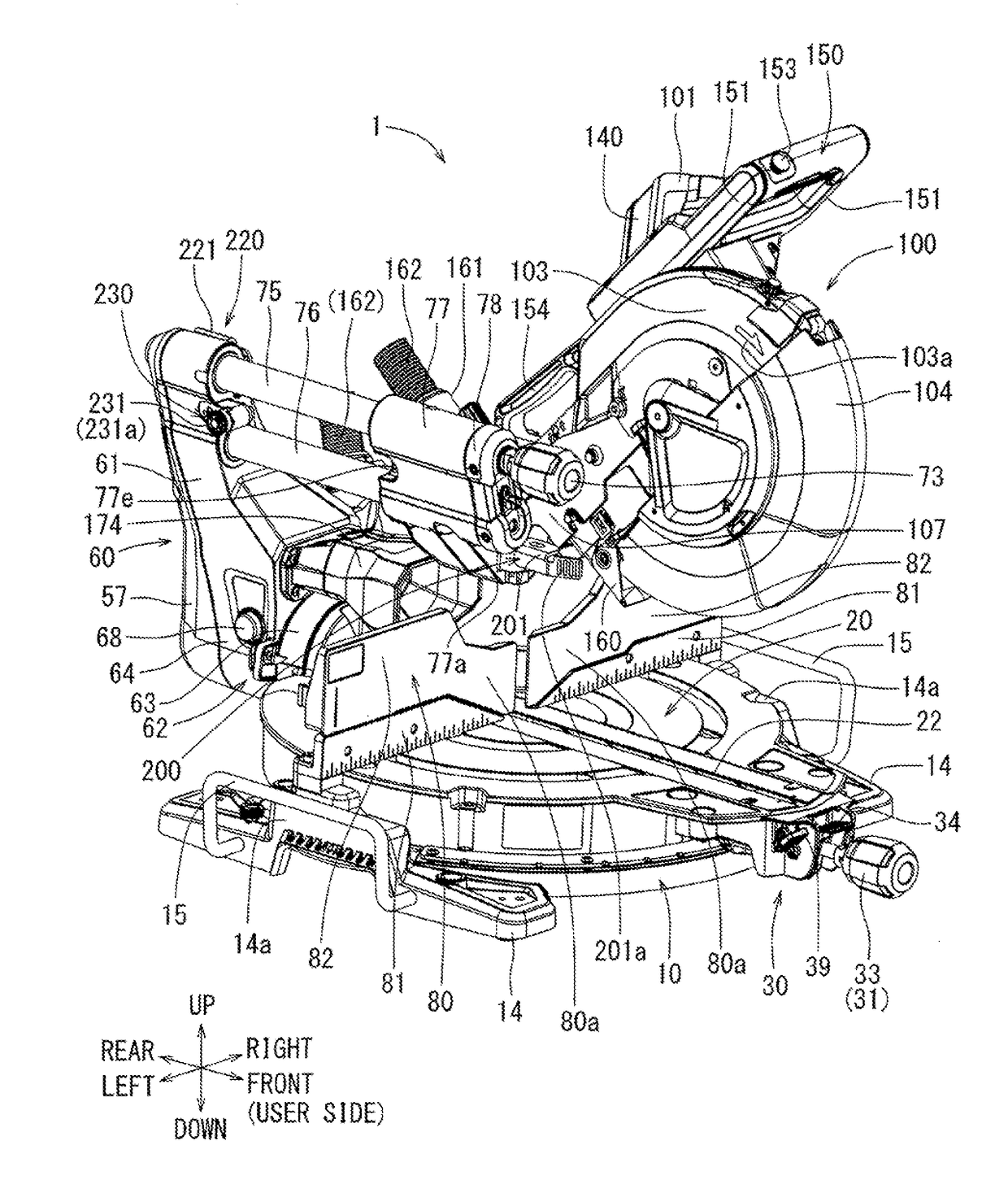

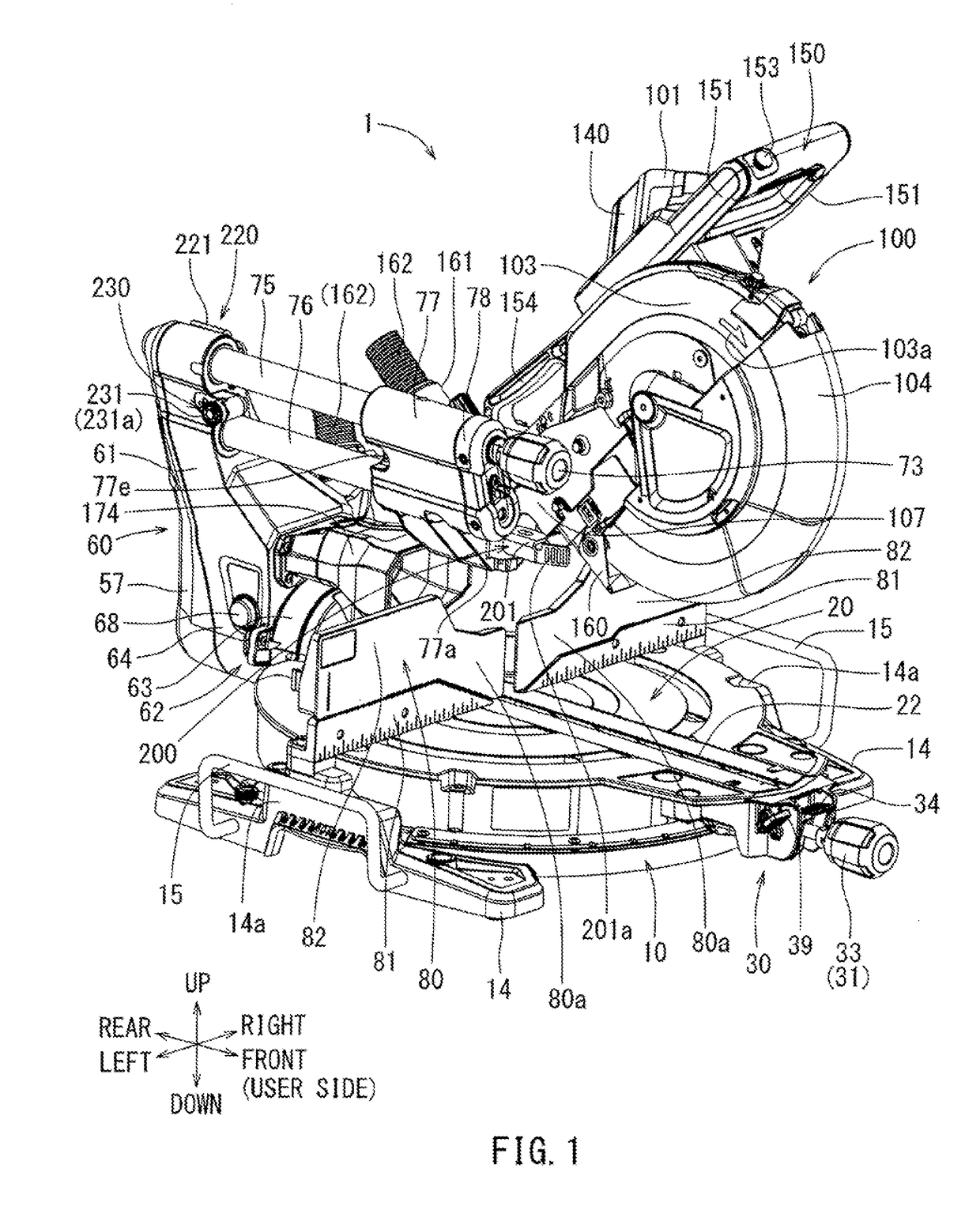

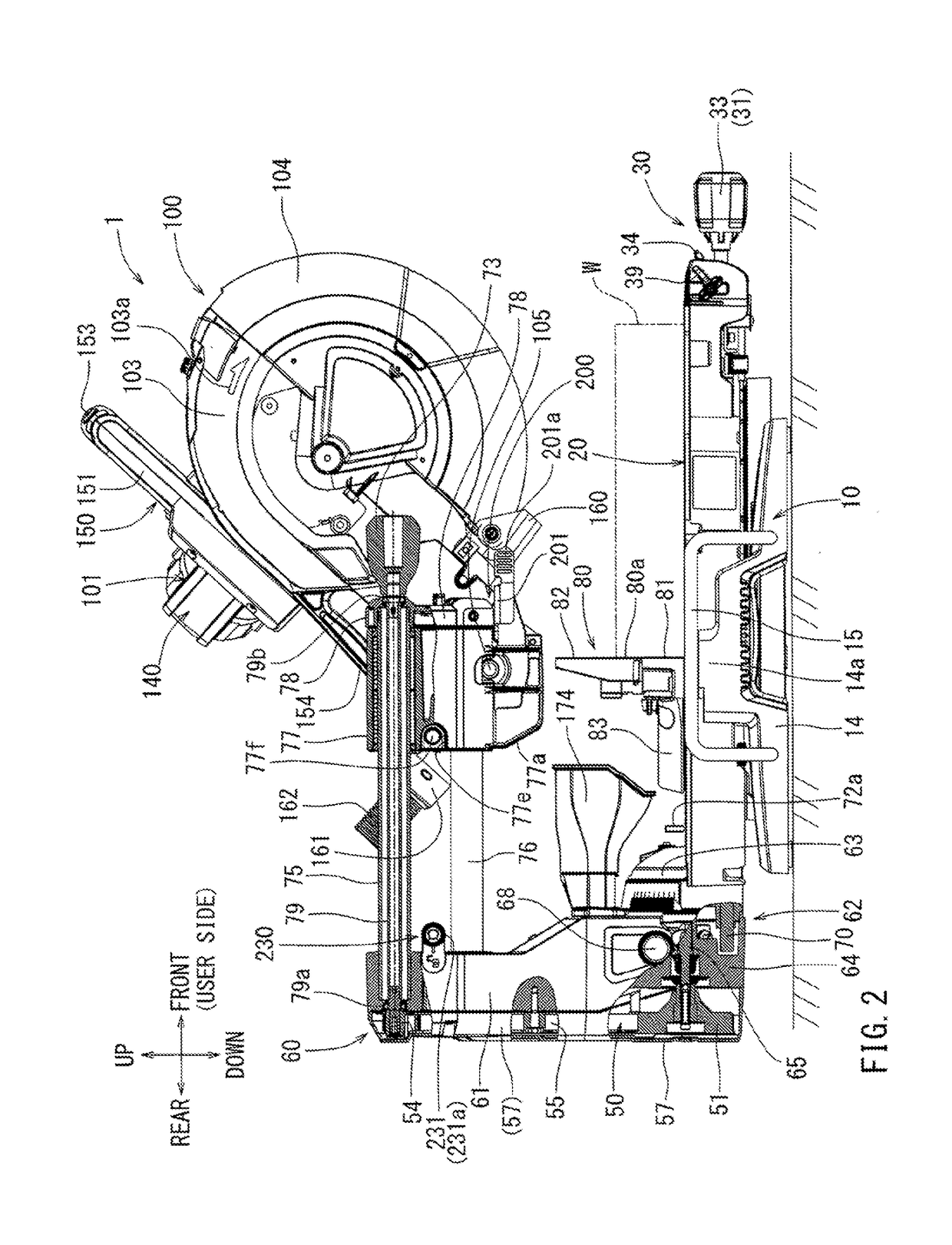

Cutting device

ActiveUS20180133817A1Easy to operateReduce the overall heightMetal sawing devicesProfiling/shaping machinesLocking mechanismEngineering

The first rotation lock mechanism 31 is configured such that a screw force produced by a rotation operation of an operation member 33 is transmitted to a lock member 42 via a transmission bracket 36 and a transmission rod 40. Through minimizing the length of the screw shaft 35, the transmission bracket 36, and the transmission rod 40, the position of a lock member which a screw shaft 35 is brought into contact with and the screw force is directly applied to is arranged to be closer to a user in comparison with conventional prior art. As a result, transmission loss of the screw force can be reduced, enhancing accuracy and consistency for the fixing force with respect to the table can be improved.

Owner:MAKITA CORP

U-shaped pipe bending mechanism

The invention discloses a U-shaped pipe bending mechanism which comprises a bending die, a clamping die and a back die. A pipe penetrates the part between the bending die and the clamping die. The back die is arranged on the side, the same with the clamping die, of the pipe. The inner side of the bending die is an arc bending die face. A crease-resisting back die is further arranged on the side, the same with the bending die, of the pipe. The crease-resisting back die corresponds to the back die. The pipe penetrates the part between the crease-resisting back die and the back die, and the crease-resisting back die abuts against the face of the bending die. The face, making contact with the face of the bending die, of the crease-resisting back die is an arc face, the arc face is matched withthe bending die, and the top end of the side, making contact with the pipe, of the arc face stretches in the side, close to the clamping die, of the bending die. By means of the U-shaped pipe bendingmechanism adopting the above technical scheme, the pipe can be flattened, in addition, the pipe cannot be wrinkled due to stress during bending, and the U-shaped pipe bending mechanism is particularly suitable for machining pipes with thin walls or soft pipes.

Owner:ZHONGSHAN JINGDA TEKE MACHINERY CO LTD

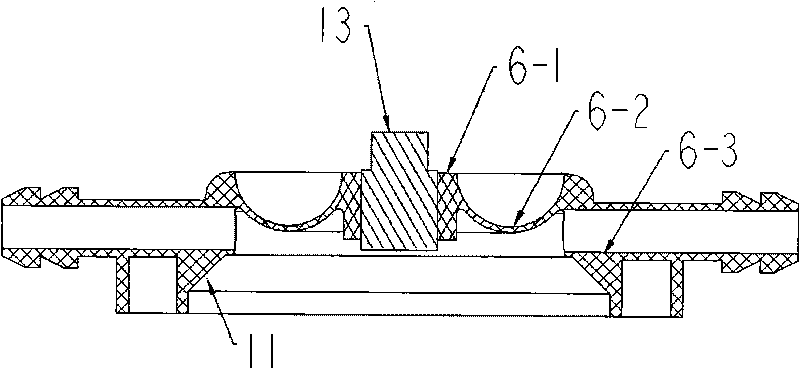

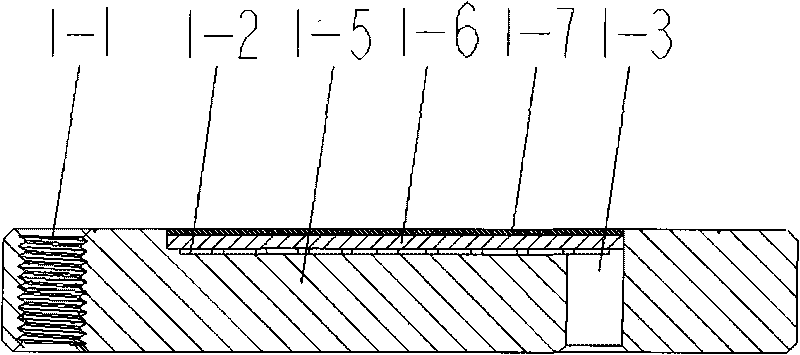

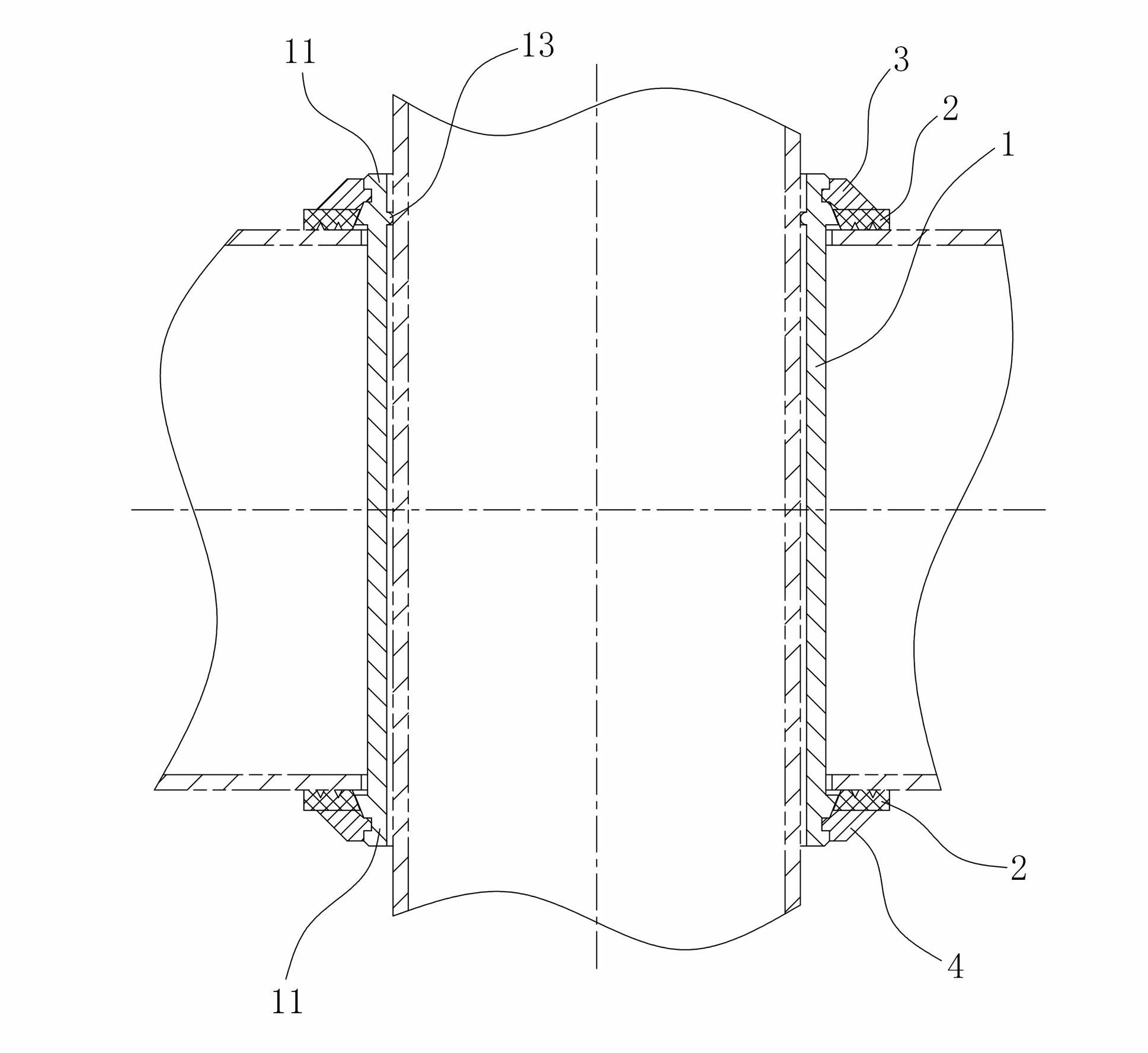

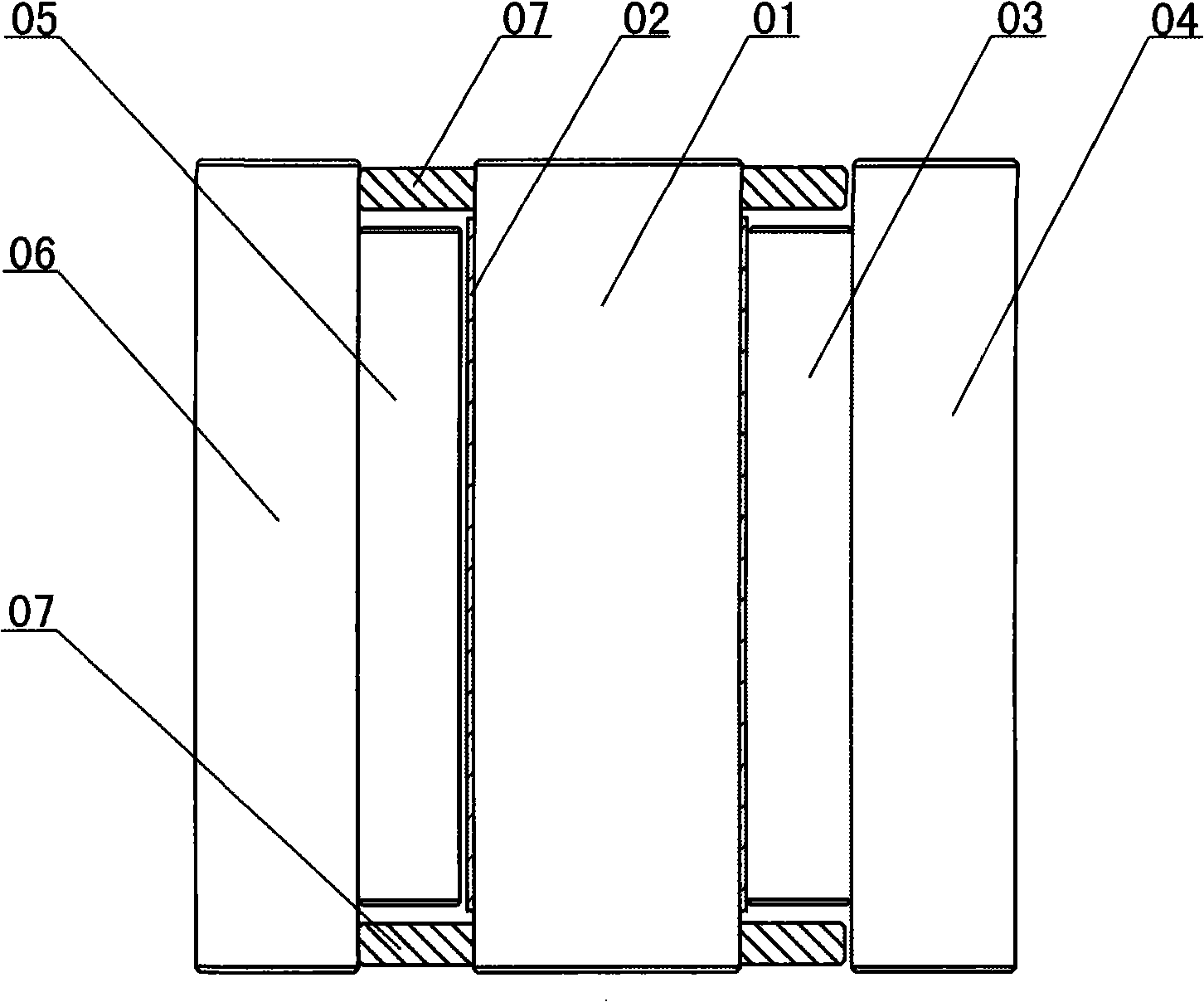

Pair punching seal sleeve for penetration and connection of tubular product

ActiveCN102121534ASimple structureEasy to manufactureEngine sealsDoor/window protective devicesPunchingMaterial Perforation

The invention discloses a pair punching-hole seal sleeve for penetration and connection of a tubular product. The seal sleeve comprises a seal sleeve body which is of a cylinder shape, wherein the upper end and the lower end of the seal sleeve body are provided with clamping edges which are matched with a pair punching hole; the clamping edge on the upper end of the seal sleeve body is provided with a first pressing block; and the lower end surface of the first pressing block is provided with a soft seal ring which can be pressed to the opening of the upper end of the pair punching hole. The pair punching-hole seal sleeve for penetration and connection of the tubular product has the advantages of good sealing property, simple structure and low cost, and is convenient to manufacture, and is convenient and rapid to install.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

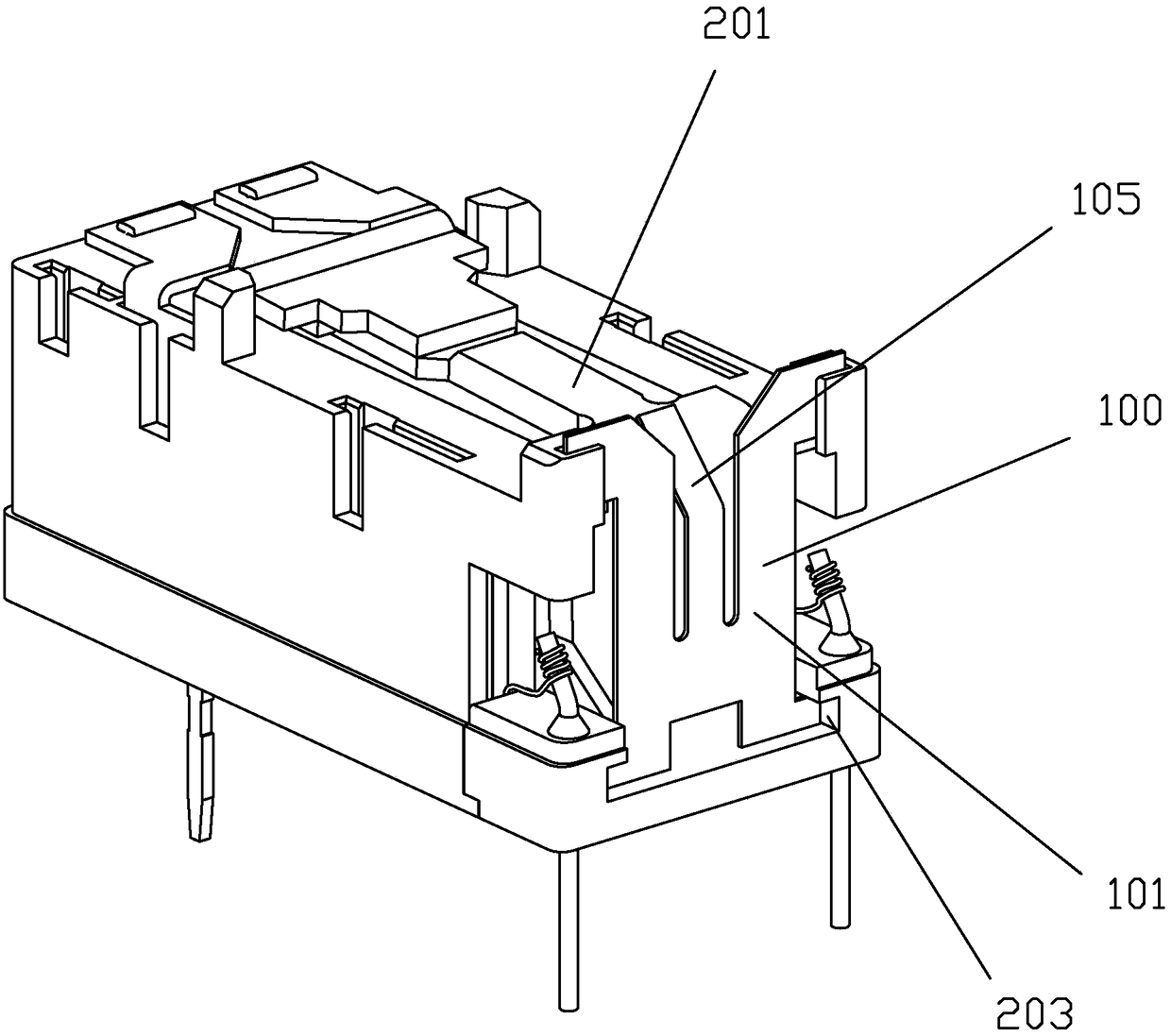

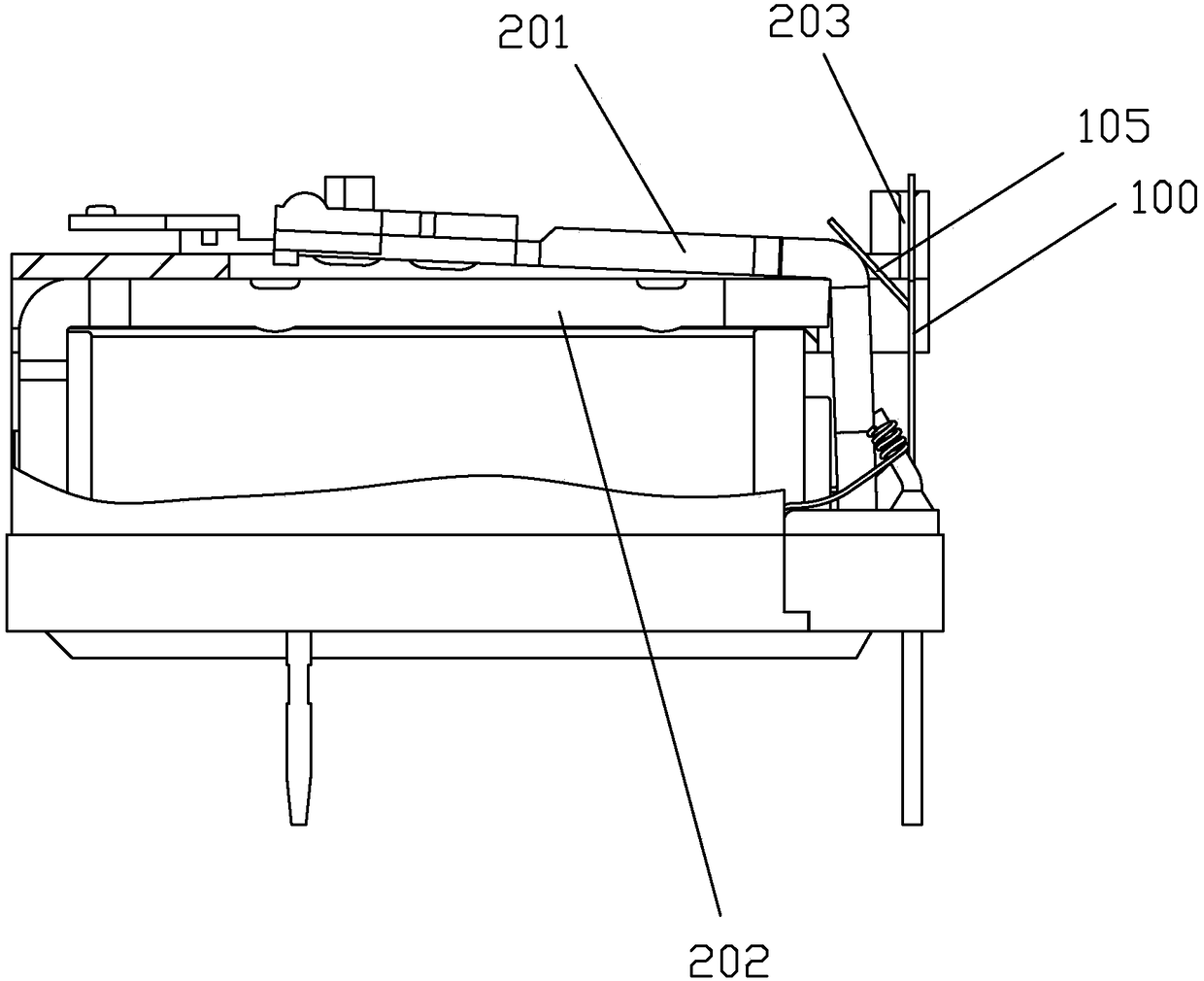

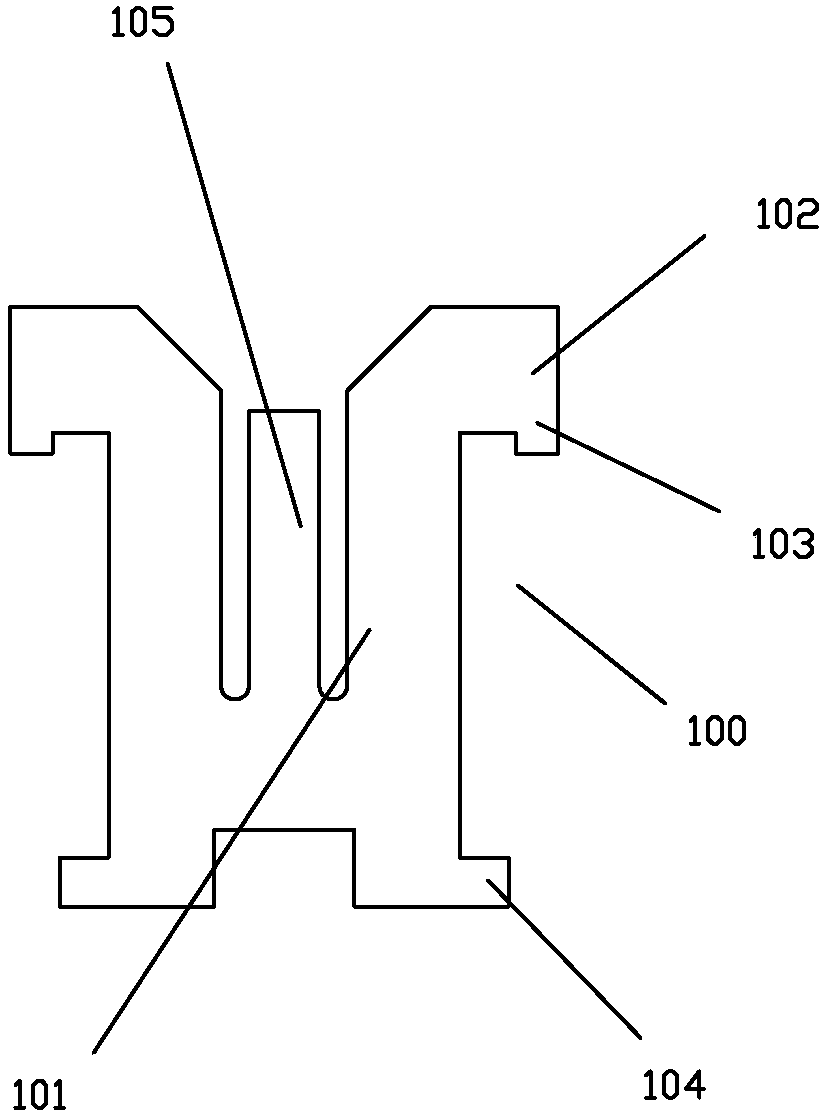

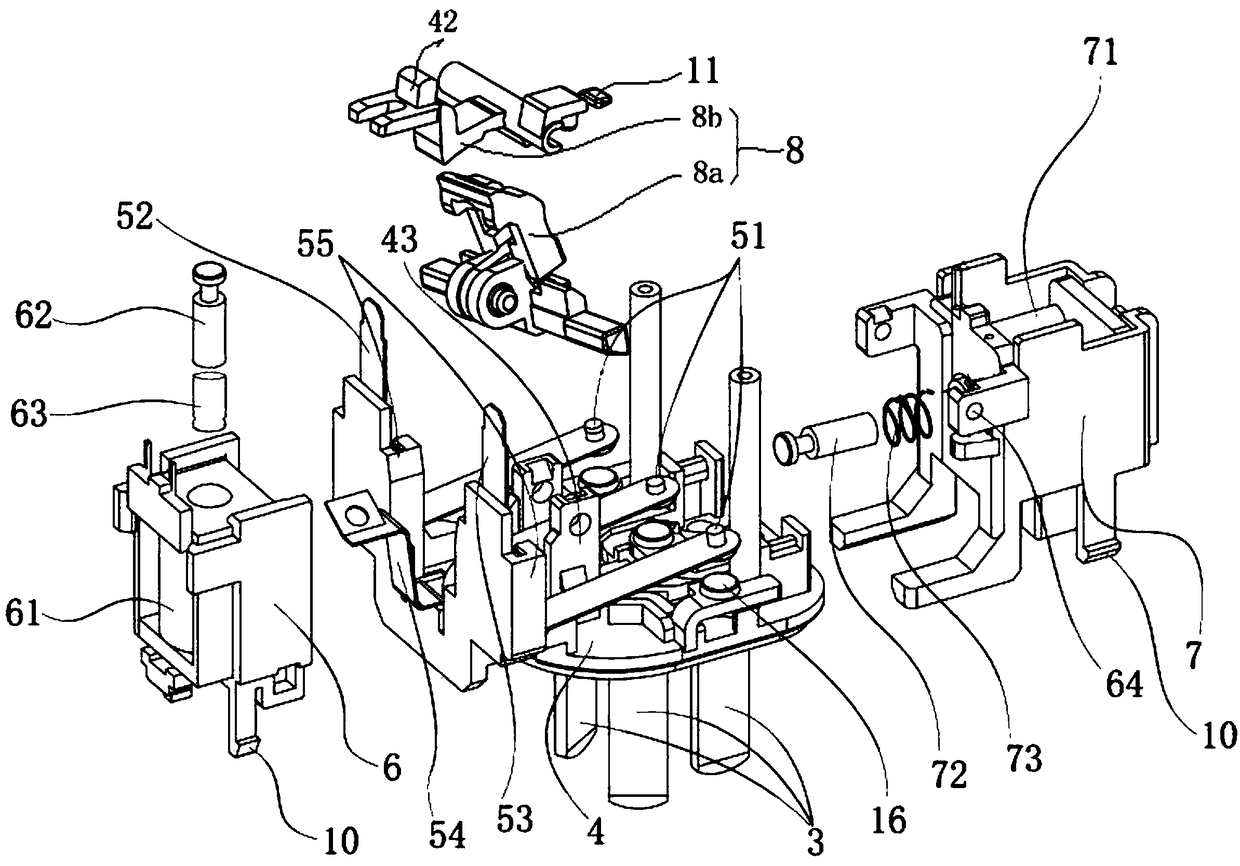

A compression spring of a snap-in electromagnetic relay

ActiveCN106024524BImprove consistencyImprove convenienceElectromagnetic relay detailsMechanical engineeringRelay

The invention discloses a beating type electromagnetic relay pressure spring. The pressure spring comprises a flat-sheet-shaped main sheet body, wherein the upper part of the main sheet body extends towards the two sides in the flat sheet manner to form upper side wings; the tail ends of the upper side wings extend downwardly in the flat sheet manner to form tail wings; the lower part of the main sheet body extends towards the two sides in the flat sheet manner to form lower side wings; a tongue-shaped sheet is arranged in the middle of the main sheet body, wherein a certain inclined angle is formed between the plane of the main sheet body and the tongue-shaped sheet; the tail wings of the main sheet body are provided with bent parts; and when the upper side wings of the pressure spring are mounted in corresponding plastic inserting grooves of the relay, the circular-arc plane formed by the bent parts is in contact with the corresponding plastic inserting grooves of the relay. By adoption of the structure, the consistency in assembling the pressure spring is improved, so that the consistency of the pressing force of the pressure spring is further improved; and meanwhile, the convenience in assembling the pressure spring is improved, so that pollution to the internal environment of the relay is reduced.

Owner:XIAMEN HONGFA SIGNAL ELECTRONICS CO LTD

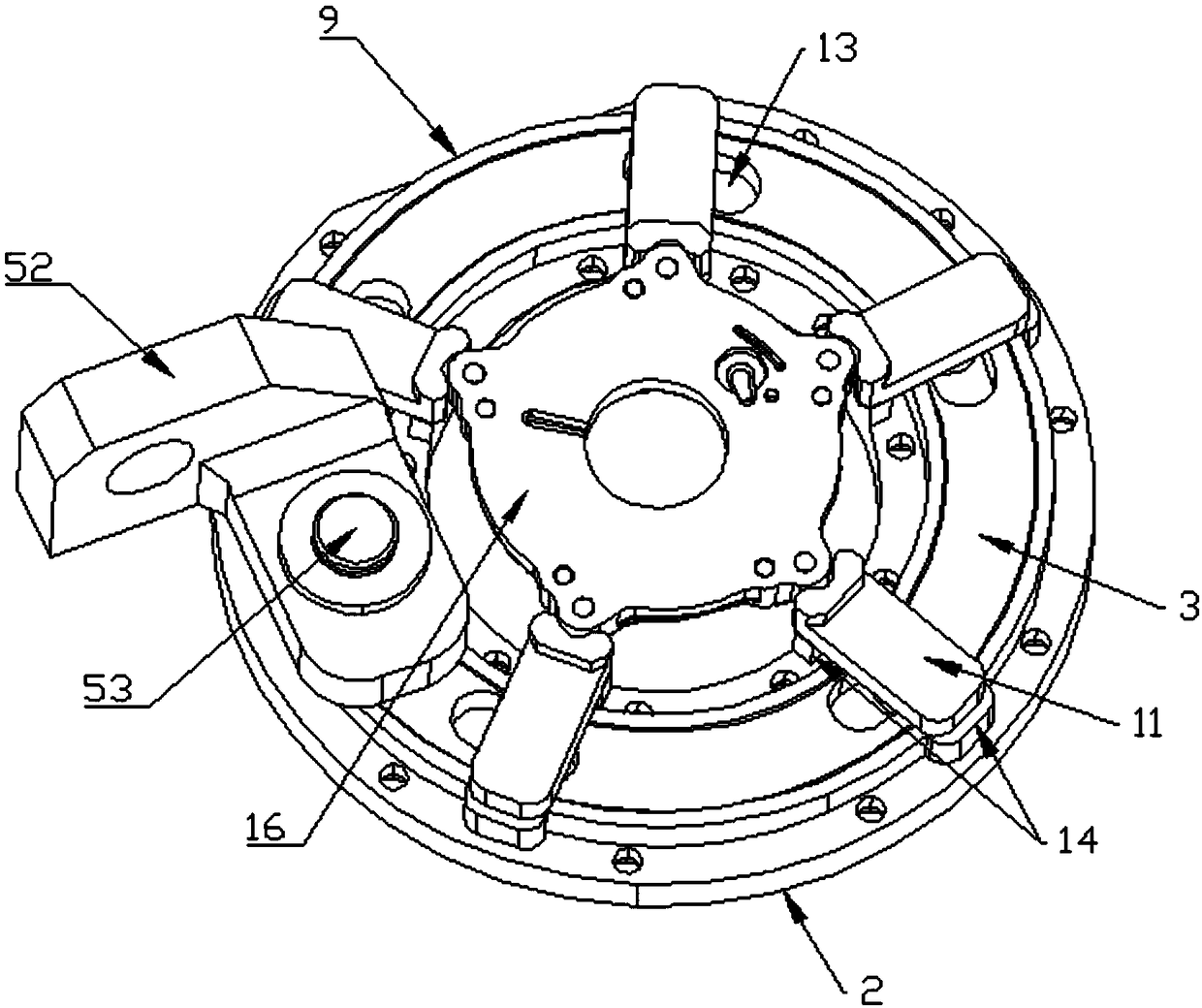

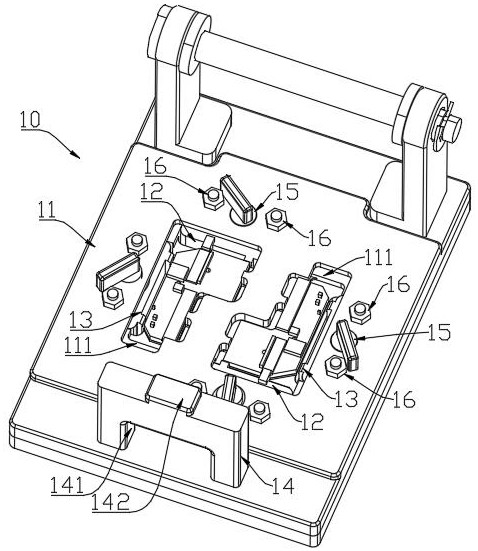

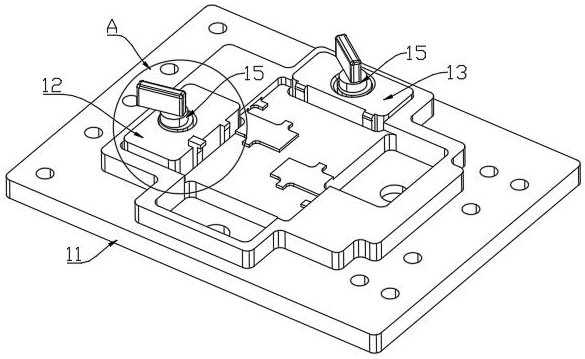

Five-claw self-centering clamping tool with detecting function

The invention discloses a five-claw self-centering clamping tool with a detecting function and relates to the technical field of aluminum alloy pressure casting. The five-claw self-centering clampingtool comprises a bottom plate, a clamping assembly and an air pressure detecting assembly. The clamping assembly comprises a rotary disc seat, a rotary disc, a compressing assembly and a pushing assembly. The air pressure detecting assembly comprises a first air pressure detecting head, a second air pressure detecting head, a third air pressure detecting head and a fourth air pressure detecting head. The five-claw self-centering clamping tool is simple in structure and convenient to operate, a placed product is pre-located firstly through the compressing assembly, then the rotary disc is pushed to rotate through the pushing assembly, and a chuck moves inwards under the action of a track groove to clamp the protruding portion around a lock cover, and clamping and locating of the product areachieved.

Owner:WUHU JINYI MACHINERY

Pressing mechanism

The invention discloses a pressing mechanism. The pressing mechanism comprises a bottom plate, a slide rail, a first slider, a second slider, a first installing plate, a pressing head assembly, a second installing plate, a push rod assembly, a driving assembly and a switching block, wherein the slide rail is fixedly connected to the bottom plate, the first slider and the second slider are slidingly arranged on the slide rail in the horizontal direction, the first installing plate is fixedly connected to the first slider, the pressing head assembly is slidingly arranged on the first installingplate in the vertical direction, the second installing plate is fixedly connected to the second slider, the push rod assembly is connected to the second installing plate, the driving assembly is usedfor driving the second slider, the push rod assembly and the first slider to move in the horizontal direction, and the switching block is connected between the push rod assembly and the first installing plate and used for converting the horizontal movement of the push rod assembly into the vertical movement of the pressing head assembly. The horizontal movement of the push rod assembly is converted into the vertical movement of the pressing head assembly through the switching block, so that a sample is extruded, a pressed object is not shielded on the upper side before and after being pressed,operations are convenient, and a wide view is given.

Owner:苏州中科医疗器械产业发展有限公司

Shell assembly clamp

The invention relates to a shell assembly clamp. The shell assembly clamp comprises an upper mold core and a lower mold core arranged in a sliding mode relative to the upper mold core. The upper mold core comprises an upper mold joint face and an upper mold side face surrounding the upper mold joint face. First suction holes are formed in the upper mold side face and used for being communicated with a negative-pressure pump. An accommodation space with an opening facing the lower mold core is formed in the upper mold joint face and used for accommodating a frame. A plurality of second suction holes are formed in the bottom of the accommodation space and are communicated with the first suction holes. The lower mold core comprises a lower mold joint face which is opposite to the upper mold joint face and used for fixing a transparent panel. A plurality of through holes are formed in the lower mold joint face, and a sliding rod is arranged in each through hole in a sliding mode. The sliding rods slide out of the through holes so as to be arranged on the periphery of the transparent panel to locate the transparent panel.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Aluminum profile horizontal calibration structure

The invention discloses a horizontal alignment structure of aluminum profiles, which includes a bottom plate, a gas pipe and a pressure gauge. Sealing rings are arranged on the vertical section and the horizontal section of the bottom plate. The detection block is fixed on the sealing ring, and a plurality of The air hole, the air pipe is divided into two paths, which respectively pass through the vertical section and the horizontal section of the bottom plate, and then communicate with the air hole. A column and a cylinder are installed on the horizontal section of the bottom plate, and an adjusting rod is hinged on the upper section of the column. A lower pressure block is installed on one end of the adjustment rod, the other end of the adjustment rod is hinged to the middle of the connecting rod, a fastening block is installed on one end of the connecting rod, the rubber block is set on the inclined surface, and a pressure sensor is installed on the outer wall of the rubber block. The cylinder output end is hinged with the other end of the connecting rod. By improving the existing detection equipment, the inventor only needs to adjust the working state of the cylinder to realize the rapid detection of the verticality of the aluminum profile, greatly reducing the abnormal working hours in the detection process.

Owner:邹跃明

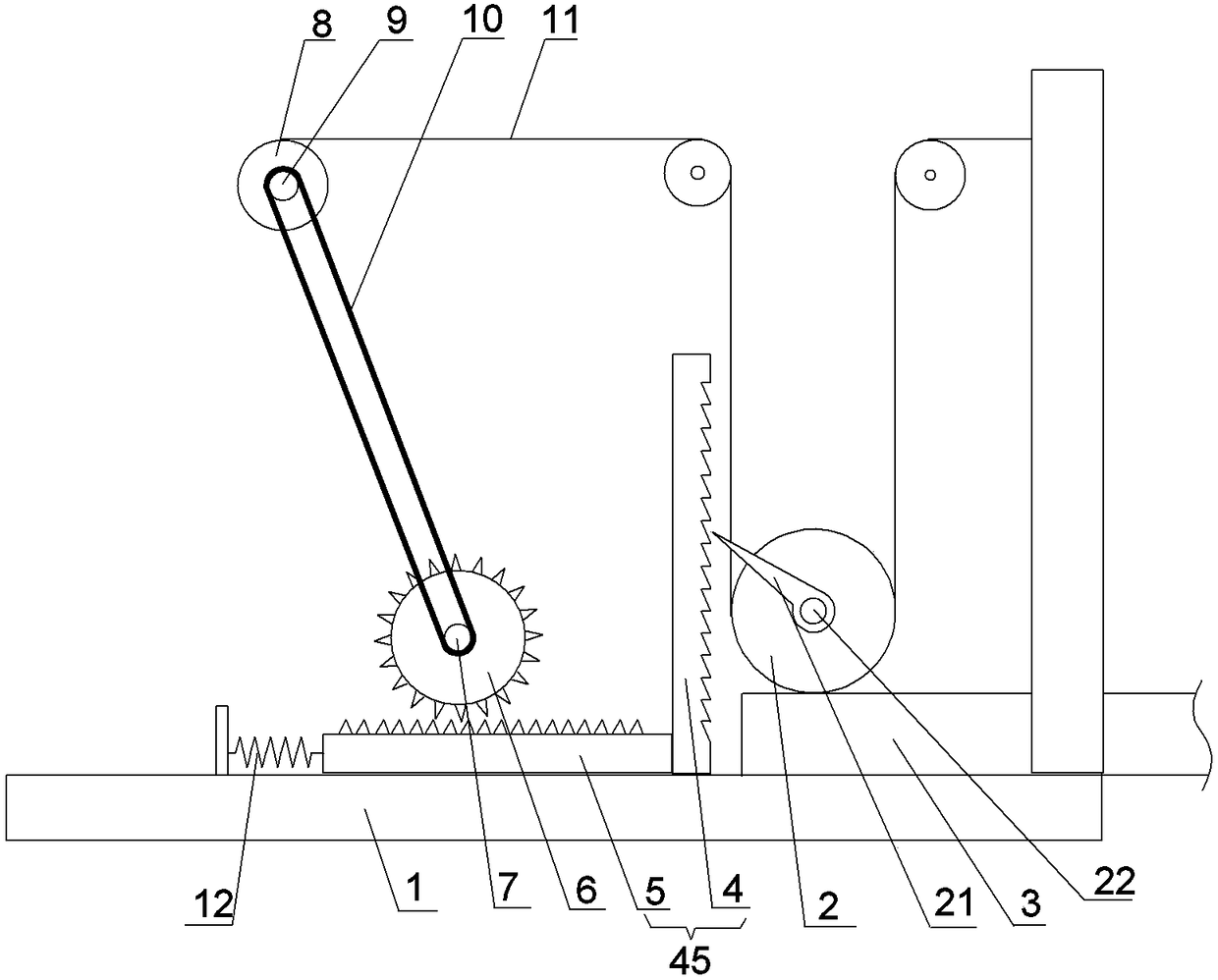

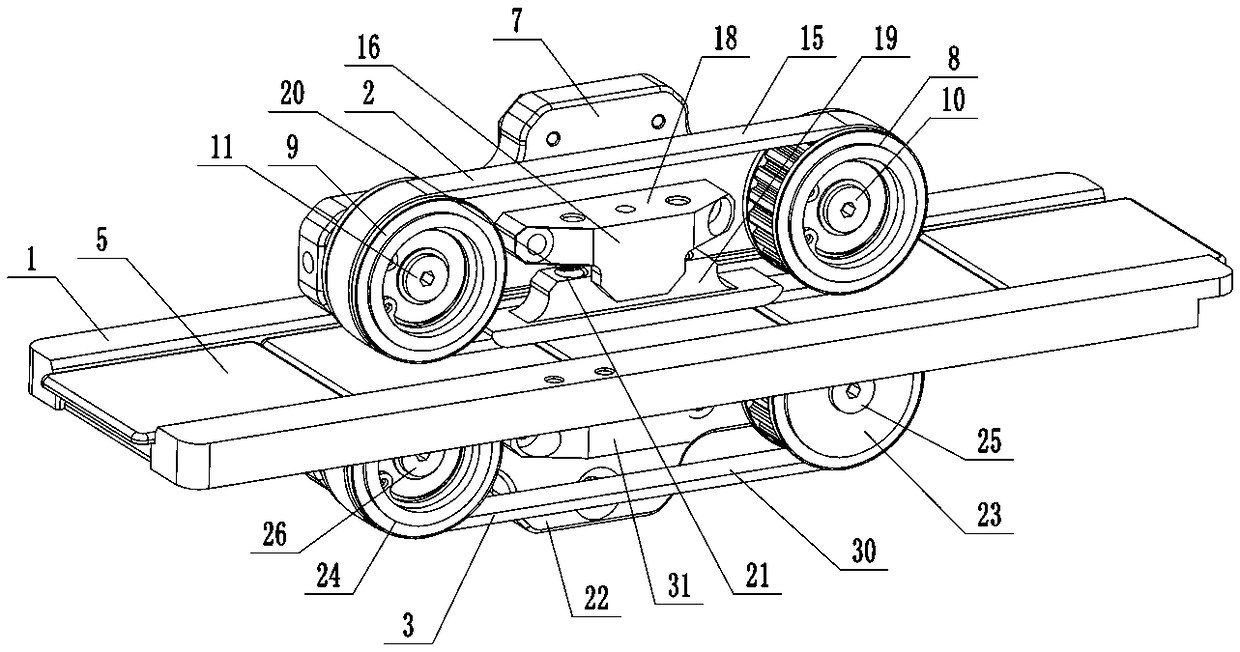

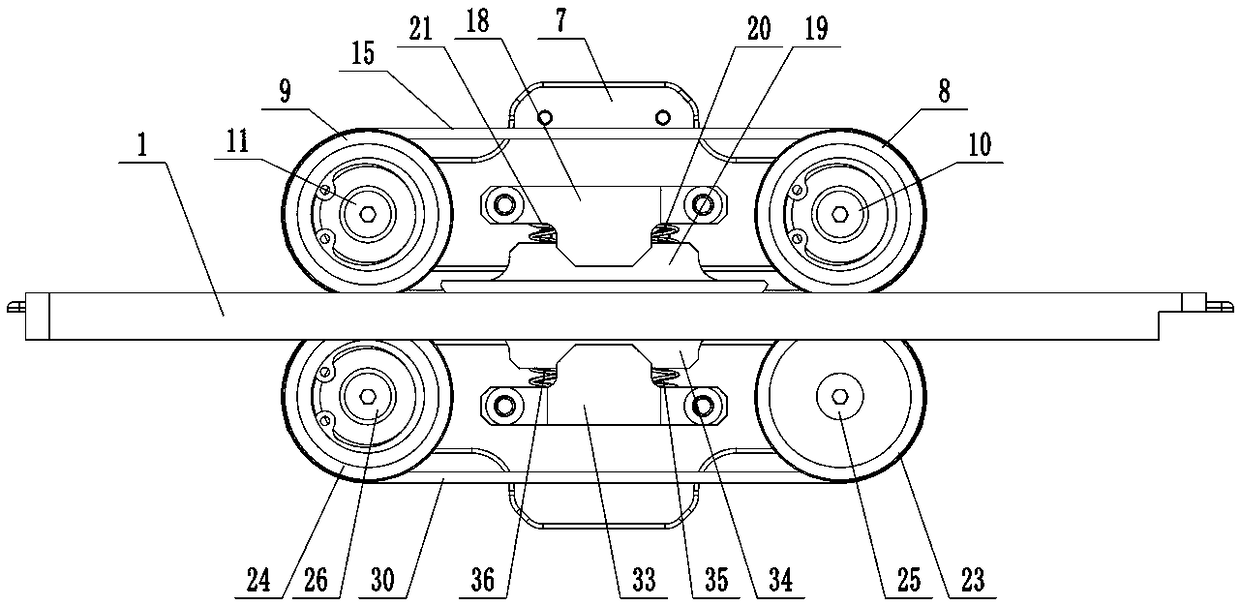

Compaction mechanism of fast-assembling dolly of engine

The invention discloses a compaction mechanism of a fast-assembling dolly of an engine, and belongs to the field of equipment for vehicle detection. The compaction mechanism comprises a soleplate, four compaction assemblies are arranged on the soleplate, each compaction assembly comprises a rotating wheel, a driving belt and a weight, and each rotating wheel is connected with a hydraulic rotatingoil cylinder; and the soleplate is provided with a weight stop mechanism which comprises a sliding body and a ratchet hinged to the axial center of the weight, the sliding body comprises a spur rack and a ratchet strip fixedly connected to the spur rack, the ratchet strip is engaged with the ratchet, the spur rack is in sliding connection to the soleplate, the frame is in rotational connection with first and second rotating shafts, the rotating wheel sleeves the first rotating shaft, a first unidirectional bearing is arranged between the rotating wheel and the first rotating shaft, the gear sleeves the second rotating shaft, a second unidirectional bearing is arranged between the gear wheel and the second rotating shaft, the spur rack is engaged with the gear, and a belt is wound around the first and second rotating shafts. Via the compaction mechanism, the magnitude of a clamp force can be adjusted freely.

Owner:郎溪品旭科技发展有限公司

Device for welding and fixing hydraulic-engineering pipes

The invention discloses a device for welding and fixing hydraulic-engineering pipes. The device is directly arranged on the hydraulic-engineering pipes in a sleeving manner, and an oil cylinder is provided for compression and pressure maintaining, so that the welded two pipes are fixed. The device is characterized in that two main U-shaped brackets are parallel with each other; the two ends of thetwo main U-shaped brackets are connected with two fixing base plates through fixing blocks correspondingly; the two fixing base plates are parallel with each other; sliding grooves are formed in thefixing base plates; two subsidiary U-shaped brackets are parallel with each other; the two ends of the subsidiary U-shaped brackets are each provided with a sliding block, and the sliding blocks are arranged in the sliding grooves correspondingly; the subsidiary U-shaped brackets are parallel with the main U-shaped brackets; the inner sides of the main U-shaped brackets and the inner sides of thesubsidiary U-shaped brackets are each provided with two grooves in a symmetrical manner; two threaded holes are symmetrically formed in each main U-shaped bracket and communicate with the grooves in the corresponding main U-shaped bracket correspondingly; and two threaded holes are symmetrically formed in each subsidiary U-shaped bracket and communicate with the two grooves in the corresponding subsidiary U-shaped bracket correspondingly.

Owner:江苏佳润管业有限公司

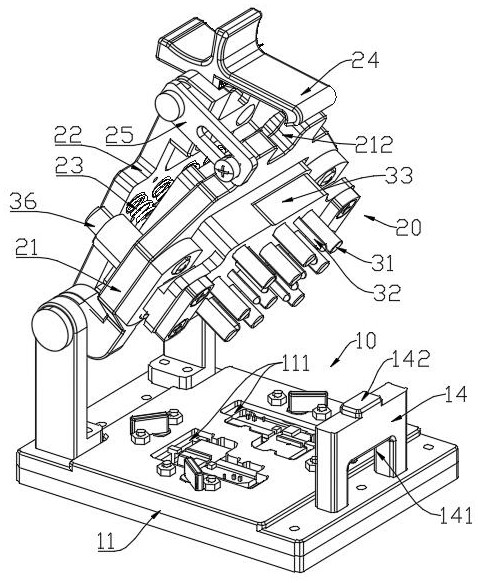

Welding clamping tool for chip-level circuit board

ActiveCN113305396AGuaranteed positionGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a welding clamping tool for a chip-level circuit board. The welding clamping tool comprises a clamping component and a pressing component. The clamping component comprises a base, and the top face of the base is provided with two rotationally symmetrical containing grooves used for containing a circuit board; and a first sliding block and a second sliding block are arranged on the side wall of each containing groove respectively to press the circuit board. The pressing component is hinged to the upper portion of one end of the base, and a buckle base is arranged at the other end of the base. The pressing component comprises a supporting plate, a pressing plate and a sliding part, the supporting plate and the pressing plate are hinged to the base along the same axis, the sliding part penetrates through the supporting plate in the vertical direction, the pressing plate is located above the supporting plate and the sliding part, and a first elastic element is arranged between the sliding part and the pressing plate. A first ejector rod and a second ejector rod are arranged at the bottom of the sliding part. When the supporting plate makes contact with the buckle base, the first ejector rod and the second ejector rod are both perpendicular to the base. The pressing plate is provided with a rotatable buckle, and the buckle seat is provided with a bayonet. According to the welding clamping tool, the product can be quickly positioned, clamped and loosened; and clamping is stable and reliable.

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

Linear drive ultrasonic motor

InactiveUS8018125B2Stable pressing forceReduce restrictionsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringUltrasonic motor

Owner:OLYMPUS CORP

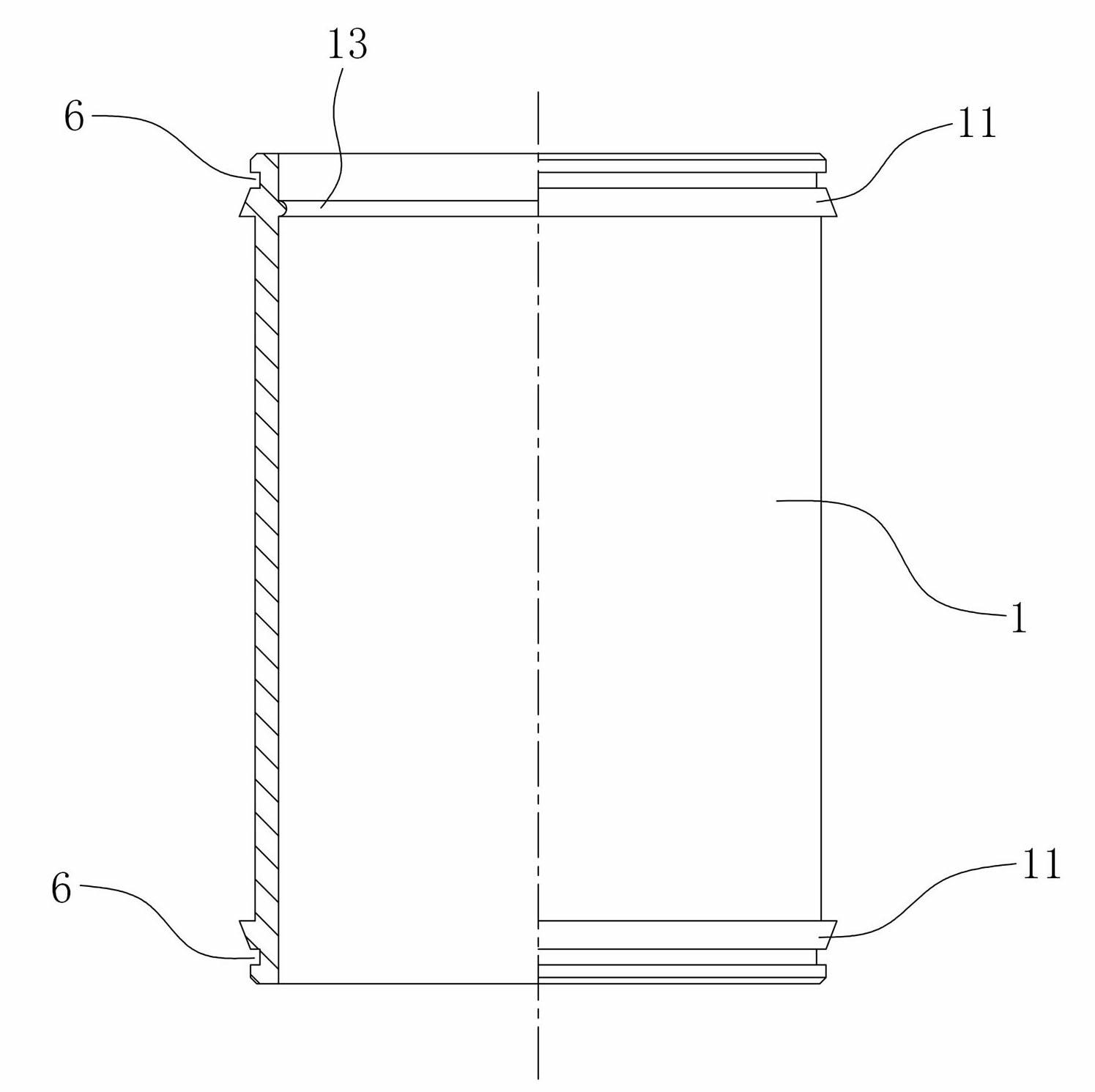

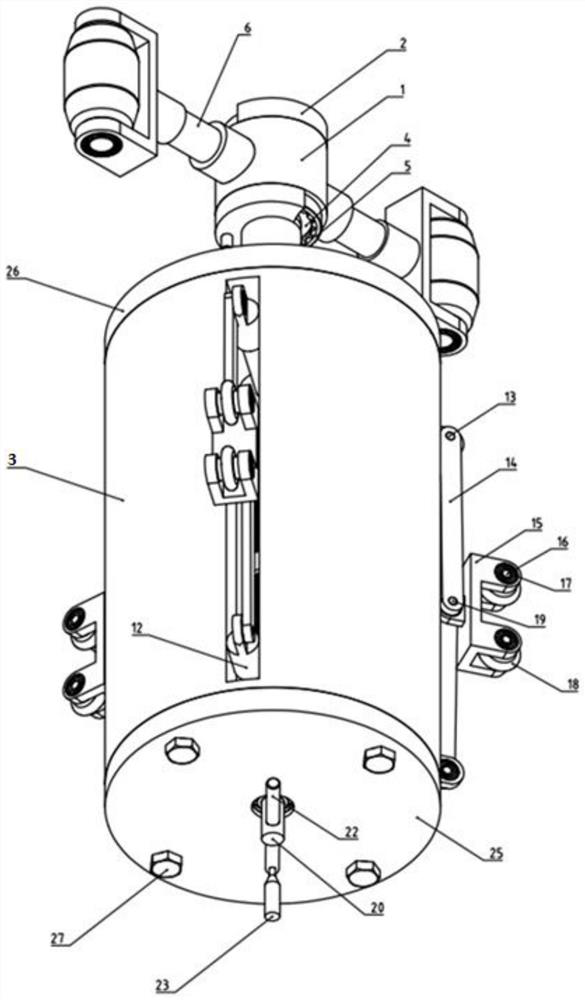

Mixing barrel locking mechanism, automatic locking system and automatic mixing system

ActiveCN110585961AConstant preloadAvoid production accidentsRotating receptacle mixersTransportation and packagingLocking mechanismEngineering

The invention relates to a mixing barrel locking mechanism, an automatic locking system and an automatic mixing system, the locking mechanism is used for locking the mixing barrel in a mixing frame; the locking mechanism comprises a first driving device, a second driving device, a clamping device, a locking pin shaft and a locking screw rod, the clamping device is used for clamping or releasing the locking pin shaft, the locking screw rod penetrates through and is connected to the locking pin shaft in a threaded mode, and the first driving device is installed on the clamping device and drivesthe locking screw rod to retract or extend from the locking pin shaft; the second driving device drives the clamping device to move and clamps the locking pin shaft into or out of the mixing frame, and when the first driving device drives the locking screw rod to extend and compress the mixing barrel, the clamping device releases the locking pin shaft. According to the mixing barrel locking mechanism, the automatic locking system and the automatic mixing system, matching of the first driving device and the second driving device is utilized, the locking screw rod extends out of the locking pinshaft and compresses the mixing barrel, a constant preload on the mixing barrel is maintained, and the production accident caused by the difference of the manual tightening torque is prevented.

Owner:国机智能技术研究院有限公司

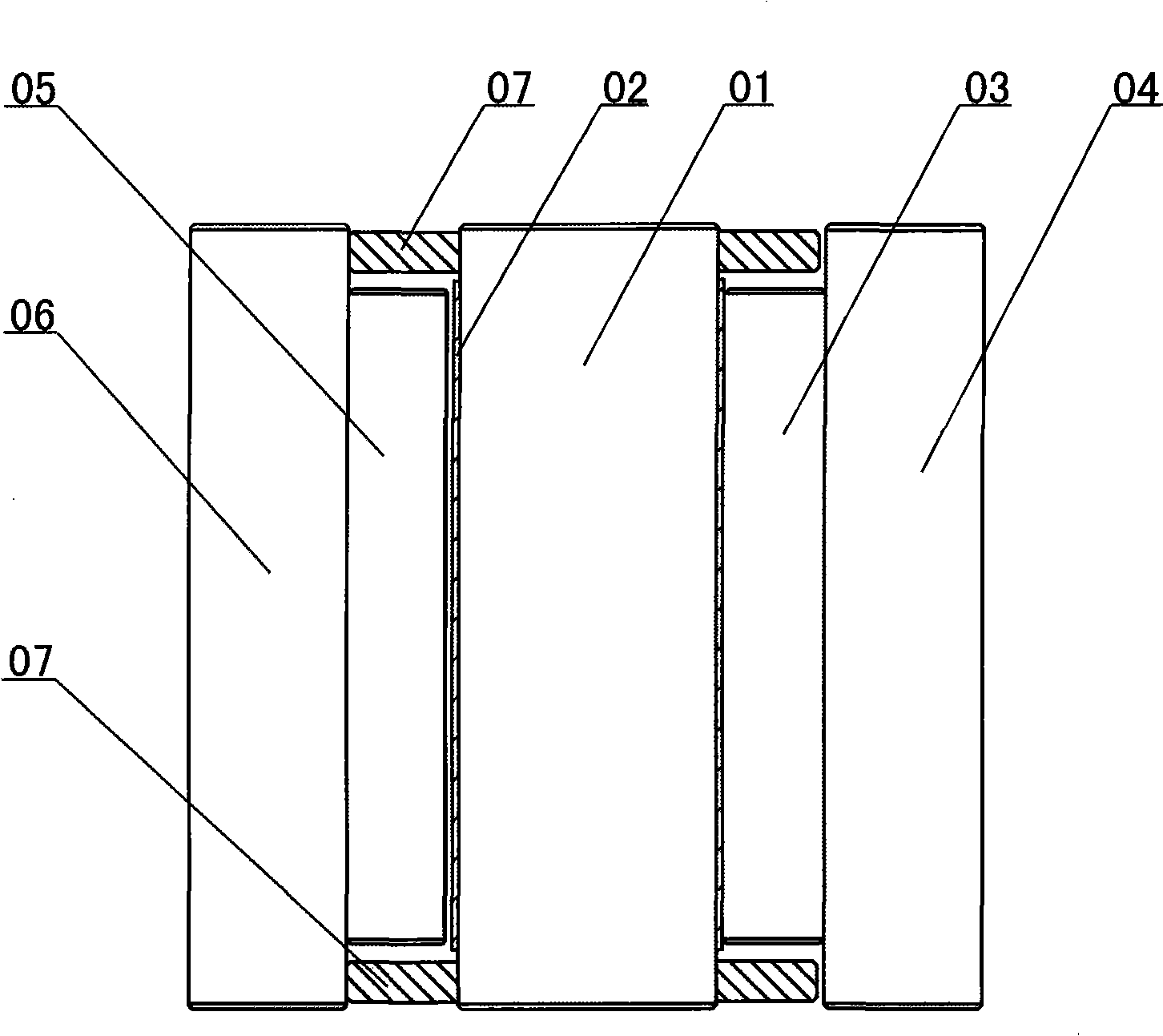

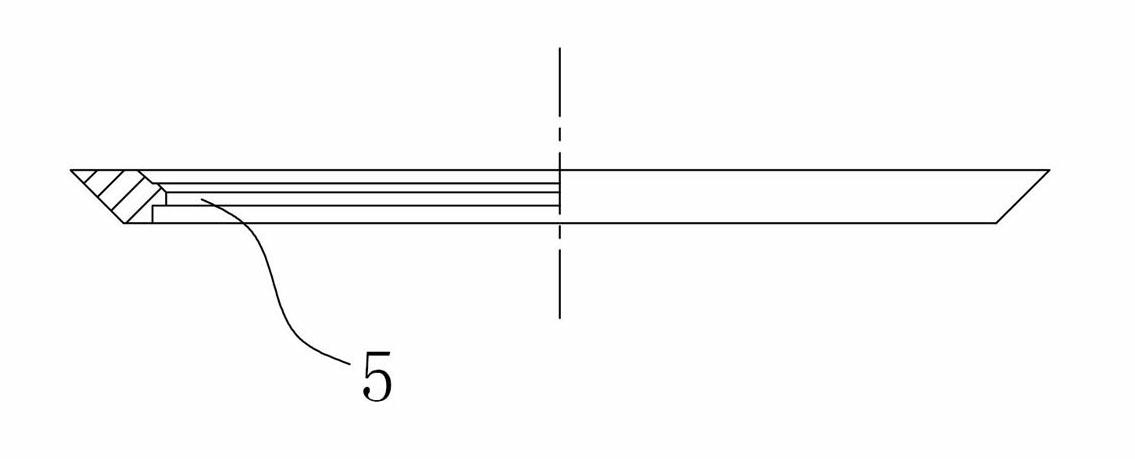

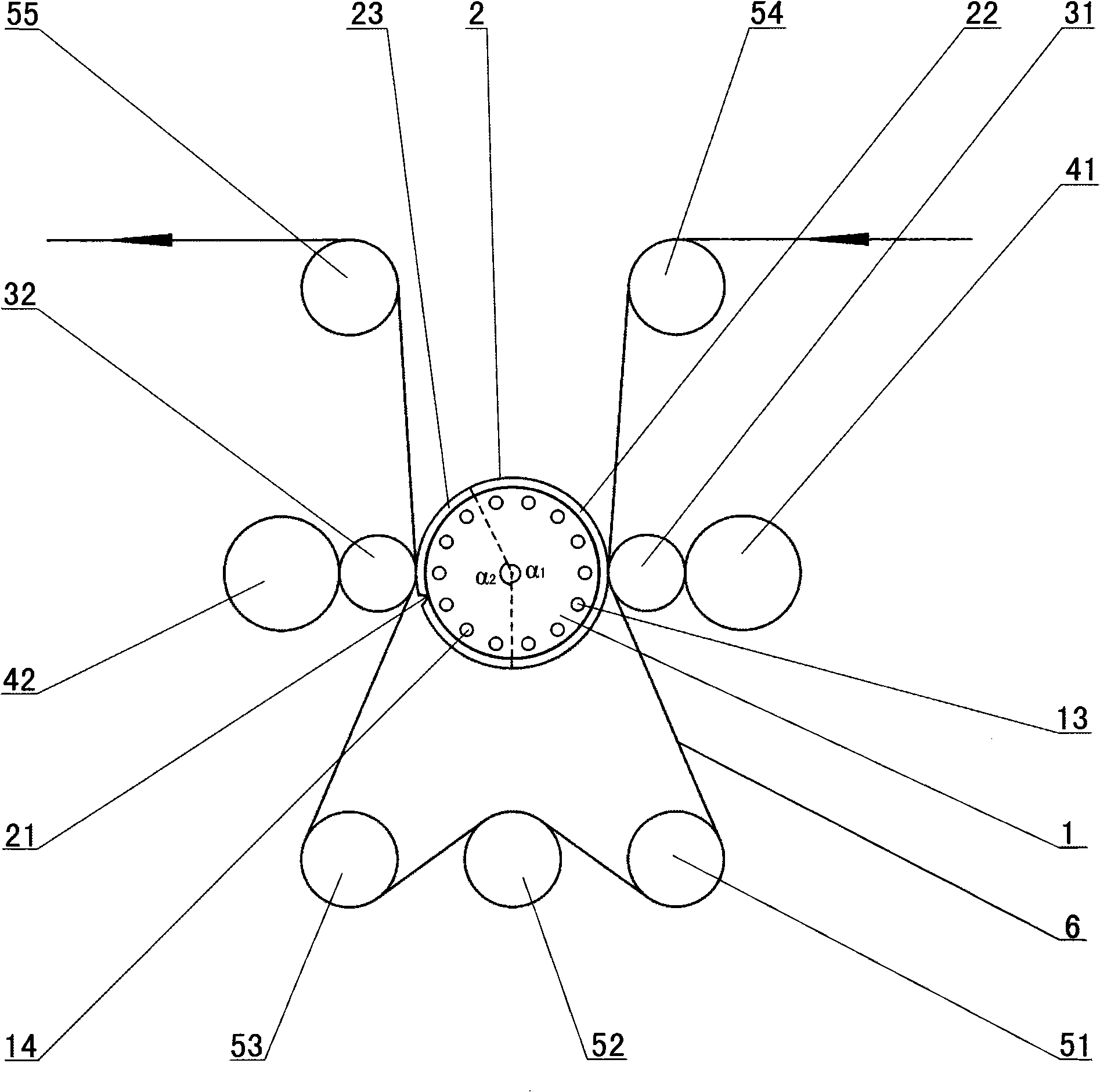

Laser holograph mould pressing device

ActiveCN101274578AWill not impact each otherStable pressing forceSpecial ornamental structuresRotary pressesEngineeringWorking temperature

The invention relates to a laser holography graph-text stamping device. The device comprises a cylinder and a stamping working plate, and the stamping working plate is installed on the cylinder. The device is characterized in that: the surface of the cylinder is divided into a high temperature area the temperature of which reaches the stamping working temperature and a low temperature area the temperature of which is lower than the stamping working temperature; the positions of the joints of the two ends of the stamping working plate correspond to the low temperature area on the surface of the cylinder; the device also comprises at least two compression rollers, and the compression rollers are arranged along the circumferential direction of the cylinder and respectively pressed with the cylinder. At least two stamping working positions are formed by the device of the invention, the laser holography graph-text stamped by each stamping working position is subsequently connected, the positions of the joints of the two ends of the stamping working plate correspond to the low temperature area temperature of which is lower than the stamping working temperature on the surface of the cylinder and no plate joints corresponding to the joints are generated at the stamping materials; the device of the invention has easy and fast installation and testing processes, stable operation, good product quality, wear resistance and long service life, and the product quality can be long-term maintained.

Owner:SHANTOU DONGFENG PRINTING CO LTD

Linear drive ultrasonic motor

InactiveUS20090267456A1Stable pressing forceReduce restrictionsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringUltrasonic motor

A linear drive ultrasonic motor includes at least an ultrasonic vibrator having a piezoelectric element, a driven member which is driven by a frictional force between the driven member and the ultrasonic vibrator, a pressing member which presses the ultrasonic vibrator such that a frictional force is generated between the ultrasonic vibrator and the driven member, a case member which accommodates the ultrasonic vibrator, the pressing member, and the driven member, and a coupling member which is coupled with the driven member at an interior of the case member. The case member includes an opening portion for allowing a part of the coupling member to pass through.

Owner:OLYMPUS CORP

Plastic plate pressing feeding mechanism

InactiveCN108820698ANo pressure lossPressure loss achievedConveyorsEngineeringMechanical engineering

The invention provides a plastic plate pressing feeding mechanism, and belongs to the technical field of plastic plate processing. The mechanism comprises a feeding platform, a feeding upper assemblyand a feeding lower assembly. An upper feeding belt of the feeding upper assembly is arranged on a first upper feeding wheel and a second upper feeding wheel in a surrounding mode, the upper and lowerends of an upper supporting spring of the supporting portion of the upper feeding belt are inserted into an upper supporting spring groove of an upper fixed supporting block and an upper supporting sprig groove of a lower movable supporting block, the lower movable supporting block is in fit with the upper feeding belt under the effect of the upper supporting spring, a lower feeding belt of the feeding lower assembly is arranged on a first lower feeding wheel and a second lower feeding wheel in a surrounding mode, the upper and lower ends of a lower supporting spring of the supporting portionof the lower feeding belt are inserted into a lower supporting spring groove of an upper movable supporting block and a lower supporting spring groove of a lower fixed supporting block, and the uppermovable supporting block is in fit with the lower feeding belt under the effect of the lower supporting spring. Pressing force can be appropriate, will not produce pressing damage to a plastic plateand also can ensure pressing for the plastic plate.

Owner:赵锋

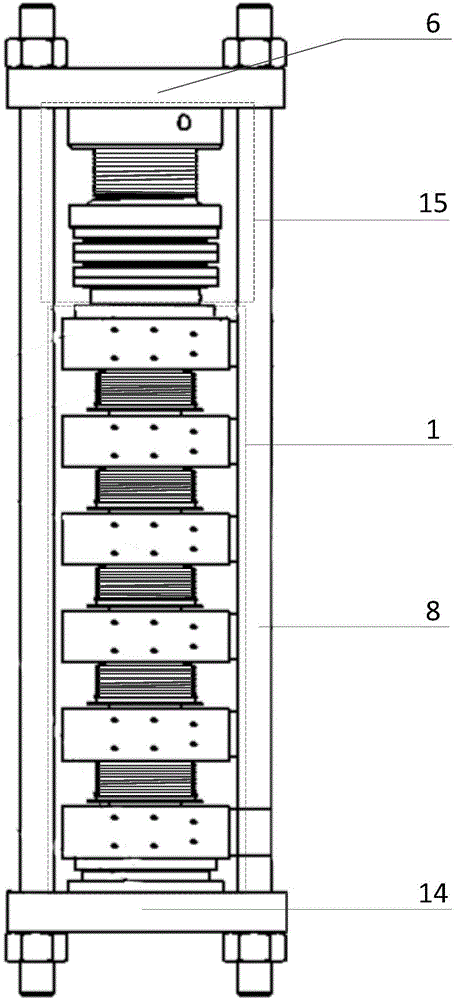

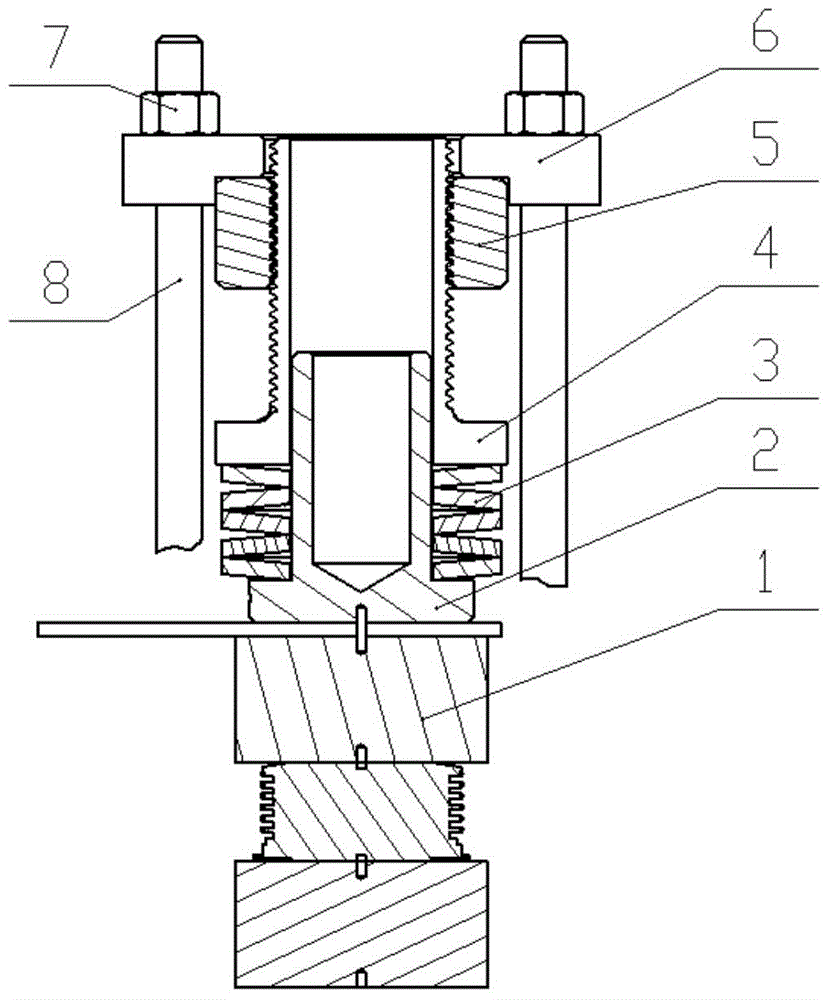

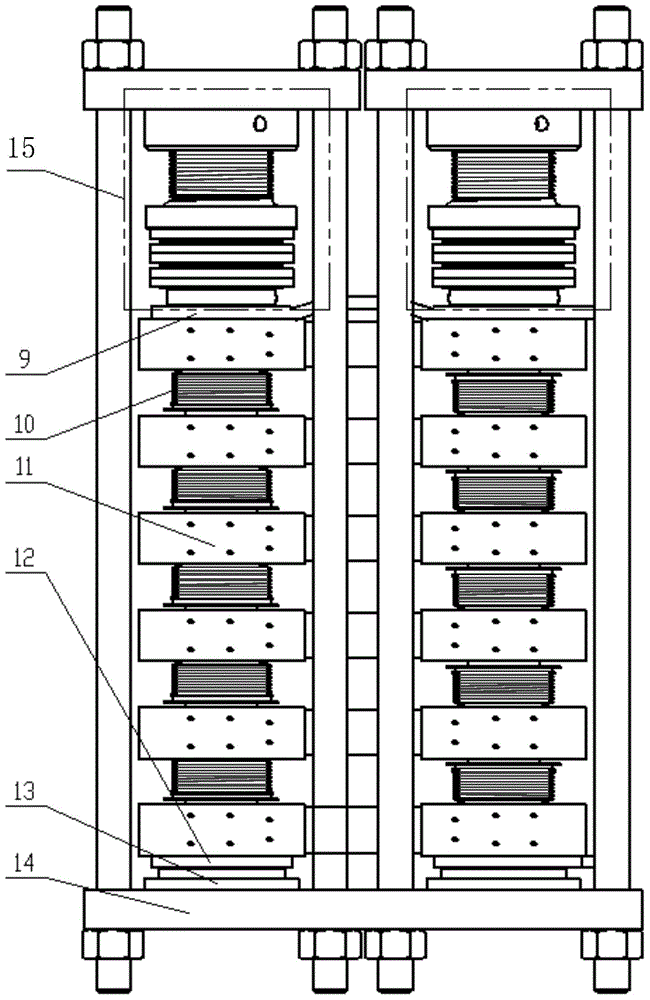

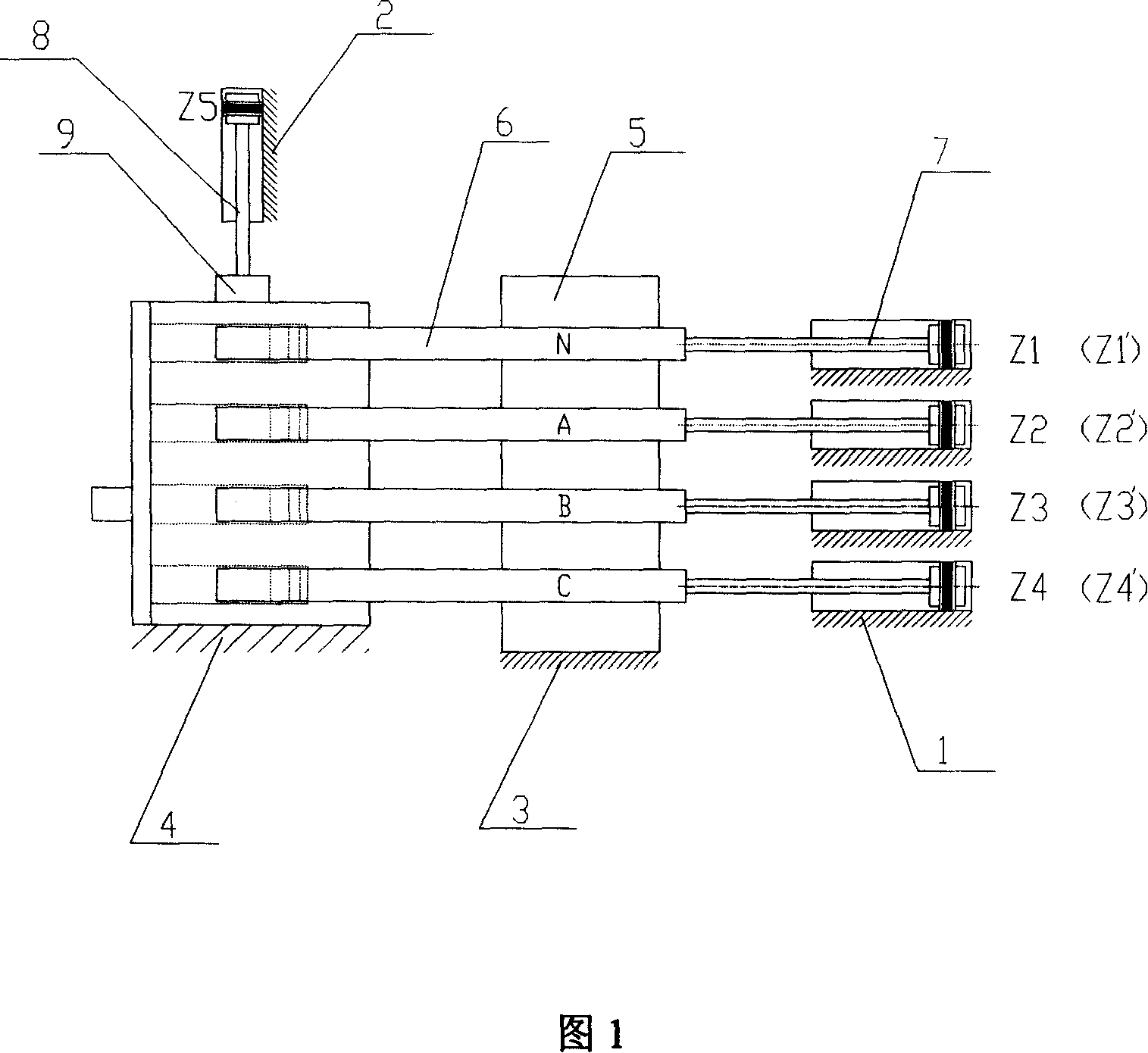

Jacking mechanism for thyristor valve

PendingCN106328577AEasy to press and apply forceSmooth hydraulic pressureSemiconductor/solid-state device manufacturingSelf lockingPower flow

The invention provides a jacking mechanism for a thyristor valve. The jacking mechanism comprises an upper end plate, a guiding jacking column which is arranged between the upper end plate and a thyristor string, and a disc spring group and a screw thread self-locking jacking rod which are arranged on the guiding jacking column in sequence, wherein a screw thread self-locking nut which is matched with the screw thread self-locking jacking rod is arranged on the screw thread self-locking jacking rod in a sleeving manner; and the upper end plate is connected with the screw thread self-locking jacking rod and clamped with the screw thread self-locking nut. The jacking mechanism provided by the invention can bear pressure-mounting force of higher than 200KN; the jacking mechanism is convenient to apply pressure-mounting force, stable and reliable in applying hydraulic force, simple and convenient to operate manually, and capable of satisfying vertical and concentric assembling precision requirement of the thyristor valve string; requirement on the alignment precision of the thyristor valve string is greatly improved; the jacking mechanism is capable of satisfying different pressure-mounting force requirements of the thyristor valve string of different pressure-mounting force; the assembling reliability and stability of the thyristor valve string are improved; and the electrical performance requirement of the thyristor valve for a high-voltage high-current high-capacity power electronic apparatus can be well satisfied.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Clamp for sliding abrasion test

ActiveCN104990790AReduce volumeStable pressing forceStrength propertiesThermodynamicsFrictional coefficient

The invention discloses a clamp for a sliding abrasion test. The clamp is especially suitable for stably clamping two workpieces for the test through a first clamping assembly and a second clamping assembly under the high-temperature and high-pressure water or steam environment, left horizontal, even and stable pressing force and right horizontal, even and stable pressing force which are the same in magnitude are provided for the two workpieces through a pressing assembly, a friction coefficient and an abrasion coefficient between a tube and a plate are quantitatively measured, loading control and measuring are stable, and operation is easy and convenient. The clamp is reasonable in structural design and functional design. The clamp can effectively control an infinitesimal displacement amplitude between the two workpieces in the testing process, guarantee even and stable loading under the high-temperature and high-pressure water or steam environment for a long time and meet the requirement for time of the abrasion test. The clamp is minimal in size, the volume in an autoclave is reduced, the equipment manufacturing cost and the running cost are reduced, and the problem of measurement of the friction coefficient and the abrasion coefficient of the fretting abrasion test under the high-temperature and high-pressure water or steam environment is solved.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Preparation method of mechanical composite pipeline based on hydraulic drive

The invention discloses a method for preparing a mechanical composite pipeline based on hydraulic driving, which comprises the following steps of: pipe expanding equipment is placed in a lining pipe to be expanded, an adjusting mechanism of a driving vehicle in the pipe expanding equipment is adjusted, wheels on three folding and unfolding assemblies which are uniformly distributed along the circumferential direction are propped against the lining pipe, and it is ensured that the driving vehicle and the lining pipe are coaxially arranged; then, motors on wheels of the driving vehicle are started, the driving vehicle is driven to move forwards, and the driving vehicle drives a pressing device of the pipe expanding equipment to move forwards synchronously; and meanwhile, a hydraulic device is started to supply oil to the interior of the pressing device, and the pressing device presses the lining pipe and starts to rotate under the driving of oil pressure, so that the pressing device gradually completes expansion of the lining pipe in the spiral movement process of combining linear advancing movement and rotating movement, the lining pipe and the carbon steel pipe are deformed, and finishing the preparation of the composite pipeline until the carbon steel pipe is in contact with a pipeline shaping outer mold. Continuous operation can be achieved, the operation process is stable, the preparation cost is low, and the production efficiency is high.

Owner:HANGZHOU DIANZI UNIV

Rivet press-fitting device

The invention provides a rivet press-fitting device, and belongs to the technical field of riveting. The rivet press-fitting device comprises a feeding mechanism and a press-fitting mechanism. A feeding curtain of the feeding mechanism surrounds a front feeding roller and a rear feeding roller. U-shaped bearing bases are arranged on the feeding curtain at equal intervals. The middle end of a leftclamping claw of the press-fitting mechanism is hinged to the left end of a clamping claw support through a left clamping claw pin shaft, and a left pressing plate is arranged at the lower end of theleft clamping claw. A centering pressing column is arranged on the right side of the left pressing plate. The upper end of a right clamping claw is hinged to the right end of the clamping claw supportthrough a right clamping claw pin shaft. A right pressing plate is arranged at the lower end of the right clamping claw. A left finger is located on the upper side of a right finger, and the left finger and the right finger are in lap joint. The left end and the right end of a tension spring are connected with a left tension spring support and a right tension spring support correspondingly. A torsion spring and a lever pin shaft are coaxially arranged. An eccentric wheel is eccentrically arranged on an eccentric wheel support shaft, and a wheel is attached to the eccentric wheel under the action of the torsion spring. The rivet press-fitting device can continuously achieve rivet press-fitting, the press-fitting force is stable, reliability is good, and the automation degree is high.

Owner:临沭县益兴供汽维修服务有限公司

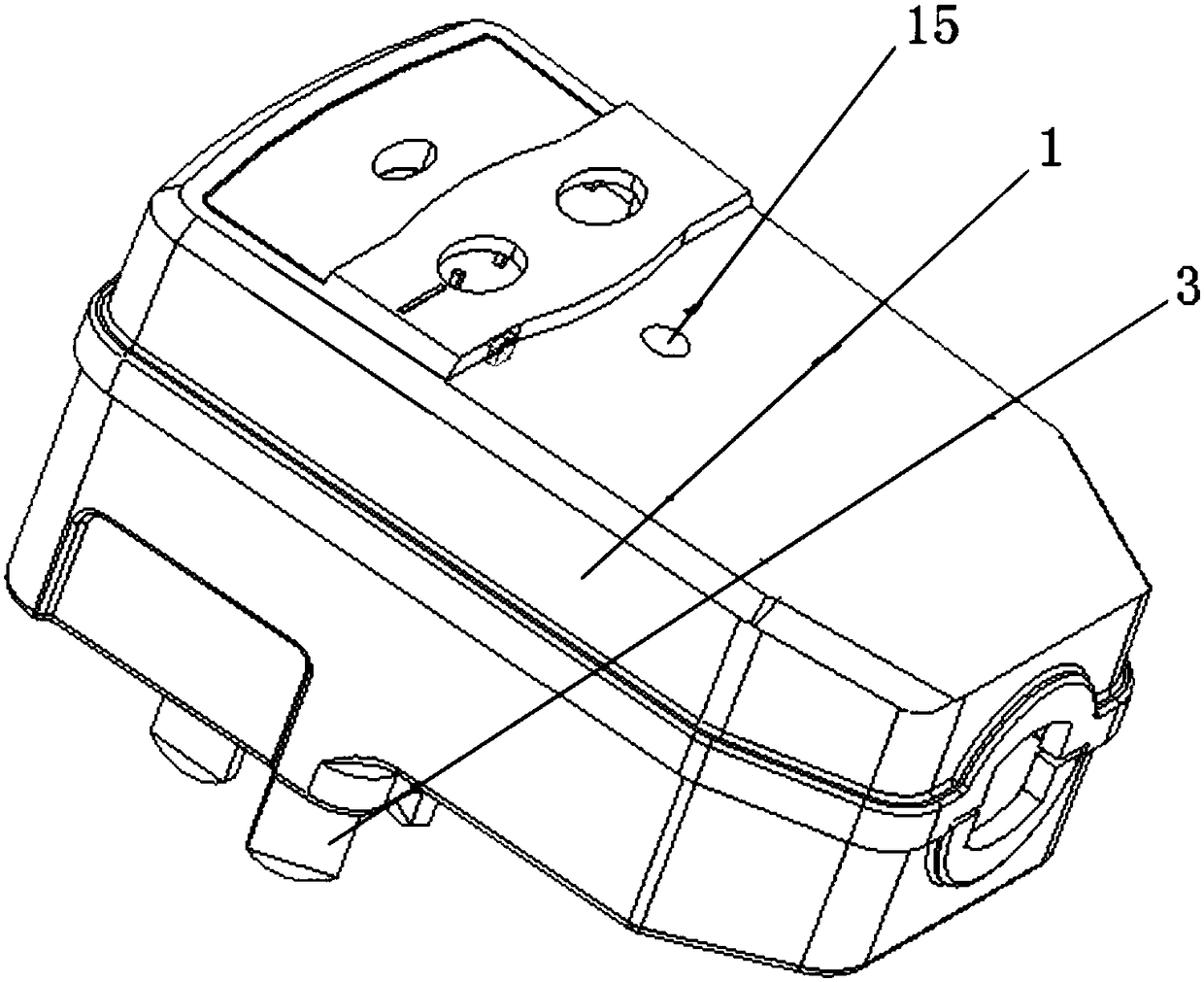

Leakage protector

PendingCN108962697AImprove securityStrong reliabilityProtective switch operating/release mechanismsEngineeringElectrical equipment

The invention, which relates to the technical field of electrical equipment protection, discloses a leakage protector comprising a protector device, pins, a bottom plate and an elastic piece. The protector device includes a communication maintaining device, a communicating device and a locking device. The locking device includes an elastic piece pressing block and a locking lifting lever; a lock catch, a transverse fork groove and a buckle sliding way are arranged at the locking lifting lever; and a pressing rod, a buckle and a vertical fork groove are arranged at the elastic piece pressing block. A second iron core extending horizontally is arranged at the communicating device and is in a clamping fit relationship with the vertical fork groove. A first iron core extending longitudinally is arranged at the communication maintaining device and is in a clamping fit relationship with the horizontal fork groove. The elastic piece pressing block includes an upper pressing block part and a lower pressing block part. According to the invention, disconnection of the leakage protector is realized based on the cooperation relationship between mechanical structures under the circumstance thatthe failure of the coil is kept. With pressing block springs, a pressing rod arranged at the lower pressing block part applies a stable compression force to the elastic piece; and with a compressiontop block, the first iron core can move to a lowest position.

Owner:YUYAO JIARONG ELECTRONICS & ELECTRIC APPLIANCE CO LTD

Instant testing platform clip

InactiveCN101089626AStable pressing forceThe test data is accurateElectrical measurement instrument detailsCircuit interrupters testingEngineeringTest data

Owner:上海亿盟电气自动化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com