Preparation method of mechanical composite pipeline based on hydraulic drive

A composite pipeline and mechanical technology, which is applied in the field of composite pipeline preparation, can solve the problems of pipeline structure damage and uneven stress on the lining tube, and achieves the effects of high production efficiency, continuous operation and improved stress uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] A method for preparing a mechanical composite pipe based on hydraulic drive, specifically as follows:

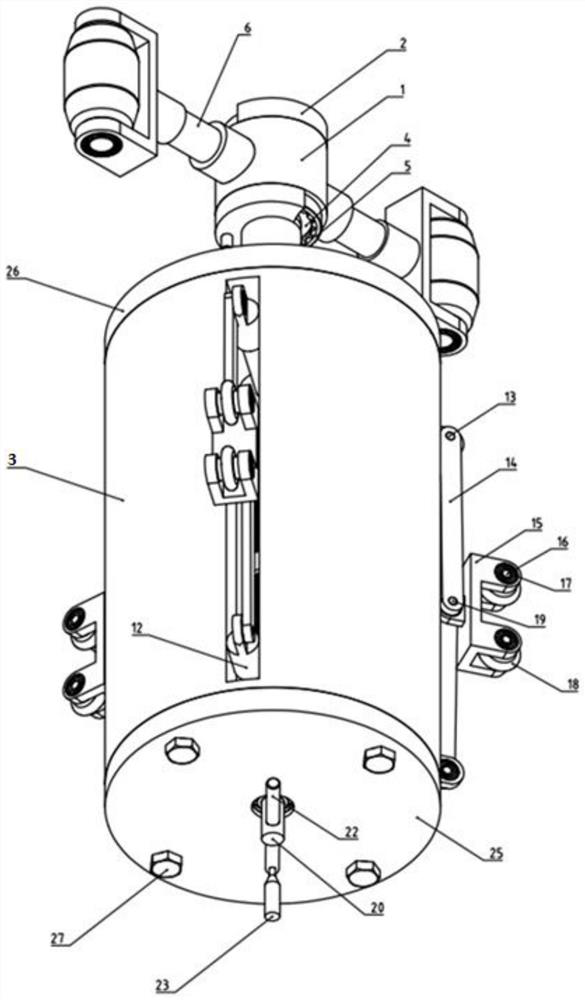

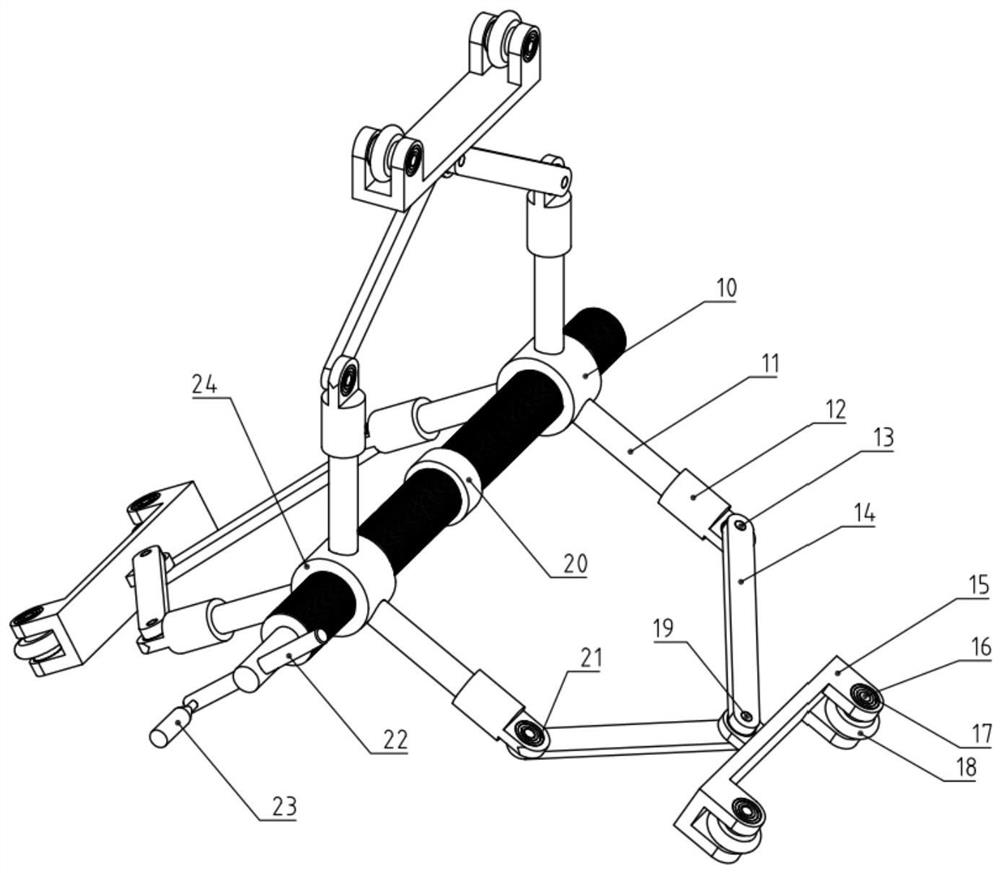

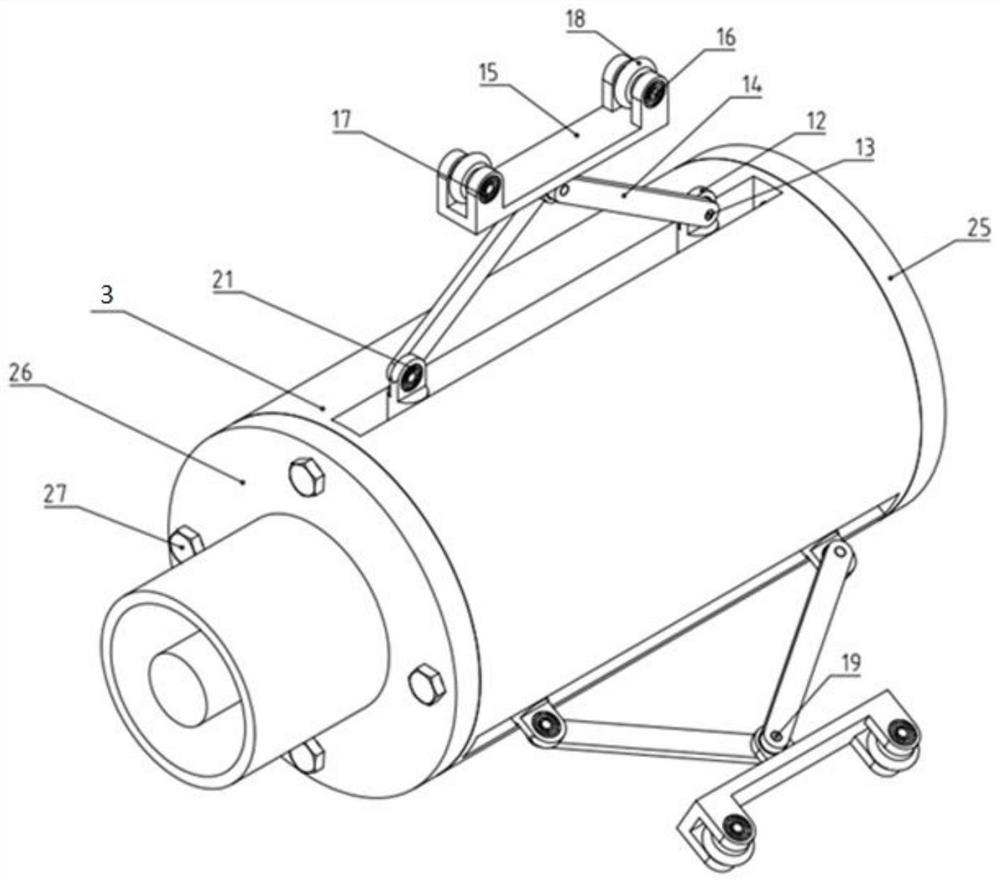

[0031] Such as figure 1 with 8 As shown, put the expansion equipment inside the inner liner 9 to be expanded, adjust the adjustment mechanism of the driving car in the expansion equipment, and put the wheels on the three folding components evenly distributed along the circumferential direction against the inner liner 9 , and ensure that the driving car is coaxially arranged with the liner pipe; then, start the motor 17 on the wheel of the driving car to drive the driving car to move forward, and the driving car drives the pressing device of the pipe expansion equipment to advance synchronously; at the same time, start the hydraulic device to move forward Oil is supplied inside the pressing device. Driven by oil pressure, the pressing device compresses the inner l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com