Multifunctional drilling and riveting actuator and working method thereof

An actuator and multi-functional technology, applied in the field of multi-functional drilling and riveting actuators, can solve the problems affecting cost, hole-making quality and hole-making efficiency, incomplete end effector functions, and insufficiently compact structure of the end part, etc. The effect of convenient and flexible bit conversion, light weight and large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

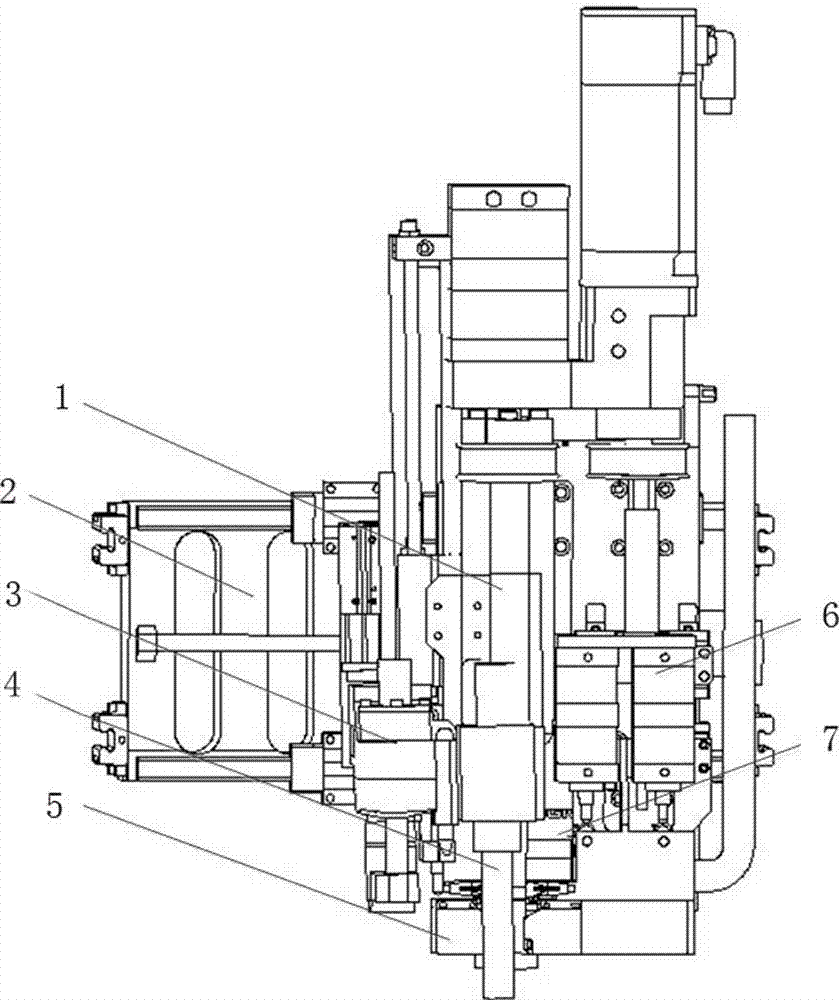

[0041] Figure 1 to Figure 8Shown is the structural representation of the present invention.

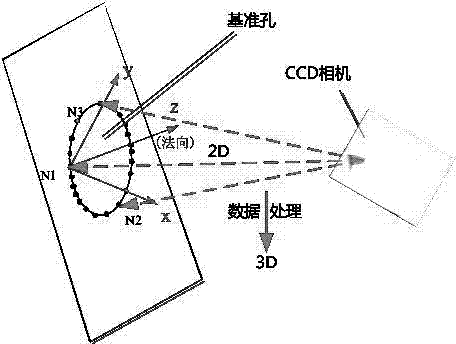

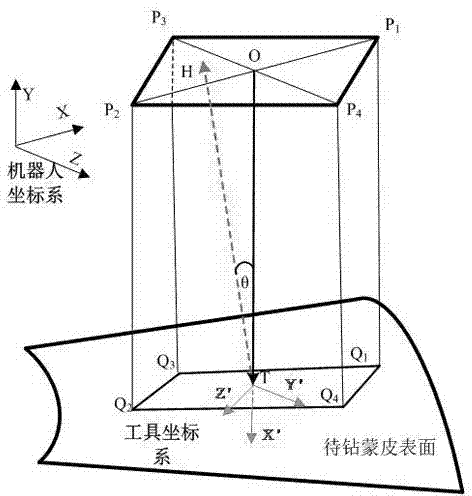

[0042] Wherein the reference numerals are: hole-making countersink module 1, length meter 11, flange plate 12, knife removal cylinder 13, hole-making motor 14, main shaft bottom plate 15, station conversion module 2, conversion slider 21, conversion Guide rail 22, servo motor 23, riveting base plate 24, spindle base plate 25, nail insertion module 3, riveting module 4, nail pipeline 41, nail feeding cylinder 42, nail clip air claw 43, riveting gun 44, normal detection module 5, Laser displacement sensor 51, pressure foot module 6, pressure foot motor 61, linear guide rail 62, guide rail slider 63, first screw connecting plate 64, pressure foot cylinder 65, chip removal pipeline 66, rolling bearing 67, second screw rod Connecting plate 68 , straw sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com